Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Elearnica - Ir 637239463318957740

Caricato da

taghdirimTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Elearnica - Ir 637239463318957740

Caricato da

taghdirimCopyright:

Formati disponibili

EXCHANGE OF EXPERIENCE

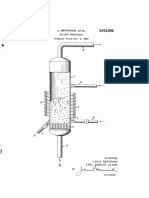

KAOLIN CHAMOTTE PRODUCED BY CALCINATION

V. P. Zibrov UDC 666.763.2.666.3.041

A kaolin calcination section of an output capacity of 50,000 ton per annum came on stream at the

Prosyanov Refractories Combine in 1970. The starting materials are wet-coneentrated and dry-concen-

trated Prosyanov kaolin.

According to Teehnieal Specifications TU 21-7-46-71 the moisture absorption of kaolin chamotte

should not exceed 10% and the calcination loss 0.5%.

The moisture absorption and calcination loss of the Prosyanov chamotte are about half these values

as a result of the calcination conditions introduced at the plant, viz., maximum calcination temperature

1500~C, cold kiln-head temperature 700"C, temperature upstream from the flue fan 120-140~C, residual

pressure (ram Hg) 2 in the hot kiln-head, i0-15 in the cold kiln-head, I00-120 upstream from the dust traps,

and 180-290 upstream from the flue fan.

The set-concentration kaolin has a moisture content of 20% or less and is calcined in a 40 m long

rotary kiln 2.5 rn in diameter with an output capacity of 6.2 ton/day.

The calcined kaolin is conveyed to a 22 m long cooler 2.3 m in diameter in which iris cooled to 50-

70~C. Next, a belt conveyer moves the material to a storage hopper from which it is loaded into railroad

trucks to be shipped to the users.

The Mln is fired by natural gas from the Shebelinsk deposits. The combustion products pass from the

kiln to a dust chamber, then to two groups of TsN-15 cyclones with six cyclones in each. The third cleans-

ing stage is in the form of a system of three SIOT No. 6 dust traps. The negative pressure is produced by

the No. 13.5 flue fan.

From the hoppers of the dust chamber and cyclones the dust is conveyed by augers to a double-shafted

mixer for wetting and, next by belt conveyer to the briquetting plant. The briquets are first in the kiln.

The dry-concentrated kaolin ks briquetted before roasting. A bucket conveyer moves the material

from the dry-concentration plant to a hopper in the briquetting division from where it is conveyed to a

double-shafted mixer for wetting and mixing. The briquets are formed in a roll press and then moved by

belt conveyer into the kiln for roasting.

Prosyanov Refractories Combine. Translated from Ogneupory, No. 10, p' 60, October, 1973.

9 1974 Consultants Bureau, a division of Plenum Publishing Corporation, 227 ff'est ]7th Street, New York, N. Y. lO0]l.

~o part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any .form or by any means,

electronic, mechanical, photocopying, microfilming, recording or otherwise, without written permission of the publisher. ,'t

copy of this article is available from the publisher .[or $15.00.

659

Potrebbero piacerti anche

- Introspective Hypnosis Class - 052017 - Antonio Sangio (2745)Documento62 pagineIntrospective Hypnosis Class - 052017 - Antonio Sangio (2745)sandra100% (4)

- mf8240 160824142620 PDFDocumento698 paginemf8240 160824142620 PDFArgopartsNessuna valutazione finora

- Cement ManufacturingDocumento10 pagineCement Manufacturinglawrence catipayNessuna valutazione finora

- Methods, Processes and Equipment Involved in Manufacturing CementDocumento26 pagineMethods, Processes and Equipment Involved in Manufacturing CementNiño Gerard JabagatNessuna valutazione finora

- Types and Forms of CommunicationDocumento22 pagineTypes and Forms of CommunicationayeshaNessuna valutazione finora

- Ash Handling Plant - by Ratan RoyDocumento31 pagineAsh Handling Plant - by Ratan RoyPoonam CrossyNessuna valutazione finora

- Ultra tech Cement Tadipatri Plant OverviewDocumento18 pagineUltra tech Cement Tadipatri Plant OverviewAshutosh SinghNessuna valutazione finora

- Law As A Command of SovereignDocumento12 pagineLaw As A Command of SovereignAdv BL Dewasi100% (2)

- Wet Cooling Towers: Rule-of-Thumb Design and SimulationDocumento32 pagineWet Cooling Towers: Rule-of-Thumb Design and SimulationMohammed Alnefayei100% (10)

- Shell Welding ProcedureDocumento7 pagineShell Welding ProcedurePravesh Modi100% (1)

- Training Manual For CIL & Elution-Final (Reviewed)Documento29 pagineTraining Manual For CIL & Elution-Final (Reviewed)mani_mett100% (5)

- Branding & Advertising (T NG H P) PDFDocumento44 pagineBranding & Advertising (T NG H P) PDFNguyễn Ngọc Quỳnh Anh100% (1)

- Cement Plant Training ReportDocumento26 pagineCement Plant Training ReportHimadri MahatoNessuna valutazione finora

- A. Indira National Power Training InstituteDocumento80 pagineA. Indira National Power Training InstituteAyan MajiNessuna valutazione finora

- Rotary Thermal Dryer Design Book - FeecoDocumento9 pagineRotary Thermal Dryer Design Book - Feecorajeevup2004Nessuna valutazione finora

- FSR & FST First Stage Regulator: Maintenance Manual FOR Authorised TechniciansDocumento23 pagineFSR & FST First Stage Regulator: Maintenance Manual FOR Authorised TechniciansпавелNessuna valutazione finora

- Project Report ON Proposed Coal Washing Plant AT Korba AreaDocumento23 pagineProject Report ON Proposed Coal Washing Plant AT Korba AreaAmitesh Joseph75% (4)

- Kiln Audit Training DetailsDocumento20 pagineKiln Audit Training DetailsTamer Fathy100% (5)

- Thermal Power Plant Plomin 2 Technical OverviewDocumento20 pagineThermal Power Plant Plomin 2 Technical OverviewdayiroNessuna valutazione finora

- Cement Mill ReportDocumento13 pagineCement Mill ReportYhaneNessuna valutazione finora

- The Calcination of Kaolin ClayDocumento7 pagineThe Calcination of Kaolin ClaytaghdirimNessuna valutazione finora

- Profitable Calcining of Non-Calcinable Pet CokeDocumento4 pagineProfitable Calcining of Non-Calcinable Pet CokeAchyutha SreeniNessuna valutazione finora

- Heat Transfer in Rotary KilnsDocumento6 pagineHeat Transfer in Rotary KilnsRafael Curiel MedinaNessuna valutazione finora

- Volume 3 Burning WorkshopDocumento59 pagineVolume 3 Burning WorkshopmkpqNessuna valutazione finora

- 17-Determination of FinenessDocumento13 pagine17-Determination of FinenessNatsir DjafarNessuna valutazione finora

- Rotary Kiln - Inst Manual English - Version 2015Documento55 pagineRotary Kiln - Inst Manual English - Version 2015taghdirim100% (5)

- Sinter PlantDocumento14 pagineSinter PlantKannan ThangarajuNessuna valutazione finora

- Rotary Dryer HandbookDocumento34 pagineRotary Dryer Handbook11331490% (10)

- Clinker Production Course - Cyclone Preheater OperationDocumento26 pagineClinker Production Course - Cyclone Preheater OperationAndreea Ștefura100% (1)

- Recovery methods at Huaron silver mineDocumento2 pagineRecovery methods at Huaron silver mineMax SalasNessuna valutazione finora

- La PlataDocumento31 pagineLa Platamarco valdiviezoNessuna valutazione finora

- Process: - : Hathi and Siddhi CementDocumento9 pagineProcess: - : Hathi and Siddhi CementJessica RobinsonNessuna valutazione finora

- Cement Mining and ManufacturingDocumento3 pagineCement Mining and ManufacturingEmmanuel ChibweNessuna valutazione finora

- Cement Manufacturing ProcessDocumento10 pagineCement Manufacturing ProcessKevin BlotsNessuna valutazione finora

- US3012862 Si Halide With Hydrogen PatentDocumento7 pagineUS3012862 Si Halide With Hydrogen PatentLiya Elizabeth JacobNessuna valutazione finora

- Calcium Hypochlorite Manufacturing Process GuideDocumento11 pagineCalcium Hypochlorite Manufacturing Process GuideUditKanoiNessuna valutazione finora

- OverviewDocumento24 pagineOverviewRishabh UpadhyayNessuna valutazione finora

- CM2019 KetinDocumento12 pagineCM2019 KetinMahdi koolivandNessuna valutazione finora

- Assignment On Operation Process of Jaypee Cement Plant: Sumbitted By: Anmol Garg (A1802014082) Mba-IbDocumento13 pagineAssignment On Operation Process of Jaypee Cement Plant: Sumbitted By: Anmol Garg (A1802014082) Mba-Ibanmolgarg129Nessuna valutazione finora

- SomincorDocumento21 pagineSomincorBruno CostaNessuna valutazione finora

- Pongkor Process Plant OverviewDocumento17 paginePongkor Process Plant OverviewImam SidikNessuna valutazione finora

- Accelerated drying of ceramic sanitary wareDocumento4 pagineAccelerated drying of ceramic sanitary wareRafaelNessuna valutazione finora

- Decreasing Pollutant Emissions..., Z.OsmanovicDocumento5 pagineDecreasing Pollutant Emissions..., Z.OsmanovicnasoonyNessuna valutazione finora

- Operational Experience With A 100 KW Solar Pilot Plant For Thermal Dissociation of Zinc OxideDocumento8 pagineOperational Experience With A 100 KW Solar Pilot Plant For Thermal Dissociation of Zinc OxidenospamplzNessuna valutazione finora

- Preparation of Si Wafer - PhotolithographyDocumento3 paginePreparation of Si Wafer - PhotolithographyAdams OdanjiNessuna valutazione finora

- CIL Process Plant Process DescriptionDocumento3 pagineCIL Process Plant Process DescriptionJheffersonNessuna valutazione finora

- Inplant TrainingDocumento13 pagineInplant TrainingAnnamalai PalaniappanNessuna valutazione finora

- WasheryDocumento4 pagineWasherysaisssms9116Nessuna valutazione finora

- Cement Manufacturing ProcessDocumento13 pagineCement Manufacturing ProcessDovah KiinNessuna valutazione finora

- Somil SewagramDocumento53 pagineSomil SewagramSomil GuptaNessuna valutazione finora

- Additional Process That Have To Be Available For The ProjectDocumento8 pagineAdditional Process That Have To Be Available For The Projectkarin33Nessuna valutazione finora

- Process Descp. Start-Up OperationDocumento24 pagineProcess Descp. Start-Up OperationManoj KumarNessuna valutazione finora

- 9 NCRIET (Automation of Clinker Cooling System Using PLC)Documento6 pagine9 NCRIET (Automation of Clinker Cooling System Using PLC)Phillip007Nessuna valutazione finora

- Manufacturing Process of Nylon 6,6 and Nylon 6Documento3 pagineManufacturing Process of Nylon 6,6 and Nylon 6Ranjana RajanNessuna valutazione finora

- Cleaner Production Assessment in CementDocumento5 pagineCleaner Production Assessment in CementMadanKarkiNessuna valutazione finora

- Comonomer PurificationDocumento2 pagineComonomer PurificationJuvielyn Garcia100% (1)

- Crystallization 0f SorbitolDocumento5 pagineCrystallization 0f SorbitolPiso VươngNessuna valutazione finora

- H3T Ooo: J. R. Crawford Drying Method and Apparatus Filed June 8, 1961Documento7 pagineH3T Ooo: J. R. Crawford Drying Method and Apparatus Filed June 8, 1961Nur Aina Ramadhani PurbaNessuna valutazione finora

- UNIT VDocumento23 pagineUNIT VDhilsanth SLNessuna valutazione finora

- History of Company and Alumina Refinery ProcessDocumento24 pagineHistory of Company and Alumina Refinery Processsrinibashb5546Nessuna valutazione finora

- Introduction To Coal Handling PlantDocumento12 pagineIntroduction To Coal Handling PlantPramod R BidveNessuna valutazione finora

- Gu'Idelines For Manufacture OF $ Gypsum Plaster in 1L Iechanized ' Pan System w?hmw6 !Documento7 pagineGu'Idelines For Manufacture OF $ Gypsum Plaster in 1L Iechanized ' Pan System w?hmw6 !SubhasRajuNessuna valutazione finora

- Putus Asa FilterDocumento20 paginePutus Asa FilterLuthfi AinunNessuna valutazione finora

- F43-Obajana Line 3-PM-04 - Clinker ProductionDocumento109 pagineF43-Obajana Line 3-PM-04 - Clinker ProductionYhane Hermann BackNessuna valutazione finora

- Gypsum Mining and Manufacturing ProcessesDocumento18 pagineGypsum Mining and Manufacturing ProcessesminingnovaNessuna valutazione finora

- Cyclon Adn FBRDocumento9 pagineCyclon Adn FBRDicky ANdestaNessuna valutazione finora

- The Explosion at Dow Kings LynnDocumento19 pagineThe Explosion at Dow Kings LynnBurgosg ValeryNessuna valutazione finora

- PET OverviewDocumento38 paginePET OverviewMunnawar Hayat100% (1)

- Coffee Making: Instant PRDocumento3 pagineCoffee Making: Instant PRAravindNessuna valutazione finora

- Us2067043 PDFDocumento4 pagineUs2067043 PDFRonak AdrojaNessuna valutazione finora

- Pig ReportDocumento6 paginePig ReportEslam ShiblNessuna valutazione finora

- Scientific American Supplement, No. 446, July 19, 1884Da EverandScientific American Supplement, No. 446, July 19, 1884Nessuna valutazione finora

- Scientific American Supplement, No. 481, March 21, 1885Da EverandScientific American Supplement, No. 481, March 21, 1885Nessuna valutazione finora

- Analysis of Cyclone Pressure Drop-IMPRIMIRDocumento7 pagineAnalysis of Cyclone Pressure Drop-IMPRIMIRMariana PatiñoNessuna valutazione finora

- Vibratory Conveying - Analysis and Design: A ReviewDocumento9 pagineVibratory Conveying - Analysis and Design: A ReviewtaghdirimNessuna valutazione finora

- Analysis of Cyclone Pressure Drop-IMPRIMIRDocumento7 pagineAnalysis of Cyclone Pressure Drop-IMPRIMIRMariana PatiñoNessuna valutazione finora

- New Understanding Compressor CapacityDocumento7 pagineNew Understanding Compressor CapacityJose SanchezNessuna valutazione finora

- Lime - Shaft Furnaces or Rotary Furnaces - StrommashinaDocumento5 pagineLime - Shaft Furnaces or Rotary Furnaces - StrommashinataghdirimNessuna valutazione finora

- Cooling Technology - Cooling TowersDocumento2 pagineCooling Technology - Cooling TowerstaghdirimNessuna valutazione finora

- 0354-98361800278F Dolomite Sintering in Shaft Kiln PDFDocumento13 pagine0354-98361800278F Dolomite Sintering in Shaft Kiln PDFtaghdirimNessuna valutazione finora

- 0354-98361800278F Dolomite Sintering in Shaft Kiln PDFDocumento13 pagine0354-98361800278F Dolomite Sintering in Shaft Kiln PDFtaghdirimNessuna valutazione finora

- The Design of Rotary Kiln With Cyclonic Heat ExchangersDocumento33 pagineThe Design of Rotary Kiln With Cyclonic Heat ExchangersAuliverKayMHNessuna valutazione finora

- Hardness Comparison - WikipediaDocumento4 pagineHardness Comparison - WikipediataghdirimNessuna valutazione finora

- Thermo-Economic Study of Hybrid Cooling Tower Systems: Full Length Research PaperDocumento15 pagineThermo-Economic Study of Hybrid Cooling Tower Systems: Full Length Research PapertaghdirimNessuna valutazione finora

- DheerajDocumento7 pagineDheerajSaksham KakarNessuna valutazione finora

- Fire Clay Composition & PropertiesDocumento4 pagineFire Clay Composition & PropertiestaghdirimNessuna valutazione finora

- Elearnica - Ir 637238678867853160Documento7 pagineElearnica - Ir 637238678867853160taghdirimNessuna valutazione finora

- Elearnica - Ir 637241874011988823Documento6 pagineElearnica - Ir 637241874011988823taghdirimNessuna valutazione finora

- Calcining MagnesiteDocumento6 pagineCalcining Magnesitetaghdirim100% (1)

- 0354-98361800278F Dolomite Sintering in Shaft KilnDocumento13 pagine0354-98361800278F Dolomite Sintering in Shaft KilntaghdirimNessuna valutazione finora

- Elearnica - Ir 637241874011988823Documento6 pagineElearnica - Ir 637241874011988823taghdirimNessuna valutazione finora

- Energy Changes When Kaolin Minerals Are HeatedDocumento10 pagineEnergy Changes When Kaolin Minerals Are HeatedtaghdirimNessuna valutazione finora

- Elearnica - Ir 637250702601036672Documento7 pagineElearnica - Ir 637250702601036672taghdirimNessuna valutazione finora

- Fire Clay Composition & PropertiesDocumento4 pagineFire Clay Composition & PropertiestaghdirimNessuna valutazione finora

- 10 1016@j Ceramint 2007 02 012 PDFDocumento7 pagine10 1016@j Ceramint 2007 02 012 PDFlami75Nessuna valutazione finora

- Suggested For You: 15188 5 Years Ago 20:50Documento1 paginaSuggested For You: 15188 5 Years Ago 20:50DeevenNessuna valutazione finora

- Materials Selection For Engineering DesignDocumento31 pagineMaterials Selection For Engineering Designsyamsudin2006Nessuna valutazione finora

- BS EN 50131-1998 Alarm Systems Intrusion Systems Part 6Documento30 pagineBS EN 50131-1998 Alarm Systems Intrusion Systems Part 6Michael Camit EsoNessuna valutazione finora

- Snel White Paper 2020Documento18 pagineSnel White Paper 2020Zgodan NezgodanNessuna valutazione finora

- Maths ReportDocumento3 pagineMaths ReportShishir BogatiNessuna valutazione finora

- Anagrams in Enhancing The Learner's Vocabolary in Filipino Language Using WordwallDocumento19 pagineAnagrams in Enhancing The Learner's Vocabolary in Filipino Language Using WordwallJARYL PILLAZARNessuna valutazione finora

- Borrero Nuevo Delaunay Mendez - 2019 - Ethnographical and Historical Accounts For Understanding The Exploration of New Lands The Case PDFDocumento16 pagineBorrero Nuevo Delaunay Mendez - 2019 - Ethnographical and Historical Accounts For Understanding The Exploration of New Lands The Case PDFBárbara Olguín MuñozNessuna valutazione finora

- Ropes and Wires: Malaysian Maritime Academy/Seamanship/May2003 1 of 6Documento6 pagineRopes and Wires: Malaysian Maritime Academy/Seamanship/May2003 1 of 6Rohit SinghNessuna valutazione finora

- Meditation and yoga relieve dysmenorrhea and absenteeismDocumento6 pagineMeditation and yoga relieve dysmenorrhea and absenteeismrifdaNessuna valutazione finora

- Appendix 1c Bridge Profiles Allan TrussesDocumento43 pagineAppendix 1c Bridge Profiles Allan TrussesJosue LewandowskiNessuna valutazione finora

- Practical Project Planning and Tracking Using Microsoft Project v2.7Documento47 paginePractical Project Planning and Tracking Using Microsoft Project v2.7Nelson Aguirre BravoNessuna valutazione finora

- t640 - Parts CatalogDocumento69 paginet640 - Parts CatalogSattittecInfomáticaNessuna valutazione finora

- METRO Otherscape PlaytestDocumento101 pagineMETRO Otherscape PlaytestthomasNessuna valutazione finora

- Worksheet Chapter 50 Introduction To Ecology The Scope of EcologyDocumento2 pagineWorksheet Chapter 50 Introduction To Ecology The Scope of EcologyFernando CastilloNessuna valutazione finora

- NB-CPR 14-612r7 Issuance of Certificates Under CPRDocumento13 pagineNB-CPR 14-612r7 Issuance of Certificates Under CPRÜmit BUCAKNessuna valutazione finora

- Original Prusa I3 MK2S To MK3 Upgrade Parts ListDocumento2 pagineOriginal Prusa I3 MK2S To MK3 Upgrade Parts ListLuan AlvesNessuna valutazione finora

- Water Is EnergyDocumento96 pagineWater Is EnergyRadu BabauNessuna valutazione finora

- The Reference Frame - Nice Try But I Am Now 99% Confident That Atiyah's Proof of RH Is Wrong, HopelessDocumento5 pagineThe Reference Frame - Nice Try But I Am Now 99% Confident That Atiyah's Proof of RH Is Wrong, Hopelesssurjit4123Nessuna valutazione finora

- "Smart Attendance Using F Ttendance Management Using Face Recognition" Anagement SystemDocumento13 pagine"Smart Attendance Using F Ttendance Management Using Face Recognition" Anagement Systemamer HNessuna valutazione finora

- FormatCARS KAAUH Alqahtani 106Documento8 pagineFormatCARS KAAUH Alqahtani 106ZEYNONessuna valutazione finora

- Geometric Design of Highways for Optimal Traffic FlowDocumento123 pagineGeometric Design of Highways for Optimal Traffic FlowGadisa TeferaNessuna valutazione finora

- Ake Products 001 2016Documento171 pagineAke Products 001 2016davidNessuna valutazione finora

- Non-Permanence Risk Report Template (Short Form) : Instructions For Completing TheDocumento5 pagineNon-Permanence Risk Report Template (Short Form) : Instructions For Completing Theferrian prabowoNessuna valutazione finora

- Transmission Line Surge Impedance Loading ExplainedDocumento3 pagineTransmission Line Surge Impedance Loading ExplainedviksoniNessuna valutazione finora