Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A560 PDF

Caricato da

Ashish PatelTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

A560 PDF

Caricato da

Ashish PatelCopyright:

Formati disponibili

Designation: A560/A560M − 12

Standard Specification for

Castings, Chromium-Nickel Alloy1

This standard is issued under the fixed designation A560/A560M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* A957M, including any supplementary requirements that are

1.1 This specification covers chromium-nickel alloy cast- indicated in the purchase order. Failure to comply with the

ings intended for heat-resisting and elevated-temperature cor- general requirements of Specification A957/A957M consti-

rosion applications, such as structural members, containers, tutes nonconformance with this specification. In case of con-

supports, hangers, spacers, and the like, in corrosive environ- flict with this specification and Specification A957/A957M,

ments up to 2000°F [1090°C]. A957/A957M shall prevail.

1.2 The values stated in either SI units or inch-pound units 4. Ordering Information

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each 4.1 Orders for material under this specification should

system shall be used independently of the other. Combining include the following information in proper sequence:

values from the two systems may result in non-conformance 4.1.1 Quantity;

with the standard. 4.1.2 Specification and grade (50 Cr-50 Ni, R20500; 60 Cr-

40 Ni, R20600; 50 Cr-50 Ni-Cb, R20501);

2. Referenced Documents

4.1.3 Description of the casting by pattern number or

2.1 ASTM Standards:2 drawing;

A781/A781M Specification for Castings, Steel and Alloy,

4.1.4 Options in the specification:

Common Requirements, for General Industrial Use

A957/A957M Specification for Investment Castings, Steel 4.1.4.1 Process,

and Alloy, Common Requirements, for General Industrial 4.1.4.2 Heat treatment,

Use 4.1.4.3 Tensile properties,

4.1.4.4 Tension tests,

3. General Conditions for Delivery

4.1.4.5 Charpy impact tests, and

3.1 Except for steel investment castings, material furnished 4.1.4.6 Test specimens or test bars.

to this specification shall conform to the requirements of

4.1.5 Supplementary requirements desired, including stan-

Specification A781/A781M, including any supplementary re-

dards of acceptance.

quirements that are indicated in the purchase order. Failure to

comply with the general requirements of Specification A781/

A781M constitutes nonconformance with this specification. In 5. Materials and Manufacture

case of conflict between the requirements of this specification 5.1 Process—The alloy for the castings shall be made by the

and Specification A781/A781M, this specification shall pre- electric-arc or induction-furnace process unless otherwise

vail. agreed upon between the manufacturer and the purchaser.

3.2 Steel investment castings furnished to this specification Castings may be poured in sand, shell, investment, or centrifu-

shall conform to the requirements of Specification A957/ gal molds.

5.2 Heat Treatment—Castings may be shipped in the as-cast

1

condition. If heat treatment is required, the treatment shall be

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee established by mutual consent between the manufacturer and

A01.18 on Castings. purchaser and shall be so specified in the inquiry, purchase

Current edition approved Nov. 1, 2012. Published November 2012. Originally order, or contract.

approved in 1966. Last previous edition approved in 2011 as A560/A560M – 11.

DOI: 10.1520/A0560_A0560M-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Chemical Composition

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 6.1 The castings shall conform to the requirements as to

the ASTM website. chemical composition prescribed in Table 1.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright by ASTM Int'l (all rights reserved); 1

A560/A560M − 12

TABLE 1 Chemical RequirementsA,B TABLE 2 Room Temperature Tensile and Charpy RequirementsA

Element Composition, % 50 Cr-50 Ni 60 Cr-40 Ni 50 Cr-50 Ni-Cb

Grade Tensile strength, min, ksi [MPa] 80 [550] 110 [760] 80 [550]

50 Cr-50 Ni 60 Cr-40 Ni 50 Cr-50 Ni-Cb Yield point, min, ksi [MPa] 50 [340] 85 [590] 50 [345]

(R20500) (R20600) (R20501) Elongation in 2 in. [50 mm], 5.0 ... 5.0

min, %

Carbon 0.10 0.10 0.10 Impact, unnotched, Charpy, min, 50 [78] 10 [14] ...

Manganese 0.30 0.30 0.30 ft·lbf [J]

Silicon 1.00 1.00 0.50

A

Sulfur 0.02 0.02 0.02 Where ellipses (...) appear in this table, there is no requirement.

Phosphorus 0.02 0.02 0.02

Nitrogen 0.30 0.30 0.16

Nitrogen + Carbon ... ... 0.20 sent the full melting practice. Chemical composition of the test

Iron 1.00 1.00 1.00

Titanium 0.50 0.50 0.50 coupons shall conform to the requirements prescribed in Table

Aluminum 0.25 0.25 0.25 1.

Columbium ... ... 1.4–1.7

Chromium 48.0–52.0 58.0–62.0 47.0–52.0 8.3 Impact test specimens are to be broken un-notched.

Nickel balance balance balance

A

9. Number of Tests and Retests

The total of the nickel, chromium, and columbium contents must exceed 97.5 %.

B

All values are maximum, unless a range or minimum is indicated. Where ellipses 9.1 Tension Test—One tension test, if required, shall be

appear (...) in this table, there is no minimum and analysis for the element need not

be determined or reported.

made from each melt.

9.2 Impact Test—One unnotched Charpy impact test, if

required, shall be made from each melt.

7. Tensile Properties 9.3 Retests:

9.3.1 Retest of a duplicate specimen will be allowed if the

7.1 Tensile properties, if required, of the alloy used for the

results of the mechanical tests for any lot do not conform to the

castings shall conform to the requirements prescribed in Table

requirements specified in Table 2.

2.

9.3.2 If the percentage of elongation of any tension test

8. Test Specimens specimen is less than specified in Table 2 and any part of the

fracture is more than 3⁄4 in. [19.0 mm] from the center of the

8.1 Test bars shall be poured in special blocks from the gage length, as indicated by scribe scratches marked on the

same heat as the castings represented. Test bars, if required, specimen before testing, a retest shall be allowed.

shall be furnished in sufficient number to furnish specimens for

the test required in Section 9. 10. Keywords

8.2 The test coupons shall be cast from the same melt from 10.1 chromium-nickel alloys; corrosion; high temperature

which the castings they represent are poured, and shall repre- applications; investment castings; steel castings

SUPPLEMENTARY REQUIREMENTS

The following supplementary requirements shall not apply unless specified in the purchase order. A

list of standardized supplementary requirements for use at the option of the purchaser is included in

Specifications A781/A781M and A957/A957M. Those that are ordinarily considered suitable for use

with this specification are given below. Others enumerated in Specifications A781/A781M and

A957/A957M may be used with this specification upon agreement between the manufacturer and the

purchaser.

S2. Radiographic Examination S8. Marking

S3. Liquid Penetrant Examination

Copyright by ASTM Int'l (all rights reserved); 2

A560/A560M − 12

SUMMARY OF CHANGES

Committee A01 has identified the location of selected changes to this standard since the last issue,

(A560/A560M – 11), that may impact the use of this standard. (Approved Nov. 1, 2012.)

(1) Editorially revised 1.2. (3) Revised Section 4 and Table 1.

(2) Revised sections/subsections 2, 3, 7.2 (deleted), 8, and 10

and introductory paragraph to Supplementary Requirements to

reference investment castings and to delete references to A370.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 3

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Tool Steel - Material Selection Guide: High Speed SteelsDocumento1 paginaTool Steel - Material Selection Guide: High Speed SteelsAlok Rawat NLMKNessuna valutazione finora

- A Case Study On Fatigue Failure of A Transmission Gearbox Input ShaftDocumento7 pagineA Case Study On Fatigue Failure of A Transmission Gearbox Input ShaftPavan KumarNessuna valutazione finora

- Astm A105 Flange SpecificationDocumento2 pagineAstm A105 Flange SpecificationSales ITANessuna valutazione finora

- Corrosion Company BrochureDocumento12 pagineCorrosion Company BrochureMythri Metallizing Pvt Ltd ProjectsNessuna valutazione finora

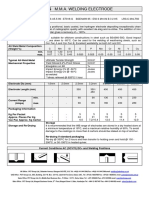

- Wb76S M.M.A. Welding Electrode: Classifications & ApprovalsDocumento1 paginaWb76S M.M.A. Welding Electrode: Classifications & Approvalslathasri78Nessuna valutazione finora

- Sadhu Forging Limite1 - 2Documento4 pagineSadhu Forging Limite1 - 2Priya KaleNessuna valutazione finora

- Manuf. Tech. - IntroductionDocumento38 pagineManuf. Tech. - IntroductionManuel Tikongyin WundengbaNessuna valutazione finora

- Indian Standard: Specification FOR Filler Rods For Gas WeldingDocumento22 pagineIndian Standard: Specification FOR Filler Rods For Gas WeldingMuthusamy ArumugamNessuna valutazione finora

- Silicon Killed Steel Nozzle CloggingDocumento8 pagineSilicon Killed Steel Nozzle CloggingMada TetoNessuna valutazione finora

- Forming QuestionsDocumento6 pagineForming Questionsibrahimtalal702Nessuna valutazione finora

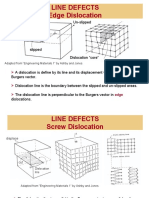

- Line Defects Edge Dislocation: Burgers VectorDocumento6 pagineLine Defects Edge Dislocation: Burgers Vectorcarlos pucciniNessuna valutazione finora

- General Principles and Processes of Isolation of Elements Class 12 Notes Chemistry Chapter 6 - CBSE LabsDocumento5 pagineGeneral Principles and Processes of Isolation of Elements Class 12 Notes Chemistry Chapter 6 - CBSE Labsavinash kishoreNessuna valutazione finora

- 4CH1 2C Que 2022Documento20 pagine4CH1 2C Que 2022mostafa barakat100% (1)

- Cement (Chapter 3)Documento13 pagineCement (Chapter 3)teweleNessuna valutazione finora

- ASTM B983 - 2016 Inconel 740Documento5 pagineASTM B983 - 2016 Inconel 740Anonymous lmCR3SkPrKNessuna valutazione finora

- Socket Weld Cap Dimension - Penn MachineDocumento1 paginaSocket Weld Cap Dimension - Penn MachineEHT pipeNessuna valutazione finora

- Machine Design 2Documento16 pagineMachine Design 2syammcNessuna valutazione finora

- Tema ExcelDocumento8 pagineTema ExcelTeodor OlaruNessuna valutazione finora

- Offer For Kiln Tyre Crack Repair - DroliaDocumento5 pagineOffer For Kiln Tyre Crack Repair - DroliaNapoleon Das100% (1)

- Introduction and Classification of Forging Processes: NPTEL - Mechanical Engineering - FormingDocumento8 pagineIntroduction and Classification of Forging Processes: NPTEL - Mechanical Engineering - FormingRashmi DhunganaNessuna valutazione finora

- Gold Market Structure and FlowsDocumento5 pagineGold Market Structure and FlowsSankar Maity100% (1)

- Refractory Datasheet 2 - KS-4V PLUSDocumento2 pagineRefractory Datasheet 2 - KS-4V PLUSSubrata DasNessuna valutazione finora

- BMP - DrawingDocumento22 pagineBMP - Drawingmantra2010Nessuna valutazione finora

- Fire AssayingDocumento28 pagineFire AssayingGeorge GomezNessuna valutazione finora

- Optical Mineralogy: Minerals in Plane Polarised LightDocumento29 pagineOptical Mineralogy: Minerals in Plane Polarised LightRidho FirdausmanNessuna valutazione finora

- Allloys: Magyarmet FinomöntödeDocumento8 pagineAllloys: Magyarmet FinomöntödeIndustrial Infra JobsNessuna valutazione finora

- eNERGY cONSUMPTIONDocumento8 pagineeNERGY cONSUMPTIONRefky FNessuna valutazione finora

- MTRL - Tower - 2 PDFDocumento38 pagineMTRL - Tower - 2 PDFjendrikoNessuna valutazione finora

- Evaluation of White Silica Sands in North Eastern Desert EgyptDocumento11 pagineEvaluation of White Silica Sands in North Eastern Desert EgyptMohamed AbdelqaderNessuna valutazione finora

- Dental Materials: Investment MaterialDocumento4 pagineDental Materials: Investment MaterialErwin GunawanNessuna valutazione finora