Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Process Code No. 951 Instant Pickles

Caricato da

Iboyaima singhDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Process Code No. 951 Instant Pickles

Caricato da

Iboyaima singhCopyright:

Formati disponibili

Process Code No.

951

INSTANT PICKLES

1. INTRODUCTION

Pickles - an adequately spiced unfermented preparation – has gained

importance in Indian menu and occupies a special place. Preservation of fruits

and vegetables in the form of pickles is an old art and a variety of these

products are made in Indian homes and consumed. From the basic

knowledge of pickles, on scientific lines CFTRI has standardized the process

of making instant pickle mix, which can be converted to a palatable pickle at

home without any difficulty by simple addition of water and oil. The dry mix

is a convenient product to pack, transport and handle in the trade channel. A

variety of dry pickle mix can be developed by using dehydrated mango, lime

(lemon), Green chillies, tomatoes, carrots, different type of leaves such as

gongura, coriander, etc.

The market for pickles and chutneys are on the ever-increasing side both in

the domestic and for export markets. The present production of traditional

pickles is about 15,000 MT valued at Rs. 30 crores per annum, of which a

substantial quantity is exported. However the Instant pickle (dry) mix new

concept, yet to become popular. By virtue of its quality, convenience to handle

this product may become popular and acceptable

2. RAW MATERIAL

Fruits and vegetables are available during different seasons, which varies

from product to product, in abundance. The raw materials are to be

processed during the season, prepared, cured, dehydrated and stored for the

ready use all-round the year. Powdered spices are the other raw materials of

importance in instant pickle preparation.

Dry powdered salt is to be used. All the materials can be locally procured.

Packaging materials also form an important input.

3. PLANT AND MACHINERY

Plant & equipment: The major equipments required are an electrically

operated dryer, spice grinding mill, heat sealing machine, frying pan,

containers and stainless steel knives and they are available indigenously.

Auxiliary equipments: Storage barrels, aluminium topped working tables,

weighing scales, etc.

4. PROJECT COST – FIXED COST – WORKING CAPITAL (in Rs. ‘000)

(Estimate for a Model Project)

a) Land & Land development (800 m2) 80.00

b) Building & civil construction (200 m2) 500.00

c) Plant and machinery 650.00

d) Misc. fixed assets 80.00

e) Pre-operative expenses 67.00

Total Fixed Capital 1377.00

Working capital margin 270.00

Total Project cost 1587.00

Total working capital required at 20% of 840.00

turnover

Means of Finance

- Promoter’s contribution 555.00

- Term loan 1032.00

5. PRODUCTION CAPACITY (Estimate)

250 kg of Instant Pickles/day (8 hr shift)

300 working days per annum

Optimum Capacity Utilization: 70%

6. TECHNOLOGY/MANUFACTURING PROCESS – Availability

CFTRI can offer the technology for Instant Pickles based on mango and lime, against

a fixed premium. The manufacturers have to take a license under FPO (Government

of India). For Technology and Technical assistance please contact

THE DIRECTOR,

CFTRI, MYSORE – 570 020

PHONE 0821-2514534

FAX 0821-2515453

E-MAIL: E-MAIL: ttbd@cftri.res.in

Webpage: www.cftri.com

Potrebbero piacerti anche

- Dehydrated Drum Stick Powder: Central Food Technological Research Institue, Mysore - 570 020Documento2 pagineDehydrated Drum Stick Powder: Central Food Technological Research Institue, Mysore - 570 020kanchanabalanNessuna valutazione finora

- Production of Papaya and Carrot Tutti-FruitiDocumento2 pagineProduction of Papaya and Carrot Tutti-FruitiIboyaima singhNessuna valutazione finora

- Amla Paste: Central Food Technological Research InstituteDocumento2 pagineAmla Paste: Central Food Technological Research InstituteSathyendra RaoNessuna valutazione finora

- Manufacturing of AgarbattiDocumento2 pagineManufacturing of AgarbattiSudhakarrao VuppalaNessuna valutazione finora

- Amla Spread: Central Food Technological Research Institute, Mysore - 570 020Documento2 pagineAmla Spread: Central Food Technological Research Institute, Mysore - 570 020Sathyendra RaoNessuna valutazione finora

- Animal Feed FormulationDocumento2 pagineAnimal Feed FormulationSathyendra RaoNessuna valutazione finora

- Tomato Products: Central Food Technological Research Institute, Mysore - 570 020Documento2 pagineTomato Products: Central Food Technological Research Institute, Mysore - 570 020Iboyaima singhNessuna valutazione finora

- Chutney SpreadsDocumento1 paginaChutney SpreadsJulius OctaviusNessuna valutazione finora

- Project Profile On Pickles: Name of The Product: Pickles Product Code (NIC) : 10306Documento12 pagineProject Profile On Pickles: Name of The Product: Pickles Product Code (NIC) : 10306Divya Bharathi-CommerceNessuna valutazione finora

- Soya Milk, Paneer, CurdDocumento11 pagineSoya Milk, Paneer, Curdpankaj_kalita100Nessuna valutazione finora

- Mysore AnnatroDocumento2 pagineMysore AnnatroWinston MarajNessuna valutazione finora

- Fruit Jam Slices: Central Food Technological Research Institute MYSORE - 570 020Documento2 pagineFruit Jam Slices: Central Food Technological Research Institute MYSORE - 570 020Rizka Dwi AnissatunisaNessuna valutazione finora

- Amla Paste: Emblica Officinalis or Indian Goose-Berry Is Highly Valued For Its Medicinal PropertiesDocumento2 pagineAmla Paste: Emblica Officinalis or Indian Goose-Berry Is Highly Valued For Its Medicinal PropertiesIboyaima singhNessuna valutazione finora

- Fdi PDFDocumento2 pagineFdi PDFTheking OfsexNessuna valutazione finora

- LCMDocumento2 pagineLCMmihirhotaNessuna valutazione finora

- Chepter 12Documento5 pagineChepter 12rajjogiNessuna valutazione finora

- Shamp PapadDocumento5 pagineShamp PapadRaj GiriNessuna valutazione finora

- Tomato Products: Central Food Technological Research Institute, Mysore - 570 020Documento2 pagineTomato Products: Central Food Technological Research Institute, Mysore - 570 020Iboyaima SinghNessuna valutazione finora

- Turmeric Powder From Fresh Turmeric Rhizome: Csir-Central Food Technological Research Instite, MysoreDocumento1 paginaTurmeric Powder From Fresh Turmeric Rhizome: Csir-Central Food Technological Research Instite, MysoreJulius OctaviusNessuna valutazione finora

- Tutti Frutti Project ReportDocumento2 pagineTutti Frutti Project ReportSri VamsiNessuna valutazione finora

- Extruded PotatochipsDocumento8 pagineExtruded PotatochipsBodhisattva AnandNessuna valutazione finora

- Project Red Oxide in IndiaDocumento8 pagineProject Red Oxide in IndiaanaazizNessuna valutazione finora

- Feasibility Study of Best Coffee Roasting, Grinding and PackingDocumento19 pagineFeasibility Study of Best Coffee Roasting, Grinding and PackingFekaduNessuna valutazione finora

- Ground and Processed Spices: Sl. Activity DurationDocumento7 pagineGround and Processed Spices: Sl. Activity DurationChitrank AgrawalNessuna valutazione finora

- G P I B Reen Epper N Rine: Green Pepper IN BrineDocumento2 pagineG P I B Reen Epper N Rine: Green Pepper IN BrineViji ThulasiramanNessuna valutazione finora

- Business Model For Tasty ChikkiesDocumento9 pagineBusiness Model For Tasty Chikkiesvenurao dindi100% (1)

- Bhagaban FlyashDocumento8 pagineBhagaban Flyashkailash naikNessuna valutazione finora

- Project Profile On P.P ThermoformingDocumento11 pagineProject Profile On P.P ThermoformingAnonymous NUn6MESxNessuna valutazione finora

- Project Report - Fly Ash BricksDocumento8 pagineProject Report - Fly Ash BricksRohit Viegas60% (5)

- Eco Friendly Shoe Uppre Leather 2011Documento12 pagineEco Friendly Shoe Uppre Leather 2011Namrit ZatakiyaNessuna valutazione finora

- 01 Blanched & Roasted PeanutsDocumento10 pagine01 Blanched & Roasted PeanutsVikas Singh PariharNessuna valutazione finora

- R S C V: Eady TO Erve Urried EgetablesDocumento5 pagineR S C V: Eady TO Erve Urried EgetablesJaydev MandalNessuna valutazione finora

- Plaster of ParisDocumento5 paginePlaster of ParisAniket Salvi100% (1)

- Project Profile FinalDocumento183 pagineProject Profile Finalvenkateswaran.M venkateswaran.MNessuna valutazione finora

- Project Feasibility Studies ch8Documento5 pagineProject Feasibility Studies ch8Pradeep KrishnanNessuna valutazione finora

- Sample Project Profile On P.P Air Thight ContainersDocumento9 pagineSample Project Profile On P.P Air Thight ContainersThirumoorthi ChellappanNessuna valutazione finora

- Ground and Processed Spices and Cereals Project ReportDocumento5 pagineGround and Processed Spices and Cereals Project ReportGirish DaryananiNessuna valutazione finora

- Pure Spice Powders-KINFRADocumento4 paginePure Spice Powders-KINFRAmanojhunkNessuna valutazione finora

- Chappal PDFDocumento10 pagineChappal PDFMakim ThakurNessuna valutazione finora

- Fruit Jam & Jelly - Preparation1Documento2 pagineFruit Jam & Jelly - Preparation1Iboyaima singhNessuna valutazione finora

- Disposable SyringeDocumento5 pagineDisposable SyringePrabhu KoppalNessuna valutazione finora

- MSME Disposable SyringesDocumento24 pagineMSME Disposable SyringesNaveenbabu SoundararajanNessuna valutazione finora

- Scented Supari ProcessingDocumento2 pagineScented Supari ProcessingJay Kishor Kumar AcharyaNessuna valutazione finora

- Moulding Machine For Besan, Soji/ Rava and Similar LaddusDocumento2 pagineMoulding Machine For Besan, Soji/ Rava and Similar LaddusramanaNessuna valutazione finora

- SurgicalcottonDocumento13 pagineSurgicalcottonArega GenetieNessuna valutazione finora

- Ground and Processed SpicesDocumento11 pagineGround and Processed SpicesAnas MKNessuna valutazione finora

- Project Profile On Glass MirrorDocumento10 pagineProject Profile On Glass MirrorHarsh GoyalNessuna valutazione finora

- Fly Ash BricksDocumento5 pagineFly Ash BricksRamachandran Mahendran100% (1)

- Fruit Squashes and SyrupsDocumento2 pagineFruit Squashes and SyrupsIboyaima singhNessuna valutazione finora

- Printing Ink Project ProfileDocumento8 paginePrinting Ink Project Profilepraveen4ppkNessuna valutazione finora

- PVC Bag Making Unit (Hdpe)Documento12 paginePVC Bag Making Unit (Hdpe)Golden Shower தமிழ்Nessuna valutazione finora

- Extruded Potato ChipsDocumento10 pagineExtruded Potato ChipsyonasNessuna valutazione finora

- Project Report Battery Manufacturing PlantDocumento14 pagineProject Report Battery Manufacturing PlantVasim Shaikh50% (4)

- Ice Cream Making UnitDocumento5 pagineIce Cream Making UnitSyed100% (1)

- Engineering Applications: A Project Resource BookDa EverandEngineering Applications: A Project Resource BookValutazione: 2.5 su 5 stelle2.5/5 (1)

- AI in Manufacturing Driving Innovation and Efficiency: A Comprehensive Toolkit for Startups and Maintenance Ladyluck M: 1, #1Da EverandAI in Manufacturing Driving Innovation and Efficiency: A Comprehensive Toolkit for Startups and Maintenance Ladyluck M: 1, #1Nessuna valutazione finora

- Waste to Energy in the Age of the Circular Economy: Compendium of Case Studies and Emerging TechnologiesDa EverandWaste to Energy in the Age of the Circular Economy: Compendium of Case Studies and Emerging TechnologiesValutazione: 5 su 5 stelle5/5 (1)

- Leveraging on India: Best Practices Related to Manufacturing, Engineering, and ItDa EverandLeveraging on India: Best Practices Related to Manufacturing, Engineering, and ItNessuna valutazione finora

- Artificial Intelligence & The Transformation of The Global ManufacturerDa EverandArtificial Intelligence & The Transformation of The Global ManufacturerNessuna valutazione finora

- Mahua: A Boon For Pharmacy and Food IndustryDocumento11 pagineMahua: A Boon For Pharmacy and Food IndustryIboyaima singhNessuna valutazione finora

- Entrepreneurship Development in The Area of Food Processing in ManipurDocumento1 paginaEntrepreneurship Development in The Area of Food Processing in ManipurIboyaima singhNessuna valutazione finora

- Effectsof Different Concentrationsof CookingDocumento6 pagineEffectsof Different Concentrationsof CookingIboyaima singhNessuna valutazione finora

- KHUMANG 2020: Program Schedule (Time Zone: IST)Documento1 paginaKHUMANG 2020: Program Schedule (Time Zone: IST)Iboyaima singhNessuna valutazione finora

- Amla Paste: Emblica Officinalis or Indian Goose-Berry Is Highly Valued For Its Medicinal PropertiesDocumento2 pagineAmla Paste: Emblica Officinalis or Indian Goose-Berry Is Highly Valued For Its Medicinal PropertiesIboyaima singhNessuna valutazione finora

- Medicinal Plants Used Against DysenteryDocumento6 pagineMedicinal Plants Used Against DysenteryIboyaima singhNessuna valutazione finora

- Common Spices Plant Used As Medicine by The Tangkhul Tribe of Ukhrul District, Manipur, IndiaDocumento4 pagineCommon Spices Plant Used As Medicine by The Tangkhul Tribe of Ukhrul District, Manipur, IndiaIboyaima singhNessuna valutazione finora

- Khumang 2020 - BrochureDocumento5 pagineKhumang 2020 - BrochureIboyaima singhNessuna valutazione finora

- Wild Edible Plants of The Sikkim HimalayDocumento16 pagineWild Edible Plants of The Sikkim HimalayIboyaima singhNessuna valutazione finora

- Wild Medicinal Plants in The Hill of Man PDFDocumento9 pagineWild Medicinal Plants in The Hill of Man PDFIboyaima singhNessuna valutazione finora

- Ensuring The Socio-Economic Empowerment of Indigenous CommunitiesDocumento4 pagineEnsuring The Socio-Economic Empowerment of Indigenous CommunitiesIboyaima singhNessuna valutazione finora

- Tomato Products: Central Food Technological Research Institute, Mysore - 570 020Documento2 pagineTomato Products: Central Food Technological Research Institute, Mysore - 570 020Iboyaima singhNessuna valutazione finora

- CSIR Innovation Award For School Children 26.09.2017Documento4 pagineCSIR Innovation Award For School Children 26.09.2017Iboyaima singhNessuna valutazione finora

- Template 1A and 1BDocumento8 pagineTemplate 1A and 1BIboyaima singhNessuna valutazione finora

- RTS Fruit Juice & BeveragesDocumento2 pagineRTS Fruit Juice & BeveragesIboyaima singhNessuna valutazione finora

- Fruit Jam & Jelly - Preparation1Documento2 pagineFruit Jam & Jelly - Preparation1Iboyaima singhNessuna valutazione finora

- Design and Construction of A Solar Dryer For MangoDocumento8 pagineDesign and Construction of A Solar Dryer For MangoIboyaima singhNessuna valutazione finora

- Fruit Squashes and SyrupsDocumento2 pagineFruit Squashes and SyrupsIboyaima singhNessuna valutazione finora

- Central Food Technological Research Institute, Mysore 570 020 Amla ProductsDocumento1 paginaCentral Food Technological Research Institute, Mysore 570 020 Amla ProductsIboyaima singhNessuna valutazione finora

- Cluster FormateDocumento4 pagineCluster FormateIboyaima singhNessuna valutazione finora

- North East IndiaDocumento1 paginaNorth East IndiaIboyaima singhNessuna valutazione finora

- CustardDocumento6 pagineCustardIboyaima singhNessuna valutazione finora

- Revised SFURTI Guidelines-2020 (6.3.20) PDFDocumento36 pagineRevised SFURTI Guidelines-2020 (6.3.20) PDFIboyaima singhNessuna valutazione finora

- Mosquito Repellent Activity of Essential Oils of Aromatic PlantsDocumento9 pagineMosquito Repellent Activity of Essential Oils of Aromatic PlantstmlNessuna valutazione finora

- Philippine Herbal MedicineDocumento28 paginePhilippine Herbal MedicineBianx BoseNessuna valutazione finora

- EXPANDING AESTHETIC BOUNDARIES OF AUSTRALIAN GARDEN DESIGN Georgia HarveyDocumento14 pagineEXPANDING AESTHETIC BOUNDARIES OF AUSTRALIAN GARDEN DESIGN Georgia Harveywilliamartin100% (1)

- RUBIACEAEDocumento24 pagineRUBIACEAEprofptrajasekharanNessuna valutazione finora

- Word Problems Problem Workbook PDFDocumento22 pagineWord Problems Problem Workbook PDFBobToms100% (2)

- 4770 20701 2 PB PDFDocumento13 pagine4770 20701 2 PB PDFAn JzahrulNessuna valutazione finora

- Rangari-B. Pharm - V-AS-2522-17.12.13 PDFDocumento15 pagineRangari-B. Pharm - V-AS-2522-17.12.13 PDFRamling PatrakarNessuna valutazione finora

- Flowers at NAACDocumento149 pagineFlowers at NAACManoj Shah0% (1)

- Croco Dahlia-UK TermsDocumento3 pagineCroco Dahlia-UK Termslectora100% (1)

- The Conceited AppleDocumento3 pagineThe Conceited Applebresail4Nessuna valutazione finora

- Farmar Problems and Role of Information Technology For AgricultureDocumento10 pagineFarmar Problems and Role of Information Technology For AgricultureGurjeet UppalNessuna valutazione finora

- Morphology and Anatomy of Flowering PlantsDocumento3 pagineMorphology and Anatomy of Flowering PlantsAyako HayashidaNessuna valutazione finora

- 7part1 4 1 PDFDocumento18 pagine7part1 4 1 PDFRyan WahyudiNessuna valutazione finora

- Dr. S. Thirumagan. PH.D.: University BuildingDocumento1 paginaDr. S. Thirumagan. PH.D.: University BuildingNandNNessuna valutazione finora

- Soal MID B. Inggris Kelas XI Genap 2023 - Akbar Ali Mustofa OkeDocumento4 pagineSoal MID B. Inggris Kelas XI Genap 2023 - Akbar Ali Mustofa OkeAkbar Ali MustofaNessuna valutazione finora

- Experimental Investigation On Drip Irrigation Using Moisture SensorDocumento6 pagineExperimental Investigation On Drip Irrigation Using Moisture SensorIJRASETPublicationsNessuna valutazione finora

- EthnoMedicinal Practices of Mamanwas - Eviota - PPTDocumento13 pagineEthnoMedicinal Practices of Mamanwas - Eviota - PPTShane AbeguelNessuna valutazione finora

- Soal BHS Inggris Kelas 6 SMT 2Documento4 pagineSoal BHS Inggris Kelas 6 SMT 2yuliNessuna valutazione finora

- Pliant Like The Bamboo (Icasiano V. Mallari)Documento2 paginePliant Like The Bamboo (Icasiano V. Mallari)Inez Chiara C. Cortes100% (4)

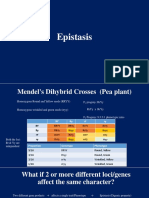

- Epistasis (Lect 16 & 17)Documento15 pagineEpistasis (Lect 16 & 17)Erum JanNessuna valutazione finora

- Nathanael Kean Dimasacat - Worksheet - Cells StructureDocumento4 pagineNathanael Kean Dimasacat - Worksheet - Cells StructureNathanael Kean DimasacatNessuna valutazione finora

- Plant Transport - IGCSE Biology Notes (2020)Documento6 paginePlant Transport - IGCSE Biology Notes (2020)Zhi En LeeNessuna valutazione finora

- Banana PDFDocumento47 pagineBanana PDFjrderamaNessuna valutazione finora

- GIUSTO, B. Et Al. 2010. Flower-Scent Mimicry Masks A Deadly Trap in The Carnivorous Plant Nepenthes RafflesianaDocumento12 pagineGIUSTO, B. Et Al. 2010. Flower-Scent Mimicry Masks A Deadly Trap in The Carnivorous Plant Nepenthes RafflesianahnmilanNessuna valutazione finora

- Region 10 CompilationDocumento2 pagineRegion 10 CompilationLaiza TadefaNessuna valutazione finora

- 7 Frida CAL Block 7 - Bouquet UK v5Documento6 pagine7 Frida CAL Block 7 - Bouquet UK v5Lucky CharmNessuna valutazione finora

- Spurge, Spotted (Prostrate Spurge) : (Chamaesyce Maculata (L.) Small) DescriptionDocumento4 pagineSpurge, Spotted (Prostrate Spurge) : (Chamaesyce Maculata (L.) Small) DescriptionAntony RajNessuna valutazione finora

- Durian Industries Limited - Durian Veneer CatalogueDocumento66 pagineDurian Industries Limited - Durian Veneer CatalogueLokesh LokiNessuna valutazione finora

- Cookware at Sears®: Egg Fried Rice-Easy Egg Fried Rice RecipeDocumento12 pagineCookware at Sears®: Egg Fried Rice-Easy Egg Fried Rice RecipeadhimadhuNessuna valutazione finora

- Shifts in An Invasive Rodent Community Favoring Black Rats (Rattus Rattus) Following Restoration of Native ForestDocumento9 pagineShifts in An Invasive Rodent Community Favoring Black Rats (Rattus Rattus) Following Restoration of Native Forestram manlaticanNessuna valutazione finora