Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Shimano 105 Gear Change Manual

Caricato da

1heUndertakerTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Shimano 105 Gear Change Manual

Caricato da

1heUndertakerCopyright:

Formati disponibili

SI-6TH0A-002-00

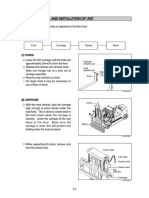

General Safety Information Operation of rear derailleur lever Operation of front derailleur levers Pass the inner cable through as shown in the illustration, and then

set the inner cable drum into the cable hook.

2. Insert an Allen key or similar tool into the

lever stud hole, and then tap it gently with

• Lever A : Shifts from smaller to larger rear sprocket.

(FD-5700) • Front lever a plastic mallet to push out the lever stud.

WARNING Lever A has a click stop at positions ⁄ and ¤. • Lever a : Shifts from smaller to larger front chainring. When the lever stud comes out, the

Operate lever b once or more to set the lever to bracket body and lever body can be

• Obtain and read the service instructions carefully prior to Outer casing

the low position. disassembled.

installing the parts. Loose, worn or damaged parts may cause Bracket body

the bicycle to fall over and serious injury may occur as a

result. We strongly recommend only using genuine Shimano Lever b Always be sure to remove

replacement parts. the lever stud in this

Cable hook

• Obtain and read the service instructions carefully prior to Operate at least once direction. If it is removed in

installing the parts. If adjustments are not carried out the opposite direction, it

correctly, the chain may come off and this may cause you to may damage the bracket

fall off the bicycle which could result in serious injury. Pass the inner cable through the cable hole. body.

Lever A

• Use the ST-5700/5703, BL-TT79 with the BR-5700. Do not use Lever a The outer casing can be routed in two directions: either through Lever stud

¤ Click

Lever A cable guide (1) (inside) or cable guide 2 (outside).

the BR-5700 in combination with previous STI levers for road start position Lever body

riding or with the BL-R770/BL-R550 brake levers for flat Lever a

⁄ Click

start position Name plate Inner cable drum

Note:

handlebars, otherwise the braking performance provided will

be much too strong.

Insert the inner cable so that the inner cable drum goes into the Assembling the bracket body and lever

4 3 winder unit as far as it can go.

• Read these Technical Service Instructions carefully, and keep

⁄ : Shifts one sprocket

If operation of lever a dose not complete the body

them in a safe place for later reference. E.x. : from 3rd to 4th chainring shift stroke, operate lever a again 1. Insert the connector lever into the main lever support, and then

for the distance (X') to complete that part of Installing the shifting cable (1) assemble the bracket

the lever stroke (X) which was short. body and lever body.

Note Cable used f 1.2 mm Next, insert the end of

• For triple front chainwheel specifications, be sure to read these • Inner cable (PTFE inner cable) •••••••••• the return spring into

Service Instructions in conjunction with the Service the notch.

Instructions for the ST-5703 and FD-5703. Full gear shift stroke f 4 mm

5 3 (2)

• Operation of the levers related to gear shifting should be made ¤ : Quick-shifts two sprockets • SP41 sealed outer casing (⁄) •••••••••• SP41 SEALED

only when the front chainwheel is turning. E.x. : from 3rd to 5th Actual stroke Connector lever

Shifting cable cover

• For smooth operation, use the specified outer casing and the f 4 mm

bottom bracket cable guide. • SP41 outer casing (¤) •••••••••••••••••• SP41 Notch

Main lever support

• Grease the inner cable and the inside of the outer casing

before use to ensure that they slide properly. • Lever b : Shifts from larger to smaller front chainring. CAUTION

• Because the high cable resistance of a frame with internal 4-mm cap Be sure to install the shifting cable cover before use. If it is not

cable routing would impair the SIS function, this type of frame installed, injury may occur.

should not be used. • Lever B : Shifts from larger to smaller rear sprocket. Derailleur side ¤

• A special grease is used for the gear shifting cable. Do not use Do not disassemble the unit cover Return spring

Press lever B once to shift from a larger to one smaller sprocket.

DURA-ACE grease or other types of grease, otherwise they at the front, otherwise it may

may cause deterioration in gear shifting performance. Plastic cap Plastic cap or 4-mm cap ⁄ cause problems with operation.

• Parts are not guaranteed against natural wear or deterioration Wire lead

resulting from normal use. 2. Align the stud holes, and then set the special tool (1) in the

Lever b position shown in the illustration to press-fit the lever stud.

• For maximum performance we highly recommend Shimano

lubricants and maintenance products. Unit cover

• For any questions regarding methods of installation, Cutting the outer casing E-ring groove

adjustment, maintenance or operation, please contact a Lever B Lever B Lever b

When cutting the outer casing, cut the opposite end to the end with

professional bicycle dealer.

start position start position the marking. After cutting the outer casing, make the end round so • Outer stopper

that the inside of the hole has a uniform 1. Install the outer stopper to the down tube.

When lever b is operated, there is diameter.

one click where trimming (the noise Outer stopper

4 3 prevention mechanism) engages,

Attach the same outer end cap to the cut end of the outer casing. Adjustment bolt

E.x. : from 4th to 3rd and a second stronger click when the

gear shift stroke is completed. After Gear shift

complete SP41 Installation bolt Do not press-fit the lever stud

trimming, the next push will complete stroke from this direction, otherwise it

Outer end cap

the gear shift stroke. 3mm Allen key may damage the bracket body.

Direct mount seat (M5)

SP41

• The correct direction for the lever stud to face is with the E-ring

Trim groove at the top.

Click operation Tightening torque: • Check that the surface of the bracket body is flush with the top

Technical Service Instructions SI-6TH0A-002 Lever stroke adjustment Click

1.5 - 2 N·m {13 - 18 in. lbs.} of the lever stud to ensure that the E-ring can fit into the

• Rear lever groove.

If you would like to make the lever stroke larger, remove the pad

spacer. Trimming (noise prevention operation) Chain position Install with the adjustment bolt tightened.

3. Remove the special tool (1), and

ST-5700 If you would like to make the lever stroke smaller, replace the

pad spacer with the accessory pad spacer (10 mm).

If the chain is on the large front chainwheel

and the larger rear sprocket, the chain will

Operate lever B at least 9 times to set the lever

to the highest position.

The adjustment range for the adjustment bolt is six full turns.

then use the special tool (2) to

install the E-ring.

rub in the front derailleur plate, producing a

5 mm pad spacer (default) 10 mm pad spacer characteristic noise. When this happens, 2. Pass the inner cable through, and set the outer casing.

Shimano Total Integration press lever b lightly (to the point where it Lever B

clicks); this causes the front derailleur to Be sure leave some excess in the outer casing, even if cutting it

move slightly towards the smaller chainwheel, Operate at least 9 times to the full length of the handlebars.

In order to realize the best performance, we recommend that thereby eliminating the noise.

the following combination be used.

If the chain is on the smallest front chainring

Series 105 Pass the inner cable through the cable hole.

and a smaller rear sprocket, the chain will rub

Shifting lever ST-5700 in the front derailleur plate, producing a The outer casing can be routed in two directions: either through Replacing the main lever support

characteristic noise. When this happens, cable guide (1) (inside) or cable guide 2 (outside). Installation:

Outer casing OT-SP41 (SIS-SP41)

press lever a lightly (to the point where it Note: Insert the main lever support so that it

Gears 20 clicks); this causes the front derailleur to Movement of the Outer stopper Outer casing pushes against the lever body drop-

front derailleur Insert the inner cable so that the inner cable drum goes into the

Front derailleur FD-5700 move slightly towards the larger chainring, winder unit as far as it can go. prevention notch.

thereby eliminating the noise. Inner cable

Front chainwheel FC-5700

Outer casing Main lever support

Rear derailleur RD-5700-SS

• Installation and removal of the pad spacer Caution on operation (1)

Freehub FH-5700 Cable hole

Cassette sprocket CS-5700 Lever Bb will also move when lever Aa is operated, but be

Chain CN-5701 Pad spacer careful not to apply pressure to lever Bb. Similarly be careful Confirm

not to press lever Aa when operating lever Bb. Gears will not Make sure the outer casing is firmly

Bottom bracket cable guide SM-SP17

shift when both levers are pressed simultaneously. seated in the outer stopper.

Cable adjuster SM-CA70 / SM-CA50 (2)

Be sure to read these service instructions in conjunction with the service

<Removal> <Installation> instructions for the RD-5700, FD-5700 before use.

Operation Inner cable Replacing the cable guide

Rear Front Installation Maintenance Cable guide

Installation to the handlebar Installation of the brake cable * The illustration shows the right-hand lever.

When removing parts in order to

Move the bracket cover forward, and then securely tightening the Cable used

replace the inner cable, the work can Bracket and lever disassembly Use this hole to replace the cable guide.

mounting nut with a 5 mm Allen key.

f 1.6 mm be carried out more easily if the unit

• Inner cable (stainless steel)

1. First use the special tool to remove the E-ring. Use part (B) of the

••••••••••••••••• cover is removed as shown in the special tool (2) to align the E-ring with the direction of removal.

Lever B Lever b

Bracket cover f 5 mm illustration. Next, set part A against the E-ring and remove the E-ring.

Lever A Lever a

• SLR outer casing ••••••••••••••••••••••••••••

Lever A : Shifts from smaller to larger rear sprocket. Tightening torque: E-ring removal direction

Lever B : Shifts from larger to smaller rear sprocket. Be sure to leave some excess cable, even if cutting it to the full 0.2 N·m {1.8 in. lbs.} Unit cover

Lever a : Shifts from smaller to larger chainring. length of the handlebars. Replacing the bracket cover

E-ring

Lever b : Shifts from larger to smaller chainring. Hollow

The tabs on the bracket cover each fit to a matching slot on the

All levers return to the starting position when released. Be careful not to cover the cable holes or the unit cover when bracket.

wrapping on the handlebar tape. If the handlebar tape covers these

places, it will not be possible to replace the inner cable.

Special E-ring removal tool

5 mm Allen key Handlebar tape

(1) (2)

Unit cover

Cable hole

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003

CAUTION Note the markings:

Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222 The correct way for clamp washer R : for right

(B) to face is so that the small Tightening torque: (A)

When removing the E-ring, it may L : for left

hollow on the surface is in the 6 - 8 N·m {52 – 69 in. lbs.}

3-77 Oimatsu-cho, Sakai-ku, Sakai-shi, Osaka 590-8577, Japan top-left corner.

suddenly spring out, so check the

safety of any nearby people or Wipe a little rubbing alcohol inside the

* Service Instructions in further languages are available at : (B) objects before removing it.

When installing the components to carbon frame/handle bar surfaces, verify with the manufacturer of the carbon bracket cover to make installation

http://techdocs.shimano.com

frame/parts for their recommendation on tightening torque in order to prevent over tightening that can cause easier.

Please note: specifications are subject to change for improvement without notice. (English)

© Mar. 2010 by Shimano Inc. XBC SZK Printed in Japan. damage to the carbon material and/or under tightening that can cause lack of fixing strength for the components.

Potrebbero piacerti anche

- 5600 Shifter ServiceDocumento1 pagina5600 Shifter ServiceMichaelRMilaniNessuna valutazione finora

- Shimano D CL LeversDocumento1 paginaShimano D CL LeversxjcaiNessuna valutazione finora

- Bike CalipersSI - 8C60H - en - v1 - m56577569830604598Documento1 paginaBike CalipersSI - 8C60H - en - v1 - m56577569830604598Stuart BaileyNessuna valutazione finora

- SI 6KFFB 001 ENG - v1 - m56577569830687361Documento1 paginaSI 6KFFB 001 ENG - v1 - m56577569830687361Onus Probandis HedonistaNessuna valutazione finora

- Shimano Front DerailleurDocumento1 paginaShimano Front DerailleurAndreiNessuna valutazione finora

- Um 3000H 006 00 EngDocumento1 paginaUm 3000H 006 00 EngGaudencio LingamenNessuna valutazione finora

- SI-8C90E-000-EnG (Jan. 2004) Disc Brake SystemDocumento1 paginaSI-8C90E-000-EnG (Jan. 2004) Disc Brake SystemboomissyNessuna valutazione finora

- Mecha Lock - MisumiDocumento1 paginaMecha Lock - MisumiDuong NguyenNessuna valutazione finora

- XT FD & Crank InstallationDocumento1 paginaXT FD & Crank InstallationMarNessuna valutazione finora

- Shimano AltusDocumento1 paginaShimano Altusbambangw_99Nessuna valutazione finora

- Quick Guide: Manual Mounting The Podium Wheel Base Attaching The Steering Wheel On and OffDocumento2 pagineQuick Guide: Manual Mounting The Podium Wheel Base Attaching The Steering Wheel On and OffmihaelkaganNessuna valutazione finora

- SST Oryg Install: Part DescriptionDocumento4 pagineSST Oryg Install: Part DescriptionMidi SyaprizalNessuna valutazione finora

- S Series Pulling Tool: Slickline Training Manual / Standard Service ToolsDocumento3 pagineS Series Pulling Tool: Slickline Training Manual / Standard Service ToolsJohnNessuna valutazione finora

- Assemble and Operate Halogen Exam LightsDocumento2 pagineAssemble and Operate Halogen Exam LightsDr. Jeisson HincapieNessuna valutazione finora

- Group 2 Removal and Installation of Unit: 1. MastDocumento16 pagineGroup 2 Removal and Installation of Unit: 1. MastAndré TarginoNessuna valutazione finora

- Procédure Installation Des Porte-FusiblesDocumento2 pagineProcédure Installation Des Porte-Fusiblesouamor djelouadjiNessuna valutazione finora

- TwoStep Linkage SSP9028 v10Documento1 paginaTwoStep Linkage SSP9028 v10David BriggsNessuna valutazione finora

- Front Drive System: Chain LengthDocumento1 paginaFront Drive System: Chain LengthNiguno ReconocidoNessuna valutazione finora

- Char-Lynn: Steering Control UnitsDocumento7 pagineChar-Lynn: Steering Control UnitsIslam ShoukryNessuna valutazione finora

- YORK VRF Old Fashion Wired Remote Controller JCWA10NEWQ - Installation & Operation Manual - H7W02215 PDFDocumento12 pagineYORK VRF Old Fashion Wired Remote Controller JCWA10NEWQ - Installation & Operation Manual - H7W02215 PDFFadul Chamie TietjenNessuna valutazione finora

- Keimei BomDocumento1 paginaKeimei BomjamartinsxNessuna valutazione finora

- Char-Lynn: Steering Control UnitsDocumento6 pagineChar-Lynn: Steering Control UnitsIslam ShoukryNessuna valutazione finora

- 71cdnCXyIGLDocumento1 pagina71cdnCXyIGLIstamsetty HanumantharaoNessuna valutazione finora

- Installing Takegawa Hyper Cam (KLX110/DRZ110)Documento1 paginaInstalling Takegawa Hyper Cam (KLX110/DRZ110)MinibikeTechNessuna valutazione finora

- BL 110Documento16 pagineBL 110Victor FloresNessuna valutazione finora

- Char-Lynn: Steering Control UnitsDocumento4 pagineChar-Lynn: Steering Control UnitsIslam ShoukryNessuna valutazione finora

- JVC Clock Radio Ipod - LVT1848-001BDocumento2 pagineJVC Clock Radio Ipod - LVT1848-001BgapNessuna valutazione finora

- Multipole Low Voltage Cable Assembly InstructionsDocumento3 pagineMultipole Low Voltage Cable Assembly Instructionsbo cephusNessuna valutazione finora

- Alivio Front Drive SystemDocumento1 paginaAlivio Front Drive SystemMarNessuna valutazione finora

- XT 2012 Brake SystemDocumento1 paginaXT 2012 Brake SystemMarNessuna valutazione finora

- Position Digital Indicators - Overview: Qfeatures Qhow To Mount: LargeDocumento1 paginaPosition Digital Indicators - Overview: Qfeatures Qhow To Mount: Largewawandev7Nessuna valutazione finora

- BR340Documento1 paginaBR340Ali HassanNessuna valutazione finora

- SI 6M10A en v1 m56577569830604102Documento1 paginaSI 6M10A en v1 m56577569830604102xjcaiNessuna valutazione finora

- Ib63928c eDocumento1 paginaIb63928c eLucas PaulaNessuna valutazione finora

- DeepLay-eks-2022-183 - Distributed Buoyancy Module For Lazy WaveDocumento13 pagineDeepLay-eks-2022-183 - Distributed Buoyancy Module For Lazy WaveGunawan SuwarnoNessuna valutazione finora

- 2007 HD TouringDocumento68 pagine2007 HD TouringRod SturgeonNessuna valutazione finora

- SMC PFMB QuickguideDocumento1 paginaSMC PFMB QuickguideFRANNessuna valutazione finora

- Si 6ngfa 004 EngDocumento1 paginaSi 6ngfa 004 EnglgsmartNessuna valutazione finora

- Manual de Usuario Obulb ProDocumento1 paginaManual de Usuario Obulb ProPere Civit QuiterioNessuna valutazione finora

- v40 Tailgate Lock Assembly ReplacingDocumento2 paginev40 Tailgate Lock Assembly ReplacingDaniel ParryNessuna valutazione finora

- Glacier One T30Documento2 pagineGlacier One T30Vladimir SolomatinNessuna valutazione finora

- Kawasaki Owner Manual OM-99976-2052-03-TH23DVX-ENDocumento1 paginaKawasaki Owner Manual OM-99976-2052-03-TH23DVX-ENA LynNessuna valutazione finora

- One Touch Hydraulic Punch Clamp Operator's ManualDocumento21 pagineOne Touch Hydraulic Punch Clamp Operator's Manualtrung vothaiNessuna valutazione finora

- Ireline EquipmentDocumento20 pagineIreline Equipmentsaid.swekNessuna valutazione finora

- R Type Scraper InstallationDocumento4 pagineR Type Scraper InstallationubabNessuna valutazione finora

- USER GUIDE FOR THE ATDSM MOUNTING DEVICEDocumento6 pagineUSER GUIDE FOR THE ATDSM MOUNTING DEVICEBernhard WeberNessuna valutazione finora

- 160d 7e RemovalDocumento16 pagine160d 7e RemovalJorge RojasNessuna valutazione finora

- Pressure Reducing Valve Kit: Hyundai/Kia A4CF1, A4CF2Documento2 paginePressure Reducing Valve Kit: Hyundai/Kia A4CF1, A4CF2ossoskiNessuna valutazione finora

- AQ Mistral Guide RoundDocumento1 paginaAQ Mistral Guide RoundgeorgelorinczNessuna valutazione finora

- Rela AbtDocumento1 paginaRela Abtjohn freddy GonzalezNessuna valutazione finora

- 04K inDocumento1 pagina04K inАнтон МалыгинNessuna valutazione finora

- SI-R917B-ENG v1 m56577569830657326Documento1 paginaSI-R917B-ENG v1 m56577569830657326Laurentiu GamanNessuna valutazione finora

- Manual Taller PDFDocumento12 pagineManual Taller PDFDiego TorresNessuna valutazione finora

- Honda CB 400 lubrication guideDocumento1 paginaHonda CB 400 lubrication guidekwlimNessuna valutazione finora

- Bath Drain: Before You Begin Before You BeginDocumento6 pagineBath Drain: Before You Begin Before You Beginarizarmani10Nessuna valutazione finora

- Mi Ho796Documento2 pagineMi Ho796warthog.expressNessuna valutazione finora

- Eng Shimano Manu 07214Documento1 paginaEng Shimano Manu 07214RodrigoMacedoNessuna valutazione finora

- CL608e/612e Mechanical AdjustmentsDocumento15 pagineCL608e/612e Mechanical AdjustmentsLukáš KadeřábekNessuna valutazione finora

- 2P162816-1 Dcs302ca61Documento1 pagina2P162816-1 Dcs302ca61Ruan FernandesNessuna valutazione finora

- Firefit Preparatory Fitness Programme 2012Documento38 pagineFirefit Preparatory Fitness Programme 20121heUndertakerNessuna valutazione finora

- MINI6935 Overview V1.2 PDFDocumento18 pagineMINI6935 Overview V1.2 PDF1heUndertakerNessuna valutazione finora

- APL40 - 20 - Gardiner Between Foraging and FarmingDocumento14 pagineAPL40 - 20 - Gardiner Between Foraging and Farming1heUndertakerNessuna valutazione finora

- Ogden Brook Historical Survey - CompleteReportDocumento35 pagineOgden Brook Historical Survey - CompleteReport1heUndertakerNessuna valutazione finora

- NASA Student Handbook For Hand SolderingDocumento125 pagineNASA Student Handbook For Hand SolderingMatt Jones100% (1)

- A Pilot Study of Black Chert Sourcing An PDFDocumento9 pagineA Pilot Study of Black Chert Sourcing An PDF1heUndertakerNessuna valutazione finora

- Note Value: Flags/beams/hooks/tails. Unmodified Note Values Are Fractional Powers of Two, For Example One, OneDocumento5 pagineNote Value: Flags/beams/hooks/tails. Unmodified Note Values Are Fractional Powers of Two, For Example One, One1heUndertakerNessuna valutazione finora

- Neolithic Flint Mines of England PDFDocumento108 pagineNeolithic Flint Mines of England PDF1heUndertaker100% (1)

- BarharpDocumento1 paginaBarharp1heUndertakerNessuna valutazione finora

- Painful Perceptive FlawDocumento1 paginaPainful Perceptive Flaw1heUndertakerNessuna valutazione finora

- Our Ultimate Foundation OrigDocumento2 pagineOur Ultimate Foundation Orig1heUndertakerNessuna valutazione finora

- BT Diverse Phone ManualDocumento60 pagineBT Diverse Phone Manual1heUndertakerNessuna valutazione finora

- 30 Day ChallengeDocumento2 pagine30 Day Challenge1heUndertakerNessuna valutazione finora

- Black Chert SourcingDocumento22 pagineBlack Chert Sourcing1heUndertakerNessuna valutazione finora

- A Pilot Study of Black Chert Sourcing AnDocumento9 pagineA Pilot Study of Black Chert Sourcing An1heUndertakerNessuna valutazione finora

- Notes On Distraction DilemmaDocumento1 paginaNotes On Distraction Dilemma1heUndertakerNessuna valutazione finora

- (TM) Volkswagen Manual de Propietario Volkswagen Beetle 2001Documento52 pagine(TM) Volkswagen Manual de Propietario Volkswagen Beetle 2001SinuheNessuna valutazione finora

- Wistron Egret - Vga Agp - Rev SBDocumento7 pagineWistron Egret - Vga Agp - Rev SBRM EletronicaNessuna valutazione finora

- Prentice Knuckleboom Loaders Spec 21200dDocumento6 paginePrentice Knuckleboom Loaders Spec 21200dCarlos AntunaNessuna valutazione finora

- Chess Simple VariantsDocumento14 pagineChess Simple VariantsWkrscribdNessuna valutazione finora

- Volvo FLDocumento11 pagineVolvo FLJoao CaetanoNessuna valutazione finora

- 2024 02 19T19 18 57 - R3dlogDocumento9 pagine2024 02 19T19 18 57 - R3dlogS Muhammad Hashim RazaNessuna valutazione finora

- Result Final Run - iXS DHC #2 Winterberg 2022Documento14 pagineResult Final Run - iXS DHC #2 Winterberg 2022racementNessuna valutazione finora

- Tencate Ms Pro Product LeafletDocumento2 pagineTencate Ms Pro Product Leafletamee101296Nessuna valutazione finora

- Game Day Jon Schmidt PDFDocumento11 pagineGame Day Jon Schmidt PDFDave Gulimlim100% (3)

- MembersListVIIthAssembly 3Documento1 paginaMembersListVIIthAssembly 3lakshayNessuna valutazione finora

- Magical Book On Puzzle PDFDocumento97 pagineMagical Book On Puzzle PDFNavSharmasNessuna valutazione finora

- How to Assassinate Katarina's Mid Lane MatchupsDocumento4 pagineHow to Assassinate Katarina's Mid Lane MatchupsBerk AliNessuna valutazione finora

- 57 Pages - Thesis About Prediction of Cricket Match OutcomeDocumento57 pagine57 Pages - Thesis About Prediction of Cricket Match OutcomeJehanNessuna valutazione finora

- RET (Mains) 2024 - JamshedprDocumento2 pagineRET (Mains) 2024 - Jamshedpraarushitv.11Nessuna valutazione finora

- PDF 03 72le ManualDocumento134 paginePDF 03 72le ManualTrần Quế ThiênNessuna valutazione finora

- TK Fuel EXe ServiceManual MY23 en-US Rev1 2022-07-14Documento19 pagineTK Fuel EXe ServiceManual MY23 en-US Rev1 2022-07-14MartinNessuna valutazione finora

- AC Milan Club & Youth Academy PresentationDocumento42 pagineAC Milan Club & Youth Academy PresentationJesus Randall100% (1)

- YCA Tournament Registration FormDocumento6 pagineYCA Tournament Registration FormMuhammad Shahid Ansari67% (3)

- Performance Evaluation Test 101Documento8 paginePerformance Evaluation Test 101moB0BNessuna valutazione finora

- Summer Camp 2019Documento3 pagineSummer Camp 2019sapdeb123Nessuna valutazione finora

- Clinical Examinations for PLAB 2Documento12 pagineClinical Examinations for PLAB 2Mandeep KaurNessuna valutazione finora

- 2012 Florida Football Media GuideDocumento196 pagine2012 Florida Football Media GuidebrianstryfeNessuna valutazione finora

- Emcee JsDocumento5 pagineEmcee JsAnonymous xagGSIdNessuna valutazione finora

- VCC GND - Com STM32F103ZET SchematicDocumento1 paginaVCC GND - Com STM32F103ZET SchematicDaniel LopesNessuna valutazione finora

- Ken Kaneki Workout Routine: By: Mike RomaineDocumento10 pagineKen Kaneki Workout Routine: By: Mike RomaineLentejas Paraguayas100% (1)

- Technoledge: Infotech Pvt. LTDDocumento2 pagineTechnoledge: Infotech Pvt. LTDanandhugsNessuna valutazione finora

- Maroon 5 - Girls Like You Ft. Cardi B (Official Music Video) - YouTubeDocumento3 pagineMaroon 5 - Girls Like You Ft. Cardi B (Official Music Video) - YouTubetvis MusicNessuna valutazione finora

- Astm A449Documento2 pagineAstm A449Vitor Rigueira de GodoyNessuna valutazione finora

- Kimberly Lee Phyz Ed SbaDocumento17 pagineKimberly Lee Phyz Ed SbaNicholas Porter0% (3)

- Who Am I Jonathan Foggfull PresentationDocumento13 pagineWho Am I Jonathan Foggfull Presentationapi-241232702Nessuna valutazione finora