Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Teava Rect 50X50X3MM PDF

Caricato da

Ciprian ShaolinTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Teava Rect 50X50X3MM PDF

Caricato da

Ciprian ShaolinCopyright:

Formati disponibili

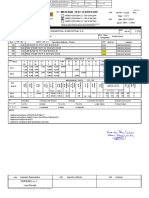

Marcegaglia THIS DOCUMENT WAS PRODUCED AUTOMATICALLY

46040 via Bresciani 16-Gazoldo degli Ippoliti Mantova-Italy Type Inspection Certificate 3.1 EN 10204 AND IS VALID WITHOUT SIGNATURE Number 10517509455 Issued On 01/09/2017

Tel. +39 - 0376 685 1 Fax. +39 - 0376 685 600

www.marcegaglia.com WELDING PROCESS QUALIFICATION: ALL THE LASER WELDING PROCESS ARE QUALIFIED ACCORDING EUROPEAN PRESSURE EQUIPMENT DIRECTIVE PED 97/23/EC BY THE

NOTIFIED BODY N.1233 EUROPED WITH WELDING PROCEDURE QUALIFICATION WPQR N° PM0907A001 Registration no. 10M203 AND WPQR N° PM907A002 Registration no. 11M017.

Stabilimento di Forlì:

via E.Mattei,20 47034 Forlimpopoli, Forlì-Cesena STILL VALID UNDER PED 2014/68/EU PER ARTICLE 48 CLAUSE 3.

tel+39.0543470111 fax+39.0543470105

Customer Code: 0000023130 Consignee Delivery Nn 8042262247 Quality Control Pages

INVESTA SPOLKA Z.O.O. Investa Sp. z o.o. Of 01/09/2017 Q.M.D./Q.M. S.Toscano

UL.ZASTAWNA 27 Smolice 1g, Tulipan Park - Hal 13/17

83000 PRUSZEZ GDANSKI PL 95010 Stryków PL Delivery note nr 1005010452 Plant Of Forlì

Material Order Nr Client Order

59000650 Test specification: Welding process 1171094356/380 CZZ17/01375

Stainless steel grade: TP 304 1.4301 X5CrNi18-10 HIGH FREQUENCY INDUCTION WELDING

Description Part Number Client Date

TXQ 50X50X3X6000 TP304 Z Tolerances: EN10305-5 EN10219-2 ASTM A554 8/08/2017

Item Identification Nr Heat Quantity MTL Quantity KG Quantity PZZ Delivery conditions Reworks

1 17PV004407 0449505 294 1241 49 BRUSHED

WE CERTIFY THAT THE ABOVE MENTIONED

PRODUCTS COMPLAY WITH THE TERMS OF

ORDER CONTRACT AND THE STANDARDS

RECALLED IN THE PRESENT TEST

CERTIFICATE

C Si Mn P S N Cr Ni

Identification Nr Chemical Type (%) (%) (%) (%) (%) (%) (%) (%)

17.5 8

0.07 1 2 0.045 0.015 0.11 19.5 10.5

17PV004407 RAW MATERIAL .027 .370 1.730 .0300 .0010 .0660 18.140 8.080

MARCEGAGLIA SPECIALTIES FORLIMPOPOLI PLANT SYSTEM CERTIFICATIONS QUALITY SYSTEM CERTIFIED ACCORDING TO EN 9001:2008 AND ISO\TS 16949:009 AND

Rp 0.2 Rp 1.0 Rm A5

ISO 3834-2:2005 AND A SAFETY SYSTEM CERTIFIED ACCORDING TO OHASAS 18001:2007 AND AN ENVIROMENTAL SYSTEM CERTIFIED ACCORDING TO ISO 14001:2004.

Identification Nr Type of mechanical test [MPa] [MPa] [MPa] (%)

MARCEGAGLIA SPECIALTIES FORLIMPOPOLI PRODUCT CERTIFICATIONS DVGW ACCORDING TO GW541 LASER AND TIG WELDED TUBES STAINLESS STEEL GRADE

210 250 520 45 1.4404 DIA FROM 15.00 TO 108.00MM AND GRADE 1.4521 FROM 15.00 TO 54.00MM.

720 TUV AD2000 W2\W10 AND PED ANNEX I, PARAGRAPH 4.3 LASER AND TIG WELDED TUBES STAINLESS STEEL GRADE 1.4301, 1.4306, 1.4307, 1.4401, 1.4404, 1.4541, 1.4571,

1.4435, 1.4436 THICKNESS FROM 0.80 TO 4.00MM AND DIAMETRS FROM 8.00 TO 283.00 MM. EHEDG FOR DAIRY TUBES TXT015. TIFQ - EUROPEAN DIRECTIVE 1935:2004

17PV004407 TUBE 284 314 624 50.6 FOR DAIRY TUBES TXT003, TXT014, TXT015.

NON DESTRUCTIVE TESTS DESTRUCTIVE TESTS

ANTIMIXING TEST: CONFORM FLATTENING TEST ACCORDING TO EN ISO 8492:2004: CONFORM

VISUAL INSPECTION AND DIMENSIONAL CONTROLS: CONFORM TENSILE TEST ACCORDING TO EN ISO 6892-1:2009

Marking

Remarks:

THE CHEMICAL COMPOSITION REFERS TO THE RAW MATERIAL USED ACCORDING TO EN 10088-2 AND 10028-7

Potrebbero piacerti anche

- TubacexDocumento1 paginaTubacexMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNessuna valutazione finora

- Outokumpu: Si MN P S CR NiDocumento3 pagineOutokumpu: Si MN P S CR NiDarkedgeNessuna valutazione finora

- E+Aod E+Aod E+Aod E+AodDocumento2 pagineE+Aod E+Aod E+Aod E+AodIonut FloricaNessuna valutazione finora

- PSP TCDocumento7 paginePSP TCPSP kanpurdehatNessuna valutazione finora

- BF20112602 English MTC PDFDocumento2 pagineBF20112602 English MTC PDFSvetlana VujovićNessuna valutazione finora

- hot rolled Φ60 AISI 304L (14.230)Documento3 paginehot rolled Φ60 AISI 304L (14.230)A. ΒρατσισταNessuna valutazione finora

- Qtap 201901 0062, Pt. Wijaya Karya Rekayasa Konstruksi, 28-01-2019 PDFDocumento2 pagineQtap 201901 0062, Pt. Wijaya Karya Rekayasa Konstruksi, 28-01-2019 PDFAddin Galih PrakosoNessuna valutazione finora

- JCOUSER03Documento1 paginaJCOUSER03Neem LalNessuna valutazione finora

- WNRF 2 MFF ItalyDocumento1 paginaWNRF 2 MFF ItalyMohamed RaafatNessuna valutazione finora

- TV 100x100x5#S235JRDocumento5 pagineTV 100x100x5#S235JRRazvan CristeaNessuna valutazione finora

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Documento2 pagineWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNessuna valutazione finora

- Certificado 3.1 y Calibracion Termopares - TecamDocumento11 pagineCertificado 3.1 y Calibracion Termopares - TecamigorNessuna valutazione finora

- Hollow Bar 304L Φ80ΧΦ50Documento6 pagineHollow Bar 304L Φ80ΧΦ50Agoritsa100% (1)

- Bhushan Power & Steel Limited: Mill Test CertificateDocumento1 paginaBhushan Power & Steel Limited: Mill Test CertificateKamal PriyanNessuna valutazione finora

- 1802 Brida Ac WN 6 X 150 SCH STD SWDocumento1 pagina1802 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNessuna valutazione finora

- Esme TF Ger 1570527 00Documento1 paginaEsme TF Ger 1570527 00Fitroh MalikNessuna valutazione finora

- S355J2 Plate MTCDocumento2 pagineS355J2 Plate MTCHarminder Kumar100% (1)

- Weflo Valve Co., LTD.: Material Test CertificateDocumento1 paginaWeflo Valve Co., LTD.: Material Test CertificateCarlosEduardoMorenoManceraNessuna valutazione finora

- MTC 17 4PH Al20201127a174Documento1 paginaMTC 17 4PH Al20201127a174Ajeng PratiwiNessuna valutazione finora

- 041101Documento1 pagina041101Carolina MolfinoNessuna valutazione finora

- Varilla B7 3-8 X 144 MT (B7)Documento1 paginaVarilla B7 3-8 X 144 MT (B7)Carlos Lluen AquinoNessuna valutazione finora

- MTC - Oufo (Argentina) - 16Documento1 paginaMTC - Oufo (Argentina) - 16Aceros DessolNessuna valutazione finora

- JSW Steel LTDDocumento1 paginaJSW Steel LTDRanjan BhatiaNessuna valutazione finora

- Test CertificateDocumento2 pagineTest CertificateTARUNKUMARNessuna valutazione finora

- Abnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Documento1 paginaAbnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Mohamed RaafatNessuna valutazione finora

- 075P80-321 TubacexDocumento1 pagina075P80-321 Tubacexsakshi patilNessuna valutazione finora

- Img 0001Documento1 paginaImg 0001Harish RanaNessuna valutazione finora

- E985F8E88F069BF1BB6F005056AC67B7Documento1 paginaE985F8E88F069BF1BB6F005056AC67B7Jose ReynosoNessuna valutazione finora

- MOE Simplex - 24.06.2016 PDFDocumento4 pagineMOE Simplex - 24.06.2016 PDFSabyasachi BangalNessuna valutazione finora

- 300 C SailDocumento2 pagine300 C Sailchandrabhushan kushwahaNessuna valutazione finora

- MTC 5Documento1 paginaMTC 5Muthazhagan SaravananNessuna valutazione finora

- Fittings ThrededDocumento2 pagineFittings ThrededreniNessuna valutazione finora

- 9q2fh6at-Brida BL Ac 300 A105 RF 2 MTFDocumento1 pagina9q2fh6at-Brida BL Ac 300 A105 RF 2 MTFantonio larotta100% (1)

- SS SAW Welding Flux Sample MTCDocumento1 paginaSS SAW Welding Flux Sample MTCKunal AjgaonkarNessuna valutazione finora

- Purchase Order: Number: 14 - SOODocumento4 paginePurchase Order: Number: 14 - SOOLê Đức ThiệnNessuna valutazione finora

- Ssab Emea Ab, Se-781 84 Borlänge, Sweden: Carbon Equivalent Etc C93-C99Documento1 paginaSsab Emea Ab, Se-781 84 Borlänge, Sweden: Carbon Equivalent Etc C93-C99angelokyoNessuna valutazione finora

- MTC Elbow 6inDocumento1 paginaMTC Elbow 6inhenryNessuna valutazione finora

- Material Product Data SheetDocumento4 pagineMaterial Product Data SheethungNessuna valutazione finora

- Vedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKDocumento23 pagineVedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKPRAKASH PANDEYNessuna valutazione finora

- Flange 8 Inch RTJDocumento3 pagineFlange 8 Inch RTJreniNessuna valutazione finora

- Universal 1-2 Clase 6000 Tipo 316Documento2 pagineUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- TC No-1451Documento1 paginaTC No-1451Structures ProductionNessuna valutazione finora

- SS420, 12mm-RamDocumento1 paginaSS420, 12mm-RamganeshNessuna valutazione finora

- 347623-Po 4503181944-Li 1Documento6 pagine347623-Po 4503181944-Li 1Rita WilliamsNessuna valutazione finora

- Neway Gate 6 X 150 RFDocumento6 pagineNeway Gate 6 X 150 RFcomercial 3Nessuna valutazione finora

- Flange Material TCDocumento1 paginaFlange Material TCSACHIN PATELNessuna valutazione finora

- Prime Fastener M20 Nut - MTCDocumento1 paginaPrime Fastener M20 Nut - MTCCyril J PadiyathNessuna valutazione finora

- Check Valve 6in HT 6YF4Documento1 paginaCheck Valve 6in HT 6YF4Juan Pablo Perdomo OrtizNessuna valutazione finora

- MTC 8,10Documento2 pagineMTC 8,10Vu NamNessuna valutazione finora

- Certificate FF 16662Documento3 pagineCertificate FF 16662Ionela IonelaNessuna valutazione finora

- 1000 Wog Ball ValveDocumento1 pagina1000 Wog Ball ValveSandi AslanNessuna valutazione finora

- DB-En 19 R-2-829 PDFDocumento4 pagineDB-En 19 R-2-829 PDFashokNessuna valutazione finora

- UGINEDocumento1 paginaUGINEjesusNessuna valutazione finora

- AcerinoxDocumento1 paginaAcerinoxOmkar PrindavankarNessuna valutazione finora

- Mechnical Property For Q235B Carbon SteelDocumento3 pagineMechnical Property For Q235B Carbon SteelPritom Ahmed100% (1)

- Flange 24 InchDocumento2 pagineFlange 24 InchreniNessuna valutazione finora

- Varilla 1 1 - 4 A193 B7Documento1 paginaVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNessuna valutazione finora

- MTC 4500528257 Iii - 210209Documento3 pagineMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNessuna valutazione finora

- Sample Test Certificate (24.12.2022)Documento1 paginaSample Test Certificate (24.12.2022)PalaniyandiNessuna valutazione finora

- W-2021-026 - 6000x2500x15 - S355J2+N (54E.187.02-C 21BL249) 54484-1 - 5Documento1 paginaW-2021-026 - 6000x2500x15 - S355J2+N (54E.187.02-C 21BL249) 54484-1 - 5johnnyNessuna valutazione finora

- Armare Grinda Transversala - 2 PDFDocumento1 paginaArmare Grinda Transversala - 2 PDFCiprian ShaolinNessuna valutazione finora

- Project: Project: PurcalcDocumento4 pagineProject: Project: PurcalcCiprian ShaolinNessuna valutazione finora

- Structura Acoperis - 8214Documento1 paginaStructura Acoperis - 8214Ciprian ShaolinNessuna valutazione finora

- Plan Cofraj Nivel Curent - 1Documento1 paginaPlan Cofraj Nivel Curent - 1Ciprian ShaolinNessuna valutazione finora

- Plan Armare Scara - 7 PDFDocumento1 paginaPlan Armare Scara - 7 PDFCiprian ShaolinNessuna valutazione finora

- Plan Armare Superioara - 5Documento1 paginaPlan Armare Superioara - 5Ciprian ShaolinNessuna valutazione finora

- General Terms and ConditionsDocumento66 pagineGeneral Terms and ConditionsCiprian ShaolinNessuna valutazione finora

- Plan Cofraj Nivel Curent - 1Documento1 paginaPlan Cofraj Nivel Curent - 1Ciprian ShaolinNessuna valutazione finora

- Plan Armare Scara - 7 PDFDocumento1 paginaPlan Armare Scara - 7 PDFCiprian ShaolinNessuna valutazione finora

- Longitudinal BEAM Reinforcement - 2Documento1 paginaLongitudinal BEAM Reinforcement - 2Ciprian ShaolinNessuna valutazione finora

- Allplan 2019 NewFeaturesDocumento115 pagineAllplan 2019 NewFeaturesCiprian ShaolinNessuna valutazione finora

- Upay Department: Frequently Asked Questions (Faqs) - CustomersDocumento13 pagineUpay Department: Frequently Asked Questions (Faqs) - CustomerstanvirNessuna valutazione finora

- HostsDocumento1 paginaHostsThet Aung Moe50% (2)

- LIS - Abbott Architect-90937-105Documento98 pagineLIS - Abbott Architect-90937-105jyoti ranjanNessuna valutazione finora

- Computer Science Paper Scheme (Marks Distribution)Documento4 pagineComputer Science Paper Scheme (Marks Distribution)Honey BunnyNessuna valutazione finora

- Brochure For Structure 2021Documento2 pagineBrochure For Structure 2021Miguel WindsorNessuna valutazione finora

- Assessment Ers5900Documento7 pagineAssessment Ers5900Asma AsmaNessuna valutazione finora

- Unit 5 Vocabulary Basic 1 Match 1-10 With A-J To Make Innovations and InventionsDocumento6 pagineUnit 5 Vocabulary Basic 1 Match 1-10 With A-J To Make Innovations and InventionsCristina Garcia50% (2)

- Oxygen Forensic SQLite ViewerDocumento1 paginaOxygen Forensic SQLite ViewerkukuhNessuna valutazione finora

- IIOTDocumento15 pagineIIOTSangeeta PandaNessuna valutazione finora

- Rev17 Volume2 PDFDocumento384 pagineRev17 Volume2 PDFhjduarteNessuna valutazione finora

- Heavyweight vs. Lightweight Methodologies: Key Strategies For DevelopmentDocumento6 pagineHeavyweight vs. Lightweight Methodologies: Key Strategies For DevelopmentgherijaNessuna valutazione finora

- z80.Eu-Tools For Virus AnalysisDocumento3 paginez80.Eu-Tools For Virus AnalysisVIC RODNessuna valutazione finora

- Structure and Detailed Syllabus - IT (5th Sem To 8th Sem)Documento72 pagineStructure and Detailed Syllabus - IT (5th Sem To 8th Sem)Randy OrtonNessuna valutazione finora

- PRB - 21 Sealed Beam Lamp Array: Website: EmailDocumento2 paginePRB - 21 Sealed Beam Lamp Array: Website: EmailHujNessuna valutazione finora

- Privacy and Data ProtectionDocumento2 paginePrivacy and Data ProtectionAloukik SharmaNessuna valutazione finora

- Introduction To CsiBridgeDocumento7 pagineIntroduction To CsiBridgeN TNessuna valutazione finora

- Cpu286 Instruction ManualDocumento24 pagineCpu286 Instruction ManualGilberto FigueroaNessuna valutazione finora

- Naming Conventions - Table and ColumnDocumento3 pagineNaming Conventions - Table and ColumnChristopher PNessuna valutazione finora

- Controls, Start-Up, Operation, Service, and TroubleshootingDocumento242 pagineControls, Start-Up, Operation, Service, and TroubleshootingAnonymous uEOZ7raPkzNessuna valutazione finora

- Global Business Environment: Lessons From The Businesses That Have Failed in The Global MarketDocumento15 pagineGlobal Business Environment: Lessons From The Businesses That Have Failed in The Global MarketKeshav ChaudharyNessuna valutazione finora

- Hydrogen Sulfide Analyzer Model 330S & 331S Model 330SDS & 331SDSDocumento87 pagineHydrogen Sulfide Analyzer Model 330S & 331S Model 330SDS & 331SDSDavidNessuna valutazione finora

- Lesson 4Documento43 pagineLesson 4Rofa Mae MedinaNessuna valutazione finora

- Lesson 8 When Technology and Humanity CrossDocumento68 pagineLesson 8 When Technology and Humanity CrossKent LabajoNessuna valutazione finora

- A New Approach To Defining Human Touch Temperature Standards: July 2010Documento8 pagineA New Approach To Defining Human Touch Temperature Standards: July 2010Edna Odette Melo UscangaNessuna valutazione finora

- Aropol in 1005 PDocumento2 pagineAropol in 1005 PPathik PatelNessuna valutazione finora

- HRM 3703 Exam Prep ALL Chapters - CarolineDocumento60 pagineHRM 3703 Exam Prep ALL Chapters - CarolineTessa Mkhomole100% (3)

- Shaqra University-Costing Sajjad V1Documento4 pagineShaqra University-Costing Sajjad V1Moody KhalidNessuna valutazione finora

- Joost Network ArchitectureDocumento29 pagineJoost Network Architecturegholkr100% (2)

- Nagaraj CH Professional SummaryDocumento7 pagineNagaraj CH Professional SummaryrecruiterkkNessuna valutazione finora

- JCB 550-80 & 560-80 Brochure - Set96414422 PDFDocumento20 pagineJCB 550-80 & 560-80 Brochure - Set96414422 PDFYutub RichardxdNessuna valutazione finora