Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

HYLAB Series Lattice Boom Truck Crane 200-Ton (181.5 MT)

Caricato da

jonny david martinez perezTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

HYLAB Series Lattice Boom Truck Crane 200-Ton (181.5 MT)

Caricato da

jonny david martinez perezCopyright:

Formati disponibili

40351.

qxd 1/7/02 1:35 PM Page 6

HC-238H 11

HYLAB Series Lattice Boom Truck Crane

150-ton (136.08 mt)

150 tons (136.08 mt) at an 10' radius

50' to 260' (15.24 - 79.25 m) of tube boom

230' + 75' (70.10 + 22.86) boom

plus jib combination

308' (93.88) maximum tip height

270' (82.30 m) maximum 360°

working radius

New luffer design: 27-ton (24.5 mt)

capacity, 347' (105.77 m) maximum

luffing boom tip height and 240'

(73.15 m) maximum 360°

working radius

35,913 lb (16 290 kg)

maximum winch line pull

557 fpm (169.77 m/min)

maximum winch line speed

HC-248H

HYLAB Series Lattice Boom Truck Crane

200-ton (181.5 mt)

200 tons (181.5 mt) at a

10' radius

50' to 280' (15.24 - 85.34 m)

of tube boom

240' + 100' (73.15 +

30.48 m) boom plus jib

combination

343' (104.54 m) maximum

tip height

270' (82.30 m) maximum

360° working radius

42.5-ton (38.5 mt) capacity

luffer - 375' (114.30 m)

maximum luffing boom tip

height and 231' (70.41 m)

maximum 360° working radius

48,620 lb (22 054 kg)

maximum winch line pull

595 fpm (181.36 m/min)

maximum winch line speed

40351.qxd 1/7/02 1:34 PM Page 1

HC-238H 11

Outstanding carrier

features with solid,

reliable performance

HYLAB Lattice Boom Truck Crane Carrier frame new, improved design

150-ton (136.08 mt) provides solid lifting platform for luffer

applications

Comfortable carrier cab provides

HC-248H

high visibility

430 hp (320 kw/h) Detroit Diesel

Series 60 engine (lower)

Eaton RTO 14908LL transmission

Jake brake provides more braking power

HYLAB Lattice Boom Truck Crane Separate steering pump allows operator to

simultaneously drive and operate outriggers,

200-ton (181.5 mt) providing smooth floating of outriggers.

Four Series 31 batteries are durable and

designed for cold weather use.

Convenient battery disconnects

Bullet-proof HYLAB hydraulic system Easy access panels allow full engine,

battery & hydraulic filter access.

Outstanding features and Fuel cooler keeps fuel temperature

lift capacity performance constant so fuel injectors wont

overheat.

Industrys best carriers, PLUS Block heater - standard

- Pick & carry performance

- Ability to walk with full

counterweight and luffer

Partial counterweight

attachment charts available

- Optimum transportability

fast outrigger box removal

No need to remove

bumper counterweight

for job site travel,

unlike competitors.

Direct drive allows

for simultaneous

operation of outrig- Smooth highway

gers and steering

system for pick & travel with superior

carry operations

pick-and-carry capacities

Front air-ride suspension (standard) provides a smooth ride

for precise handling. For "pick-and-carry" operations, the air

bags are deflated with a flick of a

switch, allowing the suspension to

rest solid.

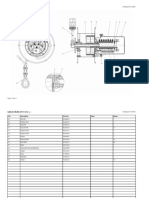

Rack and pinion Sheppard

Aluminum fuel tank

steering system is more resists corrosion,

responsive and has less play reduces travel weight.

in the wheel.

Tubeless 25 on/off highway Non-slip safety strips

tires are inherently balanced, and quick storage

Five conveniently-located catwalks provide

giving you a smoother ride. remote throttle controls

Spun disc rims are truer with sure-footed access to

allow a single operator to

a tighter tolerance and greater the crane upper.

set the outriggers.

capacities.

Interaxle differential is

permanently locked to allow

for maximum traction.

40351.qxd 1/7/02 1:34 PM Page 2

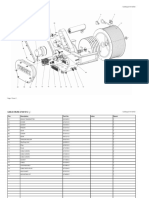

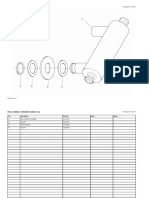

All sheaves are sealed

and maintenance-free,

giving HYLAB owners

outstanding reliability.

Fast hitch

travel links

Live mast can be used as

working boom for rigging

purposes. Optional hydraulic

system folds live mast over

rear of upper to redistribute

axle loading for highway travel.

10' self-assembly

section is available for

all boom configurations.

Fast hook and go

rear outrigger box

22' 8" (6.91 m) outrigger spread,

19' 10" (6.05 m) outrigger base

Photographs may show features that are not

available on both models. Please refer to

Specifications sheet for more information.

40351.qxd 1/7/02 1:34 PM Page 3

Access ladders with hand-rails,

removable right-side catwalks

and a large flat deck are Bullet-proof

standard on Link-Belt cranes,

providing superior operator

hydraulics and

accessibility.

a strong power plant

QUALITY PROVEN FOR

MANY YEARS IN QUALITY

LINK-BELT PRODUCTS

Powered by the biggest and most quiet engine

in its class, the Isuzu engine is fuel efficient

and has proven to be very reliable. It has a

high cooling capacity and provides high line

speeds at higher line pulls.

Load control

The variable displacement system provides

infinite control of load speed in hoist and

lowering modes. Load speed is directly pro-

portional to lever movement. This infinite con-

trol of drum speed allows the operator to

choose the most efficient speed for each load.

Fine inching control

For super precise control of load

lowering/hoisting, hydraulic pump flow can

be minimized with the flip of a switch, allowing

the operator to place loads with either the

main or rear drums with extreme accuracy.

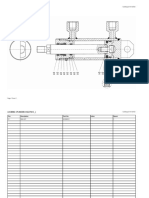

Boom hoist

Independent hydraulic boom hoist is driven by

a variable displacement axial piston motor

through a gear reduction system. This system

features infinitely variable boom hoist speed,

automatic boom hoist brake and a limiting

device that restricts hoisting boom beyond

recommended minimum radius.

Comfort and control at your fingertips

Left-hand catwalks optional

The HYLAB crane operations control Operators cab console features

center provides excellent visibility and include:

is ergonomically designed for maximum

operating comfort and control. Features Free-fall mode indicator

Load indicator

cut here .75

include:

Anti-two block override switch

Armchair mounted pilot-operated Boom hoist override switch

hydraulic controls Limit alarm indicator light

Swing-up roof window with wiper System override switch and indicator

Sliding front glass light

Engine instrumentation panel Front, rear and third drum lock switch

with backlit gauges Swing lever with swing brake and horn Õ

Six-way adjustable seat located on handle

Hand and foot throttle Mechanical drum rotation indicators

18,500 BTU air conditioning in controller

19,000 BTU heater

Load moment indicator/limiter

The standard PAT DS-350* rated capacity limiter

with display includes two lineriders, angle

sensor, computer and anti-two block equipment

Smooth swing glide to provide:

Representation of machine configuration

Hydraulic swing Graphical step-by-step machine set-up

Boom length & angle

through two hydraulic Jib length & angle

motors/drive reductions Load on hook

gives great swing Rated load

Load radius

response with fantastic Tip height

free swing. Anti-two block warning & function limiters

Operation mode

Mechanical brake Audio/visual warning and limits functions

when the load on hook is at 100% of the

release for use with cranes rated load

boom dolley Operator-settable alarms

*The HC-238H II comes standard with the PAT

DS-350G/1334 rated capacity limiter with all of

the above features in addition to a graphic display.

The PAT DS-350G/1334 is pictured to the right.

40351.qxd 1/7/02 1:35 PM Page 4

Moves in 8 loads with max boom, max jib

and full counterweight

Link-Belt leads the way in designing roadable, big capacity truck cranes and nowhere is this

more evident than with the HYLAB Series. The weight efficient design and built-in stripdown

features of the HC-238H II and HC-248H will get your big capacity crane to the next job site

quicker and at less cost.

No helper crane required

The HC-238H II and HC-248H are designed to be self-erecting and self-stripping. The

optional 10' extension with lifting sheaves is used to assemble/disassemble, or the live mast

can be used as a short boom for loading and handling counterweight, outrigger boxes and

boom sections eliminating the need for a helper crane.

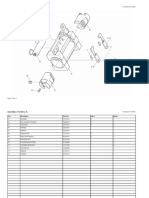

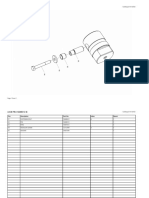

Hydraulic cylinders

pull/extend bottom pins and

rear outrigger box is simply

slipped off of hooks.

Õ

cut here .75

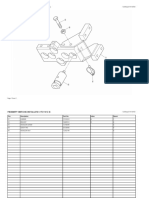

The front outrigger box

can be easily removed for

transport in locations with

severe weight restrictions.

Exclusive weight transfer option

HC-238H II base machine To optimize axle loadings, a patented weight

travels at under 85,000 lbs transfer system flips the mast over the rear of

(38 555 kg) and the HC-248H the upper structure, transferring up to 5,466 lbs.

travels at under 93,000 lbs (2 479 kg) for the HC-238H II and 9,101 lbs

(42 185 kg). (4 128 kg) for the HC-248H from the rear axle

tandem to the front axle tandem to meet the

most strict highway laws, making the HYLAB

series the most roadable large truck cranes

available today.

Air and electrical hook-ups on the rear of the carrier

for boom dolly, trailer or tag axle standard

Pusher axle mount option

allows more weight to be carried

on the machine during transport.

40351.qxd 1/7/02 1:35 PM Page 5

Available attachments provide strength and versatility

Conventional open throat boom Luffing boom attachment

HC-238H II: 50' - 260' (15.24 - 79.25 m) conventional HC-238H II:

boom 165' + 160' + 30' (50.29 + 48.77 + 9.14 m) luffing

- Using pin-connected sections and open throat top boom + luffing jib + fixed jib

section, the HC-238H II provides the longest boom Luffing boom attachment is common to LS-238H

lengths in this machine class. Luffing attachment for the HC-238H II is designed

HC-248H: 50' - 280' (15.24 - 85.34 m) conventional with luffing jib reeving anchored off the luffing boom

boom to keep reeving down low within operators view

Main chord members are made with 100,000 psi yield easy to assemble.

material with high strength lattice. Top section assembly of luffer transports as one piece

Boom suspension is achieved through 18-part boom and makes for fast, easy assembly to the luffing jib.

hoist reeving with dual pendant ropes. HC-248H:

Standard equipment deflector rollers protect lattice sec- 180' + 160' + 30' (54.86 + 48.77 + 9.14 m) luffing

tions from wire rope scuffing. boom + luffing jib + fixed jib

Luffing boom attachment is common to LS-248H

Auxiliary 5' (1.5 m) tip extension Conventional boom also serves as luffing boom

Optional designed to provide clearance between two This attachment flexibility and simplicity makes the HC-

working hoist lines 238H II and HC-248H conventional or with luffing

attachment the first machines of choice to go out of

Boom and jib open throat the yard and to the job!

HC-238H II: 230' + 75' (70.10 m + 22.86 m) boom + Hydraulic third drum mounted in boom base to provide

fixed jib two working lines with luffing is also

HC-248H: 240' + 100' (73.15 m + 30.48 m) boom + available.

fixed jib

Jib is common to other Link-Belt models. 10' (3.05 m) self-assembly section

Shown on luffing boom is available for all configura-

tions.

Required on the HC-238H II luffing boom make-up

HH All boom sections are manufactured in Lexington,

Kentucky for fast, easy service, parts and replacement.

238: ED 238: ED

248: FE 248: FE

BK2

HGX

FH

Conventional Boom with 238: BK

open throat boom 5' auxiliary tip 248: BK2

Luffing cap

10' extension

BK KF

HC-248H:

Luffing boom,

luffing jib and fixed jib

ED 238: ED

248: FE

10' extension

Lexington, Kentucky

www.linkbelt.com

HC-238H II: Boom and jib - ® Link-Belt is a registered trademark. Copyright 2001. All rights reserved.

We are constantly improving our products and therefore reserve the right

Luffing boom, open throat to change designs and specifications.

luffing jib and fixed jib

Litho in U.S.A. 12/01 #4271 (supersedes #4258)

Potrebbero piacerti anche

- Dumper Specification PDFDocumento4 pagineDumper Specification PDFravimutyamNessuna valutazione finora

- Powerscreen Chieftain 1700 BrochureDocumento1 paginaPowerscreen Chieftain 1700 BrochureAndres Astudillo100% (1)

- BH35 2Documento4 pagineBH35 2Bipin KumarNessuna valutazione finora

- Service Crane Kobelco (CKE1800-1F)Documento12 pagineService Crane Kobelco (CKE1800-1F)ArThur BangunNessuna valutazione finora

- S850&T870 Brochure ENDocumento6 pagineS850&T870 Brochure ENMacrotek ArequipaNessuna valutazione finora

- Hitachi EH3500AC Mining Haul Truck BrochureDocumento15 pagineHitachi EH3500AC Mining Haul Truck Brochureaung OoNessuna valutazione finora

- BH60M Dumper-202107061742Documento4 pagineBH60M Dumper-202107061742amir sadighiNessuna valutazione finora

- Chieftain 1400 Inclined Screen BrochureDocumento1 paginaChieftain 1400 Inclined Screen BrochureBisharat RazzaqNessuna valutazione finora

- HTC-8660 60TDocumento16 pagineHTC-8660 60TMIchael TaczaNessuna valutazione finora

- 1533 Shuttle (34HP) 1538 HST (38HP) : 1500 4WD SeriesDocumento6 pagine1533 Shuttle (34HP) 1538 HST (38HP) : 1500 4WD SeriesNayaGaadi DavangereNessuna valutazione finora

- KR En054p Eh4000ac 3Documento15 pagineKR En054p Eh4000ac 3aungaungoomanualNessuna valutazione finora

- Chieftain 2100x Inclined Screen BrochureDocumento1 paginaChieftain 2100x Inclined Screen Brochurerjan7peNessuna valutazione finora

- TMS9000e 0208Documento20 pagineTMS9000e 0208Juan ReyesNessuna valutazione finora

- Hydraulic Excavator: Model Code Engine Ratedpower Operatingweight Backhoe BucketDocumento19 pagineHydraulic Excavator: Model Code Engine Ratedpower Operatingweight Backhoe BucketAdi MNessuna valutazione finora

- Rough Ter Rain Crane: Rt100 Product GuideDocumento16 pagineRough Ter Rain Crane: Rt100 Product GuideAllan KnolNessuna valutazione finora

- BaeS RG-41Documento2 pagineBaeS RG-41engelbrechtwjNessuna valutazione finora

- Rticulated UMP Ruck: Maximum PayloadDocumento12 pagineRticulated UMP Ruck: Maximum Payloadkhang nguyenNessuna valutazione finora

- Gruas TC 40Documento2 pagineGruas TC 40Raul Alberto AlvarezNessuna valutazione finora

- National Boom Trucks Spec 15a5fcDocumento4 pagineNational Boom Trucks Spec 15a5fccubarro1234Nessuna valutazione finora

- Zoomlion RT110Documento16 pagineZoomlion RT110manwaarshafique786Nessuna valutazione finora

- Kobelco 7250-2F PDFDocumento12 pagineKobelco 7250-2F PDFDaryanto GultomNessuna valutazione finora

- WB140-150 Final - 66747-2Documento16 pagineWB140-150 Final - 66747-2email sharingNessuna valutazione finora

- WB140-150 Final - 66747-2Documento16 pagineWB140-150 Final - 66747-2email sharingNessuna valutazione finora

- Rt530e 2 - PG 1 PDFDocumento16 pagineRt530e 2 - PG 1 PDFNavarro NayraNessuna valutazione finora

- Wheel Loader: Tough World. Tough EquipmentDocumento2 pagineWheel Loader: Tough World. Tough EquipmentddfbhghNessuna valutazione finora

- Junttan PM20LC Datasheet PDFDocumento2 pagineJunttan PM20LC Datasheet PDFgustavo caicedoNessuna valutazione finora

- Kubota Tracked Dumper: Truck Easy Loading OperationDocumento4 pagineKubota Tracked Dumper: Truck Easy Loading OperationKeron TrotzNessuna valutazione finora

- Linkbelt HTC11100 SpecDocumento16 pagineLinkbelt HTC11100 SpecDaniel Cáceres TrujilloNessuna valutazione finora

- EH5000AC 3 BrochureDocumento15 pagineEH5000AC 3 BrochureJenius KPNessuna valutazione finora

- KR En049q Eh5000ac 3Documento13 pagineKR En049q Eh5000ac 3Jalil EmadiNessuna valutazione finora

- KomatsuDocumento16 pagineKomatsuGeorge BowenNessuna valutazione finora

- LF230 Hydraulic Diamond Core DrillDocumento2 pagineLF230 Hydraulic Diamond Core DrillSergeyNessuna valutazione finora

- Hitachi EH3500 ACDocumento9 pagineHitachi EH3500 ACbipin kumarNessuna valutazione finora

- Wa200-7 Venss05202 1702Documento24 pagineWa200-7 Venss05202 1702komatsu2562Nessuna valutazione finora

- Komatsu Backhoe Loaders Spec 088545 PDFDocumento16 pagineKomatsu Backhoe Loaders Spec 088545 PDFJohnny WalkerNessuna valutazione finora

- Bobcat R-Series LoadersDocumento6 pagineBobcat R-Series LoadersАндрей ТретьяковNessuna valutazione finora

- Excavator Hitachi EX2500Documento7 pagineExcavator Hitachi EX2500agdityapNessuna valutazione finora

- Grove 880E PDFDocumento20 pagineGrove 880E PDFulul khanNessuna valutazione finora

- Iam9onirveqddrlwgcs Rt100 Metric r062112Documento16 pagineIam9onirveqddrlwgcs Rt100 Metric r062112gogala papakiNessuna valutazione finora

- ZX470LCH Be-3 3 PDFDocumento19 pagineZX470LCH Be-3 3 PDFWB100% (1)

- Cke1350 1F1Documento12 pagineCke1350 1F1AndriNessuna valutazione finora

- 1100 Product Guide ImperialDocumento16 pagine1100 Product Guide ImperialReynaldo Caballero100% (1)

- T685WS11 05Documento2 pagineT685WS11 05govindsr0% (1)

- Hydraulic Crawler Crane: Max. Lifting Capacity: 550 TonDocumento12 pagineHydraulic Crawler Crane: Max. Lifting Capacity: 550 TonPatrick CunananNessuna valutazione finora

- BH 50M PDFDocumento4 pagineBH 50M PDFAnbarasanNessuna valutazione finora

- Documentos Link Belt 2024Documento38 pagineDocumentos Link Belt 2024Nicolas GeremíasNessuna valutazione finora

- Link Belt HTC 8640Documento48 pagineLink Belt HTC 8640saul dussanNessuna valutazione finora

- We-5 VESS081101 0404 EngDocumento12 pagineWe-5 VESS081101 0404 EngmhommdNessuna valutazione finora

- Grove Tms900eDocumento36 pagineGrove Tms900eJaime Flórez0% (1)

- 270 PDFDocumento16 pagine270 PDFYanwar Ibnu Lizar SetyadinNessuna valutazione finora

- Wa320 3 PDFDocumento12 pagineWa320 3 PDFMuhaiminNessuna valutazione finora

- Engine Gross Power: 2 Operating WeightDocumento5 pagineEngine Gross Power: 2 Operating WeightAndi Wardiman AnwarNessuna valutazione finora

- V3sh7djz0s7gj4b3grove Tms900e 90-Ton Hydraulic Truck Crane NetworkDocumento36 pagineV3sh7djz0s7gj4b3grove Tms900e 90-Ton Hydraulic Truck Crane NetworkRobin ChaRiNessuna valutazione finora

- Specifications: Ibratory OIL OmpactorDocumento2 pagineSpecifications: Ibratory OIL OmpactorMohamad NuhNessuna valutazione finora

- Dlupeizrdtzqtw2jgrove Tms700e Truck Crane Network PDFDocumento24 pagineDlupeizrdtzqtw2jgrove Tms700e Truck Crane Network PDFJesus SuarezNessuna valutazione finora

- Heavy Duty Class C Double Girder Series 3 Top Running Max-E-Lift Complete Cranes: Top Running Cranes For Ultimate Maximum Lift HeightDocumento4 pagineHeavy Duty Class C Double Girder Series 3 Top Running Max-E-Lift Complete Cranes: Top Running Cranes For Ultimate Maximum Lift HeightNgô MạnhNessuna valutazione finora

- New Generation LoadersDocumento6 pagineNew Generation LoadersMacrotek ArequipaNessuna valutazione finora

- Cke1800 PDFDocumento4 pagineCke1800 PDFlechinhNessuna valutazione finora

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsDa EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNessuna valutazione finora

- GTH-4013 EX GTH-4017 EX: Serial Number RangeDocumento234 pagineGTH-4013 EX GTH-4017 EX: Serial Number Rangejonny david martinez perezNessuna valutazione finora

- z45-25j Mantenimiento 2Documento255 paginez45-25j Mantenimiento 2jonny david martinez perezNessuna valutazione finora

- Manuel de Operador GTH4013 EXDocumento225 pagineManuel de Operador GTH4013 EXjonny david martinez perezNessuna valutazione finora

- Assembly Draw Frame (21916012 A)Documento2 pagineAssembly Draw Frame (21916012 A)jonny david martinez perezNessuna valutazione finora

- Z11 Z45/22 Hydraulics: Model: Serial NumberDocumento16 pagineZ11 Z45/22 Hydraulics: Model: Serial Numberjonny david martinez perezNessuna valutazione finora

- BRACKET (22717412 - ) : Catalogue ID: 82562Documento2 pagineBRACKET (22717412 - ) : Catalogue ID: 82562jonny david martinez perezNessuna valutazione finora

- BRACKET (16689512 B) : Catalogue ID: 82562Documento2 pagineBRACKET (16689512 B) : Catalogue ID: 82562jonny david martinez perezNessuna valutazione finora

- CONTROL BLOCK (00202912 - ) : Catalogue ID: 82562Documento2 pagineCONTROL BLOCK (00202912 - ) : Catalogue ID: 82562jonny david martinez perezNessuna valutazione finora

- CABLE DRUM (27311412 - ) : Catalogue ID: 82562Documento2 pagineCABLE DRUM (27311412 - ) : Catalogue ID: 82562jonny david martinez perezNessuna valutazione finora

- ACCUMULATOR (00159212 - ) : Catalogue ID: 82562Documento2 pagineACCUMULATOR (00159212 - ) : Catalogue ID: 82562jonny david martinez perezNessuna valutazione finora

- BRACKET (22444312 A) : Catalogue ID: 82562Documento2 pagineBRACKET (22444312 A) : Catalogue ID: 82562jonny david martinez perezNessuna valutazione finora

- CABLE DRUM (27401812 - ) : Catalogue ID: 82562Documento2 pagineCABLE DRUM (27401812 - ) : Catalogue ID: 82562jonny david martinez perezNessuna valutazione finora

- Mounting, Length Transmitter (45196812 B)Documento2 pagineMounting, Length Transmitter (45196812 B)jonny david martinez perezNessuna valutazione finora

- Hydraulic Pin Locking (22400012 - )Documento3 pagineHydraulic Pin Locking (22400012 - )jonny david martinez perezNessuna valutazione finora

- Distribution Box Sve (13348712 C)Documento2 pagineDistribution Box Sve (13348712 C)jonny david martinez perezNessuna valutazione finora

- Dirctional Spool Valve (46067412 - )Documento2 pagineDirctional Spool Valve (46067412 - )jonny david martinez perezNessuna valutazione finora

- Distribution Box Top Main Boom (13348212 A)Documento3 pagineDistribution Box Top Main Boom (13348212 A)jonny david martinez perezNessuna valutazione finora

- Hydraulic - Pin Locking Unit (22442512 A)Documento3 pagineHydraulic - Pin Locking Unit (22442512 A)jonny david martinez perezNessuna valutazione finora

- HOUSING (17218012 F) : Catalogue ID: 82562Documento2 pagineHOUSING (17218012 F) : Catalogue ID: 82562jonny david martinez perezNessuna valutazione finora

- Hydraulic - Pin Pulling Equipment (45166212 - )Documento2 pagineHydraulic - Pin Pulling Equipment (45166212 - )jonny david martinez perezNessuna valutazione finora

- Length Transmitter (13348912 A)Documento2 pagineLength Transmitter (13348912 A)jonny david martinez perezNessuna valutazione finora

- LOCK PIN (16688512 B) : Catalogue ID: 82562Documento2 pagineLOCK PIN (16688512 B) : Catalogue ID: 82562jonny david martinez perezNessuna valutazione finora

- Locking Cylinder (16627412 - )Documento2 pagineLocking Cylinder (16627412 - )jonny david martinez perezNessuna valutazione finora

- Proximity Switches Installatio (17211012 B) PDFDocumento2 pagineProximity Switches Installatio (17211012 B) PDFjonny david martinez perezNessuna valutazione finora

- Longitudinal Angle Transmitter, Mounting (45196612 A)Documento2 pagineLongitudinal Angle Transmitter, Mounting (45196612 A)jonny david martinez perezNessuna valutazione finora

- Hydraulic - Basic Case (45165112 B)Documento3 pagineHydraulic - Basic Case (45165112 B)jonny david martinez perezNessuna valutazione finora

- Mounting Cable Drum (45196912 C)Documento2 pagineMounting Cable Drum (45196912 C)jonny david martinez perezNessuna valutazione finora

- Selection PDFDocumento494 pagineSelection PDFjonny david martinez perez100% (1)

- Pin-Locking Cylinder (16685512 A)Documento2 paginePin-Locking Cylinder (16685512 A)jonny david martinez perezNessuna valutazione finora

- Pin-Locking Cylinder (17217912 - )Documento2 paginePin-Locking Cylinder (17217912 - )jonny david martinez perezNessuna valutazione finora

- FM Tuning Calculator 2Documento12 pagineFM Tuning Calculator 2BUFFALO BUFFALONessuna valutazione finora

- D3E8021B315-Suspension Wheels SteeringDocumento369 pagineD3E8021B315-Suspension Wheels SteeringNick CrushNessuna valutazione finora

- Pertronix Ignition Catalog 2012Documento76 paginePertronix Ignition Catalog 2012kylemadsen100% (1)

- EN SSP 332 Audi A3 Sportback PDFDocumento60 pagineEN SSP 332 Audi A3 Sportback PDFLiviu BarbuNessuna valutazione finora

- WBH Series Recip ManualDocumento6 pagineWBH Series Recip Manualjcastell100Nessuna valutazione finora

- Project ReportDocumento25 pagineProject ReportARUN KUMAR78% (9)

- MG UniversityDocumento2 pagineMG UniversityVaisakVenugopalNessuna valutazione finora

- 9 Speed TransmissionDocumento9 pagine9 Speed TransmissioniwearnexusNessuna valutazione finora

- BS32SS CarburateurDocumento14 pagineBS32SS CarburateurmoiNessuna valutazione finora

- Caterpillar C15 ACERT Dissasembly and AssemblyDocumento348 pagineCaterpillar C15 ACERT Dissasembly and AssemblyAlberto Miglino89% (9)

- O&m 730e Series A30597 & Up Ceam022201Documento174 pagineO&m 730e Series A30597 & Up Ceam022201Luis Alberto Ramirez PerezNessuna valutazione finora

- WARTSILA-SG18V34 Manual PDFDocumento230 pagineWARTSILA-SG18V34 Manual PDFАндрей ВасильевNessuna valutazione finora

- ReporteSeminuevos09 11 21Documento18 pagineReporteSeminuevos09 11 21José María CazaresNessuna valutazione finora

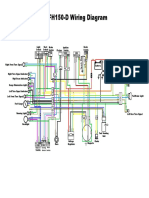

- WFH150cc-D Wiring Diagram PDFDocumento1 paginaWFH150cc-D Wiring Diagram PDFSaša Kostić100% (1)

- Mahindra Scorpio Owners Manual PDFDocumento202 pagineMahindra Scorpio Owners Manual PDFDiv_scribdNessuna valutazione finora

- Montero Sport 2016Documento3 pagineMontero Sport 2016Sis E. NegNessuna valutazione finora

- Range Rover Velar BrochureDocumento84 pagineRange Rover Velar BrochureBohemia IasiNessuna valutazione finora

- 310E 310SE and 315SE Backhoe Loaders IntroductionDocumento5 pagine310E 310SE and 315SE Backhoe Loaders IntroductionJhonny GarciaNessuna valutazione finora

- Lec 3 - Engine ParametersDocumento26 pagineLec 3 - Engine ParametersGODNessuna valutazione finora

- How To Repair Small Engines PDFDocumento4 pagineHow To Repair Small Engines PDFStephane Durel MbidaNessuna valutazione finora

- Etv 216i 2021 Specsheet en Au 2022 09 PDF DataDocumento6 pagineEtv 216i 2021 Specsheet en Au 2022 09 PDF DataNobita RaguwanshiNessuna valutazione finora

- Interactive Panel Display: Kia Soul: Engine Control Module (ECM) - Schematic DiagramsDocumento6 pagineInteractive Panel Display: Kia Soul: Engine Control Module (ECM) - Schematic DiagramsGaragem Officina MechanicaNessuna valutazione finora

- Translated Diagram 1 PDFDocumento3 pagineTranslated Diagram 1 PDFJerroldLYIG100% (1)

- Opposed Piston Pulling Rod EngineDocumento38 pagineOpposed Piston Pulling Rod Enginepaul20000Nessuna valutazione finora

- Volvo Catalog Part2Documento360 pagineVolvo Catalog Part2Denis Konovalov71% (7)

- Engine Control SystemDocumento40 pagineEngine Control SystemCarlos ZelidonNessuna valutazione finora

- Your Dash Lights: Heavy-Duty EnginesDocumento2 pagineYour Dash Lights: Heavy-Duty EnginessenthilanviewNessuna valutazione finora

- Toyota Corolla Hatchback HybridDocumento14 pagineToyota Corolla Hatchback HybridAdam MabsoutNessuna valutazione finora

- FC 4.1.11 - Fork Lift Operator's Checklist FormDocumento1 paginaFC 4.1.11 - Fork Lift Operator's Checklist FormJosef Demner Tiu PaspeNessuna valutazione finora

- Manual Doosan V158ti Doosan 2002 Español Parte 2Documento90 pagineManual Doosan V158ti Doosan 2002 Español Parte 2Erick ovalleNessuna valutazione finora