Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Service & Support: Communication Between SIMATIC S5 and Simatic S7 Over Profibus

Caricato da

Mhd Samer AlHamwiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Service & Support: Communication Between SIMATIC S5 and Simatic S7 Over Profibus

Caricato da

Mhd Samer AlHamwiCopyright:

Formati disponibili

Cover sheet

Communication between SIMATIC S5

and SIMATIC S7 over PROFIBUS

FDL protocol

FAQ February 2011

Service & Support

Answers for industry.

Question

This entry originates from the Service & Support Portal of Siemens AG, Sector

Industry, Industry Automation and Drive Technologies. The conditions of use

specified there apply (www.siemens.com/nutzungsbedingungen).

Go to the following link to download this document.

http://support.automation.siemens.com/WW/view/de/48352979

Question

How is data communicated between SIMATIC S5 and SIMATIC S7 over

PROFIBUS using the FDL protocol?

Answer

Follow the instructions and notes listed in this document for a detailed answer to

the above question.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

2 V1.0, Entry ID: 48352979

Contents

Contents

1 Introduction........................................................................................... 5

2 Overview of the Sample Program ........................................................ 6

Plant Configuration............................................................................... 6

Checking the function of the sample program...................................... 6

Overview of functions ........................................................................... 7

Data Communication............................................................................ 7

Active partner and passive partner ...................................................... 7

Program overview ................................................................................ 8

User program of the active partner S7-400 station .............................. 8

User program of the passive partner S5 station .................................. 8

Operating and monitoring..................................................................... 8

3 Plant Configuration............................................................................... 9

3.1 Overview .............................................................................................. 9

3.2 Hardware and Software Components Used......................................... 9

Hardware components ......................................................................... 9

Required cables and other hardware ................................................. 10

Software components......................................................................... 10

4 Function Mechanisms of the Sample Program .................................. 11

4.1 Working Method of the Sample Program ........................................... 11

4.1.1 Data Communication.......................................................................... 11

4.1.2 Active Partner S7-400 Station and Passive Partner S5 Station ........ 11

4.1.3 Sequence of the User Program in the Active Partner

S7-400 Station.................................................................................... 11

Send data ........................................................................................... 11

Read data........................................................................................... 11

Increase data...................................................................................... 11

4.1.4 Sequence of the User Program in the Passive Partner S5 Station ... 11

Send data ........................................................................................... 11

4.2 Functions and Function Blocks .......................................................... 11

4.2.1 Functions and Function Blocks in the User Program of the

S7-400 Station.................................................................................... 11

Task of the function FC5 “AG_SEND" ............................................... 12

Task of the function FC6 “AG_RECV" ............................................... 12

4.2.2 Functions and Function Blocks in the User Program of the S5 Station12

4.3 Details of the User Programs of the S7-400 station........................... 13

4.3.1 Program Sequence ............................................................................ 13

4.3.2 Symbol Table ..................................................................................... 13

Example ............................................................................................ 14

Overview ............................................................................................ 14

4.3.3 OB1 .................................................................................................... 14

4.3.4 FC40 "MY_SEND_CALL"................................................................... 15

Overview ............................................................................................ 15

Description ......................................................................................... 15

4.3.5 FC41 "MY_RECEIVE_CALL"............................................................. 17

Overview 17

4.4 Details of the User Program of the S5 station.................................... 19

4.4.1 Program Sequence ............................................................................ 19

4.4.2 OB1 .................................................................................................... 19

4.4.3 Send job ............................................................................................. 21

4.4.4 Receive job......................................................................................... 23

5 How to Use the Sample Program....................................................... 25

Opening the variable table in the user program of the S7-400 .......... 25

Variable table ..................................................................................... 26

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

V1.0, Entry ID: 48352979 3

Contents

Data is successfully sent and received .............................................. 27

Errors in sending and receiving the data............................................ 27

Send data ........................................................................................... 27

Closing the variable table in the user program of the S7-400............ 28

6 Other Notes, Tips and Tricks, etc....................................................... 29

6.1 Not Possible to Download Hardware Configuration, Connection or

Blocks to the S7-400 CPU ................................................................. 29

6.2 Values of the Send and Receive Data Do Not Change in the

Variable Table .................................................................................... 29

6.3 Control Values are Not Applied for the Variables in the

Variable Table .................................................................................... 30

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

4 V1.0, Entry ID: 48352979

1 Introduction

1 Introduction

This document provides information about examples of PROFIBUS communication

between S7 stations and SIMATIC S5 stations using the services SEND and

RECEIVE based on the FDL protocol.

Chapter 2 gives an overview of the sample program.

Chapter 4 gives information about the function mechanisms of the sample

program.

This document contains

An overview of the plant configuration.

An introduction to the blocks required and their communication structure.

Details of the user programs of the S7-400 station and the S5 station.

Information on how to use the sample programs.

Other Notes, Tips and Tricks, etc.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

V1.0, Entry ID: 48352979 5

2 Overview of the Sample Program

2 Overview of the Sample Program

Plant Configuration

Figure 2-1

Aktiver Partner Passiver Partner

S7-400 Station S5 Station

S5-135U

CPU 414-1

CP 443-5

CP 5431

CPU

MPI-Schnittstelle PG-Schnittstelle

PROFIBUS Netzwerk

SIMATIC Field PG mit

STEP 7, STEP 5 und NCM

Checking the function of the sample program

You can see whether the sample program is functioning correctly from variable

table of the active S7-400 station. The variable table is included in the block folder

of the STEP 7 project.

The data sent and received changes its value constantly (see chapter 5).

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

6 V1.0, Entry ID: 48352979

2 Overview of the Sample Program

Overview of functions

The overview of functions shows the principal working method of the sample

program.

Figure 2-2

Aktiver Partner Passiver Partner

S7-400 Station S5 Station

Sendedaten

vorbereiten

Daten senden (2 Byte)

Daten empfangen und in

Sendepuffer kopieren

Daten senden (2 Byte)

Empfangsdaten

speichern

Data Communication

2 bytes of data are exchanged cyclically between the two stations

involved in the communication.

Active partner and passive partner

The active S7-400 station initiates establishing of the connection and sending of the new data.

The passive S5 station receives the data from the active S7-400 and copies it into its send

buffer, i.e. after the passive partner has completely received a data block, the passive partner

sends it back to the active partner.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

V1.0, Entry ID: 48352979 7

2 Overview of the Sample Program

Program overview

Figure 2-3

Aktiver Partner S7-400 Station Passiver Partner S5 Station

MY_SEND_CALL AG_SEND FB-RECEIVE REC-T2

Datenübertragung

FC40 FC5 FB121 FB41

OB1 OB1

MY_RECEIVE_CALL AG_RECV FB-SEND SEND-T2

Datenübertragung

FC41 FC6 FB120 FB2

User program of the active partner S7-400 station

The function FC5 "AG_SEND" is called in each cycle to send a data block of 2

bytes in length.

The function FC6 "AG_RECV" is called in parallel to the send job to fetch a

received data block from the CP.

Once a data block has been received completely, the data is saved.

If the receive job has been completed successfully, then the send data is

incremented by the value "1" and the send/receive cycle starts over.

User program of the passive partner S5 station

An FB121 "RECEIVE" is triggered in each cycle.

When the FB121 "RECEIVE" receives a new data block, the data received triggers

an FB 120 "SEND" to send back the data received.

Operating and monitoring

The operating and monitoring of the sample program is possible using the variable

table provided.

The following requirements must be fulfilled for the "Monitor and modify variables"

program.

An online connection to the CPU must be established.

The "Monitor variables" function must be activated.

The control values must be marked as valid.

If the above-mentioned conditions are fulfilled, then you can tell that the sample

program is working properly by the fact that the sent and received data changes

constantly in the active partner.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

8 V1.0, Entry ID: 48352979

3 Plant Configuration

3 Plant Configuration

This chapter gives you an overview of the configuration and the hardware and

software components used to create the sample program.

3.1 Overview

Table 3-1 gives an overview of the configuration used to create the sample

program.

Table 3-1

Bus system PROFIBUS

Communication protocol FDL

FMS Client SIMATIC S7

FMS Server SIMATIC S5

Communications processors CP443-5 and CP5431

Services SEND and RECEIVE

In this sample program the FDL protocol is used with the services SEND and

RECEIVE for data communication between a SIMATIC S7 and a SIMATIC S5.

In the active partner S7-400 station a CP443-5 Basic communications processor is

used for data communication using the FDL protocol and the SEND / RECEIVE

services.

A CP5431 communications processor is used in the passive partner S5 station.

3.2 Hardware and Software Components Used

Hardware components

The following modules in the active partner S7-400 station were used to create the

sample program.

Table 3-2

Slot Module

1 PS 407 10A

3 CPU 414-1

5 CP443-5

The following modules in the passive partner S5 station were used to create the

sample program.

Table 3-3

Slot Module

1 CPU

2 CP5431

3 Power supply

4 Rack

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

V1.0, Entry ID: 48352979 9

3 Plant Configuration

Note The sample project has been created with a specific hardware configuration.

This must be maintained to ensure proper functioning.

If you use a different configuration, with a different CPU or CP, for example, then

you must change the sample program accordingly.

Required cables and other hardware

MPI cable

PROFIBUS bus cable with at least two male bus connectors

SIMATIC Field PG or PC with MPI and AS interface

Software components

STEP 7 V4.2 or higher

NCM S7 PROFIBUS V4.2 + SP1 or higher

STEP 5 V6.65

SINEC COM 5431

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

10 V1.0, Entry ID: 48352979

4 Function Mechanisms of the Sample Program

4 Function Mechanisms of the Sample

Program

This chapter describes how the sample program functions and which blocks are

required for communication and their communication structure.

4.1 Working Method of the Sample Program

4.1.1 Data Communication

2 bytes of data are exchanged cyclically between the two stations involved in the

communication.

4.1.2 Active Partner S7-400 Station and Passive Partner S5 Station

The initiative for sending and receiving data comes from the active S7-400 station.

When it receives a data block, the passive S5 station sends it back to the active

S7-400 station.

A PROFIBUS network with FDL protocol is used as the data transfer medium.

4.1.3 Sequence of the User Program in the Active Partner S7-400 Station

Send data

In each cycle a data block with a length of 2 bytes is sent to the passive partner S5

station.

Read data

In each cycle a receive job is triggered and depending on the status value of the

function FC6 "AG_SEND" the data received is transferred to the receive buffer.

Increase data

The value of the data to be sent is increased by one and the send and receive

cycle starts over.

4.1.4 Sequence of the User Program in the Passive Partner S5 Station

Receive data

A receive job is triggered in the passive partner S5 station in each cycle. When

new data is received, it is transferred to the common receive and send buffer.

Send data

A send job is triggered when new data is received.

4.2 Functions and Function Blocks

4.2.1 Functions and Function Blocks in the User Program of the S7-400

Station

The functions FC5 "AG_SEND" and FC "AG_RECV" for data transfer are called in

the user program of the S7-400 station.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

V1.0, Entry ID: 48352979 11

4 Function Mechanisms of the Sample Program

Task of the function FC5 “AG_SEND"

The function FC5 “AG_SEND" transfers data from the specified send buffer of the

CPU to the configured partner station. The pointer of the send buffer can point to a

process picture area, a marker area or a data block area.

With the S7-400 the function FC5 “AG_SEND" can only transfer a maximum of 240

bytes of data. Use the function FC50 "AG_LSEND" for transfer of up to 8192 bytes

of data.

With the S7-300 the function FC5 “AG_SEND" can only transfer a maximum of

8192 bytes of data.

The addresses and LSAP of the communications partner are defined during

configuration and receive an ID (connection number) by way of which the function

FC5 “AG_SEND" sends the data.

Note Section 4.3.4 gives a description of the input and output parameters of the

function FC5 "AG_SEND".

Task of the function FC6 “AG_RECV"

The function FC6 "AG_RECV" transfers data received from the configured partner

station to the specified receive buffer of the CPU. The pointer of the send buffer

can point to a process picture area, a marker area or a data block area.

With the S7-400 the function FC6 “AG_RECV" can only transfer a maximum of 240

bytes of data. Use the function FC60 "AG_LRECV" for transfer of up to 8192 bytes

of data.

The addresses and LSAP of the communications partner are defined during

configuration and receive an ID (connection number) by way of which the function

FC6 “AG_RECV" receives the data.

Note Section 4.3.5 gives a description of the input and output parameters of the

function FC6 “AG_RECV".

4.2.2 Functions and Function Blocks in the User Program of the S5 Station

Task of the function block FB120 "SEND"

The function block FB120 "SEND" sends the data from the specified send buffer of

the AS to the specified address area of the CP.

The addresses and LSAPs of the communications partners are defined during

configuration of the CP.

Note Section 4.4.3 gives a description of the input and output parameters of the

function block FB120 "SEND".

Task of the function block FB121 "RECEIVE"

The function block FB121 "RECEIVE" transfers the data from the specified address

area of the CP to the specified receive buffer of the AS. The pointer of the send

buffer can point to a process picture area, a marker area or a data block area.

The length of the receive buffer must be at least as long as the longest data block

to be expected.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

12 V1.0, Entry ID: 48352979

4 Function Mechanisms of the Sample Program

The addresses and LSAP of the partners are defined during configuration of the

CP.

Note Section 4.4.4 gives a description of the input and output parameters of the

function block FB121 "RECEIVE".

4.3 Details of the User Programs of the S7-400 station

4.3.1 Program Sequence

Figure 4-1

Programm- / Zyklusstart

FC5 „AG_SEND“ aufrufen

ja

Fehler an der Funktion Fehlernummer

FC5 „AG_SEND“ speichern

nein

FC6 “AG_RECV“ aufrufen

Fehler an der Funktion ja Fehlernummer

FC6 „AG_RECV“ speichern

nein

Empfangsauftrag nein

abgeschlossen

ja

Sendedaten

inkrementieren

4.3.2 Symbol Table

In the symbol table you assign symbolic names to the addresses used in the user

program of the S7-400 station.

The use of symbols increases the readability of the program code. The symbolic

name is displayed in the program code instead of the address.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

V1.0, Entry ID: 48352979 13

4 Function Mechanisms of the Sample Program

Example

The symbolic name "RECEIVE_DATA" is in the program code instead of the

address MW50.

Overview

Figure 4-2 shows the symbol table used in the user program of the S7-400 station.

Figure 4-2

4.3.3 OB1

OB1 is the block responsible for cyclic processing of the user program. The

functions FC40 "MY_SEND_CALL" and FC41 "MY_RECEIVE_CALL" are called

cyclically in OB1. The functions FC40 "MY_SEND_CALL" and FC41

"MY_RECEIVE_CALL" internally call the functions FC5 "AG_SEND" and FC6

"AG_RECV" to send and receive the data.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

14 V1.0, Entry ID: 48352979

4 Function Mechanisms of the Sample Program

Figure 4-3

4.3.4 FC40 "MY_SEND_CALL"

Overview

Figure 4-4

Description

The function FC40 "MY_SEND_CALL" is called cyclically in OB1. It internally calls

the function block FC5 "AG_SEND". 2 bytes of data are transferred from the send

buffer (DB40) to the configured communications partner.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

V1.0, Entry ID: 48352979 15

4 Function Mechanisms of the Sample Program

When the send job has been completed successfully, the function FC40

"MY_SEND_CALL" is quitted by means of a conditional block end.

If the send job is not completed successfully, the status value is stored in data

block DB43.

Input parameters of FC5 "AG_SEND"

The function FC5 "AG_SEND" has the following input parameters.

Table 4-1

Input parameters Data type Description

ACT Boolean Job trigger

ACT = 1 LEN bytes are sent from the data

area specified with the SEND parameter.

ACT = 0

ID Integer Connection number

LADDR WORD Module start address

The module start address is the address of the

CP. It is configured in the Hardware

Configuration.

SEND ANY The address and length of the data area serving

as send buffer are specified at the SEND

parameter.

LEN Integer The number of bytes sent from the data area

with the job is specified at the LEN parameter.

Output parameters of FC5 "AG_SEND"

The function FC5 "AG_SEND" has the following output parameters.

Table 4-2

Output parameters Data type Description

DONE Boolean Status parameters

DONE = 0 job is running

DONE = 1 job has been executed

ERROR Boolean Error display

STATUS WORD Status display

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

16 V1.0, Entry ID: 48352979

4 Function Mechanisms of the Sample Program

4.3.5 FC41 "MY_RECEIVE_CALL"

Overview

Figure 4-5

Description

The function FC41 "MY_RECEIVE_CALL" is called cyclically in OB1. It internally

calls the function FC6 "AG_RECV". 2 bytes of data are transferred from the

configured communications partner to the receive buffer (DB41).

If the receive job has been completed successfully, the data length is accepted, the

data word is incremented and sent back to the configured communications partner.

If the receive job is not completed successfully, the status value is stored in data

block DB43.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

V1.0, Entry ID: 48352979 17

4 Function Mechanisms of the Sample Program

Input parameters of FC6 "AG_RECV"

The function FC6 "AG_RECV" has the following input parameters.

Table 4-3

Input parameters Data type Description

ID Integer Connection number

LADDR WORD Module start address

The module start address is the address of the

CP. It is configured in the Hardware

Configuration.

RECV ANY The address and length of the data area serving

as receive buffer are specified at the RECV

parameter.

LEN Integer The number of bytes sent from the data area

with the job is specified at the LEN parameter.

Output parameters of FC6 "AG_RECV"

The function FC6 "AG_RECV" has the following output parameters.

Table 4-4

Output parameters Data type Description

NDR Boolean The NDR parameter indicates whether new data

has been received.

NDR = 1 new data

ERROR Boolean Error display

STATUS WORD Status display

LEN Integer The LEN parameter specifies the number of

bytes transferred from the PROFIBUS CP to the

data area.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

18 V1.0, Entry ID: 48352979

4 Function Mechanisms of the Sample Program

4.4 Details of the User Program of the S5 station

4.4.1 Program Sequence

Figure 4-6

Programm- / Zyklusstart

FB121 „RECEIVE“

aufrufen

Fehler bei FB121 ja Fehlernummer

„RECEIVE“ speichern

nein

Empfangsauftrag nein

abgeschlossen

ja

Sendebit zurücksetzen

FB120 „SEND“ mit

Sendebit aufrufen

ja Fehlernummer

Fehler bei FB120 „SEND“

speichern

nein

4.4.2 OB1

OB1 is the block responsible for cyclic processing of the user program. Function

blocks FB2 "SEND-T2" and FB41 "REC-T2" are called cyclically in OB1. These

function blocks internally call the function blocks FB120 and FB121 to send and

receive data.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

V1.0, Entry ID: 48352979 19

4 Function Mechanisms of the Sample Program

Figure 4-7

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

20 V1.0, Entry ID: 48352979

4 Function Mechanisms of the Sample Program

4.4.3 Send job

Overview

Figure 4-8

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

V1.0, Entry ID: 48352979 21

4 Function Mechanisms of the Sample Program

Description

The FB2 cyclically calls the function block FB120 "SEND" to transfer data.

In this example the FB120 "SEND" transfers 2 bytes of data to the configured

communications partner.

Depending on the data transfer and the value of the parameter "PAFE" the Send

bit is reset and the function block FB2 is terminated.

Parameters

The table gives an overview of the parameters of FB120 "SEND".

Table 4-5

Parameter Description

SSNR Interface number of the CP5431.

A-NR Job number which identifies the S/R connection of the CP5431.

ANZW Job status.

QTYP ID for the send buffer type.

DBNR Number of the data block (DB).

QANF Offset in the send buffer.

QLAE Length of the area to be transferred.

PAFE Error display of the block.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

22 V1.0, Entry ID: 48352979

4 Function Mechanisms of the Sample Program

4.4.4 Receive job

Overview

Figure 4-9

Description

The FB41 cyclically calls the function block FB121 "RECEIVE" to receive data.

In this example FB121 "RECEIVE" receives 2 bytes of data from the configured

communications partner and transfers the data to the receive buffer.

When a receive job has been completed successfully, the Send bit is set in FB41 to

trigger a send job.

FB41 is then terminated.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

V1.0, Entry ID: 48352979 23

4 Function Mechanisms of the Sample Program

Parameters

Parameter Description

SSNR Interface number of the CP5431.

A-NR Job number which identifies the S/R connection of the CP5431.

ANZW Job status.

ZTYP ID for the receive buffer type.

DBNR Number of the data block (DB).

ZANF Offset in the receive buffer.

ZLAE Length of the area to be transferred. If the ZLAE parameter has the

value "-1", the length is determined when the data is received.

PAFE Process picture error during processing of the function block FB121

"RECEIVE".

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

24 V1.0, Entry ID: 48352979

5 How to Use the Sample Program

5 How to Use the Sample Program

You use the variable table supplied with the user program of the S7-400 to operate

the sample program.

Opening the variable table in the user program of the S7-400

Table 5-1

No. Action

1. Use the MPI cable to connect the SIMATIC Field PG to the MPI/DP interface of

the S7-400 CPU.

2. Open the SIMATIC Manager and navigate in the project window to the block

folder of the SIMATIC 400 station.

3. In the block folder you double-click the variable table "VAT1".

4. In the variable table you establish a connection to the S7-400 by means of the

menu Target system Establish connection to Configured

CPU.

5. In the variable table you select the menu Variable Monitor to control

and monitor the defined variables.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

V1.0, Entry ID: 48352979 25

5 How to Use the Sample Program

Variable table

Figure 5-1

In the variable table you can monitor the values of the send and receive data and

the values at the output parameters of the functions FC5 "AG_SEND" and FC6

"AG_RECV".

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

26 V1.0, Entry ID: 48352979

5 How to Use the Sample Program

Data is successfully sent and received

If the data is successfully sent and received, the output parameters of the functions

FC5 "AG_SEND" and FC6 "AG_RECV" have the following values.

Table 5-2

Output parameters Addres Symbolic name Value

s

DONE M40.4 SEND_DONE The value of marker bit

M40.4 changes

constantly between 0

and 1.

ERROR M40.3 SEND_ERROR M40.3 = 0

STATUS MW42 SEND_STATUS MW42 = 0

NDR M40.2 RECV_NDR The value of marker bit

M40.2 changes

constantly between 0

and 1.

ERROR M40.1“ RECV_ERROR M40.1 = 0

STATUS MW44 RECV_STATUS MW44 = 0

The send and receive data in MW52 and MW50 changes constantly.

Errors in sending and receiving the data

If the data is not successfully sent, the output parameters of the functions FC5

"AG_SEND" and FC6 "AG_RECV" have the following values.

Table 5-3

Output parameters Addres Symbolic name Value

s

DONE M40.4 SEND_DONE M40.4 = 0

ERROR M40.3 SEND_ERROR M40.3 = 1

STATUS MW42 SEND_STATUS MW42 <> 0

NDR M40.2 RECV_NDR M40.2 = 0

ERROR M40.1 RECV_ERROR M40.1 = 1

STATUS MW44 RECV_STATUS MW44 <> 0

The status value of the function "AG_SEND" is stored in data word 0 of data block

DB43.

The status value of the function "AG_RECV" is stored in data word 2 of data block

DB43.

Send data

Proceed as follows for sending data to the passive S5 station.

Table 5-4

No. Action

1. In the variable table you enter a control value of between 0 and 32767 for the

marker word MW52.

2. The control value entered is applied for the marker word MW52 by means of

the menu Variable Activate control values.

When the data has been transferred successfully, then the receive value

transferred to the marker word MW50 also changes.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

V1.0, Entry ID: 48352979 27

5 How to Use the Sample Program

Closing the variable table in the user program of the S7-400

Close the variable table by means of the menu Table Close.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

28 V1.0, Entry ID: 48352979

6 Other Notes, Tips and Tricks, etc.

6 Other Notes, Tips and Tricks, etc.

This chapter gives you more notes, tips and tricks for the commissioning and

working of the sample program.

6.1 Not Possible to Download Hardware Configuration,

Connection or Blocks to the S7-400 CPU

If it is not possible to download the hardware configuration, connection or blocks to

the CPU, then make the following checks and take the following measures to

remedy the situation.

Table 6-1

Check Remedy

Check that the MPI cable is connected on Connect the MPI cable to the RS485

the SIMATIC Field PG and on the MPI or interface of the SIMATIC Field PG and to

MPI/DP interface of the S7-400 CPU. the MPI or MPI/DP interface of the S7-400

If the MPI cable is not connected to the CPU.

SIMATIC Field PG and to the MPI or

MPI/DP interface of the S7-400 CPU, no

connection can be established to the S7-

400 station and the configuration cannot be

downloaded to the CPU.

Check the settings in "Set PG/PC Go to Start SIMATIC STEP 7

interface...". and select the menu item "Set PG/PC

The interface parameters used must be interface".

assigned to the access point of the Under "Interface parameters used" you

application "S7ONLINE (STEP 7)". select the module to which the MPI cable

If the settings in "Set PG/PC interface..." are on the SIMATIC Field PG is connected,

not correct, no connection can be CP5611 (MPI), for example.

established between the SIMATIC Field PG Apply the settings with "OK".

and S7-400 CPU.

Open the hardware configuration. The Change the hardware configuration in the

hardware configuration in the STEP 7 STEP 7 project to match the configuration

project must match the configuration of the of the S7-400 station.

S7-400 station.

Check that the CPU has been completely If the CPU has not been completely reset,

reset. then do a complete reset of the S7-400

CPU.

6.2 Values of the Send and Receive Data Do Not Change in

the Variable Table

If the values of the send and receive data do not change in the variable table, then

make the following checks and take the following measures to remedy the

situation.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

V1.0, Entry ID: 48352979 29

6 Other Notes, Tips and Tricks, etc.

Table 6-2

Check Remedy

Check whether the PROFIBUS bus cable is Connect the PROFIBUS bus cable to the

connected to the CP443-5 in the S7-400 RS485 interface of the CP443-5 and to the

station and to CP5431 in the S5 station. L2 interface of the CP5431.

If the PROFIBUS cable is not connected to Switch on the terminator of the PROFIBUS

CP443-5 in the S7-400 station and to connector.

CP5431 in the S5 station, no connection

can be established between the two

stations. Data exchange is not possible.

Check whether "Monitor variables" function Activate the "Monitor variable" function by

is activated in the variable table. means of the menu Variable

Monitor.

6.3 Control Values are Not Applied for the Variables in the

Variable Table

If the control values for the variables in the variable table are not applied, then

make the following checks and take the following measures to remedy the

situation.

Table 6-3

Check Remedy

Check whether the control value of the Enter a control value for the marker word

marker word MW52 is in the range of valid MW52 from the valid range of values of

values. between 0 and 32767.

Note If these notes, tips and tricks etc. for the commissioning and working of the

sample program have not been of assistance, then repeat the commissioning of

the sample program.

Kommunikation zwischen SIMATIC S5 und SIMATIC S7 über PROFIBUS

30 V1.0, Entry ID: 48352979

Potrebbero piacerti anche

- SYS600 - DNP V3.00 Slave ProtocolDocumento98 pagineSYS600 - DNP V3.00 Slave ProtocolAbhijit JNessuna valutazione finora

- PLC 2 Unity ReferenceDocumento698 paginePLC 2 Unity ReferenceRodolfo BelchiorNessuna valutazione finora

- The IBM z13Documento80 pagineThe IBM z13elias.ancares8635Nessuna valutazione finora

- s7 s5s7bDocumento150 pagines7 s5s7bDwi WijayantoNessuna valutazione finora

- Embedded DSP Processor Design: Application Specific Instruction Set ProcessorsDa EverandEmbedded DSP Processor Design: Application Specific Instruction Set ProcessorsNessuna valutazione finora

- Practical Modern SCADA Protocols: DNP3, 60870.5 and Related SystemsDa EverandPractical Modern SCADA Protocols: DNP3, 60870.5 and Related SystemsValutazione: 5 su 5 stelle5/5 (6)

- SYS600 - DNP V3.00 Master ProtocolDocumento96 pagineSYS600 - DNP V3.00 Master ProtocolJose Blanco RojasNessuna valutazione finora

- Unity Pro ProgrammingDocumento722 pagineUnity Pro ProgrammingAkram Esmaellou100% (1)

- Deploying QoS for Cisco IP and Next Generation Networks: The Definitive GuideDa EverandDeploying QoS for Cisco IP and Next Generation Networks: The Definitive GuideValutazione: 5 su 5 stelle5/5 (2)

- SYS600 - Modbus Slave ProtocolDocumento46 pagineSYS600 - Modbus Slave ProtocolAbhijit JNessuna valutazione finora

- Service Awareness Flexi ISNDocumento90 pagineService Awareness Flexi ISNnhatnd88Nessuna valutazione finora

- PIC Microcontroller Projects in C: Basic to AdvancedDa EverandPIC Microcontroller Projects in C: Basic to AdvancedValutazione: 5 su 5 stelle5/5 (10)

- Microsoft SQL Server 2016: A Beginner's Guide, Sixth EditionDa EverandMicrosoft SQL Server 2016: A Beginner's Guide, Sixth EditionValutazione: 1 su 5 stelle1/5 (1)

- Simatic Step 7 v5.5 From s5 To s7Documento150 pagineSimatic Step 7 v5.5 From s5 To s7ondoy4925Nessuna valutazione finora

- Iot Workshop: HF5111B Serial Server Device User ManualDocumento58 pagineIot Workshop: HF5111B Serial Server Device User ManualBudhi HermawanNessuna valutazione finora

- VoLTE Protocol Reference GuideDocumento32 pagineVoLTE Protocol Reference Guidenjain76100% (1)

- Basic VoIPDocumento134 pagineBasic VoIPDamián MarésNessuna valutazione finora

- SYS600 - OPC Data Access ClientDocumento62 pagineSYS600 - OPC Data Access ClientDang JinlongNessuna valutazione finora

- Unity Pro XL ManualDocumento722 pagineUnity Pro XL ManualCarlos Gallegos100% (3)

- Network Processors: Architecture, Programming, and ImplementationDa EverandNetwork Processors: Architecture, Programming, and ImplementationNessuna valutazione finora

- SB ProfiBus ProfiNet TM1356 enDocumento92 pagineSB ProfiBus ProfiNet TM1356 enJulio Cesar Perez NavarroNessuna valutazione finora

- Information: Surpass Hit 7070 3.3 Technical Description (Ted)Documento156 pagineInformation: Surpass Hit 7070 3.3 Technical Description (Ted)Shahzaib AhmadNessuna valutazione finora

- A5 3 Ciphering PDFDocumento16 pagineA5 3 Ciphering PDFmudassar2k4Nessuna valutazione finora

- Service & Support: Communication Between SIMATIC S5 and Simatic S7 Over ProfibusDocumento38 pagineService & Support: Communication Between SIMATIC S5 and Simatic S7 Over ProfibusMhd Samer AlHamwiNessuna valutazione finora

- Instruction Manual: YokogawaDocumento200 pagineInstruction Manual: YokogawaRaj yadavNessuna valutazione finora

- REF 542plus REF 542plus: Installation ManualDocumento52 pagineREF 542plus REF 542plus: Installation ManualDonald SantanaNessuna valutazione finora

- STEP 7 - From S5 To S7Documento150 pagineSTEP 7 - From S5 To S7volong74Nessuna valutazione finora

- SYS600 - Communication Programming InterfaceDocumento86 pagineSYS600 - Communication Programming InterfaceNguyen DucNessuna valutazione finora

- OCCASDocumento90 pagineOCCAStarunjs8139Nessuna valutazione finora

- Ethernet Adapter SPA-ZC 400 SPA-ZC 400: Installation and Commissioning ManualDocumento52 pagineEthernet Adapter SPA-ZC 400 SPA-ZC 400: Installation and Commissioning ManualMelchor DavidNessuna valutazione finora

- PLC A120 AegDocumento236 paginePLC A120 AegMiguel Rubino0% (1)

- VIPA System 500S: SPEED7 - CPU - 515-2AJ02 - ManualDocumento154 pagineVIPA System 500S: SPEED7 - CPU - 515-2AJ02 - ManualAlberto OsunaNessuna valutazione finora

- ProductGuide CPB539 80591100Documento32 pagineProductGuide CPB539 80591100Andrew YuNessuna valutazione finora

- Process Control Systems InterfaceDocumento46 pagineProcess Control Systems InterfaceSrinivasa ReddyNessuna valutazione finora

- EM316LNXNM OT UserGuide v4.7fdr39 RevE6 r21138Documento181 pagineEM316LNXNM OT UserGuide v4.7fdr39 RevE6 r21138R GNessuna valutazione finora

- CANopen Demo For The CM ModuleDocumento78 pagineCANopen Demo For The CM ModuleYASH WANKHEDENessuna valutazione finora

- Freelance 2019: Engineering Manual Process StationsDocumento160 pagineFreelance 2019: Engineering Manual Process StationsMathias MolleNessuna valutazione finora

- BLE Application Developer Guide: Rev. - 04 April 2018Documento113 pagineBLE Application Developer Guide: Rev. - 04 April 2018Heron HaiNessuna valutazione finora

- SLC 500 Ethernet ManualDocumento70 pagineSLC 500 Ethernet ManualDave CannonNessuna valutazione finora

- S7 300 CP343-1-Lean-CX10 76Documento50 pagineS7 300 CP343-1-Lean-CX10 76Marcio Sócrates100% (1)

- CS-5200 5400 Installation Manual072705 PDFDocumento1.140 pagineCS-5200 5400 Installation Manual072705 PDFRichNessuna valutazione finora

- VIPA 315-4NE12 ManualDocumento180 pagineVIPA 315-4NE12 Manualzederick.vargas.scaNessuna valutazione finora

- Siemens Siprotec 6md63Documento54 pagineSiemens Siprotec 6md63Maulana Aji WicaksonoNessuna valutazione finora

- Actel SPI APBDocumento38 pagineActel SPI APBgangadhar11Nessuna valutazione finora

- Powerlogictm P5: User ManualDocumento604 paginePowerlogictm P5: User ManualMohamed TaherNessuna valutazione finora

- 22comm Um005c en PDocumento104 pagine22comm Um005c en Pاحتشام چوہدریNessuna valutazione finora

- DME 230 400 Profinet InterfaceDocumento44 pagineDME 230 400 Profinet InterfaceOwais JafriNessuna valutazione finora

- SAP Contact Center Client Workstation Guide: Operations Guide - Public Document Version: 13 - 2018-12-14Documento46 pagineSAP Contact Center Client Workstation Guide: Operations Guide - Public Document Version: 13 - 2018-12-14Hemanth KumarNessuna valutazione finora

- IV Field BusDocumento65 pagineIV Field BusvarunshyamNessuna valutazione finora

- SWM0066 D400 Software Configuration Guide V320 R7Documento271 pagineSWM0066 D400 Software Configuration Guide V320 R7Kevin RojasNessuna valutazione finora

- S7A Digital Signals ENDocumento18 pagineS7A Digital Signals ENShafu YenNessuna valutazione finora

- Observer InglesDocumento428 pagineObserver InglesGuillermo Chavez VelaNessuna valutazione finora

- 5620SAM Documentation MapDocumento114 pagine5620SAM Documentation Mapkalwar98esNessuna valutazione finora

- SYS600 - External OPC Data Access ClientDocumento78 pagineSYS600 - External OPC Data Access ClientAbhijit JNessuna valutazione finora

- 3BSE044222-610 A en Compact Control Builder AC 800M - PlanningDocumento174 pagine3BSE044222-610 A en Compact Control Builder AC 800M - PlanningVimal KanthNessuna valutazione finora

- Commissioning Manual v06-460 PDFDocumento582 pagineCommissioning Manual v06-460 PDFa13j4ndr0Nessuna valutazione finora

- Net Lufp7 Profibus-Dp PDFDocumento115 pagineNet Lufp7 Profibus-Dp PDFDiego CarpioNessuna valutazione finora

- Os8 - Specs 86R1 RevaDocumento82 pagineOs8 - Specs 86R1 RevaEduardo SilvaNessuna valutazione finora

- Modbus Communication ProtocolDocumento80 pagineModbus Communication ProtocolAlejandro B.Nessuna valutazione finora

- SYS600 - DNP V3.00 Master ProtocolDocumento114 pagineSYS600 - DNP V3.00 Master ProtocolEduardoNessuna valutazione finora

- Internet Technologies Handbook: Optimizing the IP NetworkDa EverandInternet Technologies Handbook: Optimizing the IP NetworkNessuna valutazione finora

- Simulation of Scheduling AlgorithmsDocumento18 pagineSimulation of Scheduling Algorithmsashishpatel_99100% (1)

- Oracle Database In-MemoryDocumento11 pagineOracle Database In-MemoryvisaobuonNessuna valutazione finora

- CurriculumDocumento184 pagineCurriculumpandsvathiNessuna valutazione finora

- Minimum and Maximum Mode of 8086 of 8086: Sutapa SarkarDocumento26 pagineMinimum and Maximum Mode of 8086 of 8086: Sutapa SarkarNishal Bharadwaj NNessuna valutazione finora

- Wireless Chatting System Using RF CommunicationDocumento61 pagineWireless Chatting System Using RF CommunicationHareesh Thantanapally100% (4)

- Measuring Experimental Error in Microprocessor SimulationDocumento12 pagineMeasuring Experimental Error in Microprocessor SimulationblackspideymakNessuna valutazione finora

- Unit 3 Interfacing DevicesDocumento76 pagineUnit 3 Interfacing DevicesRaVinder GusAinNessuna valutazione finora

- Primepower 200: Midrange ServerDocumento2 paginePrimepower 200: Midrange ServerMariusSibisteanuNessuna valutazione finora

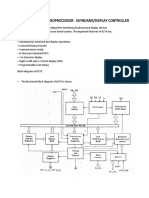

- Intel 8279 Microprocessor Keyboard Display ControllerDocumento4 pagineIntel 8279 Microprocessor Keyboard Display ControllerPrashant Kanubhai ShahNessuna valutazione finora

- Nr321402-Microprocessor and InterfacingDocumento8 pagineNr321402-Microprocessor and InterfacingSRINIVASA RAO GANTANessuna valutazione finora

- Chapter 2 Data ManipulationDocumento42 pagineChapter 2 Data ManipulationRidoy zzamanNessuna valutazione finora

- Functions of The OSDocumento1 paginaFunctions of The OSÑámè ŢħómäŝNessuna valutazione finora

- 2021 ECE391 Ch4 Basics of Computer SystemsDocumento29 pagine2021 ECE391 Ch4 Basics of Computer SystemsHoang TranNessuna valutazione finora

- mcs-012 Study MaterialsDocumento397 paginemcs-012 Study Materialshamarip111Nessuna valutazione finora

- InterruptDocumento25 pagineInterruptPallvi BhardwajNessuna valutazione finora

- Year: May/ June 2022 Formative Assessment 2A: Computer Fundamentals Cfaf05DDocumento10 pagineYear: May/ June 2022 Formative Assessment 2A: Computer Fundamentals Cfaf05DUthando SukoluhleNessuna valutazione finora

- Lesson Plan-COMPUTER ArchitectureDocumento5 pagineLesson Plan-COMPUTER ArchitectureDebabala Swain100% (1)

- CPU08 Instruction Set SummaryDocumento9 pagineCPU08 Instruction Set SummaryPrincess JoyNessuna valutazione finora

- Understanding, Scripting and Extending GDBDocumento84 pagineUnderstanding, Scripting and Extending GDBEsmo ImmoNessuna valutazione finora

- Parallel Fundamental ConceptsDocumento15 pagineParallel Fundamental ConceptsDianaRoseAcupeadoNessuna valutazione finora

- Chap 1Documento9 pagineChap 1Arafat MorshedNessuna valutazione finora

- RS3785 - Grade - 10 MicroprocessorDocumento104 pagineRS3785 - Grade - 10 MicroprocessorAshish Banstola90% (10)

- Study Viewer PDFDocumento9 pagineStudy Viewer PDFEduardo LoureiroNessuna valutazione finora

- CH 7 Numerical ControlDocumento40 pagineCH 7 Numerical ControlJapneet GhaiNessuna valutazione finora

- VLSI Design Lecture NotesDocumento117 pagineVLSI Design Lecture NotesRaji SharmiNessuna valutazione finora

- CSS Summative 1-3Documento3 pagineCSS Summative 1-3koiNessuna valutazione finora

- Research Paper On Memory HierarchyDocumento4 pagineResearch Paper On Memory Hierarchyefj02jba100% (1)

- Science NotesDocumento55 pagineScience Notesabhinv talksNessuna valutazione finora

- TEJ2O Inside The Computer Powerpoint - 2020Documento22 pagineTEJ2O Inside The Computer Powerpoint - 2020mike simsonNessuna valutazione finora