Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

E - QCD - 01 - Inspection & Test Plan

Caricato da

balakumar rajaramDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

E - QCD - 01 - Inspection & Test Plan

Caricato da

balakumar rajaramCopyright:

Formati disponibili

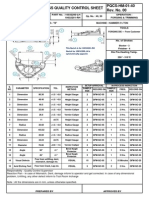

E/QCD/01

Inspection & Test Plan Issue No.00

Inspection Deputy

Sr. Content of Reference Format of

and Testing Inspection Activity & Tasks Toolfab Welding Client Remarks

No. Examination Standard Records

Stages Coordinator

Joint preparation

Technical

Welding Weld details and requirements review

1. - EN 1090-2 P R - ==

planning Performance and inspection class

Testing

Old Welder For

EN ISO

Review only &

Review of welding procedure and 15614-1 & WPS &

2. WPS & WPQR - P R/W R New Welder

qualifications EN ISO WPQR

Joined For

15609-1

Only Witness

Visual Inspection As Per

Customer

Dimension Incoming

3. Parent material 100 % Specificatio P,W == R ==

Review of Mill TC material

n&

Storage & handling Drawing

Visual Inspection EN 13479

Welding Compatibility or Incoming

4. 100 % P,W == R ==

Consumables Review of Test Certificate Applicable material

Storage & handling standard

Joint preparation, fit-up, jigging and tacking

Special requirements in the welding

procedure 100 % By

Specification suitability of working conditions Toolfab , 10

Inspection Fit –UP

5. for welding, including the environment % By Deputy EN 1090-2 P W R ==

Before Welding Report

Planning, performance and assessment of Welding

mock-ups. Coordinator

Calibration and validation of measuring,

inspection and testing equipment

Check welding parameters 100 %

Essential welding parameters Toolfab &

Inspection

6. Preheating/interpass temperature Deputy EN 1090-2 Weld Log p W R ==

During Welding

Cleaning and shape of runs and layers of Welding

weld metal Coordinator

100 %

Toolfab & Visual

Testing After Visual Examination EN ISO

7. Deputy Inspection p W R ==

Welding Final Dimension & Inspection 5817

Welding Report

Coordinator

Final

8. Review of all documents == == == == R R ==

Documentation

Note: P=Performance (Toolfab), W=Witness (Toolfab, Deputy Welding Coordinator), R=Review (Client).

Potrebbero piacerti anche

- Business Plan For Artificial JewelryDocumento20 pagineBusiness Plan For Artificial Jewelryheena zubairNessuna valutazione finora

- Excel Template Machine Wise Production Capacity v.2Documento9 pagineExcel Template Machine Wise Production Capacity v.2pankaj66668100% (1)

- Samples Inspection ReportDocumento5 pagineSamples Inspection ReportArun GuptaNessuna valutazione finora

- Flow Chart For New Enquiry HandlingDocumento1 paginaFlow Chart For New Enquiry HandlingVinod Sale100% (1)

- Equipment Calibration Record ChartDocumento3 pagineEquipment Calibration Record ChartNatarajan MurugesanNessuna valutazione finora

- Work Instruction - Plate CuttingDocumento11 pagineWork Instruction - Plate Cuttingbalakumar rajaram0% (1)

- Assignment: South Eastern University of Sri LankaDocumento12 pagineAssignment: South Eastern University of Sri LankaHasanthikaNessuna valutazione finora

- RMC - Hiware Bazar - Mamaearth - Rural Marketing StrategyDocumento18 pagineRMC - Hiware Bazar - Mamaearth - Rural Marketing StrategySwati MalpaniNessuna valutazione finora

- Hass Planning Year 3 Term 2Documento3 pagineHass Planning Year 3 Term 2api-505532021Nessuna valutazione finora

- Rahul Vs State of UP Moot COURT CASE PetitionerDocumento12 pagineRahul Vs State of UP Moot COURT CASE PetitionerRiddhi Furia100% (1)

- 03.master List of Procedure YI-ID NDocumento1 pagina03.master List of Procedure YI-ID NFendiNessuna valutazione finora

- ISO Process PlanDocumento1 paginaISO Process PlanTeti AzrilNessuna valutazione finora

- Sampling PlanDocumento9 pagineSampling PlanBalvinder SinghNessuna valutazione finora

- ISO/IEC 17025:2017 Internal Auditor: TUV India Training AcademyDocumento1 paginaISO/IEC 17025:2017 Internal Auditor: TUV India Training AcademyKamalaNessuna valutazione finora

- 23.sop - HRDDocumento4 pagine23.sop - HRDrishi gautamNessuna valutazione finora

- Production Validation TemplateDocumento1 paginaProduction Validation Templatesathyabalaraman100% (1)

- Vendor Registration FormDocumento3 pagineVendor Registration FormCorrosion FactoryNessuna valutazione finora

- Production Validation TemplateDocumento1 paginaProduction Validation TemplatesathyabalaramanNessuna valutazione finora

- PQCS Tube Flange Rough - ForgingDocumento1 paginaPQCS Tube Flange Rough - ForgingBalram JiNessuna valutazione finora

- Resume. ShyamDocumento3 pagineResume. Shyamsunder2006Nessuna valutazione finora

- F-05 Corrective Action FormDocumento1 paginaF-05 Corrective Action Formsuhara hussainNessuna valutazione finora

- BGL-FM-HR-38 Training Cum Effectiveness Record 01Documento2 pagineBGL-FM-HR-38 Training Cum Effectiveness Record 01Mohit SinghNessuna valutazione finora

- Document NumberingDocumento8 pagineDocument NumberingRaja RehaNessuna valutazione finora

- Nabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Documento10 pagineNabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Kiran AmboreNessuna valutazione finora

- Sintex Bapl LTD Quality Procedure Manual: Customer Satisfaction Feedback FormDocumento1 paginaSintex Bapl LTD Quality Procedure Manual: Customer Satisfaction Feedback FormJitesh KumarNessuna valutazione finora

- F-PD-11 Tool Development Plan (Micro Plan)Documento3 pagineF-PD-11 Tool Development Plan (Micro Plan)Trivesh SharmaNessuna valutazione finora

- BudgetingDocumento4 pagineBudgetingSapaNessuna valutazione finora

- Hardrock Attachments Pvt. LTD.: Preventive Maintenance ChecklistDocumento1 paginaHardrock Attachments Pvt. LTD.: Preventive Maintenance ChecklistSandeep KumarNessuna valutazione finora

- Daily Production Record FormatDocumento2 pagineDaily Production Record FormatVishal Deshmukh100% (1)

- Preventive CHK List Mig PDFDocumento1 paginaPreventive CHK List Mig PDFSandeep KumarNessuna valutazione finora

- FIR-garments PDFDocumento4 pagineFIR-garments PDFTarun PariharNessuna valutazione finora

- Samrudh: SOP Preparation by Checked by Approved by Authorised byDocumento10 pagineSamrudh: SOP Preparation by Checked by Approved by Authorised byirshadNessuna valutazione finora

- Fmea CastingDocumento4 pagineFmea CastingSuraj RawatNessuna valutazione finora

- Vendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefDocumento3 pagineVendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefAmit KumarNessuna valutazione finora

- Function Statement: QC&A DepartmentDocumento3 pagineFunction Statement: QC&A DepartmentMohamed100% (1)

- Monitoring and Assessment Quality Objectives - Form - Admin.2Documento3 pagineMonitoring and Assessment Quality Objectives - Form - Admin.2Vanny Joyce BaluyutNessuna valutazione finora

- Chemical Compatibility ChartDocumento13 pagineChemical Compatibility ChartManuel Mendez GomezNessuna valutazione finora

- Responsibility and Authority - QMSDocumento47 pagineResponsibility and Authority - QMSDisha Shah50% (2)

- Corrective Action Request (CAR)Documento2 pagineCorrective Action Request (CAR)Yoepy WijayaNessuna valutazione finora

- SUPPLIER Supplier - Self - Assessment - 2015 PDFDocumento6 pagineSUPPLIER Supplier - Self - Assessment - 2015 PDFOwenevan EvanowenNessuna valutazione finora

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionDocumento1 paginaMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionRohit VishwakarmaNessuna valutazione finora

- Hi-Tech Engineering: Supplier Rating FormDocumento1 paginaHi-Tech Engineering: Supplier Rating FormVinod Sale100% (1)

- QAP K-HouseDocumento4 pagineQAP K-HouseAbhinash TamangNessuna valutazione finora

- Procedure For Top Management and Management Review: Input / Output Diagram ControlsDocumento4 pagineProcedure For Top Management and Management Review: Input / Output Diagram ControlsmuthuselvanNessuna valutazione finora

- Iso DoccumentDocumento10 pagineIso DoccumentNavnath TamhaneNessuna valutazione finora

- Centurion Power Cables (P) LTD.: Control of DocumentDocumento4 pagineCenturion Power Cables (P) LTD.: Control of DocumenttriveshNessuna valutazione finora

- Sr. No. Metric Goal Data Source Base Line: TallbrosDocumento3 pagineSr. No. Metric Goal Data Source Base Line: TallbrosVikas KashyapNessuna valutazione finora

- SPC Chart BlankDocumento1 paginaSPC Chart BlankbowlinglmNessuna valutazione finora

- Mangement Review FormatsDocumento7 pagineMangement Review FormatsAnkur DhirNessuna valutazione finora

- LSAI SQA Manual FileDocumento39 pagineLSAI SQA Manual FileSivakumar L100% (1)

- Name of Employee: Performance Evaluation FormDocumento5 pagineName of Employee: Performance Evaluation FormShemu PlcNessuna valutazione finora

- Calibration Schedule Y2020Documento4 pagineCalibration Schedule Y2020kamil renovanNessuna valutazione finora

- Supplier Audit Check SheetDocumento5 pagineSupplier Audit Check SheetMotive Post100% (2)

- Procedure For Evaluation and SelectionDocumento2 pagineProcedure For Evaluation and SelectionSharif KhanNessuna valutazione finora

- Quality RequirementsDocumento26 pagineQuality RequirementsDilip PatilNessuna valutazione finora

- Master List of DocumentDocumento2 pagineMaster List of Documentmygoo0% (1)

- Quality Circle - EM58M - AUQCCDocumento75 pagineQuality Circle - EM58M - AUQCCpverma02Nessuna valutazione finora

- KPI - Goal Sheet - CONSULTANT - 2022 - FSTech v1.0Documento4 pagineKPI - Goal Sheet - CONSULTANT - 2022 - FSTech v1.0Shivani BajpaiNessuna valutazione finora

- Audit ComplianceDocumento1 paginaAudit ComplianceNitin SharmaNessuna valutazione finora

- MSA FormatDocumento4 pagineMSA FormatSaurabh PhandNessuna valutazione finora

- Joncryl 678 TDSDocumento2 pagineJoncryl 678 TDSAllen Kam100% (1)

- 4m Change & Ecn NoteDocumento1 pagina4m Change & Ecn NoteAnurag ChaudharyNessuna valutazione finora

- TKW Fasteners ProfileDocumento37 pagineTKW Fasteners ProfileRishi GautamNessuna valutazione finora

- In Process InspectionDocumento4 pagineIn Process InspectionSuraj RawatNessuna valutazione finora

- Objectives (2019 20)Documento2 pagineObjectives (2019 20)Sekar KrishNessuna valutazione finora

- Sop On Apqp & Ppap WRT Iatf 16949-2016Documento1 paginaSop On Apqp & Ppap WRT Iatf 16949-2016balakumar rajaram100% (1)

- Quality Procedure Procedure For Weld RepairDocumento1 paginaQuality Procedure Procedure For Weld Repairbalakumar rajaramNessuna valutazione finora

- Welding Inspector - Welding InspectorDocumento1 paginaWelding Inspector - Welding Inspectorbalakumar rajaramNessuna valutazione finora

- Preparation and Control of WeldingDocumento3 paginePreparation and Control of Weldingbalakumar rajaramNessuna valutazione finora

- Control of Welding ConsumablesDocumento2 pagineControl of Welding Consumablesbalakumar rajaramNessuna valutazione finora

- Welding QuestionsDocumento10 pagineWelding Questionsbalakumar rajaram100% (1)

- Cum SL - No Month Num T1 SectionDocumento3 pagineCum SL - No Month Num T1 Sectionbalakumar rajaramNessuna valutazione finora

- TOOLFAB UT ProcedureDocumento24 pagineTOOLFAB UT Procedurebalakumar rajaram100% (1)

- Toolfab Engineering Industries (P) LTD: Magnetic Particle Testing ProcedureDocumento9 pagineToolfab Engineering Industries (P) LTD: Magnetic Particle Testing Procedurebalakumar rajaramNessuna valutazione finora

- NyayabindutikaDocumento163 pagineNyayabindutikaJinyue LiuNessuna valutazione finora

- RRL - Perceived Effects of Laissez-Faire in Research Group SatisfactionDocumento39 pagineRRL - Perceived Effects of Laissez-Faire in Research Group SatisfactionMark Darrel PerezNessuna valutazione finora

- Curdev TesdaDocumento11 pagineCurdev Tesdabenchcab3873Nessuna valutazione finora

- Syllabus TemplateDocumento10 pagineSyllabus TemplateJoemar GagnaoNessuna valutazione finora

- Purdue OWL AnnotatedDocumento6 paginePurdue OWL AnnotatedbvwdavisNessuna valutazione finora

- Typical Standard Details Traffic Calming Measures: City of TshwaneDocumento1 paginaTypical Standard Details Traffic Calming Measures: City of Tshwanescelo butheleziNessuna valutazione finora

- Reflection PaperDocumento2 pagineReflection Paperapi-491789791Nessuna valutazione finora

- Letter From The KCSDADocumento3 pagineLetter From The KCSDAWWMTNessuna valutazione finora

- How To Calculate A Severity RateDocumento2 pagineHow To Calculate A Severity RateMohammed MinhajNessuna valutazione finora

- Understanding Local NetworksDocumento16 pagineUnderstanding Local NetworksJeff OrdinalNessuna valutazione finora

- The Business Case For Process SafetyDocumento24 pagineThe Business Case For Process SafetyzainonayraNessuna valutazione finora

- Anuj CV LatestDocumento2 pagineAnuj CV LatestanujrawatNessuna valutazione finora

- Strengths:-: Brand EquityDocumento4 pagineStrengths:-: Brand EquityHasnain AhmadNessuna valutazione finora

- MAR201 Consumer Behavior - UEH-ISB - Unit Guide - Thu NguyenDocumento15 pagineMAR201 Consumer Behavior - UEH-ISB - Unit Guide - Thu NguyenMyNessuna valutazione finora

- Electric ReportDocumento33 pagineElectric ReportAkshay bypNessuna valutazione finora

- Upper Intermediate: KeynoteDocumento2 pagineUpper Intermediate: KeynoteLexieNessuna valutazione finora

- Cultural Variations and Social Differences (Gender) Gender and Gender RolesDocumento26 pagineCultural Variations and Social Differences (Gender) Gender and Gender RolesAnonymousNessuna valutazione finora

- Things Fall Apart Essay 2Documento4 pagineThings Fall Apart Essay 2api-320311544100% (1)

- SM27T LC Ren Usaf 2019Documento2 pagineSM27T LC Ren Usaf 2019Stavatti Aerospace Ltd100% (1)

- Principles of Management Mg2351 Anna University Question BankDocumento4 paginePrinciples of Management Mg2351 Anna University Question BankjeebalaNessuna valutazione finora

- Business Law Exam 3 ReviewDocumento13 pagineBusiness Law Exam 3 ReviewShoma GhoshNessuna valutazione finora

- Case - GotDocumento6 pagineCase - GotPratik PatilNessuna valutazione finora

- Ashlee Dillingham Teach Resume 2 1Documento2 pagineAshlee Dillingham Teach Resume 2 1api-547670474Nessuna valutazione finora

- Leader Mai Kieu LienDocumento2 pagineLeader Mai Kieu LienÁnh NguyệtNessuna valutazione finora

- Directory of Key Officials: Consolidated by The Knowledge Management and Information Service (KMIS)Documento15 pagineDirectory of Key Officials: Consolidated by The Knowledge Management and Information Service (KMIS)josephNessuna valutazione finora