Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pump Maintenance

Caricato da

Siva Kumar TutikaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pump Maintenance

Caricato da

Siva Kumar TutikaCopyright:

Formati disponibili

PAGE 1

1.0 INTRODUCTION

Pump is the machine that lifts liquids, moves them from place to place,

pressurises them for a number of useful tasks.

Enter into a power station. A number of pumps are in action - feeding water

to boiler, cooling the condenser, oiling the bearings etc. So it is obvious that

reliability, availability and efficiency of a power station depends a lot on the

behaviour of these machines; hence the importance of maintaining pumps in a well

planned way.

Implementation of the maintenance plan needs skilled and trained

maintenance personnel. ln the following section soft his book, attempt has been

made to acquaint trainees with different types of pumps used in power stations (See

Table 1. 1 Fig. 1. 1) and the ways of maintaining them systematically. A 'trouble

shooting chart' has also been added to enable the trainees to react quickly to

abnormal conditions.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 2

TABLE-I

TYPICAL PUMP APPLICATION IN THERMAL POWER STATIONS

Sr. Location/Name Type of Pump in Use Function of the Pump Remarks

No.

1 Intake channel make up Vertical, Single Stage, To maintain water

water pump Volute casing,Centrifugal level of the channel

2 Discharge Channel Vertical, Double Stage, Pumping water When Cooling Towers

(C.T. Pump) Propeller type, Mix Flow through Cooling tower are required to main-

tain water temperature

3 Control Structure H.P.5 Stages, Vertical. To supply water to

L.P. Pumps 3-stages, various systems like

Vertical, Volute type fire fighting, E.S.P. for

flushing, bottom ash

removal,ash pump

sealing and coolign

system

4 Clarifloculator Vertifical, Centrifugal To supply water to

(Clarifired water pump) tretment plant for

demineralising and for

supplying clarifired

water to plant equip-

ment cooling

5 Intake channel inside Vertical,Mix flow, two To Provide cooling

Turbine House stage water to condenser

(Circulating water pump)

6 Hot well Vertical,Multistage, To pump water from For recycling the con-

(Condensate Extraction Centrifugal hot well through densate to Boiler

Pump) ejector to L.P. Heater

to Dearator

7 O. Metre Turbine Single-Stage, To maintain L.P.

(Drip Pump) Centrifugal, Heater level

Split casing, Horizontal

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 3

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 4

8 O.Metre, B.F.P. Multi stage, Barrel type Feeding water to

(Boiler Feed Pump) Centrifugal boiler

drum through feed

heters.

9 O.Metre, S.O.P. Vertical/Horizontal To Provide oil to Workings as taking oil

(Starting oil pump) bearings during start pump.

up.

10 O. Metre Vertical,Bowl type, To purify oil for To Provide purified

(Centrifuge Oil Purifier centrifugal recyling in the clean

pump) system oil to turbine oil system

for bearings and gover-

ning systems.

11 O Metre Boiler Bay

i) Boiler Fill Pump i) Centrifugal, Multistage, i) For filling the boiler

Guidevanetype, or Single for testing &

stage, Volute type startups.

ii) DM make up pump ii) Centrifugal,Single ii) To provide make up

Stage, Volute type water to the system

12 Ash pump House Closed impeller, To remove slurry from

(-4 M level) Centrifugal, or Single ash channel to

(Slurry pump) stage Positive head lagoons

13 13 Metre (Boiler) Reciprocating To inject trisodium

(Phosphate dosing phosphate to boiler

pump.) drum water.

14 O. Metre, Turbine Single Stage, Radial For bearing cooling of

(Booster pump) Impeller condenasate pump,

boiler feed pump A.C.

Lube oil pump, and

to provide cooling

water to Ball Mills.

PAGE 5

2.0 Classification of Pumps

Pumps are basically of three types

i Reciprocating

ii Rotary, and

iii Centrifugal

2.1 Reciprocating pump

In this type energy is added to the liquid by the to and fro movement of piston(s),

plunger(s), diaphragms etc.

Reciprocating pumps can be sub-divided into following varieties i) Piston pumps

i Plunger purnps

PDF created with pdfFactory Pro trial version www.pdffactory.com

ii Ram pumps

iii Diaphragm pumps

2.2 Rotary pumps

Here the pumping action is caused by relative movement of rotating and

stationary elements of the pump. They can be sub-divided into following categories

i) Gear pump

ii) Screw pump

iii) Vane pump

iv) Lobe pump

2..3 Centrifugal pumps

This defination is applied to all types of pumps with an impeller housed in a

suitable shaped casing so that when the impeller rotates momentum is applied

toliquid in the pump casing transporting it from the inlet to the outlet side by

changing velocity into pressure energy. Centrifugal pumps are also sub-divided into

various categories which will be discussed in next chapter.

It can be seen from Table-1 that most of the pumps engaged in power stations

are of centrifugal type. So most of the discussions in the following chapters will

centre around centrifugal pumps.PAGE 6

3.0 Centrifugal pumps

Majority of the pumps used in Power Stations are of this category. It is the

machine that moves fluid by spinning it with a rotating impeller in a casing that has

a central inlet and a tangential outlet, as shown in Fig. 3.1 The path of the fluid is an

increasing spiral from the inlet at the centre to the outlet tangent to the annulus. The

(pressure) 'head develops against the inside wall of the annulus because the curved

wall forces the fluid to move in a circular path rather than by converting velocity

head to (pressure) head.

Useful work comes from the pump when some of the spinning fluid flows

from the casing tangential outlet into the pipe system. Power from the motor

accelerates the fluid coming in the inlet to the speed of the fluid in the annulus.

Some of the power is lost in fluid friction in the casing and impeller. Head

(pressure) is controlled by rpm, impeller diameter, and flow rate.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 7

3.1 Classification of centrifugal pumps

Centrifugal pumps are generally classified as under

Types Classification based on

Volute Casing (Fig. 3.2a)

Diffuser Casing (Fig. 3.2b)

Radial Flow lmpeller

Mixed Flow lmpeller Fig. 8.

Axial Flow lmpeller

Each of the above types can be further classified in many ways detailed below :

Single stage of multistage based on number of impellers mounted on the shaft.

Single suction or double suction depending on the number of liquid entrv Path

Axially split or radially split casing (See Fig. 3.20 Vertical/Horizontal pumps

3.2 Mulii Stage Pumps

If a larger head is required more impellers are to be fitted in series, so that the

discharge from the first impeller is guided into the inlet of the second impeller. This

is repeated with the third impeller and so on until the required head is reached. Each

impeller will increase the pressure by the same amount. A pump of this type is

called a multi stage pump A typical boiler feed pump may have as many as six to

eight stages.

All the impellers are keyed to the same shaft and usually all impellers dnd

diffusers of one pump are identical. This has the advantage of reducing the labour

PDF created with pdfFactory Pro trial version www.pdffactory.com

in manufacture and stocking spares of maintenance. The discharge from each

diffuser is either circumferential or radial, this is collected by vanes attached to the

casing which direct, the liquid into the edge of the next impeller. The last diffuser

will discharge into the delivery pipe.

Fig. 3.3 shows 5 stage ring type pressure pump Fig.3.4shows a multistage vertical

pump used for condensate extraction.

PAGE 8

PAGE 9

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 10

PAGE 11

PDF created with pdfFactory Pro trial version www.pdffactory.com

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 12

4.0 Rotary Pumps

4.1 Rotary pump is a positive displacement pump employing rotary motion.

This definition can be expanded further by saying that gear and vane pumps are of

the rotary type. Therefore, a gear-type pump is a rotary, positive displacement

pump. Most hydraulic systems use rotary pumps of the gear type.

The screw type rotary pumps is also a positive displacement pump but it is

constructed differently than the gear pump. It has the same general opera ting

characteristics. Usual] y, screw type pumps are used as itransfer pumps be cause of

their large capacities.

4.2 Gear Pumps

4.2.1 Gear pumps, sometimes called external gear pumps, are probably the most common

type of rotary pumps used for industrial applications. As previously mentioned,

hydraulic systems are the prime users of gear pumps. But many machine tools use

gear pumps for bearing lubrication as well as for supplying cu ' tting fluid to the

various points on the machine. In addition, the oil pump in the engines of most fork

lift trucks is.a gear type pump.

4.2.2 The operation of a gear pump, as shown in Fig. 4.1 is quite easy to understand. One

of the most common misunderstandings that people have about gear pumps

concerns the fluid flow. Many people first think that the material being pumped is

forced between the teeth of the gears and out the discharge side. As shown by the

arrows in the illustration, the material being pumped is drawn through the space

between the rotors and the Pump casing by the gear teeth and forced out of the

discharge port. The fluid is prevented from flowing back to the suction side of the

pump by the meshing of the gears.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 13

4.2.3 Although spur gear impellers are generally the most common type used in gear

pumps, both helical and herringbone gears are also used in many pumps. Two types

are shown in Fig. 4.2.,

4.3 Internal Gear Purnps

4.3.1 Another type of rotary gear pumps is the internal gear pump. This pump is entirely

different in construction than the standard or external gear pump.

4.3.2. The internal gear pump, as shown in Fig. 4.3 also consists of two gears in mesh with

one another. The outer or external gear of the set is the driving gear. The internal

gear is the driven or idler gear of the pump. T he: crescent keeps the gears separated

and reduces eddy currents, increasing the pump efficiency. In some models, it is

movable to allow the pump to operate in either direction.

4.3.3 In operation, the rotating internal gear opens the space between the teeth of both

gears at the intake port area. Fluid is drawn in through the

PAGE 14

intake port and passes around the crescent area of the pump. As the gear teeth again

come in contact with one another near the exit port, the fluid is discharged. Notice

that the driven gear has fewer teeth than the driving gear. However, the gears mate

smoothly at all times - without causing inter-ference. This occurs because the pitch

of gears is equal, even though the pitch diameter is unequal.

PDF created with pdfFactory Pro trial version www.pdffactory.com

4.4 Vane Type Pumps

The vane type pump is another type of rotary pump used in many applications in

industrial plants. Although they are generally used for transferring hydraulic or

lubricating oil, they are also used for solvent or chemical transfer. Vane type pumps

are used for viscous materials such as paint or other heavy fluids which may contain

abrasive particles. For these applicaiions, the vanes are made of a softer material

than the pump casing. They wear less and are replaceable at a relatively low cost.

The, vane type pump shown in Fig. 4.4 is very simple in operation . As the impeller

rotates, its offset position above the pump centerline allows the vanes or blades to

extend and draw in fluid on one side. The open spaces between the impeller and the

housing at the bottom of the pump allow movement of the fluid through the pump.

As the impeller continues its rotation, the vanes are

PAGE 15

pushed back in their slot as they near the top of the pump. This constriction of

available space forces the fluid out of the discharge port.

The pump inlet and discharge ports are oval shaped and extend about three-

fourths across the casing width. This less than full opening helps con-tain the vane

within the pump casing. The oval shape smooths the fluid transfer.

PDF created with pdfFactory Pro trial version www.pdffactory.com

4.5 Screw Pumps

4.5.1 Screw ' pumps are a special type of rotary positive displacement pump in which the

flow through the pumping elements is truly axial. The liquid is carried between

screw threads on one or more rotors and is displaced axially as the screws rotate and

mesh. In all other rotary, pumps the liquid is forced to travel circumferentially, thus

giving the screw pumps with its unique axial flow pattern and low internal velocities

a number of advantages in many application areas where liquid agitation or

churning is objectionable. Fig. 4.5(a)(b)

4.5.2 The applications of screw pumps cover a diversified range of markets such as navy,

marine, and utilities fuel-oil service, marine cargo, industrial

PAGE 16

oil, burners; lubricating-oil service; chemical process; petroleum and crudeoil

industries; power hydraulics for navy and machine tools; and many others. The

screw pump can handle liquids in a range of viscosity from molasses to gasoline, as

well as synthetic liquids in a pressure range of 3.5 to 350 kg/,tm2 and flows up to

1300 L/min.

4.5.3 Because of the relatively low inertia of their rotating parts, screw pumps a re

capable of operating at' higher speeds than other rotary or reciprocating pumps of

comparable displacement. Some turbine-attached lubricating-oil pumps operate at

10,000 rpm and even higher. Screw pumps, like other rotary positive displacement

pumps, are self-priming and hav@ a delivery flow characteristic which is essentially

independent of pressure.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 17

5.0 Reciprocating Pumps

5.1 A reciprocating pump may be defined as a pump that operates using a back and

forth, straight-line motion. Frequently the reciprocating pump is driven by an air or

steam-driven 'reciprocating piston. Some types of reciprocating pumps are driven

by a rotating crank shaft powered by an internal combustion engine or electric

motor.

5.1.1 Reciprocating pumps have two sections, the liquid section, and the steam.or air

section. The liquid section does the pumping. The steam or air section provides the

driving force necessary to operate the liquid section.

5.1.2 Although the pumping and driving ends may vary in construction in different

pumps, their general operating characteristics an esign are similar. The terms used

to describe the different components in the two sections (pumping and driving) are

similar in most cases, as shown in Fig. 5.l

PAGE 18

Piston - in the drive end converts the steam or air pressure into mechnical energy.

The piston in the pumping end converts the mechanical energy into fluid movement.

Piston Ring - acts as the seating element between the piston and the cylinder walls.

Cylinder - the tubular chamber that contains the piston.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Cylinder Head the cap on the end of the cylinder. The cap seals the cylinder and

allows'the piston to convert steam or air pressure into mechanical energy.

Packing Gland or stuffing box as it is also called, is located where the connecting

rod or piston rod passes through the cylinder head. The packing gland prevents

leakage of the steam or liquid from the cylinder.

Connecting Rod connects the piston on the pumping end to the drive section.

If the driving force is a crankshaft, the liquid-section connecting rod is usually

constructed in two pieces.

Valves - the valves are of two types. Either they control the power (steam or air)

flow into the driving side or the liquid flow into the pumping side. Although both

valves control flow, they are quite different in construction and operation. Note that

the valves in the di riving side of the pump are mechanically actuated, while the

valves in the pumping side are material actuated.

5.2 Diaphregrn Pumps

5.2.1 The pumping action of a diaphragm pump is similar to a single acting reciprocating

pump. This is shown in the diagram in Fig. 5.2., As the diaphragm is drawn into the

upper portion of the pump cavity, fluid is drawn into the pump through the check

valve in the suction line. As the diaphragm is driven downward, the fluid is forced

out of the cylinder through the check valve on the discharge side. As the cycle is

repeated, the discharge valve is closed by the pressure in the discharge side and the

suction created by the intake stroke.

5.2.2 Most diaphragm pumps are operated mechanically, but some are air- operated. Air

operated pumps can be operated by either compressed-air or Vacuum-air, depending

on the pump. Becaus @ of their simple construction

PAGE 19

these pumps are used for metering, transferring, or as sump pumps. Also,. they,can handle

fluids, scurries, or sewage.

PDF created with pdfFactory Pro trial version www.pdffactory.com

5.2.3 The travel or stroke of the diaphragm in the mechanically operated pump is

controlled by an adjustable connecting r_od or other mechanism. The travel of air-

operated pumps is controlled by an adjustable diaphragm stop as shown in Fig. 4.2.

The stop limits the upward travel of the diaphragm rather than adjusting its overall

travel.

5.2.4 For handling chemicals or other corrosive fluids, pumps should be either lined or

manufactured of stainless steel or other corrosion resistant metals. If should be

remembered that the flow from a diaphragm pump is not steady, but pulsating.

PAGE 20

6.0 Construction of Centrifugal Pump

PDF created with pdfFactory Pro trial version www.pdffactory.com

The Centrifugal pump in its simplest form consists of two main partse Stationary

parts consisting. of the casing, bearings and stuffing box. Rotating parts consisting

of the impeller and the shaft.

6.1 Casing

Casing or housing is the main casting which is firstly used to restrain the

water into an approximately circular or spiral path and secondly to collect the water,

as it is delivered from the periphery of the impeller.

It is provided with the inlet 'Suction', the outlet 'Discharge' and with a

stuffing box to permit the projection of the spindle or a shaft.

6.1.1 Materials for Casing

The following criteria should be considered in the selection of material for

centrifugal pump casings :

Strength

Corrosion resistance

Abrasive-wear resistance

Casting and machining properties

Cost

For most pumping applications cast iron is the preferred material for pump

casings when evaluated against initial cost. For single-stage pumps cast iron is

usually of sufficient strength for the pressures developed. For corrosive and volatile

products it may be necessary to specify cast steel or cast stainless steels.

Cast iron casings for multistage pumps are limited to approximately 10

kg/cm2 discharge pressure and 175"C. For temperatures above 17CC and pressures

upto 150 kg/tm discharge pressure, a cast steel is usually specified for split-casing

multi-stage pumps. For pressures higher than 150 kglcm2a cast or forged steel

barrel-type casing is required.

In any evaluation of cast iron versus steel casings, consideration should be given

to the probability of casing erosion during operation. Erosion can

PAGE 21

occur from either abrasive particles 'in- the fluid or from wire drawing across the

flange of c split-case pump. While the initial cost of a steel easing is higher than that

of a cast irom casing can often be salvaged by welding the eroded portions and then

PDF created with pdfFactory Pro trial version www.pdffactory.com

remachining. Salvaging a cast iron casing by welding is not practical, and the

casing usually must be replaced.

The ductile irons are useful casing materials for pressure and temperature

ratings between cast iron and steels. While the modulus of elasticity for the ductile

irons is essentially the same as that for cast iron, the tensile strength is

approximately doubled. In any evaluation of the ductile irons as a substitute for the

steels in the intermediate pressure and temperature range, it must be remembered

that ductile iron casings cannot be effectively repair-welded in the field.

6.2 lmpeller

The, lmpeller can be described as a wheel having equally spaced Blades or

Vanes, arranged around the shaft.

At one side is the inlet or eye. From,the eye, the blades run in a curved path

to the outer edge of the wheel. (Fig. 6. 1)

6.2.1 Classification

lmpeller can be classified in various types as detailed below:

IMPELLERS

TYPE OF SUCTION FORM OF VANES MECHANICAL DESIGN

Single Double Radial Mixed Axial Over- Open Semi Closed

Suction Suction Flow Flow Flow h,u,ng Open

(See Fig. 6.2)

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 22

PAGE 23

6.2.2 Materials for lmpelier

The following criteria should be considered in the selection of the material

for the impeller :

Corrosion resistance

Abrasive-wear resistance

Cavitation resistance

Casting and machining properties

PDF created with pdfFactory Pro trial version www.pdffactory.com

Cost

For most water and other noncorrosive services bronze satisfies these criteria

on an evaluated basis. As a result bronze is the most widely used im. peller material

for these services. 13ronze illipellers, however, should not be used for Pumping

temperatures in excess of 120'C. This is a limitation imposed primarily because the

differential rate of expansion between bronze and steel will produce an unacceptable

clearance between the impeller and shaft. The result would be a loose impeller on

the shaft.

Cast iron impellers are used to a limited extent in small low-cost pumps. As

cast iron is inferior to bronze in corrosion, erosion and cavitation resistance low

initial cost.wouid be the only justification for a cast iron impetier on an evaluated

basis.

Stainless steel impellers are widely used where bronze would not satisfy the

requirements for corrosion, erosion, or cavitation resistance. The stainless steels are

not used for seawater, however, as pitting will limit their performance life. The

stainless steels should be used where the pumping temperature exceed 120 0 C as

the differential expansion problem no longer exists with a steel impeller on a steel

shaft.

The austenitic stainless steels are the next step up on the corrosion and

cavitation-resistance scale. Initial cost is a factor here that should be evaluated

against the increased performance life.

6.3 The Shaft

The basic function of the shaft is to transmit the torque and supporting the

impeller and other rotating parts. The impeller is keyed to the shaft which is

supported at either ends by bearings. (Ref. Fig. 6.3)

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 24

PAGE 25

The following criteria should be considered in the selection of the material

for a centrifugal pump shaft :

Endurance limit

Corrosion resistance

Notch sensitivity

The endurance 1'tm'tt 'is the stress below which the shaft will withstand an

infinite number of stress reversals without failure. Since one stress reversal occurs

for each revolution of the shaft this means that, ideally at least, the shaft will never

fail if the actual maximum bending stress in the shaft is less than the endurance limit

of the shaft materials.

PDF created with pdfFactory Pro trial version www.pdffactory.com

In actual practice, however, the endurance limit is substantially reduced

because of corrosion and stress raisers such as threads, keyways and shoulders on

the shaft. In the evaluation of the selection of the shaft mateiral consi- deration

must be given to the corrosion resistance of the material in the fluid being pumped

as well as the notch sensitivity.

6.3.1 Shaft Sleeves

Pump shafts are usually protected from erosion, corrosion, and wear at

stuffing boxes, leakage joints, internal bearings, and in the water ways by renewable

sleeves.

The most common shaft-sleeve function is that of protecting the shaft from

wear at a stuffing box (See Fig. 6.4).Sha'ft sleeves serving other functions

PAGE 26

are given specific names to Indicate their purpose. For example, a shaft sleeve used

between two multistage pump impellers in conjunction with the interstage bushing

to form an interstage leakage joint is called an interstage or distance sleeve.

6.4 Bearings

The function of bearings in centrifugal pumps are :

Reducing frictional force.

PDF created with pdfFactory Pro trial version www.pdffactory.com

To keep the shaft in correct alignment with the stationary parts under

the action of a radial and transverse loads.

In horizontal pumps the bearings are usually designated as inboard and

outboard. Inboard bearings are located between the casing and coupling. Because

of the heat generated by the bearing itself or the heat of the pumped liquid (more

than 120"C), the bearing temperature are kept within proper limits (40* C to 60" C)

either by a forced feed lubrication system @incorporatina oil ..ooieror by Jacket

cooling. All type: of bearings are used in centritugai :)umps depending on the

service conditions.

6.5 Punip Sealing

Sealings are provided to prevent any leakage at the point where the pump

shaft passes out through the casing. The pump seals prevent air leakage into the

pump if the pump pressure is less than atomospheric and if the pressure is above

atmospheric the function is to prevent the liquid leaking out of the pump.

Basically two types of sealings are used

Stuffing Box

Mechanical seal

6.5.1 Stuffing Box

A stuffing box consists of a number of rings of packing around the pump

shaft housed inside a cylindrical recess between the pump casing

PAGE 27

and the pump shft. The packing is compressed to give the desired fit on the shaft by

a gland that can be adjusted in the axial direction. Fig. 6.5 a It sealing the box is

desired, a lantern ring(Fig. 6.5 b)is used that separates the rings of packing into

appoximately equal sections.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Fig. 6.5 a Conventional stuffing box with bottoming ring.

Fig. 6.5 Lantern gland or seal cage

PAGE 28

6.4.3 PACKING PROCEDURE OF GLAND PACKING :

(A) PREPARING THE EQUIPMENT

1. With the pressure off the stuffing box, and liquid drained where necessary, remove

the gland follower nuts and null the gland follower clear of the stuffing box.

2. Carefully withdraw the old packing, using paired extractor tools of the correct size,

placed on opposite sides of the shaft. Remove any vestiges of the old packing and

wipe the stuffing box clean.

PDF created with pdfFactory Pro trial version www.pdffactory.com

3. Check the shaft to concentricity with the stuffing box bore.

4. Check the shaft to ensure run out does not exceed 0.025 mm T.I.R.

5. The shaft surface in way of the packing rings must be free from scars, pitting, grooves

or ridges.

PAGE 29

6. Examine the gland follower for general condition and fit. The inner radial clearance

should be .25 mm to .4 mm maximum and the outer radial clearance should be .25

mm maximum., to prevent risk of cocking or touching on the shaft.

7. Check the clearance between the neck bush and 'the r 1 haft. If this is greater than

.25 mm radiaily. it may be advantageous to employ a tin, close clearance spacer

ring in the bottom of the stuffing box, to prevent risk of packing extrusion.

PDF created with pdfFactory Pro trial version www.pdffactory.com

(C) PARKINGS

1. Gland packings are normally supplied as spirals or on a spool or coil, or as die-

formed rings made to specified dimensions. When specified as a continuous length, it

is necessary first to cut off the length of material to make the required number of

rings.

2. Place the packing round the shaft, or a- mandrel of the specified diameter. (The bore

of metallic and intruded packing spirals should conform to this diameter).

3. To assist in cutting. rings, two guide lines parallel, to the shaft axis and separated by

a distance equal to the packing section may be drawn on the spiral.

PAGE 30

4. Cut the rings from the spiral at an angle of 45' diagonally across the guide lines - no

gap is left between the ends.

PDF created with pdfFactory Pro trial version www.pdffactory.com

5. Metallic and extruded packing rings are, spirally opened ready for fittings by pulling

the ends axially apart.

6. Check the first ring to ensure a correct fit in the stuffing box, before cutting further

rings in the same way.

(C) FITTING THE PACKING

1. Check the shaft to ensure it turns freely.

2. Fit each packinq ring individually.

3. Joints are staggered by 120'.

4. Check the shaft to ensure it can be turned. afte@ fittina each packing ring.

5. If alantern ring is fitted, it must be correctly Positioned below the inlet connection

allowing for slight compression of the bottom Packing rings. Bring the gland

follower up squarely against the last packing ring and tighten the nuts to finaer

pressure.

6. Tighten the nuts finally aftpr charqinq the valve.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 31

6.44 SUMMARY OF PACKING TYPES AND PROPERTIES

Type Material Construction Temp. (Max. Maximum PH Suitable

of range) pressure for

0 0

F C lb/in2 bar

Natural fibre Cotton Plaited or bri- 199 90 - - 6-9 Water

ded with lubricant

Hemp Plaited or bri- 176 80 - - 5-9 Water

ded with lubricant

Flex Plaited or bri- 160-250 70-120 - - - Water

ded with lubricant

Synthetic Nylon,rayon Plaited or bri- Not used

fibre etc. ded for valve

impregnatedwith packing

PTEE

Asbestos White Plainted or -22 to -30 to 5-12 Steam,

asbestos braided with 570 +300 liquors,etc.

graphite, mica

or,oil lubricant

Asbestos White Plaited or -60 to -50 to 3600 to 250 to 4-11 Water,steam

(reinforced) asbestos, braided with +1380 +750 9500 650 solvents,

inconel graphite, mica hydrocarbons

wire reinforc- or oil lubricant incorporating

ement acids

and alcohols

Asbestos Asbestos Wet-spun,dust -30 to -40 to 5-12 High

graphite fibres free type +570 +300 temperaature

mixed with preferred as and stem

graphite smoother than services.

dry mix.

PTFE PTFE yaarns Plainted or -328 to -200 to 0-14 Water,steam,

or tape braided +490 +250 hydro-carbon,

soft packings

PTFE yarns

with lubricant

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 32

PTFE yarns, Plaited or -328 to -200 to 1450 100 0-14 All media,

treated with braided +570 +300 but little

PTFE used for

dispersion valves.

PTFE / PTFE / Solid +480 +250 1450 100 0-14 Water,oils

graphite graphite extrusion hydrocarbons

mix alkalis, acids,

alcohols etc.

PTFE / Aramid fibres coated fibres -364 to 220 to 2900 to 200 to 1-14 Not

aramid treated with braided or +570 +300 14500 +1000 particularly

PTFE plaited and suitable

dispersion impregnated for valve

with stem

lubricant seals.

Expanded Pure Tape form -328 to -200 to 4350 300 0-14 High

graphite expanded +1100 +600 temperature

graphite services sealing

gases and low

pure Flexible plait -328 to -200 to 4350 300 0-14 Viscosity fluids :

expanded +1100 +600 all services

'graphite requiring

superior

leak tightness.

Carbon fibre Amorphous Twisted or -328 to -200 to 0-14 High

carbon yarns plaited +1100 +600 temperature

treated with services but little

graphite used for valves

powder

Glass fibre Glass fibre Braided with Corrosive

yarns added lubricant media

(except strong

alcohols)

Alumina Alumina Plaited,with 2300 1260 0-9 Extremely high

silicate silicate or without temperature

inconel wire services.

rein forcement

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 33

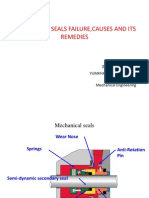

6.5.2 Mechanical Seals

The stuffing box cannot provide minimum leakage because to lubricate the

shaft and the packing, the pumped fluid must be allowed to leak out of the pump.

The packing requires periodic tightening. This leads to frictional losses and

consequent failure of the stuffing box.

In order to avoid the above, the mechanical seals are used. In mechanical

seals, the sealing surfaces are located in a plane perpendicular to the shaft.

Mechanical seal essentially consists of two, highly polished surfaces running

adjacently, one surface being placed on the shaft and the other to the stationary

portion of the pump. The lapped surfaces, made of dissimilar metals are held in

continual contact by the spring, forming fluid tight seal between the rotating and

stationary members with very little frictional losses. Fig. 6.7 shows the details of

mechanical seals of a KH 1 Boiler Feed pump.

6.5.3 Cooling of Mechanical Seals

There are a number of reasons for cooiing mechanical seals :

To prevent the destruction of the liquid film between sealing faces due to

high temperature

To prevent vaporization of the liquid at the seal faces

To protect the seal faces by oreventing overheating and continuous flushing

Basically there are two types of seal arrangements-internal and External.

Internal assembly is the one of which the rotating element is located inside

the box and is in contact with the liquid being pumped Fig. 6.6A

In External assembly the rotating element is located outside the box Fig. 6.6 b.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 34

PAGE 35

Both internal and external types always have three primary points Fig. 6.8 at which

sealing must be done as described below:

Point (1) - Between the stationary element and casing. This point. is sealed by

conventional gaskets or some synthetic 'O' ring.

Point (2) - Between the rotating element and shaft (or shaft sleeve). This point is sealed

by '0' rings, bellows or some form of flexible wedges.

Po i nt (3) - Between the mating surfaces of rotating and stationary seal elements.

Leakage between these two surfaces cannot be entirely stopped but can be

reduced to insignificant amount by maintaining a very close contact.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Whenever the temperature of liquid being pumped is above 7@ C, the thin film of

liquid entrapped between the seal faces flashes into steam because of rise of

temperature in the seal faces due to friction. This causes the seal faces to wear very

rapidly.

So, it must be ensured that liquid around seal area is limited to 7@C. While pumping

liquid at 70" C or more, arrangements must be made to cool the seal faces either by

flushing the seal faces with external cold water or by a close circuit sealing system

with external cooler.

PAGE 36

6.6 Wearing Rings

Wearing Rings are used between the pump casing-and impeller to provide a

leak tight joint using renewable parts. The wearing ring can either be fixed to the

casing or to the impeller and in some cases it is a double ring fixed to both impeller

and the casing.

There are various types of wearing ring design and selection of a type

depends on the liquid handled, the pressure differential across the leakage joint, the

rubbing speed and pump design. The various designs are shown in the Fig. 6.9 .

These designs are based on the variation of the leakage joints to provide

resistance to leakage, flow from high pressure discharge side to low pressure suction

side.

The clearance between the wearing ring mounted on the casing or casing ring and

the impeller is a function of the leakage joint, diameter.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 37

7.0 Axial thrust & hydraulic balancing

Axial thrust is the summation of unbalanced impeller forces acting in the

axial direction.

7.1 Axial thrust in single-stage pumps

The ordinary single suction radial flow impeller, with the shaft passing

through the impeller eye, is subject to axial thrust because a portion of the front

wall. is exposed to suction pressure.

Thus the net axial force will be acting towards the suction side and it will be :

(Pd - Ps) x hub area, where Pd' = discharge pressure and Ps = suction side pressure

Fig. 7.1,.

A double-suction impeller is axialy balanced with the pressure orv one side equal to

that on the other side Fig. 7.2 . Though this is theoretically true, in practice even in the

double suction pump axial unbalance persists. To compensate for this, all centrifugal

pumps incorporate thrust bearings.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 38

To eliminate the axial thrust of a singte-sijction impeller, a Pump can be provided

with both front and back wearing rings. To equalise thrust areas, the inner diameter of

both rings is made the same. Pressure approximately equal to the suction pressure is

maintained in a chamber located on the impeller side of the back wearing ring through

drilled balancing holes through the impeller Fig. 7.3.

Leakage past the back wearing rings is returned into the suction area through these

holes. In case of large single-stage single-suction pumps, balancing holes are replaced

by a piped connection to the pump suction.

7.2 Axial thrust in multistage pumps

A multistage pump essentially consists of a number of singie-stage impellers

mounted on the same shaft.

Single-stage impiollers can be mounted in two ways

i) Several impeders mounted on one shaft each having its suction and facing

in the same direction and its stages following one another in ascending

order of pressure. The axial thrust is then balanced by hydraulic balancing

device.

PAGE 39

(ii) An even number of single-suction impellers can be mounted half in one

direction, half in opposite Erection. With this arrangement, axial th. rust-on

PDF created with pdfFactory Pro trial version www.pdffactory.com

the one half is compensated by the thrust in the opposite direction on the

other half.

7.2.1 Hydraulic balancing devices

Hydraulic balancing devices are mostly used in multistage pumps to balance

the axial thrust and to reduce the pressure on the stuffing to the fast-stage impeller.

This hydraulic balancing device may be a balancing drum, a balancing disc or a

combination of the two.

7.2.2 Balancing drum

Balancing chamber is provided after the fast stage impeller. The chamber is

separated from the pump interior by a drum that is either keyed or screwed to the

pump shaft and hence it rotates with the shaft. The drum is separated by a small

radial clearance from the stationary portion of the balancing device. The balancing

chamber is connected either to the pump suction or to the vessel from which the

pump takes its suction. Thus, the back pressure in the chamber is slightly higher

than the suction pressure Fig. 7.4).

The forces acting on the balancing drum are the following :

i) Towards the discharge end -F, = Pd x front balancing area

ii) Towards the suction enct.F2 = Pb x back balancing area,

Pb = back pressure, Pd = discharge pressure.

The first force is greater than the second thereby counter balancing the axial

thrust exerted.

Since 100% balance@ is unattainable in practice, the balancing drum is often

designed to balance only 90 to 95% of total impeller thrust.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 40

However, the major disadvantage of balancing drum, is that it does not compensate

automatically for any change in the axial thrust caused by varying pump operating

conditions.

7.2.3 Bglgncing disc

In this case balancing disc rotates with the pump shaft and it is separated

from the balancing disc head (stationary part) by a srnall axial clearance. The

leakage through this clearance flows into the balancing chamber and from there

either to the pump suction or to the vessel from which the pump takes its suction.

The back of the disc is subject to the balancing chamber back pressure,

whereas the disc face experiences a range of pressures (discharge pressure at its

smallest diameter to back pressure at its periphery). The inner and outer

diameters of the disc are so chosen that the total force acting on the disc face and

that acting on its back wall will balance the impeller axial thrust Fig. 7.5.

If the axial thrust increases during operation, the disc moves tovvards the disc

head reducing the axial clearance. This will result in reduction in leakage and

hence in the back pressure in the balancing chamber. This automatically

increases the A p acting on the disc and moves it away from the disc head,

increasing the clearance. Now, the pressure builds up in the balancing chamber

and the disc is again moved towards disc head until an equilibrium 1 is reached.

Thus automatic compensation is ensured.

PDF created with pdfFactory Pro trial version www.pdffactory.com

PAGE 41

The disadvantage of a balancing disc arrangement is that the pressure on the

stuffing box packing is variable and this is quite detrimental to the life of packing.

7.2.4 Combination of balancing disc and drum

The combination of balancing disc and drum is developed to overcome the

shortcomings of the disc while retaining the advantage of automatic compensation

for any axial thrust changes Fig. 7.6).

7.2.5 Balancing device in Boiler Feed Pump

The axial thrust in case of a BFP type 200 KHI/150 KHI(BHEL)

isapproximately 34 tons and is balanced by the provision of balancing device. It

consists of a rotating balancing disc with a small axiai clearance of 0.08 to 0.12mm

against a static balancing disc. A part of the higli pressure water a fter the last

impeller is allowed to pass through the throttling bush and to act on the front surface

of the balancing disc. The back surface of the disc is exposed to suction pressure by

connecting the space behind the disc to deaerator through piping. The difference in

pressure on both sides of the disc exerts a thrust on the disc and tries to move the

entire rotor towards right. Since this force is opposite and equal to axial thrustthe

rotor comes in equilibrium position maintaining the clearance of 0,08to 0.12mm

depending on the type of pump i.e. 200 or 150 KH 1.

PAGE 42

8.0 Pump Maintenance

PDF created with pdfFactory Pro trial version www.pdffactory.com

8.1 SAFETY : While taking up any maintenance job the related safety aspects should

always be kept in mind and never be ignored. Following steps must be observed'

1) Obtain a 'permit to work' from competent authority, Permit must specify the

pump(s) to be taken up for maintenance, inform the steps to be taken for

isolating the pump from the system.

2) Ensure that isolation is actually carried out as per the instructions.

3) Drain the pump and connected pipe line before working and be sure of the

nature of the fluid being carried through the pipe. If the line handles liquid of

corrosive nature use required personnel protective equipment.

4) Allow the pump to cool down sufficiently.

5) Clean the surrounding area, make proper access to the working place. Take

care of other hot lines, if any, around the pump.

6) Choose right tools. Consult manufacturers instruction for special tools, if

required.

7) Allow only authorized persons in the work area.

8.2 Maintenance operations for centrifugal pumps fall into two categories

a) Routine preventive maintenance

b) Major overhaul or Repairs

Routine Maintenance

Routine maintenance can be classified as work done primarily to rectify the

effects of normal wear in a pump.

Overhaul or Repair are carried out to rectify the results of excessive wear,

over heating, damag e from solids in the liquids or injury or wear due to any other

cause.

PAGE 43

A maintenance record for the pump must be kept and preserved to monitor

machine performance

Maintenance Intervals

The usual intervals recommended for routine preventive maintenance are monthly,

quarterly, half-yearly and annualiv, Theseare satisfactory for all common

centrifugal pumps, provided hourly checks are regularly carried out.

8.2.1 Daily Observation of Pump Operation

PDF created with pdfFactory Pro trial version www.pdffactory.com

When operators are on constant duty, hourly and daily inspections should be

made, and any irregularities in the operation of a pump should be reported

immediately. This applies particularly to changes in the sound of running pump,

abrupt changes in bearing temperatures, and stuffing box leakage. A check of the

pressure gauges and of the flowmeter ,,if installed, should be made hourly. If

recording instruments are provided, a daily check should be made to determine

whether the capacity, pressure or power consumption indicate that further inspection

is required.

8.2.2 Monthly Check

Use a thermometer to check temperatures of each bearing of the pump.

Temperature, in no case should go beyond 720C. Before allowing any bearing to

operate at any temperature above that recommended, check with the pump

manufacturer. Much depends upon the type of bearings, its lubricant and the duty

the bearing performs in the pump. In bigger size pumps on line temperature

measuring points are provided for this purpose.

8.2.3 Quarterly

a) Check oil & Replace

Once in every 3 months, drain the oil from sleeve type bearings. Washout

the oil wells and bearings interior parts with kerosene oil. Check the oil rings.

b) Check bearing lubrication, arrangements

Rings must be free from all the dirt, completely circular and must turn freely

when the pump shaft is rotated. Repair or replace any defective oil rings. Refill

the bearing with the correct oil.

PAGE 44

c) Check Grease for Specifications

Inspect grease lubricated rolling contact and sleeve bearings for

saponification, a condition revealed by a whitish colour of the grease. It is caused

usually by leakage of Water or other liquids past the bearing shaft seal To relieve

this condition, flush all grease from the bearingluse clean warm Kerose@ne oil to

do the same. When the bearing is clean atid dry, replace it with new clean grease of

recommended grade.

d) Measure bearing clearance

PDF created with pdfFactory Pro trial version www.pdffactory.com

Place three length of metallic packing or plastic wire on top of the journal.

The wire should not be more than 0.20 mm thicker than the estimated clearance.

Replace the bearing cap and tighten its hold down nuts.

Remove the cap and measure the thickness of each of Flattened wire with

micrometer. If all leads are of the same thickness, the clearance is uniform,

throughout the bearing.

Thickness of any wire gives the bearing clearance at the point at which wire

was located. Check the clearance, and enter it in the pump record card, along with

the date of the replacement.

8.2.4 Half Yearly

Good, stuffing box must leak

Check the shaft packing by observing the leakage from it, leak should be 40

to 60 drops per minute for adequate cooling, this may vary with pump service

conditions, liquid handled and the type of the packing used.

If rate of leakage is higher than the recommended one check packing, and

replace all. Don't replace one or two packs.

Removal of old packing

Remove packing by extractor. Make sure that shaft is not scratched while

removing worn out packing.

Note down seal position

If seal cage or lantern ring is provided, note down its position. Count the

number of packing in front. or in the rear side of the seal cage.

PAGE 45

Check Shaft sleeve

Check the shaft sleeve for wear. If the sleeve is badly scarred or worn,,

replace it.

To slip the sleeve from the shaft, use sleeve puller. If there is some

difficulty, apply some heat on the sleeve and pull by puller.

Check run out of the Shaft.

If packing wear is more, and sleeves are in good condition, check the shaft

run out, use Dial Test Indicator (DT I).

PDF created with pdfFactory Pro trial version www.pdffactory.com

Check with D.T.I. and if run out is more than the permissible limits get your

shaft straightened

Find out right size of packing thickness

Measure the stuffing box bore, subtract the shaft diameter. Divide bv 2, to

find out the right size of the packing to install.

Stagger the joint at :

a) 1800' if the stuffing box has two packings

b) 120 if the stuffing box has three packings

c) 9011 if the stuffing box has four packings

Insert packings and be sure that packing has reached its proper place.

Locate Lantern Ring

Be sure each ring is firmly seated before the next one is inserted. Locate the

Lantern ring, it lines up with the centre of the cooling liquid opening. Remember

the ring moves back into the box as the packing is compressed. Allow the packing

to leak until it seats itself. As the packing, is being installed, turn the shaft by hand

in the normal direction of rotation to level off any high spots in the packing.

Gland Adjustment

Tighten the packing gland just enough to prevent excessive leakage before

starting the pump. As the packing adjust itself in the shaft, tighten the gland slowly,

one flat at a time until the desired results are achieved.

PAGE 46

Do not back off the gland nuts

Do not back off the gland nuts, while the pump is running. This will allow

the entire sets of rings to move away from the bottom of the box without relieving

pressure of the packing on the shaft sleeve. The best islif packing is too tight,to stop

the pump, and allow the stuffing box to cool, and then readjust the packing. Start

the pump and check stuffing box temperature. It may be necessary to stop and start

pump several times before the proper leakage and temperature is obtained.

8.2.5 Annual Inspection

Centrifugal pumps should be very thoroughly inspected once a year. In

addition to the semi annual maintenance procedure the bearings should be removed,

cleaned and examined for flaws. The bearing housings should be fully cleaned.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Antifriction bearings should be examined for scratches and wear after cleaning.

Immediately after inspection, antifriction bearings should be coated with oil or

grease to prevent dirt or moisture from getting into them.

The packing should be removed and the shaft sleeves, or shaft, if sleeves are

not used, should be examined for wear.

The coupling halves should be disconnected and alignment checked. In the

case of horizontal pumps with babbitt bearings, the vertical shaft movement for both

ends should be checked with the packing out and the coupling disconnected. Any

vertical movement more than 150 per cent of the original play reuires investigation

to determine the cause. If the end play is higher than allowed and recommended by

the manufacturer, the cause should be determined and corrected.

Drains, sealing water piping, cooling water piping, and other piping should

be checked and flushed. If an oil cooler is used, it should be flushed and cleaned.

The pump, stuffing boxes should be repacked and the coupling reconnected.

If instrument and monitoring devices are available, these should be

recalibrated and a test made to determine whether proper performance is obtained.

If internal repairs are made, the pump should again be tested after completion of the

repairs.

PAGE 47

8.3 Complete Overhaul

General rules cannot easily.be made to determine the proper frequency and

regularity of complete overhauls of centrifugal pumps. The type of service for

which the pump is intended, the general construction of the pump, the liciuid

handled, the materials used, the average operating time of the pump, and the

evaluation of overhaul costs against possible power savings from renewed

clearances, all enter into the decision on the frequency of complete overhauls. Some

pumps on severe service may need a complete overhaul monthly, whereas other

applications only require overhaul every two to four years or even less. frequently.

8.3.1 Stages of Major Pump Checkup

1 . Stripping the pump

Identification and marking of parts

2. General Inspection of parts removed.

PDF created with pdfFactory Pro trial version www.pdffactory.com

3. Specific fault detection.

4. Rectif ication of fau Its,

Bearing housing

Bearing replacement

Neck ring clearance

lmpeller condition

Changing gland packing

Check shaft for straightness

Keyways and keys

Shaft sleeve tolerances

Condition of nuts & bolts

5. Condition of gland and gland housing (Clearances)

6. Assembly of pumps

7. Pump alignment

PAGE 48

8.3.2 Method of Marking or Stamping items when Stripping Pumps

Stamping the Pump

1 Clean pump, motor, bedplate etc.

2. Remove any klinger cocks, valves, gauges, tundishes etc. from pump body.

3. Check if any existing marks or stampings are visible on pump, body,

couplings, gland etc.

It may be possible to use original stamping and so not to confuse when

rebuilding pump

4. Stamp glands.C.E. (coupling end) or C.D.E. (Coupling drive end) and B.E.

(back end) or N.D.E. (non drive end).

5. Stamp pedestal caps and bearings C.E. or C.D.E. and B.E. or N.D.E. on top

and bottom halves.

6. Stamp bearing housings. C. E. or C. D. E.' and B. E. or N. D. E.

7. Mark any covers to be removed including the top cover of single and twin

stage pumps.

8. All parts not suitable for stamping must be marked or lables attached i.e. oil

rings, junk rings, lantern rings, water or oil throwers, ball and roller

PDF created with pdfFactory Pro trial version www.pdffactory.com

bearings, sleeve nuts etc. and ail dowels removed from covers or feet of

pumps.

9. All bushes and neck rings must be stamped or marked from coupling end of

pumps.

10. When marking a multi-stage pumpchambers should be stamped from

coupling end of pump i.e. suction chamber is No. 1 chamber and so on.

(See. Fig. 4).

11. When marking impellers, the impeller whose necking enters suction

chamber should be marked or stamped on the delivery side of impeller.

12. All keys should be stamped from coupling end i.e. (coupling key) No.l. (No.

1 lmpeller) No. 2., (No. 2 ]mpeller) and so on right up to B.V. (Balance

Valve) Key.

13. All chamber plates should be stamped from coupling end i.e. suction

chamber plate No. 1 and so on.

14. All neck rings and bushes removed from chambers or plates should be

stamped from coupling end of pump as they will be used for reference.

15. Any Guide vane tips removed from chambers must be stamped for

reference use numbered from suction end.

PAGE 49

8.3.3 Complete Dismantli g of A Centrifugal Pump

Centrifuga pumps should be dismantled with great care. The suction and

discharge valves should be-closed and the pump casing drained. All necessary

piping and parts that would interfere with thd disassembly of the pump, such as

bearing covers, should be taken apart as required by the manufacturer's instructions.

The upper half of pumps with axially split casings should be lifted straight up

after the dowels and the nuts of the casing bolts have been removed, to prevent

damage to internal parts. The rotor should also be removed vertically to prevent

injury to the impellers, wearing rings, and other parts.

During the dismantling procedure, the various parts removed must be marked

to ensure proper reassembly. All individual parts and all important joints should be

carefully examined. If the pump has been operating satisfactorily with only a slight

PDF created with pdfFactory Pro trial version www.pdffactory.com

reduction in head and capacity due to increased leakage, a decision on

reconditioning will depend on several factors- like

Availability of spare parts.

Length of time the pump can be left out of service.

Economic considerations and importance of getting the service from the

unit without overhauls.

Generally, worn parts should be renewed if the pump is not to be examined

until the next routine period, regardless of the performance of the unit, because

when parts in new or good condition are assembled in contact with dirty or worn

parts, the new parts are very likely to wear out re-Pidly.

8.3.4 Maintenance of specific pump parts

i.) Special care is required in the reassembly of multistage pump rotors with

axially split casings. These casings are made from castings and, when the

pump is built, it is sometimes necessary to allow variations in longitudinal

dimensions on the casings. This is done by making assembly floor

adjustments to the rotor, in order to preserve the designed impellers in their

correct positions, with respect to their volutes or diffusers.

ii.) When making field renewal of rotors or of stationary parts, all lateral

PAGE 50

distances should be compared with those on the old parts and where lateral

end movement is affected, these distances should be duplicated.

iii.) The assembled rotor and stationary parts (such as casing wearing rings,

stag-pieces, diffusers) $hould be placed in the lower half of the casing and

the total lateral clearance checked.

iv.) When the thrust bearing is assembled and the shaft is in its proper position,

this total clearance should be suitably divided and the impeliers centrally

located in the volutes or diffusers. The shaft nuts can be manipulated for

final adjustments.

v.) To avoid shaft distortion, all abutting joints must be square with the shaft

axis and with each other, and the impeller and shaft sleeve nuts must not be

tightened with excessive force. Otherwise, the metal may be crushed at

these joints, exerting severe moments on the shaft. ]'he shaft may become

PDF created with pdfFactory Pro trial version www.pdffactory.com

bowed under the influence of these moments and develop a marked

vibration, in addition to the possibility of rubbing and binding at the

internal running joints.

vi.) When using locking screws of the safety, type, the assembly should be

cheked using a dial,test indicator, to make sure that the shaft is not bent in

its bearings or on centres to check for eccentricity and any eccentricity

corrected.

8.3.5 Pump reassembly :

If the pump casing is split axially, great care must be exercised in replacing

the upper casing half and tightening up the casing bolts.

ii) If more than one row of bolts is used, the row nea rest to the pump central

axis should be tightend up first. After all the bolts have been tightened once,

they should be tightened again to ensure the tightness of the casing joint.

iii) They should then betightened once more when the pump has been brought up

to operating temperature.

8.4 Spare and reoair parts

The service for which a centrifugal pump is used will determine, to a great

extent, the minimum number of spare parts that should be carried in stock at

the installation site.

PAGE 51

Average minimum for any centrifugal pump should include a set of wearing

rings, a set of shaft sleeves (or a shaft if no sleeves are used) and a set of bearings.

It is often advisable to carry a complete spare rotor for installation in the pump when

examination shows that the pump rotor has become excessively worn, or if it

becomes accidentally' damaged. Sufficient spare packing for the stuffing boxes and

material for the gasket of axially split casing pumps should always be in stock.

Spare parts should be purchased at the time the order for the complete unit is

placed. Depending upon the contemplated method for wearing ring overhaul, the

spare wearing rings are ordered either same size as the wearing rings used in the

assembly to the new pump or bored undersize.

8.4.1 How to Order for Spares :

PDF created with pdfFactory Pro trial version www.pdffactory.com

The pump serial number and size as stamped on the manufacturer's

nameplate should always be given when ordering spare and replacement parts, This

needs to be ensured so that the manufacturer may identify the pump and furnish

repair parts of correct size and materials. Most centrifugal pumps are of standard

design and a great number of combinations are made for each size of casing, using

different impeller. sizes and designs. Without an identification number, the pump

manufacturer would be at a loss to furnish correct spares even though size and type

of the pump might be known. Some manufacturers issue special formats for

ordering spares. If available, they must be us--d.

8.5 Record of inspection and repairs:

The working schedule of the half yearly and annual inspection programme

should be incorporated on maintenance cards, one for each pump in the installation.

These cards should contain the pump identification number, the date of the

scheduled inspection, a complete recrod of all the items requ@ring individual

inspection, and space for comments and observations of the inspecting personnel.

Adequate maintenance does not end with repair work on worn or aamaged parts. A

written record of the conditions of the parts to be repaired or replaced, of the rate

and appearance of the wear, and of the method by which the repair was carried out

is as important as the repair job itself. These records\can form the basis of

preventive measures which will act to reduce both the frequency and cost of

maintenance work. The type of inspection records and the extent of detail they may

contain vary with the type of pump in question and availability of personnel.

PAGE 52

It is often advisable to take photographs of badly worn parts before they are

repaired, photographs provide more accurate and more graphic record of the damage

than a description.

Complete records of maintenance and repair costs should always be kept for

each individual pumps together with a record of its operating hours; study of these

records may reveal whether a change in materials or design will be the most

economical plan to follow.

8.6 Major Repairs and Overhaul

PDF created with pdfFactory Pro trial version www.pdffactory.com

Apart from the regular maintenance discussed earlier, the pump may require

repairs or major overhaul, Repairs pertaining to each components are discussed

here.

8.6.1 Casing Repair :

Some time casing develops vapour lock conditions as shown in the Fig.

8.1(A, B). This cannot be removed even after repeated priming. This may be found

in the volute casings. Under such case the gas/vapours entrapped is to be removed

by drilling a hole of suitable size as shown in Fig. 8.1'(A, B) at suitable location.

PAGE 53

8.6.2 lmpeller Maintenance

An impeller removed from the pum p casing should be carefully examined on

all surfaces for Unusual wear, such as abrasion, corrosion or cavitation. Most pump

for general service use bronze impellers which has a reasonably long life.

Occasionally, these pumps operate on high suction lifts or at part capacities both of

which affect impeller, life. Pumps handling water containing sand may use bronze,

cast-iron, nickle or even chrome steel impellers depending upon the amount of sand,

its abrasiveness and the character of the water.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Generally, impeller materials that form a protective coating or film, which

adheres firmly to the underlying metals and is not washed off by the water stream,

should always be used. However, abrasive material naturally erodes this protective

film on many metals making their use undesirable.

Abrasion wear can be best tested by a sedimentation test. Some of the

pumped liquid is allowed to stand in a glass container for a few hours, and the

settled particles are examined for grit. A chemical laboratory analysis of the

pumped liquid is usually necessary to determine whether corrosion is responsible for

wear. Of course, if corrosion wear is detected, the substitution with better materials

becomes necessary.

Cavitation is often accompanied by pitting in the impeller suction areas and

can be detected by a crackling noise during operation. If impellers rapidly become

pitted or eroded, the increased cost of special alloys is often warranted.

In small pumps, impeller wear is best corrected by replacement of the

impetier, because the pump size does not permit its being rebuilt. Whereas

rebuilding by brazing, soldering, welding etc. is feasible, the cost is high and so

replacement is usually the better solution.

Most large impellers will -provide many years of service, regardless of

abrasion, if eroded a,-eas are treated by 'building up' the metal. Although unlikely

wear may sometimes occur in the impeller hub over the shaft mounting'or at the

keyway. The first may be caused by a porosity in the impeller casting, permitting

water to seep from the higher pressure region to the fit between the shaft and

impeller. Sometime, the shaft material is the one more readily attacked. Wear at

the keyway may occur if the impeller fits loosely on the shaft or the key is not

properly fitted.

PAGE 54

Finally, impeller cracks may develop because of excessive vibration or

strains set up during the casting process and not detected at the time the impeller

was machined. Cracked impellers cannot be successfully repaired and are best be

replaced.

lmpeller balance should be rechecked 'whenever'the impeller is removed

from the pump rotor during overhaul. For balancing by hand, the impeller is

PDF created with pdfFactory Pro trial version www.pdffactory.com

mounted on an arbor, the ends of which are placed on two parallel and level knife

edges. If the impeller is out of balance, it will turn the arbor and come to rest with

its heavy portion down. Metal must be removed from this portion in such a way that

pump performance will not be affected and so eddy currents, which accei,-rate

erosion, will not result. For these reasons, drilling holes in the excess metal is

undesirable.

For balancing a shrouded impeller, the best practice is to mount the impeller

off-centre in a lathe and take a cut (which will be deepest at thp. periphery) from the

shroud . The cut can be taken from both shrouds, depending upon their actual

thickness and the amount of metal to be removed.

In semiopen impetier pumps, the removed metal can be taken from the

shroud if the design permits or from underneath the vanes if those on the heavy side

are th.icker than the others. The latter method is the one used for balancing open

impellers

8.6.3 Wearing Ring Maintenance

8.6.3.1 Installation

Most rings are now pressed on the impeller As distortion may occur during

the mounting process, it is advisable to Check the shaft and impeller assembly on

centres to see if the new ring surfaces are true and if not, to true them up. If the

proper facilities are available, it would be just as easy to get slightly oversi7P rings

and turn their wearing surface to the proper diameter after mounting.

8.6.3.2 Clearance

One manufacturer's clearance and tolerance standards for nongailing wearing

joint metals in general service Pumps are shown in Fig. 8.2. They .apply to the

following combinations - i). Bronze with a d issimilar bronze

PAGE 55

ii). cast iron with bronze, iii). steel with bronze, !v). monel metal with bronze, and v).

cast iron with cast iron. If the metals gall easily (like the chrome steels), the values

given should be increased by about 0.002 in. In multistage pumps, the basic diameter

clearance should be increased by 0.003 in. for larger rings. The tolerance indicated is

'plus' (+) for the casing ring and 'minus' for the impetier hub or impeiler rings.

PDF created with pdfFactory Pro trial version www.pdffactory.com

In a single-stage pump with a joint of nongailing components, the correct

machining dimension for ' a casing ring diameter of 9.000 in, would be 9.000 plus

0.003 and minus 0.000 in. and for the impeller hub or ring, 9.000 minus 0.018, or

8.982 plus 0.000 and minus 0.003 in. Actual diametral clearances would be between

0.018 and 0.024. Naturally, the manufacturer's reconify@e,@ ndation for ring

clearance and tolerance should be followed.

PAGE 56

8.6.3.3 Allowable wear

It is difficult to generalize on the amount of wear allowable before apump

should be dismantled and the wearing joint renewed, because too many factors ar 1

e involved. Internal leakage through the rings naturally means an efficiency tor,,;.

Ring renewal should be such that the overhaul cost will be offset by the power

savings. lhus, with constant use and high power costs, stified. The rule of thumb

that 100 percent more frequent renewal can be ju increase in ring clearance justifies

ring renewal can be used as a guide.

Even though the clearance is not excessive and the pump can be reassembled

without renewing the wearing ring joint, always check the impetier hub diameter

and the inside diameter of the stationary wearing ring for ecce- ntricity of wear.

8.6.3.4 Measurement of clearance

PDF created with pdfFactory Pro trial version www.pdffactory.com

Wearing ring clearances may sometimes be measured by inserting a feeler

arts. If the wearing ring is L type gaugebetween the stationary and rotating p and

the lip of the L prevents inserting thegauge@he clearance may be approximately

checked without dismantling the rotor, in the following manner:

i) Mount a dial indicator o n the impeller (as shown inF@9.8.3) and with the

stationary ring resting on the impeiier wearing ring huo, set the dial reading to

zero.

ii) Without moving the impeller or dial indicator, push up on the stationary ring

from below and record the maximum dial reading. This corres- sponds to the

diametral clearance.

PAGE 57

(3) Repeat this operation for every clearance joint and make a record of all

readings.

This operation is best carried out, however, with the rotor removed from the

pump casing it is best suited to multi stage pumps because once the rotor is out of the

casing of pumps, the stationary rings may be freely removed and the clearance

determined by measuring the two diameters and calculating the difference.

One note of warning : This short-cut method gives no clue to the condition of

adjacent clearance sufaces. In other words, burrs, grooves, or indentations caused

by foreign matter passing through the clearances will go undetected, as will the

resultant damage to the surfaces.

PDF created with pdfFactory Pro trial version www.pdffactory.com

If the pump has been dismantled, normal procedure is to measure independent

the ID of the wearing ring and the OD of the impeller wearing ring hub. Use inside

and outside micrometers respectively. Several measurements will determine

whether or not the wearing ring or impeller has become worn in an egg shaped

manner. The clearance is considered to be maximum difference between the

maximum ID and the minimum OD readings.

Clearances may also be measured directly by placing the impeller within the

wearing ring and moving it laterally against a dial indicator to determine total

diametral clearance. To determine inequality in wear around the circumference, the

impeller should be rotated and the dial indicator attached to several points of the

stationary part. If the pump has been dismantled, however, the 'difference' method

is more reliable.

The impeller and wearing rings should be at the same temperature before

measurements are made. Some high pressure and high-termperature pumps use

shrunk-on impellers tha.L must be heated before removal from the shaft to at least

204*C and possibtv to as much as 260"C to 3160C. These should be allowed to

cool down to about 49"C so that measurements can be made comfortably. But if the

wearing ring is at 27 0C, say, there will be a 2eC diff-erence betweenthe two parts

and this difference can be quite significant. This error will, of course, be magnified

if the impeller diameter is measured when it's temperature is even higher than the 49

0 C we have assumed.

This possibility of error is,frequently over-looked, as many people assume that

such a small difference in metal temperatures is not of consequence.

PAGE 58

8.6.3.5 Restoring clearances when no rings are used :

To restore the clearance between impeller and casing, when no ring

is provided, consider one of the following

i) buy new parts

ii) build up worn surfaces by welding,metal spraying or other means, or

iii) Install a wearing ring or rings if sufficient metal is available in the'casing

part or on the impeller hub.

8.6.3.6 Restoring clearances of pumps with single rings.

PDF created with pdfFactory Pro trial version www.pdffactory.com

There are three ways to restore the clearance of a pump with single flat or L-

type wearing ring construction

a) Obtain a new casing ring bored undersize from the manufacturer. Then,

true up the impeller wearing ring hub by turning down in a lathe.

b) Build up the worn surface of the wearing ring by welding or metal spraying

so that it can be bored undersize. Then true up the impeller wearing ring

hub.