Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Facts at Your Fingertips-200706-Solvent Selection

Caricato da

onizuka-t2263Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Facts at Your Fingertips-200706-Solvent Selection

Caricato da

onizuka-t2263Copyright:

Formati disponibili

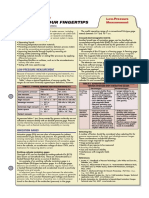

Solvent Selection

Methodology

Department Editor: Rita L. D'Aquino

A STEPWISE PROCEDURE TABLE 1. Some well-known databases and solvent selection tools

Databases Address and comments

Organic solvents have been used in many industries for centu-

ChemFinder Searchable data and hyperlink index: http://chemfinder.cambridgesoft.com

ries, but the methods and tools to select optimal solvents while

minimizing their adverse environmental, health, safety and op- Solvents Databases Solvent substitution data systems at http://es.epa.gov/ssds/ssds.html;

erational concerns are still evolving. The appropriate selection “Handbook of Solvents” from www.chemtec.org/cd/ct_23.html; and

of solvents depends to a large extent on the application — more SOLVDB at http://solvdb.ncms.org/index.html

specifically on what needs to be dissolved, and under what NIST Webbook Source of physical and chemical data at http://webbook.nist.gov

conditions. This article presents a four-step approach to solvent DIPPR and www.aiche.org/TechnicalSocieties/DIPPR/About/Mission.aspx; and

selection based upon Ref. 1*, where the reader will find a list of TAPP www.chempute.com/tapp.htm

additional resources on this topic. CAPEC Database Pure as well as mixture properties data, including solvent-solute database:

www.capec.kt.dtu.dk/Software/ICAS-and-its-Tools

Identify the challenge and solvent characteristics. Selection Tools Address and comments

The first two steps are: 1) identifying the actual problem and SMSwin A specialized software for property estimation and solvent classification:

technology or unit operation required to solve it; and 2) defining www.capec.kt.dtu.dk/documents/software/SMSWIN.htm

the requirements that must be met by the solvent, using criteria

NRTL-SAC and Activity coefficient method based on segment contributions. Predictive based

related to its physical and chemical properties (e.g., pure-solvent

eNRTL-SAC on a small set of solubility data. Useful for crystallization solvent selection

properties, such as normal boiling point, the Hildebrand solubility and extends to LLE and VLE: www.aspentech.com

parameter at 300 K, the Hansen solubility parameters; solvent-

solute properties, such as the solubility of the solute as a function

of the composition of the mixture; and functional constraints, such TABLE 2. Well-known solvents together with their related properties

as solute loss in solute).

Solvent Name Molecule type Group type Charge NBP NMP Sol. Par.

(K) (K)

Obtain reliable values of solvent properties and

narrow down selection. There are several alternatives for this 1-Methyl-2-pyrrolidinone Amide 1 NE/EPD 475.15 249.15 23.16

third step. For example, one can measure the required properties, Acetonitrile Nitrile 1 E/NPG 354.75 229.35 24.05

use a database of properties of chemicals (or solvents), or, use Dimethyl sulphoxide S-oxide 1 E/NPG 462.15 291.65 26.75

property models to estimate them. For solvent-selection problems Dimethyl formamide Amide 1 NE/NPG 426.15 212.75 23.95

not involving chemical reactions, the pattern of the desired Dimethylacetamide Amide 1 NE/NPG 438.15 253.15 22.35

solvent is established through analysis of the solute, application Diisopropyl ether Ether 2 NE/EPD 341.65 181.35 14.45

type, and other constraints. Dimethyl ether Ether 2 NE/EPD 248.35 131.65 15.12

Once this is established, a database of known solvents can Methyl tertbutyl ether Ether 2 NE/EPD 328.35 164.55 15.07

be used to identify the solvents that match the necessary pattern Tetrahydrofuran Ether 2 NE/EPD 338.15 164.85 18.97

(Table 1). On the other hand, when chemical reactions are Chlorobenzene Chloride 3 NE/P 632.35 404.9 19.35

involved, the approach is based on transition-state theory and m-xylene (also o-; p-) Aromatic HC 3 NE/P 412.27 225.3 18.05

requires consideration of the solvation energies of the reactants,

Toluene Aromatic HC 3 NE/P 383.95 178.25 18.32

products and transition states, and thus, knowledge of the reac-

Acetic acid Acid 4 PG 391.05 289.81 19.01

tion mechanism.

When the crucial values have been found, the solvent search Propionic acid Acid 4 E/PG 414.25 252.45 19.41

could be such that first, solvent-pure properties are used, followed Sulfuric acid Acid 4 E/PG 610 283.46 28.41

ordered

by solvent-EHS, then solvent-solute, and finally solvent-function.

Narrow down the list by removing the compounds that do not Propanol Alcohol 5 E/N 370.35 147.05 24.45

match desired properties. Ethanol Alcohol 5 E/N 351.35 159.05 26.13

A protocol derived by Britest Ltd. (www.britest.co.uk) seeks to Butanol Alcohol 5 E/N 390.81 183.85 23.35

use mechanistic principles to guide solvent selection (Figure). The Ethylene glycol Alcohol 5 E/N 470.45 260.15 33.7

objective is to follow the arrows according to the problem defini- Dichloromethane Chloride 6 NE/EPD 313.15 178.05 20.37

tion and a search criterion until an end-point is reached, thereby Heptane Alkane 7 NE/I 371.65 182.55 15.2

obtaining the characteristics of the candidate solvents. These Hexane Alkane 7 NE/I 341.85 177.85 14.9

characteristics are used to identify the group to which the solvents Pentane Alkane 7 NE/I 309.22 143.42 14.4

belong using solvents database (see Table 2). The corresponding Methanol Alcohol 4, 5 E/N 337.85 175.47 29.59

group-types are evaluated and a final selection is made. Water Aqueous 4, 5 E/N 373.15 273.15 47.81

Verify selection. The fourth step is to verify that the solvent NE = non-electrolytic solvent; E = electrolytic solvent; P = polarizable; EPD = electron-pair

donor; I = inert; PG = protogenic (proton donor); N= neutral (donor & acceptor); NPG =

works as expected by performing a computational validation non-protogenic (proton acceptor); NBP = normal boiling point; NMP = normal melting point;

by simulation. Experimental validation of a solvent candidate is Sol. Par. = Hildebrand solubility parameter at 300 K (MPa1/2)

required at all stages of process development.

Stability, solubility of reactants, products

Single phase or solid-liquid Two-phase or liquid-liquid Water, immiscible solvent

(polar phase is water)

Homogeous catalysis Condensation SN1/E1 SN2/E2

by Pt group complexes

High polarity

Substrate/product hydroxyl sensitive Choose ‘polarity’

Moderate polarity based on substrate

Dipolar Aromatic and reagent

aprotic hydrocarbon Yes Consider

DPA ethers, solvation No solubility. May need

(xylene) phase-transfer catalyst

aromatics

Water, carboxylic Dipolar aprotic

Group 1 Fast, low temp, Slow, high- acids, inorganic ethers Group 3

but recovery temperature, acids, lower Water,

Group 2 difficult easy recovery alcohols Group 1 alcohols Group 6

Group 3 Group 1 Group 3 Group 4 Group 2 Group 5 Group 7

*Reference: 1. Gani, R., et al., A Modern Approach to Solvent Selection, Chem. Eng., Vol. 113, No. 3, pp. 30–43, Mar. 2006. Author E-mail: rag@kt.dtu.dk

Potrebbero piacerti anche

- Measurement of Antioxidant Activity and Capacity: Recent Trends and ApplicationsDa EverandMeasurement of Antioxidant Activity and Capacity: Recent Trends and ApplicationsResat ApakNessuna valutazione finora

- Charged Aerosol Detection for Liquid Chromatography and Related Separation TechniquesDa EverandCharged Aerosol Detection for Liquid Chromatography and Related Separation TechniquesPaul H. GamacheNessuna valutazione finora

- 515 2Documento39 pagine515 2AlexSNessuna valutazione finora

- 515 1Documento33 pagine515 1AlexSNessuna valutazione finora

- 515 3Documento56 pagine515 3AlexSNessuna valutazione finora

- Astm D5837 - 15Documento9 pagineAstm D5837 - 15Alexander Nieto Vela100% (1)

- D 5837 - 99 - Rdu4mzc - PDFDocumento8 pagineD 5837 - 99 - Rdu4mzc - PDFjayakumarNessuna valutazione finora

- D 5837 - 99 - Rdu4mzctukve PDFDocumento11 pagineD 5837 - 99 - Rdu4mzctukve PDFjayakumarNessuna valutazione finora

- D 6730 - 01 AstmDocumento55 pagineD 6730 - 01 AstmSebastian GonzalezNessuna valutazione finora

- Phase Behavior and Thermodynamic Model Parameters in Simulations of Extractive Distillation For Azeotrope SeparationDocumento12 paginePhase Behavior and Thermodynamic Model Parameters in Simulations of Extractive Distillation For Azeotrope SeparationAeromoon AeroseekNessuna valutazione finora

- D 4252 - 89 R03 - RdqyntiDocumento5 pagineD 4252 - 89 R03 - RdqyntiSTAFFORDNessuna valutazione finora

- Automated Solubility and Crystallization AnalysisDocumento34 pagineAutomated Solubility and Crystallization AnalysisMaria José FuturoNessuna valutazione finora

- D4861Documento16 pagineD4861Fredi Cari CarreraNessuna valutazione finora

- 5990 5867enDocumento10 pagine5990 5867enZakaria Jado Abeido100% (1)

- TPH DirectMethodDocumento29 pagineTPH DirectMethodAEHSFOUNDATION100% (5)

- D 5739 - 00 Rdu3mzkDocumento13 pagineD 5739 - 00 Rdu3mzkAnonymous xMQd4zNessuna valutazione finora

- Analysis of Ethylene Product: Standard Guide ForDocumento2 pagineAnalysis of Ethylene Product: Standard Guide ForahmedNessuna valutazione finora

- D 5845 Method For Determination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and Tert-Butanol in Gasoline by Infrared SpectrosDocumento9 pagineD 5845 Method For Determination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and Tert-Butanol in Gasoline by Infrared SpectrosMarlon AgustínNessuna valutazione finora

- D5412 PDFDocumento10 pagineD5412 PDFZamir Danilo Morera Forero100% (1)

- IDENTIFICATION AND CHEMICAL CHARACTERIZATION OF AZADIRACHTA INDICA LEAF EXTRACTS THROUGH THIN LAYER CHROMATOGRAPHY-with-cover-page-v2Documento7 pagineIDENTIFICATION AND CHEMICAL CHARACTERIZATION OF AZADIRACHTA INDICA LEAF EXTRACTS THROUGH THIN LAYER CHROMATOGRAPHY-with-cover-page-v2zemen tadegeNessuna valutazione finora

- Astm D7463Documento8 pagineAstm D7463samuellepedealbaNessuna valutazione finora

- Determination of Individual Components in Spark Ignition Engine Fuels by 100-Metre Capillary (With Precolumn) High-Resolution Gas ChromatographyDocumento55 pagineDetermination of Individual Components in Spark Ignition Engine Fuels by 100-Metre Capillary (With Precolumn) High-Resolution Gas ChromatographyMarika KacharavaNessuna valutazione finora

- ASTM D5501-For Ethanol Greater 20%Documento4 pagineASTM D5501-For Ethanol Greater 20%FARE Labs Unit-03Nessuna valutazione finora

- D2896 - Standard Test Method For Base Number of Petroleum Products by Potentiometric Perchloric Acid TitrationDocumento10 pagineD2896 - Standard Test Method For Base Number of Petroleum Products by Potentiometric Perchloric Acid TitrationEhsan ZiaeiNessuna valutazione finora

- Method Epa 502.2Documento35 pagineMethod Epa 502.2luisin0Nessuna valutazione finora

- D 6729 - 01 - Rdy3mjkDocumento36 pagineD 6729 - 01 - Rdy3mjkLuz Adriana MorenoNessuna valutazione finora

- Analysis of Pesticide Residues in Apple Using Agilent Bond Elut Quechers European Standard en Kits by Lc/Ms/Ms DetectionDocumento14 pagineAnalysis of Pesticide Residues in Apple Using Agilent Bond Elut Quechers European Standard en Kits by Lc/Ms/Ms DetectionDesislav DonchevNessuna valutazione finora

- Determination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and - Butanol in Gasoline by Infrared SpectrosDocumento5 pagineDetermination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and - Butanol in Gasoline by Infrared SpectrosMilos PantelicNessuna valutazione finora

- Green Solvents PresDocumento74 pagineGreen Solvents PresTDSNessuna valutazione finora

- Determination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and - Butanol in Gasoline by Infrared SpectrosDocumento5 pagineDetermination of MTBE, ETBE, TAME, DIPE, Methanol, Ethanol and - Butanol in Gasoline by Infrared SpectrosBryan PariNessuna valutazione finora

- Chemosphere: Yun-Cheol Na, Kang-Jin Kim, Jongki Hong, Jung-Ju SeoDocumento6 pagineChemosphere: Yun-Cheol Na, Kang-Jin Kim, Jongki Hong, Jung-Ju SeoAditya Febrian MasriNessuna valutazione finora

- Application of A Classical Least-Squares Regression Method To The Assay of 1,4-Dihydropyridine Antihypertensives and Their PhotoproductsDocumento8 pagineApplication of A Classical Least-Squares Regression Method To The Assay of 1,4-Dihydropyridine Antihypertensives and Their Photoproductsiabureid7460Nessuna valutazione finora

- Determination of Polysorbate 80 in Parenteral FormDocumento7 pagineDetermination of Polysorbate 80 in Parenteral FormNavisa HaifaNessuna valutazione finora

- Alternative Calibration and Standardization Procedure of Iatroscan TLC FID For SARA Hydrocarbon Class QuantificationDocumento5 pagineAlternative Calibration and Standardization Procedure of Iatroscan TLC FID For SARA Hydrocarbon Class QuantificationNatalia KovalovaNessuna valutazione finora

- Detailed Hydrocarbon Analysis by High Resolution Gas Chromatography With Vacuum Ultraviolet Absorption Spectroscopy (GC-VUV)Documento45 pagineDetailed Hydrocarbon Analysis by High Resolution Gas Chromatography With Vacuum Ultraviolet Absorption Spectroscopy (GC-VUV)Sdferwste SrqreNessuna valutazione finora

- Exp't 51: Nitration of NitrobenzeneDocumento4 pagineExp't 51: Nitration of NitrobenzenelovehopeNessuna valutazione finora

- E1618-14 R1 PDFDocumento15 pagineE1618-14 R1 PDFEko AnjangNessuna valutazione finora

- 528Documento46 pagine528AlexSNessuna valutazione finora

- Method 548Documento19 pagineMethod 548AlexSNessuna valutazione finora

- 000422100-Meth Resolution Co2Documento5 pagine000422100-Meth Resolution Co2Rajesh KennyNessuna valutazione finora

- Ast D-6953Documento6 pagineAst D-6953jesrcontreras1976100% (1)

- 552 2Documento32 pagine552 2AlexSNessuna valutazione finora

- Furanic in Transform Oil ASTM D5837-1999 (2005)Documento3 pagineFuranic in Transform Oil ASTM D5837-1999 (2005)Yap Poh SiewNessuna valutazione finora

- D5837Documento8 pagineD5837usamafalakNessuna valutazione finora

- Chemical Abstracts Service Registry NumberDocumento22 pagineChemical Abstracts Service Registry NumberLeonardoNessuna valutazione finora

- EPA HQ OW 2010 0288 0012 - ContentDocumento33 pagineEPA HQ OW 2010 0288 0012 - Contentmustak kadivarNessuna valutazione finora

- Method 515.3 Determination of Chlorinated Acids in DrinkingDocumento56 pagineMethod 515.3 Determination of Chlorinated Acids in DrinkingPedro FrancoNessuna valutazione finora

- J.W. Hodgeson, A.L. Cohen - Method 551, (1990) D.J. Munch (USEPA, Office of Water) and D.P. Hautman (International Consultants, Inc.) - Method 551.1, (1995)Documento61 pagineJ.W. Hodgeson, A.L. Cohen - Method 551, (1990) D.J. Munch (USEPA, Office of Water) and D.P. Hautman (International Consultants, Inc.) - Method 551.1, (1995)Ítalo LimaNessuna valutazione finora

- Determination of Sugars, Byproducts, and Degradation Products in Liquid Fraction Process SamplesDocumento14 pagineDetermination of Sugars, Byproducts, and Degradation Products in Liquid Fraction Process SamplesfhrzsptrNessuna valutazione finora

- Furanic Compounds v2 PDFDocumento6 pagineFuranic Compounds v2 PDFAnjar TriyokoNessuna valutazione finora

- Furanic Compounds v2 PDFDocumento6 pagineFuranic Compounds v2 PDFlevymiguel3012726Nessuna valutazione finora

- Furanic Compounds v2Documento6 pagineFuranic Compounds v2Anjar TriyokoNessuna valutazione finora

- Furanic Compounds v2 PDFDocumento6 pagineFuranic Compounds v2 PDFAbdullah GhannamNessuna valutazione finora

- Furanic Compounds v2 PDFDocumento6 pagineFuranic Compounds v2 PDFusamafalakNessuna valutazione finora

- Furanic Compounds PDFDocumento6 pagineFuranic Compounds PDFAbdullah GhannamNessuna valutazione finora

- D 3921 - 2003Documento7 pagineD 3921 - 2003THANGVU100% (1)

- 526Documento49 pagine526AlexSNessuna valutazione finora

- End Group 2Documento22 pagineEnd Group 2Sabha Khalid shafiqNessuna valutazione finora

- Surfactante HPLCDocumento248 pagineSurfactante HPLCRulo RisculeseNessuna valutazione finora

- Practical Methods for Biocatalysis and Biotransformations 2Da EverandPractical Methods for Biocatalysis and Biotransformations 2John WhittallNessuna valutazione finora

- Facts at Your Fingertips-201105-Pressure Measurement ConsiderationsDocumento1 paginaFacts at Your Fingertips-201105-Pressure Measurement Considerationsonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201011-Viscosity MeasurementDocumento1 paginaFacts at Your Fingertips-201011-Viscosity Measurementonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201104-Hopper Inserts For Improved Solids FlowDocumento1 paginaFacts at Your Fingertips-201104-Hopper Inserts For Improved Solids Flowonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201103-Infrared Temperature MeasurementDocumento1 paginaFacts at Your Fingertips-201103-Infrared Temperature Measurementonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201010-MSMPR Crystallization EquipmentDocumento1 paginaFacts at Your Fingertips-201010-MSMPR Crystallization Equipmentonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201012-Project Design Decision-Making Option ListsDocumento1 paginaFacts at Your Fingertips-201012-Project Design Decision-Making Option Listsonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201101-Hansen Solubility Parameters (HSP)Documento1 paginaFacts at Your Fingertips-201101-Hansen Solubility Parameters (HSP)onizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201102-Control Valve Position SensorsDocumento1 paginaFacts at Your Fingertips-201102-Control Valve Position Sensorsonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201007-Conservation Economics Carbon Pricing ImpactsDocumento1 paginaFacts at Your Fingertips-201007-Conservation Economics Carbon Pricing Impactsonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201006-Fluid MechanicsDocumento1 paginaFacts at Your Fingertips-201006-Fluid Mechanicsonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201008-Heat Transfer Fluids System FiltrationDocumento1 paginaFacts at Your Fingertips-201008-Heat Transfer Fluids System Filtrationonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201009-Controlling Membrane FoulingDocumento1 paginaFacts at Your Fingertips-201009-Controlling Membrane Foulingonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201005-Burner Operating Characteristics PDFDocumento1 paginaFacts at Your Fingertips-201005-Burner Operating Characteristics PDFonizuka-t2263Nessuna valutazione finora

- CHE Facts 0410Documento1 paginaCHE Facts 0410gwinnruNessuna valutazione finora

- Facts at Your Fingertips-201005-Burner Operating Characteristics PDFDocumento1 paginaFacts at Your Fingertips-201005-Burner Operating Characteristics PDFonizuka-t2263Nessuna valutazione finora

- CHE Facts 0410Documento1 paginaCHE Facts 0410gwinnruNessuna valutazione finora

- Facts at Your Fingertips-201001-Low-Pressure MeasurementDocumento1 paginaFacts at Your Fingertips-201001-Low-Pressure Measurementonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201003-Steam Tracer Lines and Traps PDFDocumento1 paginaFacts at Your Fingertips-201003-Steam Tracer Lines and Traps PDFonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201002-Positive Displacement PumpsDocumento1 paginaFacts at Your Fingertips-201002-Positive Displacement Pumpsonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201002-Positive Displacement PumpsDocumento1 paginaFacts at Your Fingertips-201002-Positive Displacement Pumpsonizuka-t2263Nessuna valutazione finora

- Above and Underground Storage Tanks PDFDocumento1 paginaAbove and Underground Storage Tanks PDFrasik.kiraneNessuna valutazione finora

- Facts at Your Fingertips-201003-Steam Tracer Lines and Traps PDFDocumento1 paginaFacts at Your Fingertips-201003-Steam Tracer Lines and Traps PDFonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-201001-Low-Pressure MeasurementDocumento1 paginaFacts at Your Fingertips-201001-Low-Pressure Measurementonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-200912-Creating Installed Gain GraphsDocumento1 paginaFacts at Your Fingertips-200912-Creating Installed Gain Graphsonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-200907-Flowmeter SelectionDocumento2 pagineFacts at Your Fingertips-200907-Flowmeter Selectiononizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-200910-Chemical Resistance of ThermoplasticsDocumento1 paginaFacts at Your Fingertips-200910-Chemical Resistance of Thermoplasticsonizuka-t2263Nessuna valutazione finora

- Adsorption PDFDocumento1 paginaAdsorption PDFrasik.kiraneNessuna valutazione finora

- Facts at Your Fingertips-200909-Heat Transfer System Design IIDocumento1 paginaFacts at Your Fingertips-200909-Heat Transfer System Design IIonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-200906-Specialty MetalsDocumento1 paginaFacts at Your Fingertips-200906-Specialty Metalsonizuka-t2263Nessuna valutazione finora

- Facts at Your Fingertips-200905-Choosing A Control SystemDocumento1 paginaFacts at Your Fingertips-200905-Choosing A Control Systemonizuka-t2263Nessuna valutazione finora

- Kitchen Improvised, Complete (Blasting Caps, 2, Same As BeforeDocumento79 pagineKitchen Improvised, Complete (Blasting Caps, 2, Same As BeforeAsad Imran90% (10)

- Silicon Carbide - Vs-Tungsten Carbide: Contributed by Zoeller Engineering DepartmentDocumento1 paginaSilicon Carbide - Vs-Tungsten Carbide: Contributed by Zoeller Engineering DepartmentDikaAnindyajatiNessuna valutazione finora

- ZuzanaDocumento58 pagineZuzanaAlexanderNessuna valutazione finora

- Inorganic Chemistry Lab Report 3Documento5 pagineInorganic Chemistry Lab Report 3Dolly Naris100% (1)

- ATF - List of Explosive Chemicals 20200825-133743Documento40 pagineATF - List of Explosive Chemicals 20200825-133743serge.pungweNessuna valutazione finora

- Experiments - LBYCH34 Experiment Manual Student SDocumento24 pagineExperiments - LBYCH34 Experiment Manual Student SShean Berwin GonzalesNessuna valutazione finora

- Datasheets For Cryogenic Storage Tanks - Rev1Documento4 pagineDatasheets For Cryogenic Storage Tanks - Rev1Ahmed Ben HmidaNessuna valutazione finora

- Task 1: Elements, Compounds and MixturesDocumento4 pagineTask 1: Elements, Compounds and MixturesDesiree BuhongNessuna valutazione finora

- Iig July 2018Documento592 pagineIig July 2018Võ Đức TrọngNessuna valutazione finora

- Caustic Soda From Natural Trona 2014Documento5 pagineCaustic Soda From Natural Trona 2014MauRmzNessuna valutazione finora

- BIOL 2420: Microbiology For The Health Sciences Biochemical Test ChartDocumento2 pagineBIOL 2420: Microbiology For The Health Sciences Biochemical Test ChartMadhu RaoNessuna valutazione finora

- HISTOTECHNIQUESDocumento20 pagineHISTOTECHNIQUESZIPPORAH JESSICA NONOGNessuna valutazione finora

- (Hideo Sawada) Thermodynamics of Polymerization - (BookFi) PDFDocumento294 pagine(Hideo Sawada) Thermodynamics of Polymerization - (BookFi) PDFRendi RezaindNessuna valutazione finora

- Lube OilDocumento15 pagineLube Oilhala mrayanNessuna valutazione finora

- ODI ListDocumento21 pagineODI Listaji sulaiman100% (1)

- Chemical Changes Student ExplorationDocumento5 pagineChemical Changes Student ExplorationSujatha Vimal100% (2)

- AATCC News-Phenolic Yellowing Could Be Reversed by SunlightDocumento2 pagineAATCC News-Phenolic Yellowing Could Be Reversed by SunlightMichael ChenNessuna valutazione finora

- Amine-Based Solvent For CO2 Absorption and Its Impact On Carbon Steel Corrosion: A Perspective ReviewDocumento12 pagineAmine-Based Solvent For CO2 Absorption and Its Impact On Carbon Steel Corrosion: A Perspective ReviewEVELYN RAJAN TCR19CH023Nessuna valutazione finora

- General Phase Behaviour of SurfactantsDocumento26 pagineGeneral Phase Behaviour of SurfactantsdumboraghavNessuna valutazione finora

- Esters, Organic Ullmann PDFDocumento21 pagineEsters, Organic Ullmann PDFravi panchalNessuna valutazione finora

- Fluorocarbon Rubber: Preperation & PropertiesDocumento8 pagineFluorocarbon Rubber: Preperation & PropertiesBenjaminLeonardNessuna valutazione finora

- Chemistry Xam Idea PDFDocumento285 pagineChemistry Xam Idea PDFArunabh BhattacharyaNessuna valutazione finora

- Firas EPG RecyclingDocumento26 pagineFiras EPG RecyclingSuji Educational ServicesNessuna valutazione finora

- PeriodicityDocumento6 paginePeriodicityHadi AlnaherNessuna valutazione finora

- 9 - Factors Affecting Enzymes-1 PDFDocumento32 pagine9 - Factors Affecting Enzymes-1 PDFVivek KumarNessuna valutazione finora

- SCH014 - 5P0431Catalytic HydrogenationDocumento22 pagineSCH014 - 5P0431Catalytic HydrogenationATHIRA PNessuna valutazione finora

- VT Sir NCERT Short Notes - 1 (Solid State)Documento16 pagineVT Sir NCERT Short Notes - 1 (Solid State)Aayush KumarNessuna valutazione finora

- Cell Membranes & Transport 1Documento77 pagineCell Membranes & Transport 1Alen SheenNessuna valutazione finora

- 4 - CMOS IC Fabrication ProcessDocumento59 pagine4 - CMOS IC Fabrication Processkrishna chytanyaNessuna valutazione finora

- Quaternary Ammonium CationDocumento60 pagineQuaternary Ammonium Cationkhalid mehmoodNessuna valutazione finora