Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TD - OPTIFLUX 1000 - en - 120927 - 4000690403 - R03

Caricato da

Javier vaca villalbaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TD - OPTIFLUX 1000 - en - 120927 - 4000690403 - R03

Caricato da

Javier vaca villalbaCopyright:

Formati disponibili

OPTIFLUX 1000 Technical Datasheet

Electromagnetic flow sensor in sandwich design

• Lightweight and compact

• Excellent price performance ratio

• Quick and easy to install

The documentation is only complete when used in combination with the relevant

documentation for the signal converter.

© KROHNE 10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en

CONTENTS OPTIFLUX 1000

1 Product features 3

1.1 Cost efficient and reliable flow sensor ............................................................................ 3

1.2 Options.............................................................................................................................. 5

2 Technical data 6

2.1 Technical data................................................................................................................... 6

2.2 Measuring accuracy ....................................................................................................... 10

2.3 Dimensions and weights ................................................................................................ 11

3 Installation 13

3.1 Notes on installation ...................................................................................................... 13

3.2 Intended use ................................................................................................................... 13

3.3 Installation conditions .................................................................................................... 13

3.3.1 Vibration ................................................................................................................................ 13

3.3.2 Magnetic field........................................................................................................................ 13

3.3.3 Inlet and outlet ...................................................................................................................... 14

3.3.4 Bends in 2 or 3 dimensions................................................................................................... 14

3.3.5 T-section ............................................................................................................................... 14

3.3.6 Bends .................................................................................................................................... 15

3.3.7 Open discharge ..................................................................................................................... 15

3.3.8 Flange deviation .................................................................................................................... 16

3.3.9 Pump ..................................................................................................................................... 16

3.3.10 Control valve ....................................................................................................................... 16

3.3.11 Air venting and vacuum forces ........................................................................................... 17

3.3.12 Mounting position................................................................................................................ 18

3.3.13 Temperatures ..................................................................................................................... 18

4 Electrical connections 19

4.1 Safety instructions.......................................................................................................... 19

4.2 Grounding ....................................................................................................................... 19

4.3 Virtual reference for IFC 300 (C, W and F version) ........................................................ 20

5 Notes 21

2 www.krohne.com 10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en

OPTIFLUX 1000 PRODUCT FEATURES 1

1.1 Cost efficient and reliable flow sensor

The flangeless OPTIFLUX 1000 electromagnetic flow sensor is compact and lightweight. The

design is robust with the highly resistant, reinforced PFA liner and Hastelloy electrodes,wich

offers n excellent chemical resistance

The device is a cost efficient and reliable solution for a wide range of applications. The best

economical choice for industries varying from water and wastewater, agriculture, utilisation and

from firefighting to machine building.

1 Sandwich design

2 PFA liner

3 Hastelloy electrodes

10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en www.krohne.com 3

1 PRODUCT FEATURES OPTIFLUX 1000

Highlights

• Sandwich (wafer) design

• Lightweight and compact for easy handling and space saving installation

• Affordable price

• Excellent chemical resistance

• Bi directional measurements

• No pressure loss

• Insensitive to vibrations

• No internal moving parts, no maintenance

Target Industries

• Machine building

• Energy, HVAC

• Water & waste water

• Process industries

Applications

• Mixing, batching and dosing systems, filtration systems, pump control

• Water flow monitoring

• Water circulation and treatment systems

• Fire-fighting systems, foam mixing, control of sprinkler systems

• Heat transfer and cooling systems

• Water including; raw water, process water, wastewater, salt water, hot and cold water

• Mud, slurry, sludge, manure

4 www.krohne.com 10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en

OPTIFLUX 1000 PRODUCT FEATURES 1

1.2 Options

The OPTIFLUX 1000OPTIFLUX

1000 1000 sensor is

available in a diameter range from DN10 up to

DN150. The compact flangeless flow sensor meets

all applicable process connections: EN 1092, DIN,

ANSI and JIS.

Signal converters

The OPTIFLUX 1000 sensor is compatible with the

IFC 050, IFC 100 and IFC 300 signal converter.

The flangeless flowmeter is suitable for compact

and remote (field) mounting.

10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en www.krohne.com 5

2 TECHNICAL DATA OPTIFLUX 1000

2.1 Technical data

• The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

• Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

Measuring system

Measuring principle Faraday's law of induction

Application range Electrically conductive fluids

Measured value

Primary measured value Flow velocity

Secondary measured value Volume flow

Design

Features Sandwich (wafer) design

PFA liner and Hastelloy electrodes

Light weight and compact

Modular construction The measurement system consists of a flow sensor and a signal converter.

It is available as compact and as separate version. Additional information

can be found in the documentation of the signal converter.

Compact version With IFC 050 converter: OPTIFLUX 1050 C

With IFC 100 converter: OPTIFLUX 1100 C

With IFC 300 converter: OPTIFLUX 1300 C

Remote version In wall (W) mount version with IFC 050 converter: OPTIFLUX 1050 W

In wall (W) mount version with IFC 100 converter: OPTIFLUX 1100 W

In field (F), wall (W) or rack (R) mount version with IFC 300 converter:

OPTIFLUX 1300 F, W or R

Nominal diameter DN10...150 / 3/8...6"

Measuring accuracy

Reference conditions Medium: water

Temperature +10...+30°C / +50...+86°F

Operating pressure: 1 bar / 14,5 psi

Inlet section ≥ 5 DN

Electrical conductivity: ≥ 300 µS/cm

Maximum measuring error IFC 050: down to 0,5% of the measured value above 0,5 m/s

below 0,5 m/s; deviation ± 2.5 mm/s

IFC 100: down to 0,4% of the measured value ± 1 mm/s

IFC 300: down to 0,3% of the measured value ± 2 mm/s

The maximum measuring error depends on the on the installation

conditions.

For detailed information refer to Measuring accuracy on page 10.

Repeatability ±0.1% of MV, minimum 1 mm/s

Calibration Standard: 2 point calibration by direct volume comparison.

Operating conditions

6 www.krohne.com 10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en

OPTIFLUX 1000 TECHNICAL DATA 2

Temperature

Process temperature -25...+120°C / -13...+248°F

Ambient temperature -25…+65°C / -13…+149°F

Storage temperature -50…+70°C / -58…+158°F

Measurement range -12...+12 m/s / -40...+40 ft/s

Pressure

Ambient pressure Atmospheric

Operating pressure up to 16 bar [230 psi]

Vacuum load 0 mbar / psi absolute

Pressure loss Negligible

Pressure ranges for Pressure resistant up to 40 bar / 580 psi

secondary containment

Burst pressure up to approx. 160 bar / 2320 psi

Chemical properties

Physical condition Electrically conductive liquids

Electrical conductivity Standard: ≥ 5 μS/cm

Demineralized water: ≥ 20 μS/cm

Permissible gas content IFC 050: ≤ 3%

(volume)

IFC 100: ≤ 3%

IFC 300: ≤ 5%

Permissible solid content IFC 050: ≤ 10%

(volume)

IFC 100: ≤ 10%

IFC 300: ≤ 70%

Installation conditions

Installation Assure that the flow sensor is always fully filled.

For detailed information refer to Installation on page 13

Flow direction Forward and reverse

Arrow on flow sensor indicates positive flow direction.

Inlet run ≥ 5 DN

Outlet run ≥ 2 DN

Dimensions and weights For detailed information refer to Technical data on page 6

10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en www.krohne.com 7

2 TECHNICAL DATA OPTIFLUX 1000

Materials

Sensor housing DN10...40: malleable iron ( GTW-S-38-12)

DN50...150: sheet steel

Other materials on request

Measuring tube Austenitic stainless steel

Liner PFA

Protective coating On exterior of the meter: housing, signal converter (compact version) and /

or connection box (field version)

Standard: Polyurethane coating

Connection box Only for remote versions

Standard: die-cast aluminium

Option: stainless steel

Measuring electrodes Hastelloy® C22

Grounding rings Standard: for DN10...15 (integrated in flow sensor construction)

Optional: for DN25...150

Stainless steel 316 (1.4571) (AISI 316 Ti)

Grounding rings can be omitted with virtual reference option for the

IFC 300 converter.

Mounting material DN40...150:

Standard: rubber centering sleeves

Option: galvanized steel or stainless steel stud bolts and nuts

Process connections

Counter flanges

EN 1092-1 DN10...80: PN16 or PN40 / DN100...150: PN16 (standard) PN40 on request

ASME 3/8...6" : 150 & 300 lb / RF

JIS DN10...100: JIS 20K / DN150: JIS 10K [≤ 16 bar]

Electrical connections

For full detail; see the relevant documentation of the signal converter

Signal cable (only for remote systems)

Type A (DS) In combination with the IFC 050, IFC 100 and IFC 300 signal converter

Standard cable, double shielded.

Max. length: 600 m / 1950 ft

(depends on electrical conductivity and measuring sensor).

Type B (BTS) Only in combination with the IFC 300 signal converter

Optional cable, triple shielded.

Max. length: 600 m / 1950 ft

(depends on electrical conductivity and measuring sensor).

I/O For full details of I/O options, including data streams and protocols, see

technical datasheet of the relevant signal converter.

8 www.krohne.com 10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en

OPTIFLUX 1000 TECHNICAL DATA 2

Approvals and certifications

CE

This device fulfills the statutory requirements of the EC directives. The

manufacturer certifies successful testing of the product by applying the CE

mark.

Electromagnetic Directive: 2004/108/EC

compatibility

Harmonized standard: EN 61326-1 : 2006

Low Voltage Directive Directive: 2006/95/EC

Harmonized standard: EN 61010 : 2001

Pressure Equipment Directive: 97/23/EC

Directive

Category I, II or SEP

Fluid group 1

Production module H

Hazardous areas

FM In combination with IFC 300

Class I, Div. 2, Groups A, B, C and D

Class II, Div. 2, Groups F and G

Class III, Div. 2, Groups F and G

CSA In combination with IFC 300

Class I, Div. 2, Groups A, B, C and D

Class II, Div. 2, Groups F and G

Other approvals and standards

Custody transfer Only in combination with IFC 300 signal converter

Cold water

MID Annex MI-001 type examination certificate

Liquids other than water

MID Annex MI-005 type examination certificate

Protection category acc. to Standard: IP66/67 (NEMA 4/4X/6)

IEC 529 / EN 60529

Optional: IP68 (NEMA 6P)

Shock test IEC 68-2-27

30 g for 18 ms

Vibration test IEC 68-2-64

f = 20/2000 Hz, rms = 4.5 g, t = 30 min.

10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en www.krohne.com 9

2 TECHNICAL DATA OPTIFLUX 1000

2.2 Measuring accuracy

Each flowmeter is standard wet calibrated under reference conditions by direct volume

comparison. The performance of the flowmeter is defined and documented in an individual

calibration certificate.

Reference conditions

• Medium: water

• Temperature: +10...30°C / +50...68°F

• Pressure: 1 bar / 14.5 psi

• Inlet section: ≥ 5 DN

• Electrical conductivity: ≥ 300 μS/cm

Figure 2-1: Flow velocity vs. accuracy

X [m/s]: flow velocity

Y [%]: deviation from the actual measured value (mv)

Accuracy

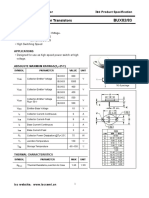

Sensor diameter Converter type Accuracy Curve

DN10...150 / 3/8...6" IFC 050 0.5% of mv above 0,5 m/s 3

4

DN10...150 / 3/8...6" IFC 100 0.4% of mv + 1 mm/s 2

DN10...150 / 3/8...6" IFC 300 0.3% of mv + 2 mm/s 1

4 ; below 0,5 m/s, deviation ± 2.5 mm/s

10 www.krohne.com 10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en

OPTIFLUX 1000 TECHNICAL DATA 2

2.3 Dimensions and weights

Remote version a = 88 mm / 3.1"

b = 139 mm / 5.5" 1

c = 106 mm / 4.2"

Total height = H + a

Compact version with a = 155 mm / 6.1"

IFC 300

b = 230 mm / 9.1" 1

c = 260 mm / 10.2"

Total height = H + a

Compact version with a = 82 mm / 3.2"

IFC 100 (0°)

(0 )

b = 161 mm / 6.3"

c = 257 mm / 10.1" 1

Total height = H + a

Compact version with a = 186 mm / 7.3"

IFC 100 (45°)

(45 )

b = 161 mm / 6.3"

c = 184 mm / 2.7" 1

Total height = H + a

Compact version with a = 101 mm / 3.98"

IFC 050 (10°)

(10 )

b = 157 mm / 6.18"

c = 260 mm / 10.24" 1

Total height = H + a

1 The value may vary depending on the used cable glands.

10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en www.krohne.com 11

2 TECHNICAL DATA OPTIFLUX 1000

• All data given in the following tables are based on standard versions of the sensor only.

• Especially for smaller nominal sizes of the sensor, the converter can be bigger than the

sensor.

• Note that for other pressure ratings than mentioned, the dimensions may be different.

• For full information on converter dimensions see relevant documentation.

EN 1092-1

Nominal size Dimensions [mm] Approx. weight

[kg]

DN L H W

10 68 137 47 1.7

15 68 137 47 1.7

25 54 147 66 1.7

40 78 162 82 2.6

50 100 151 101 4.2

80 150 180 130 5.7

100 200 207 156 10.5

150 200 271 219 15.0

ASME B16.5

Nominal size Dimensions [inches] Approx. weight

[lb]

ASME L H W

3/8" 2.68 5.39 1.85 3.7

½" 2.68 5.39 1.85 3.7

1" 2.13 5.79 2.6 3.7

1½" 3.07 6.38 3.23 5.7

2" 3.94 5.94 3.98 9.3

3" 5.91 7.08 5.12 12.6

4" 7.87 8.15 6.14 23.1

6" 7.87 10.67 8.62 33.1

12 www.krohne.com 10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en

OPTIFLUX 1000 INSTALLATION 3

3.1 Notes on installation

Inspect the cartons carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

Do a check of the packing list to make sure that you have all the elements given in the order.

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Intended use

Responsibility for the use of the measuring devices with regard to suitability, intended use and

corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

This electromagnetic flowmeter is designed exclusively to measure the flow of electrically

conductive, liquid media.

3.3 Installation conditions

3.3.1 Vibration

Figure 3-1: Avoid vibrations

3.3.2 Magnetic field

Figure 3-2: Avoid magnetic fields

10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en www.krohne.com 13

3 INSTALLATION OPTIFLUX 1000

3.3.3 Inlet and outlet

Use straight inlet- and outlet pipe sections, to prevent flow distortion or swirl, caused by bends

and T- sections

Figure 3-3: Recommended inlet and outlet

1 ; see § Bends in 2 or 3 dimensions

2 ; ≥ 2 DN

3.3.4 Bends in 2 or 3 dimensions

Figure 3-4: 2 and 3 dimensional bends, in front of flowmeter

Bends in 2 dimensions: 1 ≥ 5 DN, Bends in 3 dimensions: 1 ≥ 10 DN

3.3.5 T-section

Figure 3-5: Distance behind a T-section

1 ≥ 10 DN

14 www.krohne.com 10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en

OPTIFLUX 1000 INSTALLATION 3

3.3.6 Bends

Figure 3-6: Installation in bending pipes

Figure 3-7: Installation in bending pipes

Avoid draining or partial filling of the flow sensor

3.3.7 Open discharge

Figure 3-8: Installation in front of an open discharge

10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en www.krohne.com 15

3 INSTALLATION OPTIFLUX 1000

3.3.8 Flange deviation

Max. permissible deviation of pipe flange faces:

Lmax - Lmin ≤ 0.5 mm / 0.02"

Figure 3-9: Flange deviation

1 Lmax

2 Lmin

3.3.9 Pump

Figure 3-10: Installation behind a pump

3.3.10 Control valve

Figure 3-11: Installation in front of a control valve

16 www.krohne.com 10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en

OPTIFLUX 1000 INSTALLATION 3

3.3.11 Air venting and vacuum forces

Figure 3-12: Air venting

1 ≥5m

2 Air ventilation point

Figure 3-13: Vacuum

1 ≥5m

10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en www.krohne.com 17

3 INSTALLATION OPTIFLUX 1000

3.3.12 Mounting position

Figure 3-14: Mounting position

3.3.13 Temperatures

Protect the device from direct sunlight.

Temperature range Process [°C] Ambient [°C] Process [°F] Ambient [°F]

min. max. min. max. min. max. min. max.

Separate flow sensor -25 120 -25 65 -13 248 -13 149

Compact + IFC 300 -25 120 -25 65 -13 248 -13 149

Compact + IFC 100 -25 120 -25 65 -13 248 -13 149

Compact + IFC 050 -25 120 -25 65 -13 248 -13 149

18 www.krohne.com 10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en

OPTIFLUX 1000 ELECTRICAL CONNECTIONS 4

4.1 Safety instructions

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

Observe the national regulations for electrical installations!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

4.2 Grounding

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

Figure 4-1: Grounding

1 Metal pipelines, not internally coated. Grounding without grounding rings!

2 Metal pipelines with internal coating and non-conductive pipelines. Grounding with grounding rings!

Figure 4-2: Grounding ring number 1

Grounding ring number 1 (Optional for DN25...150):

• Thickness: 3 mm / 0.1" (tantalum: 0.5 mm / 0.02")

Note:

Note For diameter DN10 and DN15; groundingrings are standard integrated in the flow sensor

construction.

10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en www.krohne.com 19

4 ELECTRICAL CONNECTIONS OPTIFLUX 1000

4.3 Virtual reference for IFC 300 (C, W and F version)

The virtual reference option on the IFC 300 flow converter provides complete isolation of the

measurement circuit.

Benefits of virtual reference:

• Grounding rings or grounding electrodes can be omitted.

• Safety increases by reducing the number of potential leakage points.

• The installation of the flowmeters is much easier.

Figure 4-3: Virtual reference

Minimum requirements:

• Size: ≥ DN10

• Electrical conductivity: ≥ 200 µS/cm

• Electrode cable: max. 50 m / 164 ft, type DS

20 www.krohne.com 10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en

OPTIFLUX 1000 NOTES 5

10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en www.krohne.com 21

5 NOTES OPTIFLUX 1000

22 www.krohne.com 10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en

OPTIFLUX 1000 NOTES 5

10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en www.krohne.com 23

K K

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

•

© KROHNE 10/2012 - 4000690403 - TD OPTIFLUX 1000 R03 en - Subject to change without notice.

Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature meters

• Pressure meters

• Analysis products

• Products and systems for the oil & gas industry

• Measuring systems for the marine industry

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.:+49 (0)203 301 0

Fax:+49 (0)203 301 10389

info@krohne.de

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Potrebbero piacerti anche

- Optiflux 5000 Optiflux 5000 Optiflux 5000 Optiflux 5000: Electromagnetic Flowmeter in Sandwich VersionDocumento28 pagineOptiflux 5000 Optiflux 5000 Optiflux 5000 Optiflux 5000: Electromagnetic Flowmeter in Sandwich VersionJavierLugoNessuna valutazione finora

- TD - IFC100 - en - 180312 - 4000040506 - R06 Kronhe OPTIFLUX 2000Documento36 pagineTD - IFC100 - en - 180312 - 4000040506 - R06 Kronhe OPTIFLUX 2000TaQuangDucNessuna valutazione finora

- IFC 100 IFC 100 IFC 100 IFC 100: Signal Converter For Electromagnetic FlowmetersDocumento36 pagineIFC 100 IFC 100 IFC 100 IFC 100: Signal Converter For Electromagnetic FlowmetersEdwique Kudzai MukuzeNessuna valutazione finora

- IFC 300 IFC 300 IFC 300 IFC 300: Signal Converter For Electromagnetic FlowmetersDocumento52 pagineIFC 300 IFC 300 IFC 300 IFC 300: Signal Converter For Electromagnetic Flowmeterssajad hejaziNessuna valutazione finora

- Optiflux 4000Documento32 pagineOptiflux 4000jufrejjNessuna valutazione finora

- IFC 300 IFC 300 IFC 300 IFC 300: Signal Converter For Electromagnetic FlowmetersDocumento44 pagineIFC 300 IFC 300 IFC 300 IFC 300: Signal Converter For Electromagnetic FlowmetersSalgado BonéNessuna valutazione finora

- Optisonic 3400 Optisonic 3400 Optisonic 3400 Optisonic 3400Documento52 pagineOptisonic 3400 Optisonic 3400 Optisonic 3400 Optisonic 3400Didik WahyudiNessuna valutazione finora

- Krohne Flow Meter PDFDocumento40 pagineKrohne Flow Meter PDFavabhyankar9393Nessuna valutazione finora

- Optiswirl 4200 Optiswirl 4200 Optiswirl 4200 Optiswirl 4200: Vortex FlowmeterDocumento38 pagineOptiswirl 4200 Optiswirl 4200 Optiswirl 4200 Optiswirl 4200: Vortex FlowmeterJavier CarrizoNessuna valutazione finora

- H250 M40 H250 M40 H250 M40 H250 M40: Variable Area FlowmeterDocumento48 pagineH250 M40 H250 M40 H250 M40 H250 M40: Variable Area FlowmeterAbel VegaNessuna valutazione finora

- TD IFC050 en 130820 4002183702 R02Documento32 pagineTD IFC050 en 130820 4002183702 R02Sani PoulouNessuna valutazione finora

- Op Ti Flux 2000Documento32 pagineOp Ti Flux 2000Sergio Gomes100% (1)

- TD Optiflux4000 enDocumento44 pagineTD Optiflux4000 enVasileNessuna valutazione finora

- TD IFC100 en 140829 4000040504 R04Documento36 pagineTD IFC100 en 140829 4000040504 R04Fabio UnruhNessuna valutazione finora

- Krohne Accuracy CurveDocumento56 pagineKrohne Accuracy CurveBen DavisNessuna valutazione finora

- TD OPTIFLUX4000 en 140218 4000525103 R06 PDFDocumento40 pagineTD OPTIFLUX4000 en 140218 4000525103 R06 PDFJahidul IslamNessuna valutazione finora

- MFC 400 MFC 400 MFC 400 MFC 400: Signal Converter For Mass FlowmetersDocumento36 pagineMFC 400 MFC 400 MFC 400 MFC 400: Signal Converter For Mass FlowmetersCharles RodriguezNessuna valutazione finora

- TD OPTIFLUX4000 en 190921 4000525106 R09Documento44 pagineTD OPTIFLUX4000 en 190921 4000525106 R09Edwique Kudzai MukuzeNessuna valutazione finora

- TD OPTISONIC7300 en 180907 4001344705 R05Documento40 pagineTD OPTISONIC7300 en 180907 4001344705 R05Didik WahyudiNessuna valutazione finora

- Ultrasonico Krohne 3400Documento52 pagineUltrasonico Krohne 3400Fer PabNessuna valutazione finora

- TD OPTIFLUX4000 en 220106 4000525107 R10Documento48 pagineTD OPTIFLUX4000 en 220106 4000525107 R10AugustoNessuna valutazione finora

- Krohne OPTIFLUX2000 DatasheetDocumento36 pagineKrohne OPTIFLUX2000 DatasheetFrancisco GalleguillosNessuna valutazione finora

- Krohne mfc400 DatasheetDocumento32 pagineKrohne mfc400 DatasheetArnezNessuna valutazione finora

- MFC 400 KrohneDocumento36 pagineMFC 400 Krohnebokachoda786Nessuna valutazione finora

- AFC 030 ConverterDocumento32 pagineAFC 030 ConverteracromanNessuna valutazione finora

- Mass Flow MeterDocumento32 pagineMass Flow MeterClash KingNessuna valutazione finora

- TD OPTISONIC4400 en 170320 4003958501 R01Documento48 pagineTD OPTISONIC4400 en 170320 4003958501 R01Didik WahyudiNessuna valutazione finora

- TDC1000 Ultrasonic Sensing Analog Front End (AFE) For Level Sensing, Flow Sensing, Concentration Sensing, and Proximity Sensing ApplicationsDocumento60 pagineTDC1000 Ultrasonic Sensing Analog Front End (AFE) For Level Sensing, Flow Sensing, Concentration Sensing, and Proximity Sensing ApplicationsRiky Maulana FirdausNessuna valutazione finora

- Optimass 1400 Tech DatasheetDocumento32 pagineOptimass 1400 Tech DatasheetAbid Hossain RupamNessuna valutazione finora

- tdc1000 q1 PDFDocumento60 paginetdc1000 q1 PDFNorbey Barajas BustosNessuna valutazione finora

- Transmitters FCX - A II Series CatalogueDocumento36 pagineTransmitters FCX - A II Series CatalogueIsthiaq ahmedNessuna valutazione finora

- Optibar DP 7060 Optibar DP 7060 Optibar DP 7060 Optibar DP 7060Documento52 pagineOptibar DP 7060 Optibar DP 7060 Optibar DP 7060 Optibar DP 7060SafiaMohamedNessuna valutazione finora

- Optibar DP 7060 Optibar DP 7060 Optibar DP 7060 Optibar DP 7060Documento52 pagineOptibar DP 7060 Optibar DP 7060 Optibar DP 7060 Optibar DP 7060Luz Stella Calixto GomezNessuna valutazione finora

- TD OPTIBAR LC1010C en 160318 4005075701 R01 PRT 1000346341 1Documento20 pagineTD OPTIBAR LC1010C en 160318 4005075701 R01 PRT 1000346341 1sgangaraj093010Nessuna valutazione finora

- Pss - 1-6h7a - A 8400A (PFA)Documento28 paginePss - 1-6h7a - A 8400A (PFA)schreyarNessuna valutazione finora

- ITT Cannon Filter Connectors CatalogDocumento47 pagineITT Cannon Filter Connectors CatalogDenzil LawrenceNessuna valutazione finora

- AC Current Probe For Oscilloscopes: Users ManualDocumento20 pagineAC Current Probe For Oscilloscopes: Users ManualShakeel AnsariNessuna valutazione finora

- UCC25600 8-Pin High-Performance Resonant Mode Controller: 1 Features 3 DescriptionDocumento29 pagineUCC25600 8-Pin High-Performance Resonant Mode Controller: 1 Features 3 Descriptionthe profeNessuna valutazione finora

- UCC25600 8-Pin High-Performance Resonant Mode Controller: 1 Features 3 DescriptionDocumento32 pagineUCC25600 8-Pin High-Performance Resonant Mode Controller: 1 Features 3 DescriptionNasser NajaNessuna valutazione finora

- UCC25600 8-Pin High-Performance Resonant Mode Controller: 1 Features 3 DescriptionDocumento31 pagineUCC25600 8-Pin High-Performance Resonant Mode Controller: 1 Features 3 DescriptionSingam SridharNessuna valutazione finora

- Gifghig464 PDFDocumento24 pagineGifghig464 PDFahmed nawaz100% (1)

- Opticheck Opticheck Opticheck OpticheckDocumento16 pagineOpticheck Opticheck Opticheck OpticheckOmar AzzainNessuna valutazione finora

- Foxboro Flowmeter Pss1 - 6h4aDocumento36 pagineFoxboro Flowmeter Pss1 - 6h4aMukti AwanNessuna valutazione finora

- OtisonicDocumento32 pagineOtisonicsenthilrsenthilNessuna valutazione finora

- Krohne WATERFLUX3000 DatasheeDocumento36 pagineKrohne WATERFLUX3000 DatasheeAllan FurukawaNessuna valutazione finora

- Broch Specs EnglDocumento12 pagineBroch Specs EnglSteve WanNessuna valutazione finora

- Pointek CLS100 Capacitance Level InstructionDocumento25 paginePointek CLS100 Capacitance Level InstructionSırrı SeyrekNessuna valutazione finora

- Icoupler Digital Isolator: Adum1100Documento20 pagineIcoupler Digital Isolator: Adum1100teomondoNessuna valutazione finora

- Xrs-5 Transducer: Instruction Manual PL-590 January 2001Documento23 pagineXrs-5 Transducer: Instruction Manual PL-590 January 2001rohitdakngNessuna valutazione finora

- KEMA99ATEX1157Documento52 pagineKEMA99ATEX1157max barrosNessuna valutazione finora

- Transdutor Linear de Haste BTL7Documento24 pagineTransdutor Linear de Haste BTL7alamsyah_syamNessuna valutazione finora

- Liquiphant M FTL50 (H), FTL51 (H) : Technical InformationDocumento64 pagineLiquiphant M FTL50 (H), FTL51 (H) : Technical InformationsdgsghdfhNessuna valutazione finora

- BIOBASE Vertical Laminar Flow Cabinet BBS-DDC'SDC User Manual 202109Documento25 pagineBIOBASE Vertical Laminar Flow Cabinet BBS-DDC'SDC User Manual 202109SACO QCNessuna valutazione finora

- Optisonic 3400: Ultrasonic Flowmeter For Liquids in All Industrial ApplicationsDocumento16 pagineOptisonic 3400: Ultrasonic Flowmeter For Liquids in All Industrial ApplicationsOmar SaeedNessuna valutazione finora

- Instruction Manual FA 500Documento32 pagineInstruction Manual FA 500Budi SusantoNessuna valutazione finora

- Optisonic 6300 P Optisonic 6300 P Optisonic 6300 P Optisonic 6300 PDocumento32 pagineOptisonic 6300 P Optisonic 6300 P Optisonic 6300 P Optisonic 6300 PCristina GrecuNessuna valutazione finora

- Khrone 5 Beam Flow Meter DatasheetDocumento16 pagineKhrone 5 Beam Flow Meter DatasheetAnoop ChulliyanNessuna valutazione finora

- Optical Detectors Power Meter Kingfisher ManualDocumento34 pagineOptical Detectors Power Meter Kingfisher ManualMiguel San Román RosellNessuna valutazione finora

- Da Optibatch4011cDocumento24 pagineDa Optibatch4011cCharles RodriguezNessuna valutazione finora

- ANSI Flange RatingsDocumento3 pagineANSI Flange RatingsJavier vaca villalbaNessuna valutazione finora

- Manual DR900 HachDocumento358 pagineManual DR900 HachJonathan GalindoNessuna valutazione finora

- Excel TipsDocumento18 pagineExcel TipsJavier vaca villalbaNessuna valutazione finora

- Danalyzer 2350 GCDocumento306 pagineDanalyzer 2350 GCAlexisLopezNessuna valutazione finora

- MA - OPTIFLUX 1000 - en - 120927 - 4000846302 - R02Documento32 pagineMA - OPTIFLUX 1000 - en - 120927 - 4000846302 - R02Javier vaca villalbaNessuna valutazione finora

- 96e FDocumento72 pagine96e FWardanedNessuna valutazione finora

- Danalyzer Model 565Documento306 pagineDanalyzer Model 565Javier vaca villalbaNessuna valutazione finora

- HB - WATERFLUX 3000 - en - 121116 - 4001626603 - R04Documento40 pagineHB - WATERFLUX 3000 - en - 121116 - 4001626603 - R04Javier vaca villalbaNessuna valutazione finora

- Danalyzer Model 570 (2350A)Documento296 pagineDanalyzer Model 570 (2350A)Javier vaca villalbaNessuna valutazione finora

- Danalyzer Model 575Documento194 pagineDanalyzer Model 575Javier vaca villalbaNessuna valutazione finora

- N. Maintenance 5.07 (Compatibility Mode)Documento60 pagineN. Maintenance 5.07 (Compatibility Mode)Javier vaca villalbaNessuna valutazione finora

- QS - OPTIFLUX 1000 - en - 121030 - 4002298401 - R05Documento20 pagineQS - OPTIFLUX 1000 - en - 121030 - 4002298401 - R05Javier vaca villalbaNessuna valutazione finora

- Aspen HYSYSCustomization GuideDocumento353 pagineAspen HYSYSCustomization GuideEric RousselNessuna valutazione finora

- Specifications: Our Job Is To Serve - . - and We Take It Very SeriouslyDocumento5 pagineSpecifications: Our Job Is To Serve - . - and We Take It Very SeriouslyJavier vaca villalbaNessuna valutazione finora

- HB - WATERFLUX 3000 - en - 121116 - 4001626603 - R04Documento40 pagineHB - WATERFLUX 3000 - en - 121116 - 4001626603 - R04Javier vaca villalbaNessuna valutazione finora

- Manual DR900 HachDocumento358 pagineManual DR900 HachJonathan GalindoNessuna valutazione finora

- Danalyzer Model 575Documento194 pagineDanalyzer Model 575Javier vaca villalbaNessuna valutazione finora

- 9b Gasspec Cs 1110Documento4 pagine9b Gasspec Cs 1110Javier vaca villalbaNessuna valutazione finora

- Material Safety Data Sheet: Chemtherm 550Documento6 pagineMaterial Safety Data Sheet: Chemtherm 550Javier vaca villalbaNessuna valutazione finora

- CAP X - Acondicionamiento y Deshidratacion de Gas-REPSOLDocumento1 paginaCAP X - Acondicionamiento y Deshidratacion de Gas-REPSOLJavier vaca villalbaNessuna valutazione finora

- Copia de HYSYSplotsDocumento10 pagineCopia de HYSYSplotsJavier vaca villalbaNessuna valutazione finora

- Warranty Toshiba Canvio HDDocumento6 pagineWarranty Toshiba Canvio HDAndrew VasylukNessuna valutazione finora

- Jump Start Aspen HYSYS V8Documento29 pagineJump Start Aspen HYSYS V8hayfronbsterNessuna valutazione finora

- Sampling Cylinder SystemDocumento14 pagineSampling Cylinder SystemsudjonoNessuna valutazione finora

- ONGC - Internship - Report Please Don't Edit Directly Make A Copy of This FileDocumento65 pagineONGC - Internship - Report Please Don't Edit Directly Make A Copy of This File19024 Fenil PatelNessuna valutazione finora

- Lecture 2Documento8 pagineLecture 2salmanqaadirNessuna valutazione finora

- Processing Cacao Pod Husk into Low-Methoxyl PectinDocumento9 pagineProcessing Cacao Pod Husk into Low-Methoxyl PectinEmmanuel PlazaNessuna valutazione finora

- Cell Membrane TransportDocumento37 pagineCell Membrane TransportMaya AwadNessuna valutazione finora

- Railway Recruitment Board Level-1 Exam DetailsDocumento2 pagineRailway Recruitment Board Level-1 Exam Detailsrajesh naikNessuna valutazione finora

- Basic Principles of Erp RecordingDocumento14 pagineBasic Principles of Erp Recordingkeihoina keihoinaNessuna valutazione finora

- SerieventilacionDocumento37 pagineSerieventilacionCaexvenNessuna valutazione finora

- Proton Pump Inhibitors v3Documento5 pagineProton Pump Inhibitors v3shwampaNessuna valutazione finora

- SFNHS - Extension's School Learning Continuity PlanDocumento5 pagineSFNHS - Extension's School Learning Continuity PlanClaudie MabiniNessuna valutazione finora

- PSY406-MidTerm SolvedbymeDocumento6 paginePSY406-MidTerm SolvedbymeAhmed RajpootNessuna valutazione finora

- Test - Ans SEAFOOD COOKERY 10Documento7 pagineTest - Ans SEAFOOD COOKERY 10EVANGELINE VILLASICANessuna valutazione finora

- Cable Laying and Pulling JSEADocumento17 pagineCable Laying and Pulling JSEAJayson EscamillanNessuna valutazione finora

- ZDHCPNP V3.0Documento13 pagineZDHCPNP V3.0Wendo BijaksonoNessuna valutazione finora

- Prathamesh 9 TH DDocumento20 paginePrathamesh 9 TH Dnikita londhe100% (1)

- Isc BUX82/83: Isc Silicon NPN Power TransistorsDocumento2 pagineIsc BUX82/83: Isc Silicon NPN Power TransistorsCarlos HCNessuna valutazione finora

- PE and Health 3 Week 2 FINALDocumento8 paginePE and Health 3 Week 2 FINALFritzie SulitanaNessuna valutazione finora

- Ds 1018Documento2 pagineDs 1018Ramesh ChandNessuna valutazione finora

- Aafreen Project Report SIPDocumento19 pagineAafreen Project Report SIPshubham moonNessuna valutazione finora

- SE7000 Application GuideDocumento102 pagineSE7000 Application GuideHujiLokoNessuna valutazione finora

- Nadilla Choerunnisa 2B S.KepDocumento3 pagineNadilla Choerunnisa 2B S.KepNadilla ChoerunnisaNessuna valutazione finora

- Dna BHP AllInOne 2021-04 ENDocumento1 paginaDna BHP AllInOne 2021-04 ENKevin Patrick PalmerNessuna valutazione finora

- Homework 1Documento10 pagineHomework 1Nam Anh KiraiNessuna valutazione finora

- Regulatory Updates on Japan's MO169 Medical Device Quality Management OrdinanceDocumento7 pagineRegulatory Updates on Japan's MO169 Medical Device Quality Management OrdinanceHong XuyenNessuna valutazione finora

- HVAC Psychrometric Analysis To Avoid Moisture ProblemsDocumento30 pagineHVAC Psychrometric Analysis To Avoid Moisture ProblemsmohdrashidNessuna valutazione finora

- Crude Palm Oil MSDS Provides Safety InformationDocumento3 pagineCrude Palm Oil MSDS Provides Safety InformationCarlos MontanoNessuna valutazione finora

- Green Destination (HR Analytics)Documento16 pagineGreen Destination (HR Analytics)snehal patilNessuna valutazione finora

- Pehealth11 q2 Mod2of2 H.O.P.E v2Documento26 paginePehealth11 q2 Mod2of2 H.O.P.E v2Avillz Mar LeeNessuna valutazione finora

- SSC DWDocumento4 pagineSSC DWsanketpavi21Nessuna valutazione finora

- P50 Agile: GE Grid SolutionsDocumento268 pagineP50 Agile: GE Grid SolutionsPrasenjit MaityNessuna valutazione finora

- Test Bank For Cultural Diversity in Health and Illness 8th Edition Rachel e SpectorDocumento25 pagineTest Bank For Cultural Diversity in Health and Illness 8th Edition Rachel e SpectorCatherine Smith100% (32)