Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Rocker Breaker Boom: Your Choice For Quality Spreaders and Related Equipment

Caricato da

Woelinton Tinco CrisostomoDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Rocker Breaker Boom: Your Choice For Quality Spreaders and Related Equipment

Caricato da

Woelinton Tinco CrisostomoCopyright:

Formati disponibili

About EARLS

Your choice for quality spreaders and related equipment.

About the Company Our Manufacturing Facility

EARLS is a dynamic, 3rd generation family owned Our Metro Vancouver plant is located in the suburb

and directed company currently in our 59th year of of Port Coquitlam where we have a 21,000 sq ft

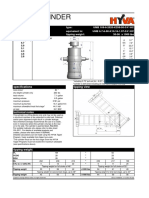

MODEL #361/371

continuous operation in the Vancouver, Canada factory and 7,500 sq ft office located on a 1.4 acre

area. Over the course of the past several decades

EARLS has grown to become a full fledged

engineered product manufacturer. Currently we

industrial property. The factory consists of three

bays, one each for machining, welding/fabricating,

and electro-hydraulic & mechanical assembly. All

Rocker Breaker Boomwith Pedestal Mount for Primary Crusher

have equipment working throughout the western EARLS spreaders are built to order at this location.

hemisphere and we are looking to add customers,

partners, and agent representation around the

world.

Total Commitment

EARLS total commitment to the customer encompasses all aspects of product development, design, manufacture,

marketing, and after sales service. The delivery of a product to a customer marks the beginning of a permanent

relationship.

Our Location Local Support Partner - India

EARLS Industries Ltd. Chirayush I. Gandhi

Address: 1616 Kebet Way, Port Coquitlam, BC, Director Sales and Technical Support.

V3C 5W9, Canada BSc, MSc, B-Econ, MBA, NY Univ, & Univ of Boston

Phone: +1 604-941-8388 Email: cigandhi@emcogroup.co.in

Fax: +1 604-941-8302

Emco Group Companies

Web: www.earlsindustries.com

Address: 5/6 Magnum Opus Plaza, Shanthinagar,

Vakola, Mumbai 400055.

Phone: 91-22-2-6651771/2/4/5/6/7.

Web: www.indiamart.com/emcogroup

1616 Kebet Way, Port Coquitlam, T: +1 604-941-8388

BC, V3C 5W9 F: +1 604-941-8302

Rev 2013 Q1 Canada www.earlsindustries.com E: info@earlsindustries.com

Model 361/371 Articulating Rocker Breaker Boom

The EARLS rock breaker boom is a high

strength articulating structure designed to

manipulate hydraulic breaker hammers, rock

grapples, and rock points. It consists of the

following major components; base mount,

boom foot swivel, boom, stick and tool

mount.

The boom design is robust, using oversize pins

and bushings at all joints. A centralised

lubrication system maintains a steady flow of

grease to every rotating joint.

Power is provided by a remote hydraulic

power pack and most installations have

remote controls running to an operator’s

booth.

The motion of the boom is driven by hydraulic

cylinders with the exception of the swing

motion that uses a double ended cylinder

driving a large rack and pinion.

Hydraulic Supply Pressure: Boom Weight: Maximum Horizontal Reach: Lubrication System:

- 18.6 MPa/2700 psig (boom only). - 10,886 kg/24,000 lbs (no hammer). - 10.5 m/34’6” (no hammer). - Fully automatic (series progressive style)

lube system including lube pump, control

Hydraulic Supply Flow Rate: Maximum Hammer Weight: Maximum Vertical Reach: system, and individual feeders.

- 140 lpm/37 USGPM (boom only). - 3,175 kg/7,000 lbs. - 5.75 m/18’10” (no hammer).

Paint: 3 Coat System (Devoe)

Hydraulic Oil Type: Hydraulic Filtration: Maximum Swing Angle: - Inorganic Zinc Primer.

- Century Centraulic AF32 or equivalent. - Oil filtered to 10 microns on return and - 180 degrees (nominal). - Epoxy Intermediate Coat.

pressure lines (minimum requirement). - Aliphatic Polyurethane Top Coat.

Potrebbero piacerti anche

- How to Rebuild & Modify Rochester Quadrajet CarburetorsDa EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsValutazione: 5 su 5 stelle5/5 (2)

- Batri Waali K CellDocumento22 pagineBatri Waali K CellGOURAV KHARTANessuna valutazione finora

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDa EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideValutazione: 4.5 su 5 stelle4.5/5 (8)

- Flow-Moto 250GPM@8Bar End-Suction UL&FM DJDocumento73 pagineFlow-Moto 250GPM@8Bar End-Suction UL&FM DJKarim NasserNessuna valutazione finora

- Company Profile 2015-2016Documento21 pagineCompany Profile 2015-2016Berkat Mulia Wiratama PtNessuna valutazione finora

- McCormick C-Max TractorsDocumento2 pagineMcCormick C-Max TractorshuskerchampsNessuna valutazione finora

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsDa EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsValutazione: 5 su 5 stelle5/5 (5)

- BmaDocumento6 pagineBmaraouf youssefNessuna valutazione finora

- High-Performance GM LS-Series Cylinder Head GuideDa EverandHigh-Performance GM LS-Series Cylinder Head GuideValutazione: 4.5 su 5 stelle4.5/5 (2)

- 6 Months Industrial Training AT: Mahindra and Mahindra Swaraj, MohaliDocumento46 pagine6 Months Industrial Training AT: Mahindra and Mahindra Swaraj, MohaliJagdeep SinghNessuna valutazione finora

- Oil SkimersDocumento139 pagineOil SkimerszirimiaNessuna valutazione finora

- Diesel Engine Care and Repair: A Captain's Quick GuideDa EverandDiesel Engine Care and Repair: A Captain's Quick GuideValutazione: 5 su 5 stelle5/5 (1)

- Max Air Product Overview Brochure 2016Documento28 pagineMax Air Product Overview Brochure 2016jeff_141036490Nessuna valutazione finora

- Mega Cataloguem, MDocumento22 pagineMega Cataloguem, MJohn Ma0% (1)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreDa EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreValutazione: 4.5 su 5 stelle4.5/5 (11)

- Himax CR2816-1100 Himax CR2816-1100 Himax CR2816-1100 Himax CR2816-1100 Himax CR2816-1100Documento1 paginaHimax CR2816-1100 Himax CR2816-1100 Himax CR2816-1100 Himax CR2816-1100 Himax CR2816-1100Nohelia Luz Jiménez ValenzuelaNessuna valutazione finora

- How Are Supercars Made? Technology Book for Kids 4th Grade | Children's How Things Work BooksDa EverandHow Are Supercars Made? Technology Book for Kids 4th Grade | Children's How Things Work BooksNessuna valutazione finora

- Internship Report On BemlDocumento29 pagineInternship Report On BemlYasewn KALAWANTNessuna valutazione finora

- TP25M4 Truck Pump-TruemaxDocumento5 pagineTP25M4 Truck Pump-TruemaxJeara MikleinNessuna valutazione finora

- Astero E0201E-20 991063Documento186 pagineAstero E0201E-20 991063Thinh Nguyen100% (1)

- Bettis Valve Actuator GuideDocumento12 pagineBettis Valve Actuator Guideprufino2Nessuna valutazione finora

- Cable Reeling DrumDocumento4 pagineCable Reeling DrumBanamali NaskarNessuna valutazione finora

- Hydraulic Breaker TOR Series: Break Anything... Except The BankDocumento6 pagineHydraulic Breaker TOR Series: Break Anything... Except The BankYeison RamirezNessuna valutazione finora

- Meditran SX Sae 15w 40 API CH 4Documento1 paginaMeditran SX Sae 15w 40 API CH 4Aam HudsonNessuna valutazione finora

- 2G TZ Brochure TrapzillaDocumento16 pagine2G TZ Brochure TrapzillaNigel AngNessuna valutazione finora

- TesmacDocumento44 pagineTesmacJianJianti0% (1)

- FC81081Documento2 pagineFC81081Khalid ZaeemNessuna valutazione finora

- S 58 SX / S 61 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomDocumento6 pagineS 58 SX / S 61 SX: Truck-Mounted Concrete Pump With 4-Section Placing BoomMihnea-Bogdan NicolaescuNessuna valutazione finora

- Ko Belt Steering GuideDocumento37 pagineKo Belt Steering GuideJorgelino ParkerNessuna valutazione finora

- K3V K5V eDocumento15 pagineK3V K5V evyvy83Nessuna valutazione finora

- 80-0421-13 80-0421-14 Tech Manual REV 20160314 (Hi-Rez)Documento181 pagine80-0421-13 80-0421-14 Tech Manual REV 20160314 (Hi-Rez)j1h2o3n4Nessuna valutazione finora

- Beml Report PDFDocumento32 pagineBeml Report PDFCrazy TamizhaNessuna valutazione finora

- Bombas Estacionarias SP 2800Documento2 pagineBombas Estacionarias SP 2800SchwingLatinoamerica100% (1)

- Akros Multi FCT 10W-30 Transmission OilDocumento10 pagineAkros Multi FCT 10W-30 Transmission OilFer EmilNessuna valutazione finora

- Model 6200 ManualDocumento11 pagineModel 6200 ManualJaime RamìrezNessuna valutazione finora

- Canary Global Sourcing - 2023Documento24 pagineCanary Global Sourcing - 2023John LongNessuna valutazione finora

- CoBall EN 2014 PDFDocumento4 pagineCoBall EN 2014 PDFRizki LarasatiNessuna valutazione finora

- Overrunning Clutches and Backstops: Regal RexnordDocumento8 pagineOverrunning Clutches and Backstops: Regal RexnordNebojsa GaletovicNessuna valutazione finora

- CTC Agriculture 26-10-2018 Low ResDocumento130 pagineCTC Agriculture 26-10-2018 Low ResPEX Hydraulics Moçambique, Lda.Nessuna valutazione finora

- C ClutchesDocumento131 pagineC ClutchesjonarosNessuna valutazione finora

- Bestway MKR5000D Series OwManual (EN)Documento9 pagineBestway MKR5000D Series OwManual (EN)VicNessuna valutazione finora

- Batching Plant PDFDocumento8 pagineBatching Plant PDFfakhli bisaNessuna valutazione finora

- Renold Sugar Chain 1007Documento6 pagineRenold Sugar Chain 1007Omar Ahmed ElkhalilNessuna valutazione finora

- Instrument TransformerDocumento12 pagineInstrument Transformernandorg1113Nessuna valutazione finora

- Tur-Flwmtr Nf00152 0912fDocumento2 pagineTur-Flwmtr Nf00152 0912fAntonio ImperiNessuna valutazione finora

- Washing Equipment Product Handbook - WEB - 06 2016Documento52 pagineWashing Equipment Product Handbook - WEB - 06 2016Lmf DanielNessuna valutazione finora

- 76 Hydraulic Tractor Fluid TDSDocumento2 pagine76 Hydraulic Tractor Fluid TDSAkrm GobranNessuna valutazione finora

- Tection Global 15W - 40Documento2 pagineTection Global 15W - 40carmaNessuna valutazione finora

- Superior Pipeline EquipmentsDocumento68 pagineSuperior Pipeline Equipmentsaliyildizx17730Nessuna valutazione finora

- CVC 1103Documento2 pagineCVC 1103Avinash KaleNessuna valutazione finora

- Shreeraj Industries BrochureDocumento38 pagineShreeraj Industries BrochureM2 XNessuna valutazione finora

- Vaas Head Office DetailsDocumento8 pagineVaas Head Office DetailsDanielle JohnsonNessuna valutazione finora

- Walco Bolt Torquing Services 2015Documento6 pagineWalco Bolt Torquing Services 2015servicesNessuna valutazione finora

- FEB 2011 UptimeDocumento52 pagineFEB 2011 UptimeLammie Sing Yew LamNessuna valutazione finora

- Accupat DADocumento19 pagineAccupat DANenad BrajovicNessuna valutazione finora

- PDF Informe Tecnico n95 19 HM Aesa Standarizacion de Seguridad de Scaler Pau DLDocumento5 paginePDF Informe Tecnico n95 19 HM Aesa Standarizacion de Seguridad de Scaler Pau DLWoelinton Tinco CrisostomoNessuna valutazione finora

- Application Driven Solutions: Hydraulic Rockbreaker SystemsDocumento6 pagineApplication Driven Solutions: Hydraulic Rockbreaker SystemsWoelinton Tinco CrisostomoNessuna valutazione finora

- BX & BXR Series Hydraulic BreakersDocumento6 pagineBX & BXR Series Hydraulic BreakersWoelinton Tinco CrisostomoNessuna valutazione finora

- (Dimensions Shown in Feet/inches) (Dimensions Shown in Feet/inches)Documento2 pagine(Dimensions Shown in Feet/inches) (Dimensions Shown in Feet/inches)Woelinton Tinco CrisostomoNessuna valutazione finora

- BTI Hydraulic Rockbreaker Systems 2013 PDFDocumento6 pagineBTI Hydraulic Rockbreaker Systems 2013 PDFWoelinton Tinco CrisostomoNessuna valutazione finora

- CTM812 Titanium Brochure - LR - EnglishDocumento2 pagineCTM812 Titanium Brochure - LR - EnglishWoelinton Tinco CrisostomoNessuna valutazione finora

- FB815 Titanium Brochure - LR - EnglishDocumento2 pagineFB815 Titanium Brochure - LR - EnglishWoelinton Tinco CrisostomoNessuna valutazione finora

- RB1250 XD: Extreme Duty Pedestal Boom: South AfricaDocumento2 pagineRB1250 XD: Extreme Duty Pedestal Boom: South AfricaWoelinton Tinco CrisostomoNessuna valutazione finora

- Umb 71406578Documento2 pagineUmb 71406578Woelinton Tinco CrisostomoNessuna valutazione finora

- 70577402Documento2 pagine70577402Woelinton Tinco CrisostomoNessuna valutazione finora

- Model Predictive Direct Torque Control Methods For SpeedDocumento25 pagineModel Predictive Direct Torque Control Methods For SpeedAayush PatidarNessuna valutazione finora

- Propeller N Intermediete ShaftDocumento56 paginePropeller N Intermediete ShaftPetrus Kanisius Wiratno100% (2)

- The Aerodynamics of An Isolated Wheel Rotating in Contact With The GroundDocumento277 pagineThe Aerodynamics of An Isolated Wheel Rotating in Contact With The GroundatilolaNessuna valutazione finora

- What Is The Pressure at The End of A Pipe Which Is Discharging To AtmosphereDocumento2 pagineWhat Is The Pressure at The End of A Pipe Which Is Discharging To AtmospheremwardNessuna valutazione finora

- Application Guide - Aerospace Sealants PDFDocumento4 pagineApplication Guide - Aerospace Sealants PDFRiki NurzamanNessuna valutazione finora

- Rheology of Complex FluidsDocumento130 pagineRheology of Complex FluidsghfdlfNessuna valutazione finora

- 262A Service Parts Manual PDFDocumento206 pagine262A Service Parts Manual PDFGerman Junior Diaz DonadoNessuna valutazione finora

- Company Overview-Madhuri AgencyDocumento12 pagineCompany Overview-Madhuri AgencyEros IliyaNessuna valutazione finora

- Sub-Spec 023 - Tenaris DSTJ, WT™Documento4 pagineSub-Spec 023 - Tenaris DSTJ, WT™Josue FishNessuna valutazione finora

- Lecture 34 PDFDocumento49 pagineLecture 34 PDFalfredomotaNessuna valutazione finora

- Technical Standard Specification - Mechanical Section 03 - Pumps, Compressors, Blowers, and CuttersDocumento51 pagineTechnical Standard Specification - Mechanical Section 03 - Pumps, Compressors, Blowers, and CuttersRenju RadhakrishnapillaiNessuna valutazione finora

- Input Data: Package: Bridge Name: Pier Name: 1. General Input DataDocumento7 pagineInput Data: Package: Bridge Name: Pier Name: 1. General Input DataTuanNessuna valutazione finora

- Floating JointDocumento2 pagineFloating JointEDUARDO NICOLASNessuna valutazione finora

- Instruction Manual Shinva 45litre Autoclave240V With PrinterDocumento21 pagineInstruction Manual Shinva 45litre Autoclave240V With PrinterEnfant Perdu100% (3)

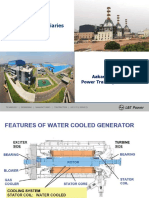

- Generator AuxiliariesDocumento39 pagineGenerator Auxiliariesharry2586Nessuna valutazione finora

- Design of Intermediate Beam: S E: 200000 MPO B T F D: 554.50 MM T H: D 2t H 0.502 M R W M CB PLL: 4800 Pa H IDocumento3 pagineDesign of Intermediate Beam: S E: 200000 MPO B T F D: 554.50 MM T H: D 2t H 0.502 M R W M CB PLL: 4800 Pa H IMike GocotanoNessuna valutazione finora

- Subaru Justy L3-1.2 2wd Carb RepairDocumento557 pagineSubaru Justy L3-1.2 2wd Carb RepairAriel Alexander Lauvrie100% (2)

- Ex-G DST Light en Compressed Si#170172Documento6 pagineEx-G DST Light en Compressed Si#170172biagio riccioNessuna valutazione finora

- 01 EJS Metal Technical CatalogDocumento85 pagine01 EJS Metal Technical CatalogGicuNessuna valutazione finora

- Ms Productline 2021 n09Documento28 pagineMs Productline 2021 n09Francisco NavasNessuna valutazione finora

- Unit 08.26 - Komatsu 930E Haul TruckDocumento19 pagineUnit 08.26 - Komatsu 930E Haul TruckJose Pablo Fuentes100% (1)

- Food Extrusion FoodkidaDocumento38 pagineFood Extrusion Foodkidamonicaad shankarNessuna valutazione finora

- I Removal of TurbochargerDocumento6 pagineI Removal of TurbochargerDavid QuispeNessuna valutazione finora

- 103 TOP Heat Transfer - Mechanical Engineering Multiple Choice Questions and Answers List - MCQs Preparation For Engineering Competitive ExamsDocumento19 pagine103 TOP Heat Transfer - Mechanical Engineering Multiple Choice Questions and Answers List - MCQs Preparation For Engineering Competitive ExamsNagaraj Muniyandi100% (2)

- Inspection and Testing Program Fire Protection Equipment: A. Statement of ProblemDocumento12 pagineInspection and Testing Program Fire Protection Equipment: A. Statement of ProblemdinduntobzNessuna valutazione finora

- 6 Some Important Features of Stone Column TreatmentDocumento7 pagine6 Some Important Features of Stone Column TreatmentBilal Ahmed BarbhuiyaNessuna valutazione finora

- 3b. Column Base Plate Ce134p Escruz LRFDDocumento17 pagine3b. Column Base Plate Ce134p Escruz LRFDjohn devonNessuna valutazione finora

- Ms-Combination enDocumento39 pagineMs-Combination enCarlos VandréNessuna valutazione finora

- A Guide To Well ConstructionDocumento127 pagineA Guide To Well ConstructionEliezer JimenezNessuna valutazione finora

- PLI (Pounds Per Linear Foot)Documento5 paginePLI (Pounds Per Linear Foot)ccorp00890% (1)