Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pump Performance Curve - XPS230-SS-VTS

Caricato da

josephDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pump Performance Curve - XPS230-SS-VTS

Caricato da

josephCopyright:

Formati disponibili

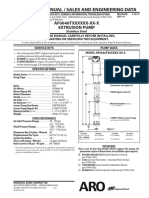

Section 5

PERFORMANCE

Pump Model: XPS230/SSAAA/VTS/VT/STV

PS220/PS230 METAL

RUBBER-FITTED

Ship Weight ...........Aluminum 19 kg (41 lb)

Ductile Iron 29 kg (64 lb)

316 Stainless Steel 31 kg (68 lb)

Air Inlet ................................... 13 mm (1/2")

Inlet ............................................ 25 mm (1")

Outlet ......................................... 25 mm (1")

Air inlet Pressure :

Suction Lift ....................... 6.9 m Dry (22.7')

9.0 m Wet (29.5')

2.76 brag

Disp. Per Stroke1 ................... 0.30 L (0.08 gal) Air consumption:20.4Nm3/hr

Max. Flow Rate .............. 204 lpm (54 gpm)

Max. Size Solids .................... 6.4 mm (1/4")

2 Bar

1

Displacement per stroke was calculated at

4.8 bar (70 psig) air inlet pressure against a

2.1 bar (30 psig) head pressure.

Example: To pump 140 lpm (37 gpm)

against a discharge pressure head of

2.8 bar (40 psig) requires 5.5 bar (80 psig) 4m3/hr (66.68LPM)

and 60 Nm3/h (38 scfm) air consumption.

(See dot on chart.) Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation

parameters will fall in the center of the pump's performance curve.

PS220/PS230 METAL

TPE-FITTED

Ship Weight ...........Aluminum 19 kg (41 lb)

Ductile Iron 29 kg (64 lb)

316 Stainless Steel 31 kg (68 lb)

Air Inlet ................................... 13 mm (1/2")

Inlet ............................................ 25 mm (1")

Outlet ......................................... 25 mm (1")

Suction Lift ....................... 5.9 m Dry (19.3')

9.0 m Wet (29.5')

Disp. Per Stroke1 ................... 0.26 L (0.07 gal)

Max. Flow Rate .............. 212 lpm (56 gpm)

Max. Size Solids .................... 6.4 mm (1/4")

1

Displacement per stroke was calculated at

4.8 bar (70 psig) air inlet pressure against a

2.1 bar (30 psig) head pressure.

Example: To pump 144 lpm (38 gpm)

against a discharge pressure head of

2.8 bar (40 psig) requires 5.5 bar (80 psig)

and 63 Nm3/h (40 scfm) air consumption.

(See dot on chart.) Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily operation

parameters will fall in the center of the pump's performance curve.

WILDEN PUMP & ENGINEERING, LLC 6 WIL-11560-E-04

Potrebbero piacerti anche

- 3DX29GSI 3DX30GSI: Direct-Drive Plunger PumpDocumento4 pagine3DX29GSI 3DX30GSI: Direct-Drive Plunger PumpLuis Rafael P. CoronaNessuna valutazione finora

- Design and Analysis of Centrifugal CompressorsDa EverandDesign and Analysis of Centrifugal CompressorsNessuna valutazione finora

- Cat 2sfx35gsDocumento5 pagineCat 2sfx35gsAinur RohmanNessuna valutazione finora

- 15 Frame Plunger Pump: Standard Brass ModelDocumento4 pagine15 Frame Plunger Pump: Standard Brass Modelmantilla7Nessuna valutazione finora

- Direct-Drive Plunger Pumps: Electric ModelsDocumento4 pagineDirect-Drive Plunger Pumps: Electric Modelsab5951Nessuna valutazione finora

- Manual Bomba Cat 66dx30g1i - FDocumento4 pagineManual Bomba Cat 66dx30g1i - FIvan Fernando Colqui CordovaNessuna valutazione finora

- X Series PumpsDocumento8 pagineX Series PumpsJorge GalarceNessuna valutazione finora

- 724J 4WD LoaderDocumento8 pagine724J 4WD Loaderwalk01Nessuna valutazione finora

- Denison Hydraulics Vane Pumps - Single, Double, Triple T6 Mobile ApplicationDocumento35 pagineDenison Hydraulics Vane Pumps - Single, Double, Triple T6 Mobile ApplicationZoran Jankov100% (1)

- Operator'S Manual / Sales and Engineering Data: AF0646TXXXXXX-XX-X Extrusion PumpDocumento4 pagineOperator'S Manual / Sales and Engineering Data: AF0646TXXXXXX-XX-X Extrusion PumpSaul PerezNessuna valutazione finora

- Axial Piston Pumps: Series Pvplus - Design Series 47 Variable DisplacementDocumento72 pagineAxial Piston Pumps: Series Pvplus - Design Series 47 Variable DisplacementJhonata CavalcanteNessuna valutazione finora

- MSG30-3245 UkDocumento68 pagineMSG30-3245 Ukoperacion hydratekNessuna valutazione finora

- Cat Pump Parts DiagramDocumento4 pagineCat Pump Parts Diagramvinnman87Nessuna valutazione finora

- Pump Magnun SeriesDocumento63 paginePump Magnun SeriesDANIZACHNessuna valutazione finora

- 4V4B-6.1 High Pressure Oxygen Comressor: FeaturesDocumento2 pagine4V4B-6.1 High Pressure Oxygen Comressor: FeaturesAljamali Alhofashi100% (1)

- Buldozer - CASE 550H - Specs 1-18-2012 - ENDocumento4 pagineBuldozer - CASE 550H - Specs 1-18-2012 - ENMaurizio De LucaNessuna valutazione finora

- DCP 1080 Product Sheet 2018 Re 1519056261Documento2 pagineDCP 1080 Product Sheet 2018 Re 1519056261Manuel Octavio Hernandez DiazNessuna valutazione finora

- AOP 3inch PDFDocumento1 paginaAOP 3inch PDFCitra IntiNessuna valutazione finora

- Graco Husky 716 Diaphragm Pump Data SheetDocumento8 pagineGraco Husky 716 Diaphragm Pump Data SheetMROstop.comNessuna valutazione finora

- PC400-6 (1.8m3,-20C, Sandy Arrang) ENGDocumento11 paginePC400-6 (1.8m3,-20C, Sandy Arrang) ENGBudi WaskitoNessuna valutazione finora

- PC40MR-2: IntroductoryDocumento2 paginePC40MR-2: IntroductoryFrederikusNessuna valutazione finora

- ContinentalPVR50 70Documento65 pagineContinentalPVR50 70Juan Carlos Bermudez CardenasNessuna valutazione finora

- PC35MR - Service ManualDocumento8 paginePC35MR - Service ManualJeffrey Evans50% (2)

- 544J 4WD LoaderDocumento8 pagine544J 4WD Loaderwalk01Nessuna valutazione finora

- Waste Handler Wheel Loaders J Series DkajpldrwhDocumento7 pagineWaste Handler Wheel Loaders J Series DkajpldrwhBilly HenleyNessuna valutazione finora

- S2T 2 S2TAL 2 Spec SheetDocumento2 pagineS2T 2 S2TAL 2 Spec Sheetfranciscojcortesrojas6Nessuna valutazione finora

- Raje-Dia AODD PumpsDocumento24 pagineRaje-Dia AODD PumpsZai QuêNessuna valutazione finora

- Cat 2520-2525 Pump Spare PartsDocumento4 pagineCat 2520-2525 Pump Spare PartsjncNessuna valutazione finora

- Manual TITON PDFDocumento53 pagineManual TITON PDFIvanVelasquez100% (3)

- 18 Frame Block-Style 10K - Triplex Positive Displacement Plunger Pump ModelDocumento4 pagine18 Frame Block-Style 10K - Triplex Positive Displacement Plunger Pump Modelmahmod alrousanNessuna valutazione finora

- 35 Frame Plunger Pump Model: Features SpecificationsDocumento4 pagine35 Frame Plunger Pump Model: Features SpecificationsallaboutfreeNessuna valutazione finora

- 310 Backhoe Loader 12,519 LB (5678 KG) : Continued On Next PageDocumento3 pagine310 Backhoe Loader 12,519 LB (5678 KG) : Continued On Next PagepaulNessuna valutazione finora

- YukenPiston PumpsDocumento146 pagineYukenPiston PumpsCahyo DiyantoNessuna valutazione finora

- Bobcat S130 SkidsteerDocumento6 pagineBobcat S130 SkidsteerBruno PilieciNessuna valutazione finora

- Merkur High Pressure Sprayer: Instructions-PartsDocumento30 pagineMerkur High Pressure Sprayer: Instructions-PartsdcsamaraweeraNessuna valutazione finora

- Graco XT Auto BrusurDocumento4 pagineGraco XT Auto Brusurcav4444Nessuna valutazione finora

- Catalogo ParkerDocumento64 pagineCatalogo ParkerGicuţă Şi Geta Zvîncă100% (1)

- Hidro TransmisijaDocumento31 pagineHidro TransmisijaMaximus MaxisNessuna valutazione finora

- Cat 3507 LDocumento4 pagineCat 3507 LJordan aguilarNessuna valutazione finora

- Pu 0027618Documento4 paginePu 0027618Anonymous DjTnqWXUNessuna valutazione finora

- PC400 6 (1.8m3, 20C, Sandy Arrang) ENGDocumento12 paginePC400 6 (1.8m3, 20C, Sandy Arrang) ENGRahmawati AyudiaNessuna valutazione finora

- Wilden h800 EomDocumento28 pagineWilden h800 Eomanon_819441268Nessuna valutazione finora

- Cat Pumps Catalog PAGESDocumento41 pagineCat Pumps Catalog PAGESMiguel Angel Santos PintadoNessuna valutazione finora

- 1403E Under Over Stripper PDFDocumento16 pagine1403E Under Over Stripper PDFOvRrj AhmedNessuna valutazione finora

- Ks-En215id ZX350H-5G IdDocumento2 pagineKs-En215id ZX350H-5G Idrth equipmentNessuna valutazione finora

- HMAP BR 201410-00 ZX470LC-5G Indonesia PDFDocumento2 pagineHMAP BR 201410-00 ZX470LC-5G Indonesia PDFIndra PurnamaNessuna valutazione finora

- Operator'S Manual & Sales and Engineering Data: AF0430GXXXXXX-XX-X Two-Ball Pump SeriesDocumento4 pagineOperator'S Manual & Sales and Engineering Data: AF0430GXXXXXX-XX-X Two-Ball Pump Seriestaller.copiapoNessuna valutazione finora

- Komatsu Bulldozer D85A-21Documento11 pagineKomatsu Bulldozer D85A-21Waldir Jesús Rodríguez Juárez100% (1)

- Power: Group-L 9Documento33 paginePower: Group-L 9nadaNessuna valutazione finora

- Merkur High Pressure Sprayer: Instructions-PartsDocumento30 pagineMerkur High Pressure Sprayer: Instructions-PartsdosenmarioNessuna valutazione finora

- City Pump 2112HP Quote FormDocumento1 paginaCity Pump 2112HP Quote FormJuan Esteban Giraldo100% (1)

- Accessory CatalogDocumento42 pagineAccessory Catalogluis mirandaNessuna valutazione finora

- Manual de Partes Cat 3507Documento4 pagineManual de Partes Cat 3507Julito Santa CruzNessuna valutazione finora

- 3CP1221 3CP1231 3CP1241: 3CP Stainless Steel Plunger PumpDocumento4 pagine3CP1221 3CP1231 3CP1241: 3CP Stainless Steel Plunger Pump81q1iyNessuna valutazione finora

- Fluid System 04-Centrifugal PumpDocumento46 pagineFluid System 04-Centrifugal PumpFuad AlhamidNessuna valutazione finora

- Stainless Steel: Direct-Drive Plunger PumpDocumento4 pagineStainless Steel: Direct-Drive Plunger PumpSyed SamsamuddinNessuna valutazione finora

- 4.06 10M-15M Striper PackerDocumento16 pagine4.06 10M-15M Striper Packeroswaldo58100% (1)

- Lenntech: 18 Frame Block-Style Stainless Steel Plunger PumpDocumento4 pagineLenntech: 18 Frame Block-Style Stainless Steel Plunger Pumpdiv02Nessuna valutazione finora

- LT36499 Hydraulic Filters 0Documento43 pagineLT36499 Hydraulic Filters 0khans21840Nessuna valutazione finora

- Test For HomogeneityDocumento10 pagineTest For HomogeneityjosephNessuna valutazione finora

- Understanding State Variations in SAT Scores: Printed in Great Britain. 0 1993Documento6 pagineUnderstanding State Variations in SAT Scores: Printed in Great Britain. 0 1993josephNessuna valutazione finora

- Understanding State Variations in SAT Scores: Printed in Great Britain. 0 1993Documento6 pagineUnderstanding State Variations in SAT Scores: Printed in Great Britain. 0 1993josephNessuna valutazione finora

- Logistic RegressionDocumento31 pagineLogistic Regressionqxkurt_641211805Nessuna valutazione finora

- Suction Lift Curve - XPS230-SS-VTS PDFDocumento1 paginaSuction Lift Curve - XPS230-SS-VTS PDFjosephNessuna valutazione finora

- GeoTechnical FormulasDocumento34 pagineGeoTechnical FormulasTptaylor100% (3)

- Randolph White OTC 19128Documento16 pagineRandolph White OTC 19128josephNessuna valutazione finora

- Composite Materials: Asst - Prof. Dr. Ayşe KALEMTAŞDocumento32 pagineComposite Materials: Asst - Prof. Dr. Ayşe KALEMTAŞŞebnem Gül İlarslanNessuna valutazione finora

- Bracket An743Documento2 pagineBracket An743RhianNessuna valutazione finora

- CIEN 30043 Lecture No. 4Documento24 pagineCIEN 30043 Lecture No. 4One Less than TwiceNessuna valutazione finora

- SABIC® PP - 5271K - Global - Technical - Data - SheetDocumento1 paginaSABIC® PP - 5271K - Global - Technical - Data - SheetjituniNessuna valutazione finora

- Incorporating Long-Term Set-Up Into Load and Resistance Factor Design of Driven Piles in SandDocumento16 pagineIncorporating Long-Term Set-Up Into Load and Resistance Factor Design of Driven Piles in SandmarcvenzNessuna valutazione finora

- Ce 431 - Concrete Technology Project: Milwaukee Art MuseumDocumento22 pagineCe 431 - Concrete Technology Project: Milwaukee Art MuseumSumanNessuna valutazione finora

- Analysis and Proportioning of Retaining WallsDocumento25 pagineAnalysis and Proportioning of Retaining Wallsአንተነህ ኃይሌ ክንፈገብርኤልNessuna valutazione finora

- Trial Mix Design Report PDFDocumento38 pagineTrial Mix Design Report PDFTimothy HughesNessuna valutazione finora

- Textile Testing & Quality Assurance: Crease RecoveryDocumento5 pagineTextile Testing & Quality Assurance: Crease RecoveryTauqeer Raza100% (1)

- Experimental Behaviour of Concrete-Filled Stiffened Thin-Walled Steel Tubular ColumnsDocumento11 pagineExperimental Behaviour of Concrete-Filled Stiffened Thin-Walled Steel Tubular ColumnshanlamphamNessuna valutazione finora

- Job Procedure For Puncture/Floatation/Rain Water Accumulation TestDocumento4 pagineJob Procedure For Puncture/Floatation/Rain Water Accumulation Testfaisal jasim100% (1)

- Manual On Hazard Resistant ConstructionDocumento117 pagineManual On Hazard Resistant Constructionprs226Nessuna valutazione finora

- BOQDocumento4 pagineBOQMark Roger Huberit IINessuna valutazione finora

- Estimating RC Model Aerodynamics and PerformanceDocumento11 pagineEstimating RC Model Aerodynamics and PerformanceMito MiguelNessuna valutazione finora

- Civil / Structural Construction Notes: Nearest Faultline Site Location FromDocumento1 paginaCivil / Structural Construction Notes: Nearest Faultline Site Location FromVince Bagsit PolicarpioNessuna valutazione finora

- Introduction To Geotechnical EngineeringDocumento3 pagineIntroduction To Geotechnical EngineeringMesmerize BuccatNessuna valutazione finora

- Spreadsheets To Bs 8110 The Concrete Centre: Bigbucks PLC Pilecap G14Documento2 pagineSpreadsheets To Bs 8110 The Concrete Centre: Bigbucks PLC Pilecap G14DavidNessuna valutazione finora

- Slope Stability AnalysisDocumento18 pagineSlope Stability Analysisshivaji_sarvadeNessuna valutazione finora

- Construction On Flexible PavementDocumento16 pagineConstruction On Flexible PavementABHAY SHRIVASTAVANessuna valutazione finora

- AISC DG31 Example 001Documento11 pagineAISC DG31 Example 001alejandro mantillaNessuna valutazione finora

- 2022 KIN LONG Door Control Hardware Typical Product CatalogueDocumento160 pagine2022 KIN LONG Door Control Hardware Typical Product CatalogueStructural TenderNessuna valutazione finora

- Minutes April 7 2022 LexterDocumento5 pagineMinutes April 7 2022 LexterLexter Collen NavarroNessuna valutazione finora

- WCD P3Documento43 pagineWCD P3RupaliNessuna valutazione finora

- Worksheet - 970336500hydropower Excersise - 1Documento15 pagineWorksheet - 970336500hydropower Excersise - 1Khadar teeriNessuna valutazione finora

- MS0401C0291-V00.C - (Bearing-Plate-&-Steel-Plate-for-Moving-Walk-&-Escalator) PDFDocumento18 pagineMS0401C0291-V00.C - (Bearing-Plate-&-Steel-Plate-for-Moving-Walk-&-Escalator) PDFnoufalNessuna valutazione finora

- Analysis of Concrete Beams Prestressed and Posttensioned With Externally Unbonded Carbon Fiber Reinforced Polymer TendonsDocumento14 pagineAnalysis of Concrete Beams Prestressed and Posttensioned With Externally Unbonded Carbon Fiber Reinforced Polymer TendonsTan Duy LeNessuna valutazione finora

- Development On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaDocumento12 pagineDevelopment On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaAustin AnindoNessuna valutazione finora

- UCE 806 Design of Hydraulic Structure: Course Objective: The Objective of This Subject Is To Focus OnDocumento23 pagineUCE 806 Design of Hydraulic Structure: Course Objective: The Objective of This Subject Is To Focus OnBhabani Shankar DasNessuna valutazione finora

- A Study of Modeling and Finite Element Analysis of Automotive Vehicle Wheel Rim Assembly For The Deformation and Various Stress DistributionDocumento6 pagineA Study of Modeling and Finite Element Analysis of Automotive Vehicle Wheel Rim Assembly For The Deformation and Various Stress DistributionHakim SakibNessuna valutazione finora

- ASTT Horizontal Directional DrillingDocumento14 pagineASTT Horizontal Directional DrillingSen HuNessuna valutazione finora

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDa EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeValutazione: 4.5 su 5 stelle4.5/5 (10)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesDa EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesValutazione: 5 su 5 stelle5/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDa EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tValutazione: 4.5 su 5 stelle4.5/5 (27)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDa EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionValutazione: 4.5 su 5 stelle4.5/5 (543)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosDa EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosValutazione: 5 su 5 stelle5/5 (1)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsDa EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsValutazione: 3.5 su 5 stelle3.5/5 (2)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialDa EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialValutazione: 3.5 su 5 stelle3.5/5 (3)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsDa EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsNessuna valutazione finora

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonDa EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonValutazione: 5 su 5 stelle5/5 (2)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersDa Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersValutazione: 5 su 5 stelle5/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceDa EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNessuna valutazione finora

- Current Interruption Transients CalculationDa EverandCurrent Interruption Transients CalculationValutazione: 4 su 5 stelle4/5 (1)

- Build Your Own Electronics WorkshopDa EverandBuild Your Own Electronics WorkshopValutazione: 3.5 su 5 stelle3.5/5 (3)

- A Mind at Play: How Claude Shannon Invented the Information AgeDa EverandA Mind at Play: How Claude Shannon Invented the Information AgeValutazione: 4 su 5 stelle4/5 (53)

- Beginner's Guide to Reading Schematics, Third EditionDa EverandBeginner's Guide to Reading Schematics, Third EditionNessuna valutazione finora

- Heat Transfer Engineering: Fundamentals and TechniquesDa EverandHeat Transfer Engineering: Fundamentals and TechniquesValutazione: 4 su 5 stelle4/5 (1)

- Teach Yourself Electricity and Electronics, 6th EditionDa EverandTeach Yourself Electricity and Electronics, 6th EditionValutazione: 3.5 su 5 stelle3.5/5 (15)

- Power Electronics Diploma Interview Q&A: Career GuideDa EverandPower Electronics Diploma Interview Q&A: Career GuideNessuna valutazione finora