Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Inspection-Test-plan For Block Work

Caricato da

Abdulrahman AlkilaniTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Inspection-Test-plan For Block Work

Caricato da

Abdulrahman AlkilaniCopyright:

Formati disponibili

Main Contractor: AL MAJAL INTERNATIONAL TRADING & CONTRACTING Project name : ANDAZ HAYAT 5 STARS HOTEL

ITP for AAC Block works

ARAB ENGINEERING

AL MIRQAB TOURIST COMPANY ANDAZ HAYAT 5 STARS HOTEL

BUREAU

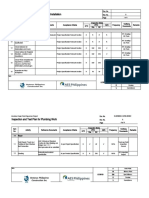

Inspection and Test Plan for AAC Block Works

Rev: Date: Comments: Prepared By: Reviewed By: Approved By:

XInspection & Test Plan

Date: Page 1 of 3 Inspection and Test Plan Number:

Main Contractor: AL MAJAL INTERNATIONAL TRADING & CONTRACTING Project name : ANDAZ HAYAT 5 STARS HOTEL

ITP for AAC Block works

Title/Description AAC Block works ITP No. :

Unit Area: INTERNAL AREA Discipline: AAC Block work

Rev. 00

Verifying Documents

/Demonstrated Evidence

Inspection Test Requirements Reference Documentation Inspections / Verification

Report Checklist

Activity (Reference Number)

Activity / Description

No.

Test or

Contract

Inspection Stage/Frequency Code/Spec/etc Acceptance Criteria Engr. Employer

o

Performed

1 Approval / Permits/Preliminaries

Preparation of

ITP,

Prior to Start of Specification Section

1.1 Method Statement Approval Code 1/ 2 E R H Approved Submittals

Work Number

Material Submittals

Drawings

2 Material Inspections (Delivery on Site)

Material Arrival on Specification Section Material Receiving

2.1 Materials Visual E W S

Site Number Inspection Report (MRIR)

Material Arrival on Specification Section As per approved Material Material Receiving

2.2 Accessories Visual E W S

Site Number Submittals Code 1/2 Inspection Report (MRIR)

3 Work Process

3.1 Prior to Start Blockwork

As per approved IRF

One Wall Panel Approved Drawings As per approved shop IRF

Mock up

3.1.1 Visual with all required Specification Section drawing E W H Method Statement Checklist:

accessories used Number All required accessories Checklist number

included in the mock up

3.2 Blocks Laying/ Installation

Date: Page 2 of 3 Inspection and Test Plan Number:

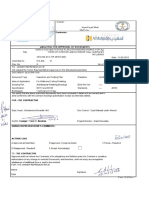

Main Contractor: AL MAJAL INTERNATIONAL TRADING & CONTRACTING Project name : ANDAZ HAYAT 5 STARS HOTEL

ITP for AAC Block works

Approved Shop As per approved survey

Setting out & Surface Prior to laying of Checklist:

3.2.1 Visual Drawing for Block layout E W W

Preparation every first course Checklist number

work layout No unsatisfactory condition

All accessories required are

Approved shop installed and verified.

During block laying Checklist:

3.2.2 Block layer installation Visual drawings for block All MEP required E S S

works Checklist number

work layout embedment's and openings

are placed and verified

Construction Tolerances:

1. For Vertical lines. Plumb

shall not vary by more than

6mm in 6m height.

2. For vertical alignment of

exposed head joints, do not

vary from plumb by more

than 6mm by 3m, nor 12mm

Approved Shop max.

Every 18 bays for

Drawings block work 3. For horizontal line, do not

CFS Bldg. Checklist:

layout vary from level by more

3.2.3 Final Inspection Visual For other buildings E H W Checklist number

than 6mm in 6m, nor 12mm

every completed

Specification Section max.

First Course

Number 4. For exposed bed joints,

do not vary from thickness

by more than +/- 3mm &

adjacent course with a max.

thickness limited to 12mm.

5. For exposed head joints,

do not vary from thickness

by more than +/- 3mm.

4.0 As - built Drawings Approval Progressively Code 1 E R R Approved As-Built Drawings

Legend: I-Inspection, T-Test, W-Witness Point, H-Mandatory Hold Point for Inspection, R-Document Review, S-Surveillance, E-Execution, RE-Records

Date: Page 3 of 3 Inspection and Test Plan Number:

Potrebbero piacerti anche

- SAIC-RT-2001 Revw of RT ProcedureDocumento1 paginaSAIC-RT-2001 Revw of RT ProcedureKirubhakarPooranamNessuna valutazione finora

- The Balance of Power in World Politics TDocumento23 pagineThe Balance of Power in World Politics TVali IgnatNessuna valutazione finora

- Part 2 - ITP Details: Inspection & Test Plan For Precast Concrete WorksDocumento5 paginePart 2 - ITP Details: Inspection & Test Plan For Precast Concrete WorksErickson Malicsi100% (2)

- Pre Concreting ChecklistDocumento1 paginaPre Concreting ChecklistFahmi ZahariNessuna valutazione finora

- Checklist For Painting WorksDocumento4 pagineChecklist For Painting WorksIfeanyi IwuallaNessuna valutazione finora

- QA QC Daily ReportDocumento2 pagineQA QC Daily Reportanon_688841981Nessuna valutazione finora

- Inspection and Test Plan: Cement Stucco (Exterior Plastering)Documento3 pagineInspection and Test Plan: Cement Stucco (Exterior Plastering)Alvene TagocNessuna valutazione finora

- Inspection & Test Plan (Itp) : Gypsum Board False CeilingDocumento1 paginaInspection & Test Plan (Itp) : Gypsum Board False CeilingLOPA THANDARNessuna valutazione finora

- The Law of Attraction Work For YouDocumento7 pagineThe Law of Attraction Work For YouBambang PrasetyoNessuna valutazione finora

- Check List For False CeilingDocumento1 paginaCheck List For False CeilingShyamontika Choudhury Chakrabarti83% (6)

- Itp For Painting WorksDocumento28 pagineItp For Painting WorksAhmed saberNessuna valutazione finora

- PC-ITP-001 - Backfilling and ExcavationDocumento2 paginePC-ITP-001 - Backfilling and ExcavationHusam zayedNessuna valutazione finora

- FPM 221 Checklist Earth WorkDocumento2 pagineFPM 221 Checklist Earth WorkPrabaharan K100% (1)

- Check List Handover Rev.0Documento1 paginaCheck List Handover Rev.0Ali Mari BalochNessuna valutazione finora

- 1.SRO-QPITP - Mechanical WorksDocumento2 pagine1.SRO-QPITP - Mechanical Worksachusanachu100% (1)

- DLL Gen Math Ems AnnuitiesDocumento13 pagineDLL Gen Math Ems AnnuitiesFreyy Agad Maligot0% (1)

- Appendix E: Checklist For Kerbstone WorksDocumento3 pagineAppendix E: Checklist For Kerbstone WorksJericFuentes100% (2)

- Inspection Test Plan (Itp) : Althamra Self Owned Property Leasing & Management ServicesDocumento11 pagineInspection Test Plan (Itp) : Althamra Self Owned Property Leasing & Management Servicespunk cmNessuna valutazione finora

- 025-ITP For Sewer & Drainage PDFDocumento6 pagine025-ITP For Sewer & Drainage PDFKöksal PatanNessuna valutazione finora

- Checklist Door, Window, S&P, Plinth ProtectionDocumento7 pagineChecklist Door, Window, S&P, Plinth Protectionsoumya0% (1)

- Etihad Towers Project: Inspection & Test Plan - Ceramic Tiles (For Walls)Documento4 pagineEtihad Towers Project: Inspection & Test Plan - Ceramic Tiles (For Walls)jini100% (2)

- Bed 2381 Q Itp XX 000 00 PDFDocumento1 paginaBed 2381 Q Itp XX 000 00 PDFKareem GhazyNessuna valutazione finora

- Complete Wedding With DJ Worksheets.4pgsDocumento4 pagineComplete Wedding With DJ Worksheets.4pgsDanniNessuna valutazione finora

- Itp Brickwork and BlockworkDocumento2 pagineItp Brickwork and Blockworkapi-3722518100% (1)

- Checklist - Internal Painting WorkDocumento7 pagineChecklist - Internal Painting WorkR HarshavardhanaNessuna valutazione finora

- ITP-CONCRETE Blinding WorkDocumento2 pagineITP-CONCRETE Blinding WorkYash Sharma100% (1)

- Check List For Backfilling WorksDocumento2 pagineCheck List For Backfilling WorksYash SharmaNessuna valutazione finora

- Installation of LV Cables: Inspection and Test Plan ForDocumento1 paginaInstallation of LV Cables: Inspection and Test Plan ForHussainShabbirNessuna valutazione finora

- Civils - Trenching - ExcavationsDocumento2 pagineCivils - Trenching - Excavationsmitendra singhNessuna valutazione finora

- ItpDocumento7 pagineItpJose Sherin100% (1)

- ITP For Plumbing & Drainage SystemDocumento97 pagineITP For Plumbing & Drainage Systemmagdi badran100% (7)

- Assessment - Manage Quality Customer Service - BSBCUS501 PDFDocumento29 pagineAssessment - Manage Quality Customer Service - BSBCUS501 PDFEricKang26% (19)

- Project Title:: Checklist For Block WorkDocumento2 pagineProject Title:: Checklist For Block Workalfie100% (1)

- ITP - Plaster WorkDocumento1 paginaITP - Plaster Workmahmoud ghanemNessuna valutazione finora

- Grid Ceiling Checklist-R1Documento1 paginaGrid Ceiling Checklist-R1KishoreNessuna valutazione finora

- Check List For CONCRETE Blinding WorksDocumento1 paginaCheck List For CONCRETE Blinding WorksYash SharmaNessuna valutazione finora

- Doc27 - Checklist For Aluminium WindowsDocumento2 pagineDoc27 - Checklist For Aluminium Windowshkshyla89100% (1)

- Itp For Construction of Precast FoundationDocumento7 pagineItp For Construction of Precast FoundationKhyle Laurenz Duro100% (1)

- ITP For Block WorkDocumento9 pagineITP For Block WorkMohammed Ghareib Nasr100% (1)

- ITP Check List For Metal Deck InstallationDocumento2 pagineITP Check List For Metal Deck InstallationLeo PascualNessuna valutazione finora

- Dasarathi Naik and Engineers PVT - Ltd. Check List For ReinforcementDocumento1 paginaDasarathi Naik and Engineers PVT - Ltd. Check List For ReinforcementTusarranjan BhuyanNessuna valutazione finora

- 1LPS 3 BoQ TemplateDocumento369 pagine1LPS 3 BoQ TemplateAbdulrahman AlkilaniNessuna valutazione finora

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Documento2 pagineET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- Method Statement For Plaster Work Doc No: GEPSIPL/2020-21/FQA/MS/029Documento6 pagineMethod Statement For Plaster Work Doc No: GEPSIPL/2020-21/FQA/MS/029Sumit OmarNessuna valutazione finora

- Material Inspection Request (MIR) : Plot No. (4151)Documento2 pagineMaterial Inspection Request (MIR) : Plot No. (4151)Velmurugan Balasubramanian100% (2)

- Installation of Instrument Switches (Pressure - Flow - Temperature - Level) CLDocumento1 paginaInstallation of Instrument Switches (Pressure - Flow - Temperature - Level) CLZulfequar R. Ali KhanNessuna valutazione finora

- Check List For Excavation: Company NameDocumento4 pagineCheck List For Excavation: Company NameVipin Kumar ParasharNessuna valutazione finora

- Method Statement & Itp For Waterproofing WorkDocumento7 pagineMethod Statement & Itp For Waterproofing WorkRumi ZamNessuna valutazione finora

- Checklist For GlazingDocumento2 pagineChecklist For GlazingMohammad TaushifNessuna valutazione finora

- ITP For Drywall & Furring Wall InstallationDocumento2 pagineITP For Drywall & Furring Wall Installationexia1992100% (1)

- ITP & Checklist FOR Excavation & Backfilling and CompactionDocumento7 pagineITP & Checklist FOR Excavation & Backfilling and CompactionAmran Hossain100% (4)

- Check List For Floor Screed WorksDocumento1 paginaCheck List For Floor Screed WorksYash SharmaNessuna valutazione finora

- y D Starter PDFDocumento13 paginey D Starter PDFnazar750Nessuna valutazione finora

- Inspection ChecklistDocumento1 paginaInspection ChecklistMohammad Hadoumi Saldan100% (1)

- Sample - ITP For Architectural WorksDocumento3 pagineSample - ITP For Architectural Worksiman arief100% (4)

- Concrete Post Pour Check ListDocumento1 paginaConcrete Post Pour Check ListKamal FitriNessuna valutazione finora

- Quality Control - Works Inspection: Glazed DoorsDocumento1 paginaQuality Control - Works Inspection: Glazed DoorsParasNessuna valutazione finora

- Checklist For Granite/Marble Works: Project: Doc. No.: Client: Project LocationDocumento4 pagineChecklist For Granite/Marble Works: Project: Doc. No.: Client: Project LocationBeni N SoloNessuna valutazione finora

- Inspection & Test Plan For DrywallDocumento2 pagineInspection & Test Plan For Drywallexia1992100% (1)

- Inspection and Test PlanDocumento6 pagineInspection and Test PlanMadison ChanNessuna valutazione finora

- Quality Checklist For Site Works: Water ProofingDocumento1 paginaQuality Checklist For Site Works: Water ProofingLordgie AgtucaNessuna valutazione finora

- ITP-CI-026a-02 (Building Finishing Works)Documento4 pagineITP-CI-026a-02 (Building Finishing Works)Delta akathehuskyNessuna valutazione finora

- Government vs. AlburalDocumento2 pagineGovernment vs. Alburalpoppy2890100% (2)

- Steel Gables and Arches PDFDocumento52 pagineSteel Gables and Arches PDFMonny MOM100% (1)

- DisasterDocumento10 pagineDisasterMixsz LlhAdy100% (1)

- Ref. No. MHSB/QC/ARCH/01/008 Architectural Work Inspection Form ExternalDocumento8 pagineRef. No. MHSB/QC/ARCH/01/008 Architectural Work Inspection Form ExternalSean ChanNessuna valutazione finora

- Inspection Test Plan ITP Painting WorksDocumento4 pagineInspection Test Plan ITP Painting WorksMichael AntipuestoNessuna valutazione finora

- Structural Steel Work Check ListDocumento1 paginaStructural Steel Work Check ListAhmad Bilal100% (1)

- Checklist Curtain WallDocumento1 paginaChecklist Curtain WallSukant KamathNessuna valutazione finora

- ITP-MEP-006 Dismantling of MEPDocumento1 paginaITP-MEP-006 Dismantling of MEPjagathmukundhan00Nessuna valutazione finora

- Inspection Request: RecipientDocumento2 pagineInspection Request: RecipientAbdulrahman AlkilaniNessuna valutazione finora

- f84835752 ERECTION PROGRESS REPORT FOR Gulf MallDocumento5 paginef84835752 ERECTION PROGRESS REPORT FOR Gulf MallAbdulrahman AlkilaniNessuna valutazione finora

- Daily Report: O T A LDocumento2 pagineDaily Report: O T A LAbdulrahman AlkilaniNessuna valutazione finora

- F 84810584Documento1 paginaF 84810584Abdulrahman AlkilaniNessuna valutazione finora

- f75146080 ERECTION PROGRESS REPORT FOR Gulf MallDocumento5 paginef75146080 ERECTION PROGRESS REPORT FOR Gulf MallAbdulrahman AlkilaniNessuna valutazione finora

- Daily Report: O T A LDocumento2 pagineDaily Report: O T A LAbdulrahman AlkilaniNessuna valutazione finora

- f75142368 ERECTION PROGRESS REPORT FOR Factory For Production of Reinforced SteelDocumento6 paginef75142368 ERECTION PROGRESS REPORT FOR Factory For Production of Reinforced SteelAbdulrahman AlkilaniNessuna valutazione finora

- PROGRESS REPORT FOR Corrotech J (436) December 1-2011: Description of Work ProgressDocumento7 paginePROGRESS REPORT FOR Corrotech J (436) December 1-2011: Description of Work ProgressAbdulrahman AlkilaniNessuna valutazione finora

- Daily Report: O T A LDocumento2 pagineDaily Report: O T A LAbdulrahman AlkilaniNessuna valutazione finora

- Inspection Request: RecipientDocumento2 pagineInspection Request: RecipientAbdulrahman AlkilaniNessuna valutazione finora

- f75046400 ERECTION PROGRESS REPORT FOR Factory For Production of Reinforced SteelDocumento6 paginef75046400 ERECTION PROGRESS REPORT FOR Factory For Production of Reinforced SteelAbdulrahman AlkilaniNessuna valutazione finora

- Erection Progress REPORT For Steel Factory: Date:23-08-2012Documento6 pagineErection Progress REPORT For Steel Factory: Date:23-08-2012Abdulrahman AlkilaniNessuna valutazione finora

- Daily Report: O T A LDocumento2 pagineDaily Report: O T A LAbdulrahman AlkilaniNessuna valutazione finora

- Inspection Request: RecipientDocumento2 pagineInspection Request: RecipientAbdulrahman AlkilaniNessuna valutazione finora

- Project Progress Status: Description of Work ProgressDocumento4 pagineProject Progress Status: Description of Work ProgressAbdulrahman AlkilaniNessuna valutazione finora

- Daily Report: O T A LDocumento2 pagineDaily Report: O T A LAbdulrahman AlkilaniNessuna valutazione finora

- PROGRESS REPORT FOR QF-off Site W/H (J 435) December 1-2011Documento8 paginePROGRESS REPORT FOR QF-off Site W/H (J 435) December 1-2011Abdulrahman AlkilaniNessuna valutazione finora

- PROGRESS REPORT FOR Corrotech J (436) December 1-2011: Description of Work ProgressDocumento7 paginePROGRESS REPORT FOR Corrotech J (436) December 1-2011: Description of Work ProgressAbdulrahman AlkilaniNessuna valutazione finora

- PROGRESS REPORT FOR QF-off Site W/H (J 435) December 1-2011Documento8 paginePROGRESS REPORT FOR QF-off Site W/H (J 435) December 1-2011Abdulrahman AlkilaniNessuna valutazione finora

- F 75408864Documento1 paginaF 75408864Abdulrahman AlkilaniNessuna valutazione finora

- Brother Mfl-Pro Suite Readme FileDocumento3 pagineBrother Mfl-Pro Suite Readme FileYudistira DunggioNessuna valutazione finora

- PROGRESS REPORT FOR QF-off Site W/H (J 435) December 1-2011Documento8 paginePROGRESS REPORT FOR QF-off Site W/H (J 435) December 1-2011Abdulrahman AlkilaniNessuna valutazione finora

- Progress Report For Sheikh Khaled: Re RoofingDocumento4 pagineProgress Report For Sheikh Khaled: Re RoofingAbdulrahman AlkilaniNessuna valutazione finora

- f73994056 ERECTION PROGRESS REPORT FOR Gulf MallDocumento5 paginef73994056 ERECTION PROGRESS REPORT FOR Gulf MallAbdulrahman AlkilaniNessuna valutazione finora

- Erection Progress Report For CDC Erection Progress Report For CDCDocumento7 pagineErection Progress Report For CDC Erection Progress Report For CDCAbdulrahman AlkilaniNessuna valutazione finora

- Erection Progress Report For CDC Erection Progress Report For CDCDocumento6 pagineErection Progress Report For CDC Erection Progress Report For CDCAbdulrahman AlkilaniNessuna valutazione finora

- f73999416 ERECTION PROGRESS REPORT GWC-QAFDocumento4 paginef73999416 ERECTION PROGRESS REPORT GWC-QAFAbdulrahman AlkilaniNessuna valutazione finora

- Submittal For Approval of Document: Receiving by Sub-Contractor NameDocumento4 pagineSubmittal For Approval of Document: Receiving by Sub-Contractor NameAbdulrahman AlkilaniNessuna valutazione finora

- Answers For TimesetDocumento11 pagineAnswers For TimesetMuntazirNessuna valutazione finora

- The Impact of Dementia On The ClinicalDocumento8 pagineThe Impact of Dementia On The ClinicalihsansabridrNessuna valutazione finora

- 6C33C-B OTL Amplifier - Background and OTL CircuitsDocumento14 pagine6C33C-B OTL Amplifier - Background and OTL CircuitsettorreitNessuna valutazione finora

- Kerala University PHD Course Work Exam SyllabusDocumento4 pagineKerala University PHD Course Work Exam Syllabuslozuzimobow3100% (2)

- Phed 239 Syllabus s14-1st Half-3Documento7 paginePhed 239 Syllabus s14-1st Half-3api-249627241Nessuna valutazione finora

- Past Simple PDFDocumento4 paginePast Simple PDFderlinNessuna valutazione finora

- Thesis Report On: Bombax InsigneDocumento163 pagineThesis Report On: Bombax InsigneShazedul Islam SajidNessuna valutazione finora

- Purification and Detection of Linamarin From Cassava Root Cortex by HPLCDocumento5 paginePurification and Detection of Linamarin From Cassava Root Cortex by HPLCJohn Eiver BelalcazarNessuna valutazione finora

- 2 Cor 37Documento2 pagine2 Cor 37M. Div ChoudhrayNessuna valutazione finora

- Gentle Genitty UnderstandingDocumento8 pagineGentle Genitty UnderstandingANDREW ROBERT BASCUGUINNessuna valutazione finora

- Ansari Ibnarabdoctrine 1999Documento45 pagineAnsari Ibnarabdoctrine 1999JYOTI PALNessuna valutazione finora

- Pain Assessment AND Management: Mr. Swapnil Wanjari Clinical InstructorDocumento27 paginePain Assessment AND Management: Mr. Swapnil Wanjari Clinical InstructorSWAPNIL WANJARINessuna valutazione finora

- Ucsp Module 6 W:B Answer SheetDocumento5 pagineUcsp Module 6 W:B Answer SheetAl Cheeno Anonuevo100% (1)

- Stetment 10 PDFDocumento4 pagineStetment 10 PDFvaraprasadNessuna valutazione finora

- Item Analysis Third QuarterDocumento4 pagineItem Analysis Third Quarterwhite valeNessuna valutazione finora

- Project SelectingDocumento29 pagineProject SelectingayyazmNessuna valutazione finora

- Global University Rankings and Their ImpactDocumento85 pagineGlobal University Rankings and Their ImpactКино ФильмNessuna valutazione finora

- Candi MendutDocumento3 pagineCandi MendutEdi YantoNessuna valutazione finora

- Ecdis-24 01Documento4 pagineEcdis-24 01Leandro PintoNessuna valutazione finora

- Education and Socialisim or Socialist Order in IndiaDocumento30 pagineEducation and Socialisim or Socialist Order in IndiaAman RajoraNessuna valutazione finora

- American Colonial Empire - Julian GoDocumento6 pagineAmerican Colonial Empire - Julian GoBert M DronaNessuna valutazione finora