Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Vaa /ru /DL 12: Pressure Relief Valves

Caricato da

Sachin RamadasanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Vaa /ru /DL 12: Pressure Relief Valves

Caricato da

Sachin RamadasanCopyright:

Formati disponibili

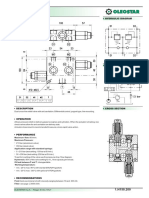

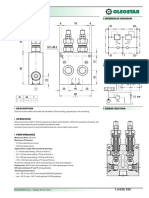

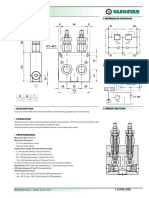

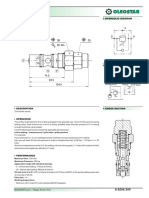

PRESSURE RELIEF VALVES

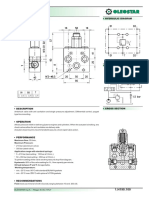

VAA /RU /DL 12

• DIMENSIONS (mm) • HYDRAULIC DIAGRAM

• ASSEMBLY DIAGRAM

• DESCRIPTION • CROSS SECTION

Antishock valve with anti cavitation and single pressure adjustment. Differential control, poppet

type line mounting.

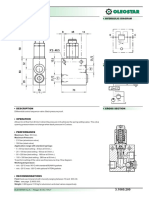

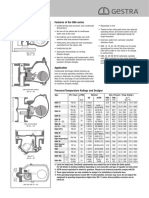

• OPERATION

Allows pressure relief on delivery pipes to engines and cylinders. When the actuator is braking, two

check valves allow for anti cavitation on delivery side.

Actuator close mount is recommended to assure a more rapid valve action.

• PERFORMANCE

Maximum flow: 60 l/min.

Maximum Pressure:

− 210 bar (aluminium valve)

− 350 bar (steel valve)

Application range with standard springs:

− 5 ÷ 210 bar (test setting: 150 bar at 5 l/min.)

− 50 ÷ 250 bar (test setting: 250 bar at 5 l/min.)

To perform setting of the valve see the pressure drop / flow diagram.

Hysteresis: 85% of the valve setting for 1 L. flow capacity per minute.

Oil leaks between P and T: disregardable.

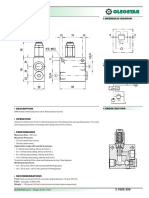

Working temperature:

− min. -25°C max. 90°C with standard BUNA N gaskets

− min. -20°C max. 120°C with optional VITON gaskets

• RECOMMENDATIONS

Fluid: best use mineral oil with viscosity ranging between 10 and 200 cSt.

OLEOSTAR S.p.A. – Reggio Emilia ITALY 1.H190.200

02/11/1998

Filter: see page Z.9000.000.

Weight:

− aluminium valves 1.15 kg

− steel valves 2.29 kg

Cartridge used: see page 1.2000.200.

Material: internal components made out of high-grade steel duly treated and fabricated.

For more information please ask our technical office .

Variations and modifications of technical features and dimensions are reserved. OLEOSTAR S.p.A. also reserves the right to stop production of

each and any model listed in the catalogue with no notice.

Copyrights on the text contained herein belong to OLEOSTAR S.p.A. . Partial and full reproductions or copies of this catalogue are forbidden.

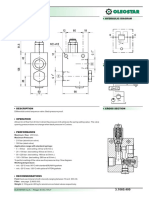

• RATING DIAGRAMS

• CODE NUMBER

VAA /RU /DL 12/ pp . S / pp

Pressure settings (bar) Body material

TS) 5÷210 _ Aluminium

TR) 50÷350 ac Steel

1.H190.200

Potrebbero piacerti anche

- CAT C 32 Marine Maintenance Schedule PDFDocumento48 pagineCAT C 32 Marine Maintenance Schedule PDFRei_bud100% (1)

- Bobcat T300Documento1.074 pagineBobcat T300Облачно86% (7)

- The Manual Book of Electric Control BoxDocumento56 pagineThe Manual Book of Electric Control Boxfernando Diaz Gonzalez88% (17)

- Vail 5 - PP: Pressure Relief ValvesDocumento2 pagineVail 5 - PP: Pressure Relief ValvesSachin RamadasanNessuna valutazione finora

- Denso Edc v3 v4 v5 Injection PumpDocumento48 pagineDenso Edc v3 v4 v5 Injection PumpHoang Vu Tran100% (1)

- 7-Speed Dual Clutch Gearbox 0AMDocumento127 pagine7-Speed Dual Clutch Gearbox 0AMEduardo Yagüe Gomez94% (16)

- Yanmar Excavator Vio20-3 Service Manual + Electrical Wiring Diagrams + Parts CatalogDocumento230 pagineYanmar Excavator Vio20-3 Service Manual + Electrical Wiring Diagrams + Parts Catalogmarlon macaspacNessuna valutazione finora

- Vaddl /va 12: Pressure Relief ValvesDocumento2 pagineVaddl /va 12: Pressure Relief ValvesSachin RamadasanNessuna valutazione finora

- Vaa /ru /DL 38: Pressure Relief ValvesDocumento2 pagineVaa /ru /DL 38: Pressure Relief ValvesSachin RamadasanNessuna valutazione finora

- Vaddl 12: Pressure Relief ValvesDocumento2 pagineVaddl 12: Pressure Relief ValvesSachin RamadasanNessuna valutazione finora

- 1H050200 PDFDocumento2 pagine1H050200 PDFSachin RamadasanNessuna valutazione finora

- Vaddl /va 38: Pressure Relief ValvesDocumento2 pagineVaddl /va 38: Pressure Relief ValvesSachin RamadasanNessuna valutazione finora

- 1H050100 PDFDocumento2 pagine1H050100 PDFSachin RamadasanNessuna valutazione finora

- 1H050100 PDFDocumento2 pagine1H050100 PDFSachin RamadasanNessuna valutazione finora

- 1H050100 PDFDocumento2 pagine1H050100 PDFSachin RamadasanNessuna valutazione finora

- Vail /va 12: Pressure Relief ValvesDocumento2 pagineVail /va 12: Pressure Relief ValvesSachin RamadasanNessuna valutazione finora

- Vail /va 34: Pressure Relief ValvesDocumento2 pagineVail /va 34: Pressure Relief ValvesSachin RamadasanNessuna valutazione finora

- VAIL 10 - PP: Pressure Relief ValvesDocumento2 pagineVAIL 10 - PP: Pressure Relief ValvesSachin RamadasanNessuna valutazione finora

- 1H000200 PDFDocumento2 pagine1H000200 PDFSachin RamadasanNessuna valutazione finora

- 1H000200 PDFDocumento2 pagine1H000200 PDFSachin RamadasanNessuna valutazione finora

- 1H000200 PDFDocumento2 pagine1H000200 PDFSachin RamadasanNessuna valutazione finora

- VADDL /VA 34 (100) : Pressure Relief ValvesDocumento2 pagineVADDL /VA 34 (100) : Pressure Relief ValvesSachin RamadasanNessuna valutazione finora

- Vaa /ru /DL 38: Pressure Relief ValvesDocumento2 pagineVaa /ru /DL 38: Pressure Relief ValvesLibinNessuna valutazione finora

- VRPRL 38: Pressure Reducing ValvesDocumento2 pagineVRPRL 38: Pressure Reducing ValvesHELY PEÑANessuna valutazione finora

- Sequence: Dimensions (MM) Hydraulic DiagramDocumento2 pagineSequence: Dimensions (MM) Hydraulic DiagramSachin RamadasanNessuna valutazione finora

- VDSD /B 12: SequenceDocumento2 pagineVDSD /B 12: SequenceSachin RamadasanNessuna valutazione finora

- VDSD /B 34: SequenceDocumento2 pagineVDSD /B 34: SequenceSachin RamadasanNessuna valutazione finora

- Vabal /SF 12: Overcenter ValvesDocumento2 pagineVabal /SF 12: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- 3aa00200 PDFDocumento2 pagine3aa00200 PDFSachin RamadasanNessuna valutazione finora

- Sd11 / Iam: SequenceDocumento2 pagineSd11 / Iam: SequenceSachin RamadasanNessuna valutazione finora

- VDSD /B 100: SequenceDocumento2 pagineVDSD /B 100: SequenceSachin RamadasanNessuna valutazione finora

- Vabal /SF 38: Overcenter ValvesDocumento2 pagineVabal /SF 38: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- Voslp /F 12: Overcenter ValvesDocumento2 pagineVoslp /F 12: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- 04BR05Documento6 pagine04BR05martiguada1Nessuna valutazione finora

- VIA/AP 10-12: SequenceDocumento2 pagineVIA/AP 10-12: SequenceSachin RamadasanNessuna valutazione finora

- Overcenter Valves: Dimensions (MM) Hydraulic DiagramDocumento2 pagineOvercenter Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNessuna valutazione finora

- Overcenter Valves: Dimensions (MM) Hydraulic DiagramDocumento2 pagineOvercenter Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNessuna valutazione finora

- 6H000200 PDFDocumento2 pagine6H000200 PDFSachin RamadasanNessuna valutazione finora

- Model GP-1000 Series Pressure Reducing Valve Installation & Operation ManualDocumento14 pagineModel GP-1000 Series Pressure Reducing Valve Installation & Operation ManualJefanthony StevanoyaNessuna valutazione finora

- 26 2000 Pressure Reducing RegulatorDocumento4 pagine26 2000 Pressure Reducing RegulatorMFERRNessuna valutazione finora

- Vabal/Sc/F 12/omr: Overcenter Valves (Danfoss Motor)Documento2 pagineVabal/Sc/F 12/omr: Overcenter Valves (Danfoss Motor)jbsb1Nessuna valutazione finora

- 1377 Duragauge Pressure Gauge: Data SheetDocumento4 pagine1377 Duragauge Pressure Gauge: Data SheetkarthikNessuna valutazione finora

- 2.25.e.rp45 Pressure Reducing Valve DN15-100-EnDocumento5 pagine2.25.e.rp45 Pressure Reducing Valve DN15-100-EnMa KiepNessuna valutazione finora

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocumento2 paginePressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNessuna valutazione finora

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocumento2 paginePressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNessuna valutazione finora

- Vabal 38: Overcenter ValvesDocumento2 pagineVabal 38: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- Vaddl 38: Pressure Relief ValvesDocumento2 pagineVaddl 38: Pressure Relief ValvesLibinNessuna valutazione finora

- Model DDV Diaphragm Deluge Valve: Table ADocumento15 pagineModel DDV Diaphragm Deluge Valve: Table ACoordinador TecnicoNessuna valutazione finora

- Condensate Recovery Pump: ModelDocumento2 pagineCondensate Recovery Pump: ModelCTHNessuna valutazione finora

- Air Trap RL1090 - RL1290Documento2 pagineAir Trap RL1090 - RL1290satphoenixNessuna valutazione finora

- Ratio Pressure Reducing ValvesDocumento4 pagineRatio Pressure Reducing Valveskanem1Nessuna valutazione finora

- Vabal 34: Overcenter ValvesDocumento2 pagineVabal 34: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- VOSLP /F 34 (100) : Overcenter ValvesDocumento2 pagineVOSLP /F 34 (100) : Overcenter ValvesSachin RamadasanNessuna valutazione finora

- Cc251 - Bray-rite-Ansi Series 150model210smz - CutsheetDocumento3 pagineCc251 - Bray-rite-Ansi Series 150model210smz - Cutsheetjacquesstrappe06Nessuna valutazione finora

- E30C - Globe Valves NewDocumento20 pagineE30C - Globe Valves NewTaha FaNessuna valutazione finora

- Jetcontrol 600-S UK 17072014Documento4 pagineJetcontrol 600-S UK 17072014Zeko AmeenNessuna valutazione finora

- Flanged Ball Valves ANSI CLASS 150 & 300: Full BoreDocumento20 pagineFlanged Ball Valves ANSI CLASS 150 & 300: Full BoreBayu Aji100% (1)

- Williams - Válvulas Compuerta Globo Cheque Bola Fundidas API 600Documento28 pagineWilliams - Válvulas Compuerta Globo Cheque Bola Fundidas API 600espanolasaNessuna valutazione finora

- Load Sensing Directional Control Valve: 1 DescriptionDocumento14 pagineLoad Sensing Directional Control Valve: 1 DescriptionDavid AltarribaNessuna valutazione finora

- Jamesbury Ball Valves PDFDocumento20 pagineJamesbury Ball Valves PDFGabriel Andrés Barcha Angulo100% (1)

- Manuals 1190 Low Pressure Gas Blanketing Regulator Instruction Manual Fisher en en 5985974Documento24 pagineManuals 1190 Low Pressure Gas Blanketing Regulator Instruction Manual Fisher en en 5985974marinjerman6Nessuna valutazione finora

- Gestra Una Float Steam TrapDocumento6 pagineGestra Una Float Steam TrapJORGE ALBERTO PEREZ RAMIREZNessuna valutazione finora

- E5174 RbeDocumento4 pagineE5174 RbeVinod YbNessuna valutazione finora

- Walvoil Cartridge Ventielen HICDocumento20 pagineWalvoil Cartridge Ventielen HICddNessuna valutazione finora

- High-Strength Low-Alloy (HSLA) Steels For Cold Forming: DescriptionDocumento20 pagineHigh-Strength Low-Alloy (HSLA) Steels For Cold Forming: Descriptionnandi_engineerNessuna valutazione finora

- Voslp /CC 12: Overcenter ValvesDocumento2 pagineVoslp /CC 12: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- Voslp /CC 38: Overcenter ValvesDocumento2 pagineVoslp /CC 38: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- Voslp /F 12: Overcenter ValvesDocumento2 pagineVoslp /F 12: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- Voslp /F 38: Overcenter ValvesDocumento2 pagineVoslp /F 38: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- VOSLP /F 34 (100) : Overcenter ValvesDocumento2 pagineVOSLP /F 34 (100) : Overcenter ValvesSachin RamadasanNessuna valutazione finora

- VDSD /B 12: SequenceDocumento2 pagineVDSD /B 12: SequenceSachin RamadasanNessuna valutazione finora

- VDSRL 20 - 34 /APP: SequenceDocumento2 pagineVDSRL 20 - 34 /APP: SequenceSachin RamadasanNessuna valutazione finora

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocumento2 paginePressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNessuna valutazione finora

- VDSD /B 100: SequenceDocumento2 pagineVDSD /B 100: SequenceSachin RamadasanNessuna valutazione finora

- VDSD /B 34: SequenceDocumento2 pagineVDSD /B 34: SequenceSachin RamadasanNessuna valutazione finora

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocumento2 paginePressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNessuna valutazione finora

- VDFR 38-12: Flow Regulator Pressure CompensatedDocumento2 pagineVDFR 38-12: Flow Regulator Pressure CompensatedSachin RamadasanNessuna valutazione finora

- VDSD /B 38: SequenceDocumento2 pagineVDSD /B 38: SequenceSachin RamadasanNessuna valutazione finora

- Overcenter Valves: Dimensions (MM) Hydraulic DiagramDocumento2 pagineOvercenter Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNessuna valutazione finora

- Pressure Relief Valves: Dimensions (MM) Hydraulic DiagramDocumento2 paginePressure Relief Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNessuna valutazione finora

- Vabal /SF 38: Overcenter ValvesDocumento2 pagineVabal /SF 38: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- VDFR 38-12: Flow Regulator Pressure CompensatedDocumento2 pagineVDFR 38-12: Flow Regulator Pressure CompensatedSachin RamadasanNessuna valutazione finora

- 6H000200 PDFDocumento2 pagine6H000200 PDFSachin RamadasanNessuna valutazione finora

- Check Valves: Dimensions (MM) Hydraulic DiagramDocumento2 pagineCheck Valves: Dimensions (MM) Hydraulic DiagramSachin RamadasanNessuna valutazione finora

- 3aa00200 PDFDocumento2 pagine3aa00200 PDFSachin RamadasanNessuna valutazione finora

- 3aa00100 PDFDocumento2 pagine3aa00100 PDFSachin RamadasanNessuna valutazione finora

- Vabal /SF 34: Overcenter ValvesDocumento2 pagineVabal /SF 34: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- Vabal /SF 12: Overcenter ValvesDocumento2 pagineVabal /SF 12: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- VABAL 100: Overcenter ValvesDocumento2 pagineVABAL 100: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- 6H000200 PDFDocumento2 pagine6H000200 PDFSachin RamadasanNessuna valutazione finora

- Vabal 38: Overcenter ValvesDocumento2 pagineVabal 38: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- 3B000100Documento2 pagine3B000100LibinNessuna valutazione finora

- VIA/AP 10-12: SequenceDocumento2 pagineVIA/AP 10-12: SequenceSachin RamadasanNessuna valutazione finora

- Vabal 34: Overcenter ValvesDocumento2 pagineVabal 34: Overcenter ValvesSachin RamadasanNessuna valutazione finora

- Sd11 / Iam: SequenceDocumento2 pagineSd11 / Iam: SequenceSachin RamadasanNessuna valutazione finora

- Gas Turbine Power PlantDocumento11 pagineGas Turbine Power PlantCK Godinez100% (1)

- Masai A450 Service RepairDocumento138 pagineMasai A450 Service RepairBarryNessuna valutazione finora

- Technical Large RoofTopsDocumento48 pagineTechnical Large RoofTopsnairam2003Nessuna valutazione finora

- Ventiloconvectoare CITIZEN 2011Documento6 pagineVentiloconvectoare CITIZEN 2011office8200Nessuna valutazione finora

- DC Motors and Generatos QuestionsDocumento2 pagineDC Motors and Generatos QuestionsvpzfarisNessuna valutazione finora

- Battle GasDocumento36 pagineBattle Gaspsn_kylmNessuna valutazione finora

- Sanyo Wall Mounted Multi Split System Indoor Units Sell SheetDocumento2 pagineSanyo Wall Mounted Multi Split System Indoor Units Sell Sheete-ComfortUSANessuna valutazione finora

- Design of A Tuned Intake Manifold H W Engelman Asme Paper 73 Wa DGP 2Documento9 pagineDesign of A Tuned Intake Manifold H W Engelman Asme Paper 73 Wa DGP 2Ahmed ShaabanNessuna valutazione finora

- Line List (Ibr)Documento3 pagineLine List (Ibr)vtbkNessuna valutazione finora

- Aa4v56 Series 1 Service Parts ListDocumento36 pagineAa4v56 Series 1 Service Parts Listhamza HamzaNessuna valutazione finora

- VW Golf Engine RattleDocumento2 pagineVW Golf Engine RattleArtin HykoNessuna valutazione finora

- Technical Service Guide: 24-And 27-In. Unitized Laundry CentersDocumento69 pagineTechnical Service Guide: 24-And 27-In. Unitized Laundry CentersCesar Calderon GrNessuna valutazione finora

- MindaDocumento48 pagineMindaRohit JindalNessuna valutazione finora

- Engine Control System 3UR FEDocumento20 pagineEngine Control System 3UR FEalejandro chavezNessuna valutazione finora

- Wta 2010Documento39 pagineWta 2010Walter GutiérrezNessuna valutazione finora

- Thrust Bearing Design GuideDocumento56 pagineThrust Bearing Design Guidemjscar100% (1)

- 06 SafDocumento67 pagine06 SafOleksandr U.Nessuna valutazione finora

- Manual Operador Alzadora 2254 (2000)Documento65 pagineManual Operador Alzadora 2254 (2000)Esteban MunaresNessuna valutazione finora

- Ac/Dc Distribution Panel: Electrical System 3500B Generator Set With EMCP 3Documento4 pagineAc/Dc Distribution Panel: Electrical System 3500B Generator Set With EMCP 3hector gutierrezNessuna valutazione finora

- SYSVRF CatalogueDocumento39 pagineSYSVRF CatalogueSilas MirandaNessuna valutazione finora

- Perbedaan Motor Sinkron Dan Asinkron: Oleh 1. Akbar Putra 2. Brenda Yuniel 3. Galuh Ramadhan A.S 4. Muhammad Marozy EDocumento11 paginePerbedaan Motor Sinkron Dan Asinkron: Oleh 1. Akbar Putra 2. Brenda Yuniel 3. Galuh Ramadhan A.S 4. Muhammad Marozy EMarozi EffendiNessuna valutazione finora

- Catalog Murphy 2016 - EN PDFDocumento400 pagineCatalog Murphy 2016 - EN PDFjoendryNessuna valutazione finora

- Ue List Update September 2013Documento13 pagineUe List Update September 2013Jaya LoundriNessuna valutazione finora

- Engine Honing Tooling and AccessoriesDocumento66 pagineEngine Honing Tooling and AccessoriesAnonymous UcmNTu6rNessuna valutazione finora