Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chemax Tracit Heat Transfer Compound

Caricato da

Miguel Martinez Guerrero0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

58 visualizzazioni1 paginaChemax TRACIT heat transfer compounds have been used for over 65 years to maximize heat transfer in heat tracing systems. The compounds improve thermal efficiency by increasing contact area between surfaces and eliminating air gaps, allowing heat to transfer directly through conduction. Only one TRACIT line is needed to maintain pipe temperature compared to three to five bare tracers otherwise. The mastics can be easily applied, are durable, fire-resistant, safe, reliable, and cost less than jacketed systems.

Descrizione originale:

Cemento Termico

Titolo originale

CHEMAX TRACIT HEAT TRANSFER COMPOUND

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoChemax TRACIT heat transfer compounds have been used for over 65 years to maximize heat transfer in heat tracing systems. The compounds improve thermal efficiency by increasing contact area between surfaces and eliminating air gaps, allowing heat to transfer directly through conduction. Only one TRACIT line is needed to maintain pipe temperature compared to three to five bare tracers otherwise. The mastics can be easily applied, are durable, fire-resistant, safe, reliable, and cost less than jacketed systems.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

58 visualizzazioni1 paginaChemax Tracit Heat Transfer Compound

Caricato da

Miguel Martinez GuerreroChemax TRACIT heat transfer compounds have been used for over 65 years to maximize heat transfer in heat tracing systems. The compounds improve thermal efficiency by increasing contact area between surfaces and eliminating air gaps, allowing heat to transfer directly through conduction. Only one TRACIT line is needed to maintain pipe temperature compared to three to five bare tracers otherwise. The mastics can be easily applied, are durable, fire-resistant, safe, reliable, and cost less than jacketed systems.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

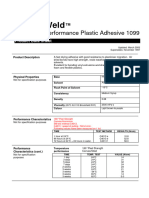

TRACIT Heat Transfer Compounds

Applications & Benefits

For almost 70 years, Chemax TRACIT heat transfer compounds

have been an integral component of heat tracing systems.

Chemax compounds/cement/mastics are essential for maximizing

heat transfer rates and improving thermal efficiency.

The primary purpose of TRACIT cements is to improve the heat

transfer between two surfaces by increasing the contact area and

eliminating the air flow. Heat is then transferred directly to the

pipe wall by conduction. Only one TRACIT line is required to

maintain pipe temperature, where 3-5 bare (convection) tracers

would otherwise be needed.

Due to the excellent adhesive properties of these mastics, they

can be applied to almost any clean surface. Figure 1: Typical Steam Tracing Application

Advantages

User-Friendly: TRACIT heat transfer compounds are

pliable and have a putty-like consistency, which allows

for easy application by mortar trowel.

Durable: Compounds can withstand considerable me-

chanical and thermal shock, and will last for the life of

the installation.

Fire-Resistant: Compounds will not burn or support

combustion.

Figure 2: Mastic Being Applied to Bare Tracer

Safe: Chemax mastics are non-hazardous.

Reliable: Over 65 years of proven performance.

Low-Cost: TRACIT mastics cost far less than jacketed

systems and provide an equivalent heat transfer with

steam tracings.

Contact a representative for additional information.

Figure 3: Cured Mastic Now Creates Uninterrupted

Thermal Connection Between Tracer and Pipe Wall

CHEMAX MANUFACTURING CORPORATION | TEL: (800) 804-4596 | FAX: (302) 328-0261 | sales@chemax.com

Potrebbero piacerti anche

- TAYLOR FORGE - Catalog 722 PDFDocumento79 pagineTAYLOR FORGE - Catalog 722 PDFMiguel Martinez Guerrero0% (1)

- Shigley Mechanical Engineering Design SODocumento182 pagineShigley Mechanical Engineering Design SOAtidech Tepputorn100% (1)

- What's Where On Earth Atlas - DKDocumento162 pagineWhat's Where On Earth Atlas - DKMiguel Martinez Guerrero100% (2)

- Tubular Heat Exchanger Lab ReportDocumento21 pagineTubular Heat Exchanger Lab ReportMuhammad Zafrulhafiz80% (5)

- Air Cooler Design Guidelines Rev 6, Jul 2012Documento36 pagineAir Cooler Design Guidelines Rev 6, Jul 2012Miguel Martinez GuerreroNessuna valutazione finora

- 3M Electronics Assembly Solutions Product Selection GuideDocumento44 pagine3M Electronics Assembly Solutions Product Selection GuideSven BaeldenNessuna valutazione finora

- Thermal Radiation Heat TransferDocumento194 pagineThermal Radiation Heat Transfersandyengineer13Nessuna valutazione finora

- DesignGuideline DraftDocumento213 pagineDesignGuideline DraftrajkumarNessuna valutazione finora

- Self-healing Ceramic Matrix Composites: A MonographDa EverandSelf-healing Ceramic Matrix Composites: A MonographNessuna valutazione finora

- Experiment 2: The Temperature Profile and Rate of Heat Transfer For Radial Conduction Through The Wall of CylinderDocumento5 pagineExperiment 2: The Temperature Profile and Rate of Heat Transfer For Radial Conduction Through The Wall of CylinderSafwan NasirNessuna valutazione finora

- Thermal Management Silicones For Electronics BrochureDocumento12 pagineThermal Management Silicones For Electronics BrochureZenón RodríguezNessuna valutazione finora

- Brochure DF TECASINT Compendium enDocumento24 pagineBrochure DF TECASINT Compendium enkgrier8966Nessuna valutazione finora

- MilitaryAeroTherm 6003595Documento8 pagineMilitaryAeroTherm 6003595shahinNessuna valutazione finora

- DS - 1080S - 14.04.2016Documento4 pagineDS - 1080S - 14.04.2016McFlyNessuna valutazione finora

- 1 s2.0 095671439595010V MainDocumento4 pagine1 s2.0 095671439595010V Main1711076053Nessuna valutazione finora

- Industrial Apps Brochure Rev1Documento5 pagineIndustrial Apps Brochure Rev1ninatenaNessuna valutazione finora

- Ventilated Façade System - Technical DocumentDocumento5 pagineVentilated Façade System - Technical DocumentArthur BianchiNessuna valutazione finora

- Product Data Sheet TIC 9061 Heat Transfer Cement: DescriptionDocumento2 pagineProduct Data Sheet TIC 9061 Heat Transfer Cement: DescriptionsusantaNessuna valutazione finora

- Fire Protection Solutions Rigid and Flexible EnclosuresDocumento2 pagineFire Protection Solutions Rigid and Flexible Enclosuresdwi sutiknoNessuna valutazione finora

- Conbextra EP120 TDS PDFDocumento3 pagineConbextra EP120 TDS PDFzulfikarNessuna valutazione finora

- Promatect® TF-X: Matrix Engineered Mineral BoardDocumento4 paginePromatect® TF-X: Matrix Engineered Mineral BoardNicolas LozanoNessuna valutazione finora

- Gluing Components: Practical GluesDocumento4 pagineGluing Components: Practical GluesonafetsNessuna valutazione finora

- Conbextra EP75 PlusDocumento4 pagineConbextra EP75 Plusm.elsanee.cubicNessuna valutazione finora

- 01-Mi-Dti Cut Sheet 0715Documento2 pagine01-Mi-Dti Cut Sheet 0715Marvin EstradaNessuna valutazione finora

- Tehnički List - WALLMESH HRDocumento3 pagineTehnički List - WALLMESH HRMARKO MATUHANessuna valutazione finora

- 3M 8810 Thermal AdhesiveDocumento8 pagine3M 8810 Thermal Adhesivecsanders7Nessuna valutazione finora

- 3M TC-2707-TDSDocumento4 pagine3M TC-2707-TDSJavierNessuna valutazione finora

- 3m 9703Documento5 pagine3m 9703Waheed IdreesNessuna valutazione finora

- MICA Band Heaters - ManualDocumento5 pagineMICA Band Heaters - ManualAmit Kumar OjhaNessuna valutazione finora

- Fa Outdoor Gudiance Notes 10-08-12Documento16 pagineFa Outdoor Gudiance Notes 10-08-12royal guard of oman rgoNessuna valutazione finora

- FAB Elec Thermal Management App Sheet PDFDocumento4 pagineFAB Elec Thermal Management App Sheet PDFdqwdqNessuna valutazione finora

- Thermally Conductive Adhesive Transfer Tapes: Technical Data April, 2002Documento5 pagineThermally Conductive Adhesive Transfer Tapes: Technical Data April, 2002chayanunNessuna valutazione finora

- Seal Arm TPE TapesDocumento4 pagineSeal Arm TPE TapesJoeNessuna valutazione finora

- Rayfit The Advanced Raychem Heat-Shrinkable Joint Sleeve For Medium Voltage Joints Up To 36 KVDocumento8 pagineRayfit The Advanced Raychem Heat-Shrinkable Joint Sleeve For Medium Voltage Joints Up To 36 KVADIL BASHIRNessuna valutazione finora

- TDS 13050310 EN Silicone HT 300Documento1 paginaTDS 13050310 EN Silicone HT 300rezaNessuna valutazione finora

- Technical Data Sheet CFM™ Carbon Fiber Mesh CTech LLCDocumento2 pagineTechnical Data Sheet CFM™ Carbon Fiber Mesh CTech LLCVivekanandanNessuna valutazione finora

- Constrictor GFRP PDFDocumento4 pagineConstrictor GFRP PDFKevin PradanaNessuna valutazione finora

- Medium Voltage Cold Shrink Joints Brochure LTDocumento4 pagineMedium Voltage Cold Shrink Joints Brochure LTfaisalardy20Nessuna valutazione finora

- Masterseal TC 257 TdsDocumento2 pagineMasterseal TC 257 TdsfirozembrayilNessuna valutazione finora

- 05 - TDS - Concresive 1441 MET WSDocumento3 pagine05 - TDS - Concresive 1441 MET WSAlexi ALfred H. TagoNessuna valutazione finora

- Tec 304 VHS (KSA) : Very High Strength Shrinkage Compensated GroutDocumento2 pagineTec 304 VHS (KSA) : Very High Strength Shrinkage Compensated Groutmanikandan4strlNessuna valutazione finora

- Thermomass TL Series Connector DatasheetDocumento2 pagineThermomass TL Series Connector DatasheetEliseu GonçalvesNessuna valutazione finora

- Katalog StomixDocumento94 pagineKatalog StomixEzeval GráficaNessuna valutazione finora

- Tec 301 HCS (UAE) : Non Shrink Very High Strength GroutDocumento2 pagineTec 301 HCS (UAE) : Non Shrink Very High Strength Groutmanikandan4strlNessuna valutazione finora

- Masterflow 400: DegussaDocumento2 pagineMasterflow 400: Degussafaisal nadeemNessuna valutazione finora

- TDS Conbextra EP160 Saudi ArabiaDocumento4 pagineTDS Conbextra EP160 Saudi ArabiajasonNessuna valutazione finora

- Thermomass TL Series Connector DatasheetDocumento2 pagineThermomass TL Series Connector DatasheetMika DartsmeliaNessuna valutazione finora

- Tyco Inline Joint Single Core Unarmoured Xlpe Mechanical Conn PDFDocumento8 pagineTyco Inline Joint Single Core Unarmoured Xlpe Mechanical Conn PDFYolnner SerranoNessuna valutazione finora

- Technical Data Sheet: DescriptionDocumento4 pagineTechnical Data Sheet: Descriptionerode els erodeNessuna valutazione finora

- Nitoseal 280Documento2 pagineNitoseal 280talatzahoorNessuna valutazione finora

- Thermal PasteDocumento3 pagineThermal PastejuarezcruzNessuna valutazione finora

- FB Sealant CP 25WB Plus PDS Cg1Documento2 pagineFB Sealant CP 25WB Plus PDS Cg1Miguel SordoNessuna valutazione finora

- Terostat Ms 939-EnDocumento2 pagineTerostat Ms 939-EnZoli PoliNessuna valutazione finora

- Tehnički List - WALLMESH MRDocumento3 pagineTehnički List - WALLMESH MRMARKO MATUHANessuna valutazione finora

- ChemFlo AsDocumento2 pagineChemFlo Assmart construction solution solutionNessuna valutazione finora

- Raychem MWTM Medium WallDocumento4 pagineRaychem MWTM Medium WallpigulusNessuna valutazione finora

- Pe SH Iel DS: Mapeshield SDocumento4 paginePe SH Iel DS: Mapeshield SFabioNessuna valutazione finora

- 915 Mapesonic-Cr GBDocumento4 pagine915 Mapesonic-Cr GBTheFreeSpiritNessuna valutazione finora

- Assignment # 01 (TE-671) 10-NTU-6012Documento12 pagineAssignment # 01 (TE-671) 10-NTU-6012Sajid FaheemNessuna valutazione finora

- JZ-20220423 Siliocne Composite Tape Bochure-ENDocumento12 pagineJZ-20220423 Siliocne Composite Tape Bochure-ENLongsun KejiNessuna valutazione finora

- PN50020 Heat Transfer Compounds InstallationDocumento8 paginePN50020 Heat Transfer Compounds InstallationPat HealyNessuna valutazione finora

- Masterflow 648CP PLUS - PDS - ASEAN - 161209Documento2 pagineMasterflow 648CP PLUS - PDS - ASEAN - 161209Andri AjaNessuna valutazione finora

- The SCRIMP ProcessDocumento56 pagineThe SCRIMP ProcessM PraveenNessuna valutazione finora

- Fevitite Super Strong Epoxy AdhesivesDocumento3 pagineFevitite Super Strong Epoxy AdhesivesTARUNNessuna valutazione finora

- Eps Pipe Section InsulationDocumento1 paginaEps Pipe Section InsulationAlankar Nana Ambwade/Infrastructure Solutions-MEP/MUMBAINessuna valutazione finora

- 3M Welding Masks BrochureDocumento4 pagine3M Welding Masks BrochureMichael TadrosNessuna valutazione finora

- MultimediaDocumento3 pagineMultimediaD. D.Nessuna valutazione finora

- Enercon Best Practices Developments in Solventless LaminatingDocumento5 pagineEnercon Best Practices Developments in Solventless LaminatingHafiani HichamNessuna valutazione finora

- 4.5 External Pressure Design For Flat Bottom Cone Roof (RBCR) TanksDocumento7 pagine4.5 External Pressure Design For Flat Bottom Cone Roof (RBCR) TanksMiguel Martinez GuerreroNessuna valutazione finora

- 4.3 Basic Design Awwa D100 & Api 650Documento7 pagine4.3 Basic Design Awwa D100 & Api 650Miguel Martinez Guerrero100% (1)

- Icaf Aislamiento y Proteccion PersonalDocumento1 paginaIcaf Aislamiento y Proteccion PersonalMiguel Martinez GuerreroNessuna valutazione finora

- II Tank Capacities: Mechanical Engineering Rev. Date Section 3.1 Tank Reference Manual PageDocumento6 pagineII Tank Capacities: Mechanical Engineering Rev. Date Section 3.1 Tank Reference Manual PageMiguel Martinez GuerreroNessuna valutazione finora

- 4.2 Miscellaneous Data and Design in TanksDocumento5 pagine4.2 Miscellaneous Data and Design in TanksMiguel Martinez GuerreroNessuna valutazione finora

- Rti Brochure Astm Compliance Chart Na enDocumento2 pagineRti Brochure Astm Compliance Chart Na enMiguel Martinez GuerreroNessuna valutazione finora

- Tank Weights: Mechanical Engineering Tank Reference Manual Rev. Date: SECTION: 3.2 12-95Documento6 pagineTank Weights: Mechanical Engineering Tank Reference Manual Rev. Date: SECTION: 3.2 12-95Miguel Martinez GuerreroNessuna valutazione finora

- Tipos de Aletas para Tubos AletadosDocumento8 pagineTipos de Aletas para Tubos AletadosMiguel Martinez GuerreroNessuna valutazione finora

- Specification Compliance: and Reference GuideDocumento12 pagineSpecification Compliance: and Reference GuideMiguel Martinez GuerreroNessuna valutazione finora

- Pipe & Mechanical InsulationDocumento36 paginePipe & Mechanical InsulationMiguel Martinez GuerreroNessuna valutazione finora

- Mineral Wool Pipe InsulationDocumento4 pagineMineral Wool Pipe InsulationMiguel Martinez GuerreroNessuna valutazione finora

- Especificacion de Ingenieria E-401 Requirement For Design and Fabircation of Destillation Tower Plates and InternalsDocumento16 pagineEspecificacion de Ingenieria E-401 Requirement For Design and Fabircation of Destillation Tower Plates and InternalsMiguel Martinez GuerreroNessuna valutazione finora

- Astm D2143 - 2005 PDFDocumento3 pagineAstm D2143 - 2005 PDFMiguel Martinez GuerreroNessuna valutazione finora

- 512-ET-08-REV-1-Atmopheric TanksDocumento17 pagine512-ET-08-REV-1-Atmopheric TanksMiguel Martinez GuerreroNessuna valutazione finora

- ASME Interpretation VIII-1!16!85Documento1 paginaASME Interpretation VIII-1!16!85Miguel Martinez GuerreroNessuna valutazione finora

- Specifications/Grades: Key BenefitsDocumento2 pagineSpecifications/Grades: Key BenefitsMiguel Martinez GuerreroNessuna valutazione finora

- (UNS N08904) : NAS High Corrosion Resistant Stainless SteelDocumento4 pagine(UNS N08904) : NAS High Corrosion Resistant Stainless SteelMiguel Martinez GuerreroNessuna valutazione finora

- Bearing Friction Torque in Bolted Joints, Sayed A Nassar, G C Barber, Dajun ZuoDocumento17 pagineBearing Friction Torque in Bolted Joints, Sayed A Nassar, G C Barber, Dajun ZuoMiguel Martinez GuerreroNessuna valutazione finora

- Heat Transfer ManualDocumento50 pagineHeat Transfer ManualBen PepperNessuna valutazione finora

- Thermal Conductivity ReportDocumento5 pagineThermal Conductivity ReportHisyamAl-MuhammadiNessuna valutazione finora

- Week-1-4 MDL CM 3Q NTS112Documento38 pagineWeek-1-4 MDL CM 3Q NTS112matthew estoNessuna valutazione finora

- 10 10 15Documento115 pagine10 10 15Meena VelayuthamNessuna valutazione finora

- NozzleheattransferDocumento6 pagineNozzleheattransferintaliallitaNessuna valutazione finora

- Heat TransferDocumento42 pagineHeat TransferKundan KumarNessuna valutazione finora

- District Unified Summative Test in Science 7 (3rd-2nd Half)Documento4 pagineDistrict Unified Summative Test in Science 7 (3rd-2nd Half)Mariejoy Vargas Adlawan-SartigaNessuna valutazione finora

- 7E's-LP Sci7 3RDDocumento5 pagine7E's-LP Sci7 3RDCarmina DuldulaoNessuna valutazione finora

- Module 1-C1 Heat TransferDocumento10 pagineModule 1-C1 Heat TransferKlucifer XinNessuna valutazione finora

- Heat Transfer CHE0301 LECTURE 2 Basics of Heat TransferDocumento21 pagineHeat Transfer CHE0301 LECTURE 2 Basics of Heat TransfermiraNessuna valutazione finora

- Culminating Performance Task Jeff.Documento8 pagineCulminating Performance Task Jeff.Kristian Karl Bautista Kiw-isNessuna valutazione finora

- Department of Industrial and Production Engineering Shah Jalal University of Science and Technology Sylhet-3114, BangladeshDocumento19 pagineDepartment of Industrial and Production Engineering Shah Jalal University of Science and Technology Sylhet-3114, Bangladeshshajib_sust0% (1)

- Scie 4Documento7 pagineScie 4Jam LumasacNessuna valutazione finora

- ConductionDocumento43 pagineConductionandreyan P.NNessuna valutazione finora

- Conduction Shape FactorDocumento6 pagineConduction Shape FactorCeline NathaliaNessuna valutazione finora

- Film and Dropwise CondensationDocumento14 pagineFilm and Dropwise CondensationakpNessuna valutazione finora

- Cdi 106 ModuleDocumento6 pagineCdi 106 ModuleFrancheska Kate LabiosNessuna valutazione finora

- Grade 7-31 Energy TransferDocumento5 pagineGrade 7-31 Energy Transferوسلاتي مريمNessuna valutazione finora

- 08aa604 Heat and Mass TransferDocumento2 pagine08aa604 Heat and Mass TransferMari MuthuNessuna valutazione finora

- Heat Transfer2 PDFDocumento13 pagineHeat Transfer2 PDFChaitanya Kishore ChitikenaNessuna valutazione finora

- Charging Process by ConductionDocumento8 pagineCharging Process by ConductionMark Gerald DalanonNessuna valutazione finora

- AllDisciplinesPart IDocumento111 pagineAllDisciplinesPart IprinceshubhaNessuna valutazione finora

- 6 Gradient of A Scalar Function: F X F y F ZDocumento1 pagina6 Gradient of A Scalar Function: F X F y F ZakshathNessuna valutazione finora

- Me 2251 HMTDocumento15 pagineMe 2251 HMTMohanraj SubramaniNessuna valutazione finora

- Zielenkiewicz W., Margas E., Theory of Calorimetry (Kluwer 2004)Documento197 pagineZielenkiewicz W., Margas E., Theory of Calorimetry (Kluwer 2004)aiiiinNessuna valutazione finora