Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

5 Pierburg Single

Caricato da

vanapeerDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

5 Pierburg Single

Caricato da

vanapeerCopyright:

Formati disponibili

Single carburettor (Pierburg)

To remove

Disconnect the positive {+) lead from the bat-

tery.

1 Disconnect the hoses to the EGR valve and

distributor.

2 Disconnect the earth lead from the top of the

carburettor.

3 Disconnect the electrical lead from the float

chamber ventilation shuft-off valve.

4 Disconnect the accelerator and choke

cables.

5 Disconnect the inlet hose from the carburet-

tor flange.

6 Remove the flange and the gaskets.

7 Remove the fuel hose from the carburettor,

complete with vapour trap and clamp.

8 Unbolt the carburettor from the flange on the

inlet manifold.

To dismantle

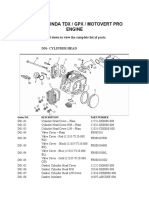

1 Remove the damper piston (1) and the cover

(2).

2 Remove the carburettor cover (3) and the

spring (4).

3 Remove the vacuum piston (8) and dia-

phragm (7).

4 Release the setscrew and remove the

needle (9) from the piston.

5 Remove the diaphragm (7) from the piston

(8) by removing the screws, the retaining

ring (5) and the plastic washer (6).

Carburettor

1 Damper piston 6 Plastic washer

2 Cover 7 Diaphragm

3 Carburettor cover 8 Piston

4 Spring 9 Needle

5 Metal retaining ring

A Passage under vacuum piston

B Float chamber vent passage

6 Remove the float chamber cover (10).

7 Remove the jet (15) and the spring (16).

8 Remove the plastic bracket (17) for the

float, and then remove the float (11).

9 Remove the float valve (12) and the washer.

10 Remove the choke (13).

11 Remove the modulator valve (18).

10 Float chamber cover 15 Jet

11 Float 16 Jet spring

12 Float valve 17 Plastic bracket

13 Choke mechanism 18 Modulator valve

14 Carburettor body

C Signal outlet for distributor

D Signal outlet for EGR

E Fuel inlet spigot

F Modulator valve spigot

To clean

Wash the carburettor components in paraffin

(kerosine).

Note

Clean the diaphragm in paraffin (kerosine) only.

Do not use highly-volatile cleaning agents such

astrichlorethylene.

Check that the diaphragm is in good condition. If

it has split, fit a new one.

Check the needle for wear and replace it if it is

bent or worn. Check that all contact and sealing

surfaces are undamaged.

Check that the choke disc and corresponding

sealing surface on the carburettor body are not

scratched. Clean the holes in the choke disc with

compressed air.

To assemble

1 Fit the diaphragm on the vacuum piston so

that the inner locating tab (A) engages the

corresponding slot in the piston.

Note

If, after drying for a while, the diaphragm is still

so distended that it will not fit into the slot, renew

it. A distended diaphragm will usually revert to its

normal shape after being allowed to dry for a

while.

Place the plastic washer and metal retaining

ring in position so that the screw holes are in

line with those in the piston and diaphragm,

without twisting the ring, and with the notch

matching the tab on the diaphragm. Fit and A Innertaband matching slot in vacuum piston

tighten the screws. B Outer tab to match slot in carburettor body

2 Fit the needle as follows:

a Insert the spring housing of the needle

into the vacuum piston, with the flat sur-

face facing the setscrew.

b Adjust the needle so that the shoulder is

flush with the bottom of the piston.

Needle should flush with bottom of piston

c Tighten the setscrew.

Fit the float valve and washer and the float

and spindle. Make sure that the adjusting

tab on the float is inserted under the locking

needle of the float valve. Fit the plastic brac-

ket.

4 Check/adjust the float level

Press down on the plastic bracket to position

the float correctly. Tilt the carburettor (ap-

prox. 10°) until the float arm just touches the

ball on the needle valve.

Note

The ball must not be pressed home.

Measure the float height to the gasket face.

Adjust the height, as necessary, to the cor-

rect value of 8 ± 1mm by bending the tab at

the needle valve.

5 Fit the jet spring and the jet.

6 Fit the float chamber cover.

7 Carry out basic setting of the fuel jet.

Adjust the height by means of the adjusting

screw on the float chamber cover. The jet should

be 2,5 mm (0.098 in) below the face of the jet

bridge (at 20°C;68°F).

Note

Take care not to press down on the spring-loaded

jet with the calliper, as this will affect the read-

ins.

8 Fit the piston, with the diaphragm and

spring, into the carburettor body. Make sure

that the tab on the diaphragm fits into the

corresponding slot in the carburettor body.

Fit the carburettor cover in position as indi-

cated by the marks, and tighten it.

9 Fit the cover and the damper piston.

10 Fit the modulator valve.

11 Fit the choke.

To refit

1 Fit the carburettor to the rubber of the inlet

manifold.

2 Connect the fuel hose to the carburettor and

fit the vapour trap and clamp.

3 Fit the flange to the carburettor.

4 Connect the inlet hose to the carburettor.

5 Fit the throttle and choke cables.

6 Connect the electrical lead to the float

chamber ventilation shut-off valve.

7 Fit the earth lead to the top of the carburet-

tor.

8 Connect the hoses for the EGR valve and dis-

tributor.

9 Fill the damper cylinder with oil.

10 Run the engine until it reaches normal

operating temperature and then adjust the

CO setting, idling speed and fast idling

speed.

Changing the adjusting screw

in the vacuum piston

(Stromberg)

Removal (vacuum piston with needle

removed)

1 Using a drift, press out the adjusting screw

until it protrudes a few centimetres (an inch

or so) beyond the bottom of the piston.

Potrebbero piacerti anche

- 3 Stromberg SingleDocumento7 pagine3 Stromberg SinglevanapeerNessuna valutazione finora

- Stromberg NeedleDocumento2 pagineStromberg Needlevanapeer100% (2)

- CIS-E Airflow Sensor Potentiometer Replacement GuideDocumento2 pagineCIS-E Airflow Sensor Potentiometer Replacement Guideazizja1100% (2)

- Fuel Pump Flow RatesDocumento6 pagineFuel Pump Flow Rateshenry0% (1)

- 072-090 2Documento15 pagine072-090 2hishammahrousm89Nessuna valutazione finora

- Pierburg Carburetor 2E3 Settings and TroubleshootingDocumento43 paginePierburg Carburetor 2E3 Settings and TroubleshootingGjorgi Ljubotenski79% (14)

- Pierburg 2E3Documento13 paginePierburg 2E3Michiel Dequidt67% (3)

- Mercedes W123 Models HistoryDocumento4 pagineMercedes W123 Models HistoryDeadFace98lolNessuna valutazione finora

- REPAIRING THE CIS JETRONICDocumento0 pagineREPAIRING THE CIS JETRONICFareTrade Kubin100% (1)

- Pierburg 2E3 ComponentsDocumento2 paginePierburg 2E3 Componentsmoatzfawzi100% (1)

- Citroen GSA ManualDocumento174 pagineCitroen GSA Manualladis61100% (2)

- Bosch K-Jet (CIS)Documento14 pagineBosch K-Jet (CIS)gjm126Nessuna valutazione finora

- 1 PDFDocumento17 pagine1 PDFMaxim MackenzyNessuna valutazione finora

- Adjust Bosch KE3-Jetronic Mixture on Mercedes 560Documento5 pagineAdjust Bosch KE3-Jetronic Mixture on Mercedes 560asamu10Nessuna valutazione finora

- TP31127-1 700 Body Fittings IncompleteDocumento155 pagineTP31127-1 700 Body Fittings IncompleteAchim Maximilian Naumann d'Alnoncourt100% (3)

- Tuning spark ignition engines with the ECUMaster EMU BlackDocumento230 pagineTuning spark ignition engines with the ECUMaster EMU Blacksxp100% (1)

- Mercedes Benz w123Documento34 pagineMercedes Benz w123mink4uNessuna valutazione finora

- 1986 Mercedes Benz Cis-E Fuel Injection System-1Documento23 pagine1986 Mercedes Benz Cis-E Fuel Injection System-1Jen Steel100% (8)

- Bosch K Jetronic Fuel InjectionDocumento10 pagineBosch K Jetronic Fuel Injectionvictoson100% (5)

- Overvoltage protection relay function and testingDocumento4 pagineOvervoltage protection relay function and testingHernan Martinez Lamas100% (2)

- Stromberg 175Documento17 pagineStromberg 175vanapeer100% (10)

- 420 SEL 560 SEL 560 SEC: Owner's ManualDocumento121 pagine420 SEL 560 SEL 560 SEC: Owner's ManualCons100% (1)

- Mercedes 190eDocumento144 pagineMercedes 190eJames50% (2)

- Idle, Slow Running and Progression: 8 Theidle SpeedissetbyanadjusttDocumento13 pagineIdle, Slow Running and Progression: 8 Theidle Speedissetbyanadjustt14carlos14100% (1)

- Mercedes DifferentialsDocumento8 pagineMercedes DifferentialsAntonio Sanchez SanchezNessuna valutazione finora

- MB M110 Engine Vacuum ConnectsDocumento4 pagineMB M110 Engine Vacuum ConnectsApa Ongpin73% (11)

- w124 Relay PositionsDocumento8 paginew124 Relay PositionsJugoslav Zivanovic100% (2)

- Land Rover Series I Workshop ManualDocumento194 pagineLand Rover Series I Workshop ManualAlmir Garcia50% (2)

- Tips - Autodata 1989 90 Carburettor Maunual PDFDocumento531 pagineTips - Autodata 1989 90 Carburettor Maunual PDFstoica100% (6)

- Resolving Mercedes M103 Idle IssuesDocumento8 pagineResolving Mercedes M103 Idle IssuesGraham Manning100% (1)

- Pierburg 2e3 Maintenance and RepairDocumento11 paginePierburg 2e3 Maintenance and Repairq1q1q1q1100% (2)

- 2 DescriptionDocumento24 pagine2 Descriptionvanapeer100% (3)

- 1985-1996 Mercedes E-Class W124 Fuse Box DiagramDocumento14 pagine1985-1996 Mercedes E-Class W124 Fuse Box Diagramaakritich100% (3)

- 740-760-780 1982-92Documento308 pagine740-760-780 1982-92Rodrigo Faunes Correa100% (1)

- 1,6 HDI, 1,6 TDCI API-PresentationDocumento44 pagine1,6 HDI, 1,6 TDCI API-PresentationdonlukaszNessuna valutazione finora

- MERCEDES W123 Service Manual ClimateDocumento248 pagineMERCEDES W123 Service Manual Climateriomaior89% (27)

- Problems With K-Jetronic SystemDocumento4 pagineProblems With K-Jetronic SystemVladimir Lalošević100% (1)

- Mercedes M110 Engine Testing and Adjusting Firing PointDocumento4 pagineMercedes M110 Engine Testing and Adjusting Firing Pointsixstring100% (1)

- Of Gear Aps: Mercedes Model 722.6 5 Speed + Lockup Gearbox ControllerDocumento61 pagineOf Gear Aps: Mercedes Model 722.6 5 Speed + Lockup Gearbox ControllerSvetoslav Arnaudov100% (2)

- Metric Mechanic m42 and m44 Engine BookletDocumento25 pagineMetric Mechanic m42 and m44 Engine BookletArvydas RaščikasNessuna valutazione finora

- Manual Pajero 4x4 Rear AxleDocumento32 pagineManual Pajero 4x4 Rear AxleGIAN CARLO MAMANI GILES.Nessuna valutazione finora

- The 4A-GE Block: A Submission by Richard WhiteDocumento9 pagineThe 4A-GE Block: A Submission by Richard WhiteJohn Phillpotts100% (2)

- Audi - The 2.7-Litre V6 BiturboDocumento72 pagineAudi - The 2.7-Litre V6 BiturboLola Selo100% (3)

- Saab 9-5 Head Gasket Replacement GuideDocumento3 pagineSaab 9-5 Head Gasket Replacement GuideDerrick ChongNessuna valutazione finora

- 03-01C Engine, 4.0L V-66ford 4.0 Repair ManualDocumento206 pagine03-01C Engine, 4.0L V-66ford 4.0 Repair ManualMike GunionNessuna valutazione finora

- Me Piston Replacement ProcedureDocumento6 pagineMe Piston Replacement ProcedureGaurav MaithilNessuna valutazione finora

- Sopras Sub Jupiter Diaphragm First Stage: Maintenance InstructionsDocumento13 pagineSopras Sub Jupiter Diaphragm First Stage: Maintenance InstructionscesarecontoNessuna valutazione finora

- Engine Turbocharger Removal and Installation GuideDocumento9 pagineEngine Turbocharger Removal and Installation GuideBimMariusNessuna valutazione finora

- 1977 Jeep-1977 TSBDocumento126 pagine1977 Jeep-1977 TSBperzaklieNessuna valutazione finora

- 1B Moottorinkorjauskäsikirja BensapetrooliDocumento33 pagine1B Moottorinkorjauskäsikirja BensapetroolimajoristiNessuna valutazione finora

- Rammer 1655 Service 2015Documento52 pagineRammer 1655 Service 2015SerkanAlNessuna valutazione finora

- Sci Mop Bombas Espuma Cgp80 - ChemguardDocumento13 pagineSci Mop Bombas Espuma Cgp80 - Chemguarddiuska13Nessuna valutazione finora

- Accumulator Maintenance Instructions Rev BDocumento6 pagineAccumulator Maintenance Instructions Rev BJohn Néstor Ramirez CalderónNessuna valutazione finora

- Repair Information: Eaton Hydrualics DivisionDocumento8 pagineRepair Information: Eaton Hydrualics DivisionZafiro Feliz GalanNessuna valutazione finora

- Toyota Prius Timing Chain Service GuideDocumento13 pagineToyota Prius Timing Chain Service Guidefernando ortizNessuna valutazione finora

- A21 Engine - 1.6Documento53 pagineA21 Engine - 1.6ahmedNessuna valutazione finora

- TCM IO520 OverhaulManualDocumento5 pagineTCM IO520 OverhaulManualhector eduardo moya benavidesNessuna valutazione finora

- Chapter C Air Conditioning SystemsDocumento54 pagineChapter C Air Conditioning Systemsara.mon872Nessuna valutazione finora

- Technology, LLC: Fuel Pro 382 Filter Change ProcedureDocumento1 paginaTechnology, LLC: Fuel Pro 382 Filter Change ProcedureศุภกิจNessuna valutazione finora

- Volvo 850 EngineDocumento15 pagineVolvo 850 Enginevanapeer100% (3)

- GT Instruments 1973-1980, Assembly InstructionsDocumento4 pagineGT Instruments 1973-1980, Assembly InstructionsvanapeerNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- TP2103201Documento68 pagineTP2103201vanapeer83% (6)

- Mts Radio 1981 - , Instructions Incl Frequency Map of SwedenDocumento26 pagineMts Radio 1981 - , Instructions Incl Frequency Map of Swedenvanapeer100% (1)

- Volvo p1800s Stromberg 175 Instruction BookDocumento8 pagineVolvo p1800s Stromberg 175 Instruction Bookvanapeer100% (2)

- Mitsubishi TD04 Melett PartlistDocumento11 pagineMitsubishi TD04 Melett Partlistvanapeer100% (3)

- Melett Price List 2Documento49 pagineMelett Price List 2vanapeer100% (1)

- Melett Price ListDocumento30 pagineMelett Price ListvanapeerNessuna valutazione finora

- Superpro Volvo 240 Bushings Complete ListingDocumento9 pagineSuperpro Volvo 240 Bushings Complete ListingvanapeerNessuna valutazione finora

- Pic As ADocumento1 paginaPic As AvanapeerNessuna valutazione finora

- B21etl-Grpa Installation Instructions For B21ETLDocumento32 pagineB21etl-Grpa Installation Instructions For B21ETLvanapeer100% (1)

- Volvo 240 1979Documento28 pagineVolvo 240 1979vanapeerNessuna valutazione finora

- Homologation FisaDocumento89 pagineHomologation FisavanapeerNessuna valutazione finora

- TP11740-2 Carburetted Fuel SystemsDocumento116 pagineTP11740-2 Carburetted Fuel Systemsvanapeer100% (5)

- TP31201-1 700 Multi-Link Rear SuspensionDocumento42 pagineTP31201-1 700 Multi-Link Rear Suspensionvanapeer100% (1)

- 283782-Manual CB Radio - Owner's ManualDocumento8 pagine283782-Manual CB Radio - Owner's Manualvanapeer100% (1)

- Volvo Ecu and Amm ApplicationDocumento1 paginaVolvo Ecu and Amm ApplicationvanapeerNessuna valutazione finora

- Sun Shade in Front of Rear-View MirrorDocumento1 paginaSun Shade in Front of Rear-View Mirrorvanapeer100% (1)

- CB RadioDocumento4 pagineCB RadiovanapeerNessuna valutazione finora

- Intake Protection 1973-1985Documento1 paginaIntake Protection 1973-1985vanapeerNessuna valutazione finora

- (Dec. 79) Electrically Operated Rear View Mirror 1974-1985Documento8 pagine(Dec. 79) Electrically Operated Rear View Mirror 1974-1985vanapeerNessuna valutazione finora

- (Aug 81) Map Reading LampDocumento1 pagina(Aug 81) Map Reading LampvanapeerNessuna valutazione finora

- 8-89-112 (May 95) Fixed TowbarDocumento12 pagine8-89-112 (May 95) Fixed TowbarvanapeerNessuna valutazione finora

- 8-89-3 (March 81) Towing HitchDocumento4 pagine8-89-3 (March 81) Towing HitchvanapeerNessuna valutazione finora

- 8-89-68 (Dec. 90) Ski RackDocumento4 pagine8-89-68 (Dec. 90) Ski RackvanapeerNessuna valutazione finora

- 8-88-40 (Jan 88) Additional Instrument Cover 240 1981Documento5 pagine8-88-40 (Jan 88) Additional Instrument Cover 240 1981vanapeerNessuna valutazione finora

- 8-87-142 (May 95) Intake Protection (Snowcap) 1986Documento2 pagine8-87-142 (May 95) Intake Protection (Snowcap) 1986vanapeer100% (1)

- 8-88-39 (Dec. 87) Adjustable Front Belt HeightDocumento5 pagine8-88-39 (Dec. 87) Adjustable Front Belt HeightvanapeerNessuna valutazione finora

- 8-87-16 (Feb 89) Electrical Heater 4-CylDocumento16 pagine8-87-16 (Feb 89) Electrical Heater 4-CylvanapeerNessuna valutazione finora

- Pierburg 2E3Documento13 paginePierburg 2E3Michiel Dequidt67% (3)

- Engine Performance Data at 1500 RPM: QSK 1 Cummins IncDocumento4 pagineEngine Performance Data at 1500 RPM: QSK 1 Cummins IncFranyusmid Gómez BolivarNessuna valutazione finora

- Lamborghini Diablo Engine Parts ManualDocumento40 pagineLamborghini Diablo Engine Parts ManualAndrei Huţanu100% (1)

- Filters Part No. CPCB1 and CPCB2Documento34 pagineFilters Part No. CPCB1 and CPCB2Gorav rajput393100% (1)

- Grand Vitara 2010Documento191 pagineGrand Vitara 2010Fernando OrtizNessuna valutazione finora

- IAD Uc4Documento5 pagineIAD Uc4Edna Alliones ValienteNessuna valutazione finora

- Warning: Vehicles With Different Configurations and Wiring DiagramsDocumento11 pagineWarning: Vehicles With Different Configurations and Wiring DiagramsluisNessuna valutazione finora

- Timberpro P/N 50690: Optional Auxiliary Cooler Return Logic Block Load Sense ValveDocumento2 pagineTimberpro P/N 50690: Optional Auxiliary Cooler Return Logic Block Load Sense ValveЕвгений МакаровNessuna valutazione finora

- BerlinWind BladeAngleMeasurements enDocumento1 paginaBerlinWind BladeAngleMeasurements envdmoorthy123Nessuna valutazione finora

- QuincyDocumento1 paginaQuincyJavier100% (1)

- Radial Engine Solidworks 00 PDFDocumento42 pagineRadial Engine Solidworks 00 PDFOscar Osorno67% (6)

- Ingersoll Rand - SpécificationsDocumento1 paginaIngersoll Rand - SpécificationsMAMI RAKOTOMAHANINANessuna valutazione finora

- Stanadyne P/N John Deere P/N'sDocumento6 pagineStanadyne P/N John Deere P/N'sЕкатерина КалашниковаNessuna valutazione finora

- PT. TURBO DIESEL SERVICE REPORT FOR MT.PALUSIPAT AUX ENGINE TURBOCHARGERDocumento15 paginePT. TURBO DIESEL SERVICE REPORT FOR MT.PALUSIPAT AUX ENGINE TURBOCHARGERaang anggaraNessuna valutazione finora

- DC13 072A. 403-487 KW (456-553 kVA) : Fuel OptimizedDocumento2 pagineDC13 072A. 403-487 KW (456-553 kVA) : Fuel OptimizedJulio SullaymeNessuna valutazione finora

- Detailing To Infuse Reaction .: Design of Components of Francis TurbineDocumento50 pagineDetailing To Infuse Reaction .: Design of Components of Francis TurbineTonny Suak100% (1)

- KTM prepares potent V-twin streetbike after decade of success in off-road racingDocumento6 pagineKTM prepares potent V-twin streetbike after decade of success in off-road racingAlvaro Gomez RivasNessuna valutazione finora

- Parts of Motorcycle EngineDocumento12 pagineParts of Motorcycle EngineRj Saneubac Guhabac100% (1)

- PSI 8.8L ServiceDocumento197 paginePSI 8.8L Serviceedelmolina100% (1)

- 2 Valves and Injectors Adjustment VEBDocumento21 pagine2 Valves and Injectors Adjustment VEBRuju RujuNessuna valutazione finora

- LEHM20671-00 - C4.4 Electronic Data SheetDocumento3 pagineLEHM20671-00 - C4.4 Electronic Data Sheetkman548Nessuna valutazione finora

- Non Linear Transient Analysis of a Camshaft AssemblyDocumento3 pagineNon Linear Transient Analysis of a Camshaft AssemblyvenkyNessuna valutazione finora

- Jenbacher 616 GS-N.L Gas Engine Specs & 2.433kW OutputDocumento4 pagineJenbacher 616 GS-N.L Gas Engine Specs & 2.433kW OutputMartin KratkyNessuna valutazione finora

- Explore the specifications of the IO-520 aircraft engine seriesDocumento1 paginaExplore the specifications of the IO-520 aircraft engine seriescalibranrNessuna valutazione finora

- EUROVANDocumento4 pagineEUROVANricardo romeroNessuna valutazione finora

- Repuestos Motor C-07Documento11 pagineRepuestos Motor C-07Wilson BalbinNessuna valutazione finora

- @@er650 - Er6n 2012-2013Documento112 pagine@@er650 - Er6n 2012-2013Diego AldanaNessuna valutazione finora

- Pds Meditran SX Sae 20w-50 API Cg-4 (Overseas Mengacu Kimap No A070111175)Documento1 paginaPds Meditran SX Sae 20w-50 API Cg-4 (Overseas Mengacu Kimap No A070111175)Muhammad Irwan AnisNessuna valutazione finora

- 4200 Wet Sump - Engine OverhaulDocumento0 pagine4200 Wet Sump - Engine Overhaulaiigee100% (8)

- Engine Guideline Engine Guideline: Engine Mechanical F8B EngineDocumento42 pagineEngine Guideline Engine Guideline: Engine Mechanical F8B EnginePraveen KumarNessuna valutazione finora