Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PVV Pumps: Technical Bulletin

Caricato da

Rolando RodriguezTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PVV Pumps: Technical Bulletin

Caricato da

Rolando RodriguezCopyright:

Formati disponibili

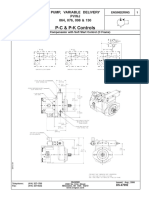

Technical Bulletin ENGINEERING 1

PVV PUMPS

Application Guidelines

The following information should be considered when applying Oilgear PVV Pumps. These guidelines are to be used to help

design systems for continuous duty. Please consult the Oilgear Technical Sales Department when application and/or system

requirement vary (even) slightly from the following.

Specifications

(Also See "Additional Notes") PVV 200 PVV 250 PVV 440 PVV 540

DRIVE

Maximum rpm

Flooded Inlet (suction) 1800 1800 N/A 1200

Supercharged Inlet 1800 1800 1500 ** 1500 **

Minimum rpm

Flooded Inlet (suction) 600 600 N/A 600

Supercharged Inlet 600 600 600 600

Torque to turn shaft (ft. -lbs.) 14 14 36 36

** Consult Oilgear Tech. Sales Dept.

Inlet

Pressure (psia)

1800 rpm 14.3 14.7 N/A -

1500 rpm 10.8 11.5 ** **

1200 rpm 8.0 10.0 29 11.1

** Consult Oilgear Tech. Sales Dept.

Output

Pressure (psi)

Maximum

Peak (See "additional notes") 6500 5800 7250 5800

Continuous 6000 5000 6500 5000

Minimum 100 100 100 100

Minimum Volume

(gpm) @ rated pressure, and indicated speed 86 109 125 155

for full displacement @ 1800 rpm @ 1800 rpm @ 1200 rpm @ 1200 rpm

Pumps should not be run at neutral for

more than 30 consecutive minutes. For

longer times, a 10% minimum

stroke should be maintained.

Case

Maximum Pressure psi w/Std. Shaft Seal 25 25 25 25

Minimum Drain Size (inch tube) 1.25 1.25 1.5 1.5

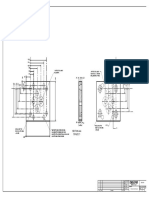

Orientation: See Oilgear Service Instructions Bulletins 947027, 947028, or 947029 for horizontal mounting.

See Oilgear Service Instruction Bulletin 90014 for vertical mounting.

Telephone: (414) 327-1700 OILGEAR Revised: February, 2010

st

Fax: (414) 327-0532 2300 So. 51 . Street

Website: www.oilgear.com Milwaukee, WI USA 53219 Bulletin 847028-D

Technical Bulletin ENGINEERING 2

PVV PUMPS

Application Guidelines

Specifications PVV 200 PVV 250 PVV 440/540 PVV 540

(Also See "Additional Notes") "A" Series "B" Series

Control

Minimum Pilot Pressure (psi)

for Volume Controls (VM, VS & RU) 700 700 500 700

Maximum Pilot Pressure (psi)

for Volume Controls (VM, VS & RU) 1000 1000 1000 1000

Stroking Rate (msec.) at rated pressure

Pressure Controls (minimum)*

On Stroke 140 140 N/A/300 350

Off Stroke 100 100 N/A/100 100

Volume Controls (VM, VS & RU)

with minimum control psi

On and Off stroke 375 375 375/375 270

* Fastest possible time; stroking times may be

Slower, depending on conditions.

Consult Oilgear Technical Sales Department.

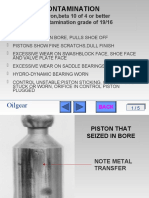

Fluids Also see “Additional Notes” for filtration

and contamination levels. Mineral oil fluids shall

include an anti-wear package

Viscosity SSU

Minimum 80 80 80 80

Maximum 2000 2000 2000 2000

Operating Temperature (Fo)*

Inlet

Maximum 160 160 160 160

Minimum -20 -20 -20 -20

Case maximum 210 210 200 200

* Minimum and maximum viscosity

should be observed.

OILGEAR Telephone: (414) 327-1700

st

Revised: February, 2010 2300 So. 51 . Street Fax: (414) 327-0532

Bulletin 847028-D Milwaukee, WI 53219 Website: www.oilgear.com

Technical Bulletin ENGINEERING 3

PVV PUMPS

Application Guidelines

ADDITIONAL NOTES

Inlet

1. Pumps mounted above the reservoir must be arranged to insure pump will "prime" when started.

PVV-440 is available for supercharged service only.

2. When supercharging:

a) Maximum allowable supercharge pressure is 200 psi.

b) Volume must be sufficient to maintain inlet pressure.

3. For low viscosity and HF water based fluids consult factory.

Outlet

1. Peak Pressure:

The unit can be operated at peak pressure for 1% or less of every minute.

Case

1. Drain

a) Fill case with fluid before starting

b) Arrange case drain line to keep case full of fluid

c) Use a minimum of bends returning case drain line to reservoir below minimum fluid level.

2. Orientation

Pump orientation is not restricted. But, case drain must be arranged to keep case full of fluid at all times.

See Oilgear Service Bulletin 947027, 947028 or 947029 for horizontally mounted units. For vertically

mounted units, see Bulletin 90014 “Service Instructions, Installation of Vertically Mounted Axial

Piston Units”.

Control

1. Case bleed of 2 gpm is recommended for volume controlled pumps and/or pumps hydraulically remote

controlled. Note: A bleed orifice is incorporated internally on all VM, VS, & RU controlled pumps.

Fluid

1. Filtration

a) At least 1/3 of pump volume must be filtered with an element having a B10 (c) = 200.

b) All fluid to a swing-plate servo valve control must be filtered with an element having a B10 (c) = 200

c) All fluid to other servo valve controls must be through a B10 (c) 200 element.

2. Maximum contamination level of ISO (c) 20/18/15 and 0.1% of maximum of water.

3. Pumps must be run with anti-wear type mineral oil.

4. For low viscosity and HF water base fluids consult factory.

Start-up

1. Priming - Provisions must be made to bleed air from the high pressure lines.

Telephone: (414) 327-1700 OILGEAR Revised: February, 2010

st

Fax: (414) 327-0532 2300 So. 51 . Street

Website: www.oilgear.com Milwaukee, WI USA 53219 Bulletin 847028-D

Potrebbero piacerti anche

- Technical Bulletin PVK Pumps: Application Guide LinesDocumento4 pagineTechnical Bulletin PVK Pumps: Application Guide LinesRolando RodriguezNessuna valutazione finora

- Dynexpf 2000 SpecialmountDocumento5 pagineDynexpf 2000 SpecialmountOILSERVICES COQUIMBONessuna valutazione finora

- Catalogo Denison Serie PVDocumento4 pagineCatalogo Denison Serie PVEdison YesidNessuna valutazione finora

- PV4000 Series Mechcanical Variable Pumps: Contact InformationDocumento5 paginePV4000 Series Mechcanical Variable Pumps: Contact InformationMiguel VlntìnNessuna valutazione finora

- EFP - MISO 100-250 750USGPM @110mDocumento5 pagineEFP - MISO 100-250 750USGPM @110mRahmanu AribowoNessuna valutazione finora

- Workshop Stanadyne 06479Documento4 pagineWorkshop Stanadyne 06479Kevin TtitoNessuna valutazione finora

- Engineering Catalog: CD250M Dri-Prime Pump Engineering DataDocumento7 pagineEngineering Catalog: CD250M Dri-Prime Pump Engineering DataNils Enrique Hansen GamarraNessuna valutazione finora

- MR-HL510 Data SheetDocumento1 paginaMR-HL510 Data SheetAlmaNessuna valutazione finora

- Injection Pump - PDDocumento4 pagineInjection Pump - PDCyrielle AlarsonNessuna valutazione finora

- 3ME - Technical CatalogueDocumento24 pagine3ME - Technical CatalogueRamonNessuna valutazione finora

- PF1000 Series Fixed Displacement Pumps: Contact InformationDocumento6 paginePF1000 Series Fixed Displacement Pumps: Contact InformationMiguel VlntìnNessuna valutazione finora

- Mrhf-820t Data SheetDocumento1 paginaMrhf-820t Data SheetMars ROCK DRILLNessuna valutazione finora

- Bomba MecanicaDocumento2 pagineBomba MecanicaBanupriya BalasubramanianNessuna valutazione finora

- SRC Technical DataDocumento6 pagineSRC Technical DataKamel NaitNessuna valutazione finora

- Model: T-8045: Installation & ServiceDocumento28 pagineModel: T-8045: Installation & ServiceAlisson FelipeNessuna valutazione finora

- Injection Pump Specification ©Documento4 pagineInjection Pump Specification ©Port CranesNessuna valutazione finora

- 85,000 Barrels Every Day!: 8L-912Y Series Standard Product SpecificationsDocumento6 pagine85,000 Barrels Every Day!: 8L-912Y Series Standard Product SpecificationsManuel GimenezNessuna valutazione finora

- BRAKES Air Cooled BrakesDocumento6 pagineBRAKES Air Cooled Brakes张淼Nessuna valutazione finora

- Injection Pump Specification ©Documento4 pagineInjection Pump Specification ©admin tigasaudaraNessuna valutazione finora

- Okada America Inc.: SpecificationsDocumento2 pagineOkada America Inc.: SpecificationsWidya RaniNessuna valutazione finora

- 2DRE Technical CatalogueDocumento20 pagine2DRE Technical CatalogueLuis CaballeroNessuna valutazione finora

- Stanadyne db2435 4942Documento4 pagineStanadyne db2435 4942nelson vasquezNessuna valutazione finora

- 1) SCP-200-460-HA (280kw, 4 Pole) Data SheetDocumento6 pagine1) SCP-200-460-HA (280kw, 4 Pole) Data Sheetنايفف بن عبداللهNessuna valutazione finora

- Dynex PF1000 10 SpecsDocumento8 pagineDynex PF1000 10 SpecsLuis Enrique López LeónNessuna valutazione finora

- RepairDocumento4 pagineRepairKevin Ttito100% (1)

- Evfuel Gespa-Bdp200-G140aDocumento1 paginaEvfuel Gespa-Bdp200-G140aapi-525617690Nessuna valutazione finora

- nc150s Isuzu 4le2x Us 200gpa0001420 - Us PDFDocumento2 paginenc150s Isuzu 4le2x Us 200gpa0001420 - Us PDFjuanpantera24Nessuna valutazione finora

- Premier Piston Pump Sales Catalog Страницы 4 6,8 9,30,34,43Documento8 paginePremier Piston Pump Sales Catalog Страницы 4 6,8 9,30,34,43Michail ArmitageNessuna valutazione finora

- Stanadyne K3 DB4427-4951Documento4 pagineStanadyne K3 DB4427-4951Micael FigueiraNessuna valutazione finora

- XAVS450 LEAFLET2@New CrusherDocumento5 pagineXAVS450 LEAFLET2@New Crusherสิทธิพล โพธิ์ประยูร100% (1)

- Inverter Range DatasheetDocumento1 paginaInverter Range DatasheetvasilzhmendakNessuna valutazione finora

- Injection Pump Specification ©Documento4 pagineInjection Pump Specification ©murillo_rodriguez8382Nessuna valutazione finora

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocumento4 pagineInjection Pump Specification ©: Use Latest Revision For All Referenced DocumentsTurbo TruckNessuna valutazione finora

- Plano de Teste e Lista de Peças DB2435-4972 KORVANDocumento4 paginePlano de Teste e Lista de Peças DB2435-4972 KORVANGiovaniBalzaniNessuna valutazione finora

- Rebuild StanadyneDocumento4 pagineRebuild StanadyneKevin TtitoNessuna valutazione finora

- PF1000 Series Checkball Piston Pumps: Pressures To 10 000 PsiDocumento7 paginePF1000 Series Checkball Piston Pumps: Pressures To 10 000 PsiRodo RequenaNessuna valutazione finora

- Compressores - SabroeDocumento2 pagineCompressores - SabroemarceloNessuna valutazione finora

- PU LPH 80540 80553 Esite GBDocumento7 paginePU LPH 80540 80553 Esite GBAl-Alamiya TradeNessuna valutazione finora

- W1500 Series Hydraulic Pump: Concentric ABDocumento12 pagineW1500 Series Hydraulic Pump: Concentric ABvut73 a100% (1)

- 2DRE - Technical CatalogueDocumento20 pagine2DRE - Technical CatalogueBsaltda GestionNessuna valutazione finora

- Gear Pumps and Motors "B" Series Group 2,5: Technical CatalogueDocumento29 pagineGear Pumps and Motors "B" Series Group 2,5: Technical CatalogueLucyan IonescuNessuna valutazione finora

- 05354Documento4 pagine05354GiovaniBalzaniNessuna valutazione finora

- 1.5DRE - Technical CatalogueDocumento16 pagine1.5DRE - Technical CatalogueBsaltda GestionNessuna valutazione finora

- Injection Pump Specification ©Documento4 pagineInjection Pump Specification ©Alejandro Manzano CumpianNessuna valutazione finora

- Vane Pumps Single, Double & Triple T6 Mobile ApplicationDocumento12 pagineVane Pumps Single, Double & Triple T6 Mobile Applicationdelhi hydraulics100% (1)

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocumento4 pagineInjection Pump Specification ©: Use Latest Revision For All Referenced Documentsjohnny sabinNessuna valutazione finora

- PMC Mog HDocumento4 paginePMC Mog HsaikiranNessuna valutazione finora

- HLX5 Drifter Manufactured by Delta Grup DeliciDocumento1 paginaHLX5 Drifter Manufactured by Delta Grup DeliciAlma100% (1)

- 2PE Salami PDFDocumento35 pagine2PE Salami PDFMartin MiaNessuna valutazione finora

- Injection Pump Specification ©Documento4 pagineInjection Pump Specification ©admin tigasaudaraNessuna valutazione finora

- DB4427-5370 Lionn Auto SoftwareDocumento4 pagineDB4427-5370 Lionn Auto SoftwareOFFICE DANACNessuna valutazione finora

- TC FLS Sihi Leh 1200 1500 1800 enDocumento10 pagineTC FLS Sihi Leh 1200 1500 1800 enGustavo ZavalaNessuna valutazione finora

- Gear Pump PGP511Documento11 pagineGear Pump PGP511Ayman AlhalfawyNessuna valutazione finora

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocumento4 pagineInjection Pump Specification ©: Use Latest Revision For All Referenced DocumentsAnonymous 5tkF5bFwONessuna valutazione finora

- Injection Pump Specification ©Documento4 pagineInjection Pump Specification ©Mr CupuNessuna valutazione finora

- VD10A - VD12A - Technical CatalogueDocumento34 pagineVD10A - VD12A - Technical CatalogueDavid AltarribaNessuna valutazione finora

- Service Instructions "PVWJ" A-FRAME PUMPS - 011/-014/-022 For Type "P-1Nn" and "P-LNN" Pressure Compensating ControlsDocumento16 pagineService Instructions "PVWJ" A-FRAME PUMPS - 011/-014/-022 For Type "P-1Nn" and "P-LNN" Pressure Compensating ControlsRolando RodriguezNessuna valutazione finora

- Improper Inlet Conditions Suction Strainer Not RecommendedDocumento2 pagineImproper Inlet Conditions Suction Strainer Not RecommendedRolando RodriguezNessuna valutazione finora

- Ds 47992Documento1 paginaDs 47992Rolando RodriguezNessuna valutazione finora

- Pump, Variable Delivery PVWJ 025, 034 & 046 P-1NN/F, P-LNN/F, P-1NNN/J, P-LNN/J P-1NN/K and P-LNN/K ControlsDocumento2 paginePump, Variable Delivery PVWJ 025, 034 & 046 P-1NN/F, P-LNN/F, P-1NNN/J, P-LNN/J P-1NN/K and P-LNN/K ControlsRolando RodriguezNessuna valutazione finora

- 5 Case DrainDocumento9 pagine5 Case DrainRolando RodriguezNessuna valutazione finora

- 2 Fluid ProblemDocumento4 pagine2 Fluid ProblemRolando RodriguezNessuna valutazione finora

- Heat Where It Comes From: OilgearDocumento2 pagineHeat Where It Comes From: OilgearRolando RodriguezNessuna valutazione finora

- Pump, Variable Delivery PVV-200 or 250 "Ru" Control: Engineering 1Documento1 paginaPump, Variable Delivery PVV-200 or 250 "Ru" Control: Engineering 1Rolando RodriguezNessuna valutazione finora

- 3 OverpressureDocumento4 pagine3 OverpressureRolando RodriguezNessuna valutazione finora

- 1 NoiseDocumento2 pagine1 NoiseRolando RodriguezNessuna valutazione finora

- 1 ContaminationDocumento5 pagine1 ContaminationRolando RodriguezNessuna valutazione finora

- "V-M" Control: Pump, Variable Delivery PVV-540 "B1" WithDocumento1 pagina"V-M" Control: Pump, Variable Delivery PVV-540 "B1" WithRolando RodriguezNessuna valutazione finora

- PVG ApplicationDocumento9 paginePVG ApplicationRolando RodriguezNessuna valutazione finora

- "V-R" Control: Pump, Variable Delivery PVV-540 "B1" WithDocumento1 pagina"V-R" Control: Pump, Variable Delivery PVV-540 "B1" WithRolando RodriguezNessuna valutazione finora

- "V-M Control: Pump, Variable Delivery PVV-440 "A2"Documento1 pagina"V-M Control: Pump, Variable Delivery PVV-440 "A2"Rolando RodriguezNessuna valutazione finora

- Ds m47683 PDFDocumento1 paginaDs m47683 PDFRolando RodriguezNessuna valutazione finora

- "R-U" Control: Pump, Variable Delivery PVV-540 "B1" WithDocumento1 pagina"R-U" Control: Pump, Variable Delivery PVV-540 "B1" WithRolando RodriguezNessuna valutazione finora

- Ds 47168 PDFDocumento1 paginaDs 47168 PDFRolando RodriguezNessuna valutazione finora

- "P-2Nn" Dual Pressure Compensator Control: (With 4-Way Pilot Control Valve)Documento4 pagine"P-2Nn" Dual Pressure Compensator Control: (With 4-Way Pilot Control Valve)Rolando RodriguezNessuna valutazione finora

- Service Instructions Pvv-440 - A2 Series PumpDocumento28 pagineService Instructions Pvv-440 - A2 Series PumpRolando RodriguezNessuna valutazione finora

- Pump, Variable Delivery PVM 011, 014 & 022 A-Frame: Engineering 1Documento4 paginePump, Variable Delivery PVM 011, 014 & 022 A-Frame: Engineering 1Rolando RodriguezNessuna valutazione finora

- 228MX 1 ModelDocumento1 pagina228MX 1 ModelRolando RodriguezNessuna valutazione finora

- "B" Frame: Pump, Variable Delivery PVM 065/075Documento7 pagine"B" Frame: Pump, Variable Delivery PVM 065/075Rolando RodriguezNessuna valutazione finora

- Pump, Variable Delivery PVV-540 "B1" With "F" Control: Engineering 1Documento1 paginaPump, Variable Delivery PVV-540 "B1" With "F" Control: Engineering 1Rolando RodriguezNessuna valutazione finora

- "F" Control: Pump, Variable Delivery PVV-200 or 250Documento1 pagina"F" Control: Pump, Variable Delivery PVV-200 or 250Rolando RodriguezNessuna valutazione finora

- Oilgear Type "PVM" Pumps - 011/-014/-022/-025/-034/-046/ - 064/-065/-075/-076/-098/-130 Service InstructionsDocumento64 pagineOilgear Type "PVM" Pumps - 011/-014/-022/-025/-034/-046/ - 064/-065/-075/-076/-098/-130 Service InstructionsRolando RodriguezNessuna valutazione finora

- "B" Frame: Pump, Variable Delivery PVM 025, 034 & 046Documento7 pagine"B" Frame: Pump, Variable Delivery PVM 025, 034 & 046Rolando RodriguezNessuna valutazione finora

- "C" Frame: Pump, Variable Delivery PVM 064, 076, 098 &130Documento5 pagine"C" Frame: Pump, Variable Delivery PVM 064, 076, 098 &130Rolando RodriguezNessuna valutazione finora

- Stauff Clamps EnglishDocumento54 pagineStauff Clamps EnglishRolando RodriguezNessuna valutazione finora

- Refrigerating Plant Test and Performance Sample ProblemsDocumento2 pagineRefrigerating Plant Test and Performance Sample ProblemsMerie Ann DudangNessuna valutazione finora

- Surface TensionDocumento16 pagineSurface Tensionjay danenjeyanNessuna valutazione finora

- Distillation ColumnDocumento23 pagineDistillation ColumnRanjani J DeepakNessuna valutazione finora

- Velocity DiagramDocumento4 pagineVelocity DiagramlitrakhanNessuna valutazione finora

- Empire Rubber & EnggDocumento2 pagineEmpire Rubber & Enggmanoj_doshi_1Nessuna valutazione finora

- Electrical Driven 2 Stage T 30 Series High Pressure Compressor enDocumento3 pagineElectrical Driven 2 Stage T 30 Series High Pressure Compressor enemmanuel slimNessuna valutazione finora

- OISD-118: Layouts For Oil and Gas InstallationsDocumento21 pagineOISD-118: Layouts For Oil and Gas InstallationsLakshman TumpatiNessuna valutazione finora

- General Design ProcedureDocumento5 pagineGeneral Design ProcedureMutiaraNessuna valutazione finora

- Cryogenics & LNG Application GuideDocumento16 pagineCryogenics & LNG Application GuidesusantoNessuna valutazione finora

- W5 - Neraca Massa Dengan Reaksi Kimia 2Documento28 pagineW5 - Neraca Massa Dengan Reaksi Kimia 2yuniNessuna valutazione finora

- Flare Sizing Rel 1 - 1Documento50 pagineFlare Sizing Rel 1 - 1Andreea AntohiNessuna valutazione finora

- 0304Documento14 pagine0304Hair Samayoa BrionesNessuna valutazione finora

- Vertical Spiral Rib Tubeless Steam BoilersDocumento6 pagineVertical Spiral Rib Tubeless Steam BoilersbenNessuna valutazione finora

- Spirometers Types and PrinciplesDocumento20 pagineSpirometers Types and PrinciplesGrupo APMNessuna valutazione finora

- SR DenasriDocumento284 pagineSR DenasriDjie GuerrNessuna valutazione finora

- Principles of Flight - 081 POFDocumento476 paginePrinciples of Flight - 081 POFobrajiorNessuna valutazione finora

- AtD PptsDocumento230 pagineAtD PptsLikhith DogiparthiNessuna valutazione finora

- Icab Paper Flow Analysis of Rocket Nozzle Using Compitutional Fluid DynamicsDocumento7 pagineIcab Paper Flow Analysis of Rocket Nozzle Using Compitutional Fluid DynamicsSAMEER MOHDNessuna valutazione finora

- Make List - Fire FightingDocumento3 pagineMake List - Fire FightingsureshkanuboyinaNessuna valutazione finora

- Experiment 1 With ValuesDocumento3 pagineExperiment 1 With Valuesgideon abhiNessuna valutazione finora

- Reservoir FluidsDocumento17 pagineReservoir FluidsMusab AlzwayiNessuna valutazione finora

- Contractor'S Material and Test Certificate For Aboveground PipingDocumento5 pagineContractor'S Material and Test Certificate For Aboveground PipingIbrahim Benmansour100% (1)

- Handbook Gas Utilisation FacilitiesDocumento23 pagineHandbook Gas Utilisation FacilitiesJack TouNessuna valutazione finora

- HansenDocumento4 pagineHansenBruna MacedoNessuna valutazione finora

- Safety Meeting Attendence SheetDocumento1 paginaSafety Meeting Attendence SheetHaleem Ur Rashid BangashNessuna valutazione finora

- Pressure Changes Gas LawsDocumento6 paginePressure Changes Gas LawstyytrdgNessuna valutazione finora

- Fluid MechanicsDocumento8 pagineFluid MechanicsajaydevmalikNessuna valutazione finora

- Types of SteamDocumento13 pagineTypes of SteamDuy Nguyen Duc100% (1)

- DNG CompressorDocumento4 pagineDNG CompressorsirtmxNessuna valutazione finora

- Fundamentals of Compressible Flow: Measurement Diagnostics and Experimental Facilities For Compressible FlowDocumento6 pagineFundamentals of Compressible Flow: Measurement Diagnostics and Experimental Facilities For Compressible Flowkushal bosuNessuna valutazione finora