Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ddaily Drift Calibration Procedure: 1. Scope

Caricato da

John Dolan0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

97 visualizzazioni1 paginaTitolo originale

Daily Drift Procedure

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

97 visualizzazioni1 paginaDdaily Drift Calibration Procedure: 1. Scope

Caricato da

John DolanCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

THAILAND INDUSTRIAL PROCEDURE

DEI EQUIPMENT IN-HOUSE CHECK

Approved: J Dolan

DDaily Drift Calibration Procedure

1. SCOPE

In-House daily calibrations of Drifts shall conform to applicable standards.

2. REFERENCE

2.1 DS-1™ Drill Stem Inspection TH Hill and Associates 3rd Edition Volume 3

2.2 API 5A5 – Field Inspection of New Casing, Tubing, and Plain-End Drill Pipe

3. APPARATUS

3.1 Calibrated Vernier Caliper.

4. PROCEDURE

4.1 The mandrel diameter shall be measured using a micrometer or mechanical

caliper that displays the readout in hundredths of a millimeter (thousandths of

an inch). These measurements shall be made with the drift mandrel and

micrometer at the same temperature. Measurements shall be made at each

end ofthe drift mandrel. Each measurement shall be made in two locations,

90° apart. The allowable mandrel tolerance shall be 0,000 mm to +0,013 mm

(0.000 in to +0.005 in) from the specified ISO/API dimensions. Drift mandrels

larger than the upper tolerance of +0,013 mm (+0.005 in) may be used for

acceptance but not for rejection. In case of dispute, a precision steel drift

mandrel made to the appropriate ISO/API dimensions shall be used to

resolve whether the lengths are acceptable or rejectable.

4.2. This procedure will be carried out at the start of a shift and at least once every

500 joints.

5. REPORT

The report should have the following information:

a) Name of equipment

b) Asset or serial number of equipment

c) Date of checking

d) Result of check

e) Name of personnel carrying out the check

f) Signature of personnel carrying out the check

g) Identification of reference equipment used

6. Proforma

6.1 PF-(AU)-[IND]-IN- 060 – Black Light / UV /Visible Light Meter

Potrebbero piacerti anche

- Daily Drift Calibration Procedure: 1. ScopeDocumento1 paginaDaily Drift Calibration Procedure: 1. ScopeJohn DolanNessuna valutazione finora

- Ultrasonic Testing ProcedureDocumento12 pagineUltrasonic Testing ProcedureRohit Kumar Mishra100% (1)

- IRIS - Finfans Inspection Report PDFDocumento14 pagineIRIS - Finfans Inspection Report PDFnaoufel1706Nessuna valutazione finora

- Phased Array Ut Procedure For Welds: Industrial Engineering ServicesDocumento14 paginePhased Array Ut Procedure For Welds: Industrial Engineering ServicesAmit Hasan100% (2)

- 3.7 Appendix D - Minimum RequirementsDocumento14 pagine3.7 Appendix D - Minimum RequirementsendyNessuna valutazione finora

- Drift 005Documento4 pagineDrift 005tofa01100% (1)

- IRIS - Boiler Tubes Inspection Report PDFDocumento11 pagineIRIS - Boiler Tubes Inspection Report PDFGandika Putra100% (1)

- Dimensional Control ProcedureDocumento12 pagineDimensional Control ProcedureBethel NdifonNessuna valutazione finora

- EOB-WI-INS-139 Rev.5Documento2 pagineEOB-WI-INS-139 Rev.5adi RukunNessuna valutazione finora

- SB1345Documento7 pagineSB1345Yarisa VangeNessuna valutazione finora

- TAI SERVICES, INC. Eddy Current Inspection Procedures and SpecificationDocumento4 pagineTAI SERVICES, INC. Eddy Current Inspection Procedures and SpecificationPrakashNessuna valutazione finora

- MS For Heat ExchangersDocumento6 pagineMS For Heat ExchangersravikumarNessuna valutazione finora

- Procedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesDocumento10 pagineProcedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesJonathan Espinoza MejiaNessuna valutazione finora

- AWSD1.1 Procedure UtDocumento19 pagineAWSD1.1 Procedure Utkevin desai50% (2)

- Procedure For ULTRASONIC THICKNESSDocumento4 pagineProcedure For ULTRASONIC THICKNESSKarrar TalibNessuna valutazione finora

- WI-INSP-02 R1 Work Instruction - Heat Exchanger InspectionDocumento5 pagineWI-INSP-02 R1 Work Instruction - Heat Exchanger InspectionRakesh MishraNessuna valutazione finora

- Load Test ProcedureDocumento70 pagineLoad Test ProcedureMohammed Rizwan Ahmed75% (4)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocumento2 pagineInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNessuna valutazione finora

- Volume Calibration - ICL CalibrationDocumento5 pagineVolume Calibration - ICL CalibrationMuhammed BatureNessuna valutazione finora

- Induction Bends - COPIDocumento12 pagineInduction Bends - COPIAdvis100% (1)

- Ultrasonic Wall Thickness (TSCI-WP-DS-003)Documento3 pagineUltrasonic Wall Thickness (TSCI-WP-DS-003)RonniNessuna valutazione finora

- Iso Work InstructionsDocumento115 pagineIso Work InstructionsEkondroNessuna valutazione finora

- MBS-001, Rotor Shaft Specification - SemifinishedDocumento4 pagineMBS-001, Rotor Shaft Specification - SemifinishedNirmit GandhiNessuna valutazione finora

- Awsd11 Procedure Ut CompressDocumento19 pagineAwsd11 Procedure Ut Compressparag wadekarNessuna valutazione finora

- Insulation Tester 1 CI 02 I2Documento13 pagineInsulation Tester 1 CI 02 I2ebbasinghNessuna valutazione finora

- General Requirements For Ultrasonic ExaminationsDocumento11 pagineGeneral Requirements For Ultrasonic ExaminationsmaheshNessuna valutazione finora

- Eddy Current SpecificationsDocumento7 pagineEddy Current SpecificationsBhavani PrasadNessuna valutazione finora

- Schedule of Technical Requirement (STR)Documento9 pagineSchedule of Technical Requirement (STR)Rahul MauryaNessuna valutazione finora

- Liqiid Penetrant InspectionDocumento5 pagineLiqiid Penetrant InspectionY ShameyaNessuna valutazione finora

- Helium Leak Testing Procedure-Heat ExchangerDocumento5 pagineHelium Leak Testing Procedure-Heat ExchangerDanielNessuna valutazione finora

- Process Piping Inspection Procedure Rev.2 PDFDocumento34 pagineProcess Piping Inspection Procedure Rev.2 PDFLevi Porter100% (6)

- Quality Assurance and Reliability: DiodesDocumento6 pagineQuality Assurance and Reliability: DiodesmJ vvelascoNessuna valutazione finora

- CB Testing and Commissioning 76-92Documento17 pagineCB Testing and Commissioning 76-92Vijaya KumarNessuna valutazione finora

- CB Testing and Commissioning 76-92 PDFDocumento17 pagineCB Testing and Commissioning 76-92 PDFVijaya Kumar100% (2)

- Method Statement Ground TestDocumento3 pagineMethod Statement Ground Testm.bakrNessuna valutazione finora

- Egatra: Quality ControlDocumento6 pagineEgatra: Quality ControlAndreas Schlager100% (3)

- Ultrasonic Thickness MeasurementDocumento12 pagineUltrasonic Thickness MeasurementmaheshNessuna valutazione finora

- ECTDocumento17 pagineECTvikramNessuna valutazione finora

- Lead STD Cal 8Documento3 pagineLead STD Cal 8John Dolan100% (1)

- Welding Repair Procedure BHELDocumento1 paginaWelding Repair Procedure BHELPrabir Pal100% (1)

- AWSD1 1 Procedure UtDocumento19 pagineAWSD1 1 Procedure UtGhilman0529Nessuna valutazione finora

- QC - 08 PTCDocumento5 pagineQC - 08 PTCmahendraNessuna valutazione finora

- SOP-QAD-001 - Inhouse CalibrationDocumento4 pagineSOP-QAD-001 - Inhouse Calibrationdanaka00750% (2)

- Soqr Jisipl-463Documento1 paginaSoqr Jisipl-463Rajeev KumarNessuna valutazione finora

- DOMEINSTSOP002-R00-Instrument Installation & TestingDocumento6 pagineDOMEINSTSOP002-R00-Instrument Installation & TestingProfessional TrustNessuna valutazione finora

- Construction Leak Test ProcedureDocumento6 pagineConstruction Leak Test Procedurezack zeeartNessuna valutazione finora

- User Manual MOdel EDIR 500Documento10 pagineUser Manual MOdel EDIR 500Ashish DubeyNessuna valutazione finora

- Magnetic Flux Leakage InspectionDocumento10 pagineMagnetic Flux Leakage InspectionAmin ThabetNessuna valutazione finora

- Magnetic Particle Tests - NDT WiDocumento4 pagineMagnetic Particle Tests - NDT WiY ShameyaNessuna valutazione finora

- Boiler Safety Audits PDFDocumento6 pagineBoiler Safety Audits PDFSyaran BudimanNessuna valutazione finora

- 8600 Mil STD 810G Test ReportDocumento67 pagine8600 Mil STD 810G Test ReportBoulHich BoulHichNessuna valutazione finora

- TSH-IP-00.0028 - 03 Drift InspectionDocumento7 pagineTSH-IP-00.0028 - 03 Drift Inspectionhuyenhvtc252Nessuna valutazione finora

- Fuller Roller Mill Lever - UT Inspection ProcedureDocumento5 pagineFuller Roller Mill Lever - UT Inspection ProcedurealexisNessuna valutazione finora

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocumento2 pagineInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNessuna valutazione finora

- ASME V Presentation 1Documento56 pagineASME V Presentation 1hreer100% (2)

- Document 1Documento2 pagineDocument 1renebbNessuna valutazione finora

- Work Scope - Pelotn Runner Refurbishment !Documento3 pagineWork Scope - Pelotn Runner Refurbishment !manikanthNessuna valutazione finora

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionDa EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionValutazione: 4.5 su 5 stelle4.5/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDa EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisValutazione: 4 su 5 stelle4/5 (2)

- 5315 MISTRAS WindEnergyDocumento8 pagine5315 MISTRAS WindEnergyAnkur SavitaNessuna valutazione finora

- Ultrasonic Inspection: Part 1 IntroductionDocumento172 pagineUltrasonic Inspection: Part 1 IntroductionJohn DolanNessuna valutazione finora

- Penetrant TestingDocumento43 paginePenetrant TestingVineet JeswaniNessuna valutazione finora

- RR - CA - 001 Privacy NoticeDocumento4 pagineRR - CA - 001 Privacy NoticeJohn DolanNessuna valutazione finora

- Car Parking Area Office and ToiletsDocumento1 paginaCar Parking Area Office and ToiletsJohn DolanNessuna valutazione finora

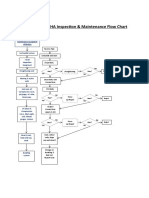

- DP Insp Flow Chart CW EquipmentDocumento1 paginaDP Insp Flow Chart CW EquipmentJohn DolanNessuna valutazione finora

- IPS Brief Profile PresentationDocumento22 pagineIPS Brief Profile PresentationJohn DolanNessuna valutazione finora

- Daily Check of DC Coil and AC YokeDocumento2 pagineDaily Check of DC Coil and AC YokeJohn DolanNessuna valutazione finora

- Ac Yoke and Coil Check Log: Thailand Industrial Proforma FormDocumento1 paginaAc Yoke and Coil Check Log: Thailand Industrial Proforma FormJohn DolanNessuna valutazione finora

- Black Light Daily Check Log: Thailand Industrial Proforma FormDocumento1 paginaBlack Light Daily Check Log: Thailand Industrial Proforma FormJohn DolanNessuna valutazione finora

- Index: Daily, 6 Monthly and Yearly Equipment Calibration ChecksDocumento1 paginaIndex: Daily, 6 Monthly and Yearly Equipment Calibration ChecksJohn DolanNessuna valutazione finora

- Daily Drift Calibration LogDocumento1 paginaDaily Drift Calibration LogJohn DolanNessuna valutazione finora

- INDIN 077 - BHA ReportDocumento1 paginaINDIN 077 - BHA ReportJohn DolanNessuna valutazione finora

- INDIN 077 - BHA ReportDocumento1 paginaINDIN 077 - BHA ReportJohn DolanNessuna valutazione finora

- MPI Report 008 Travelling Block E-5071Documento1 paginaMPI Report 008 Travelling Block E-5071John DolanNessuna valutazione finora

- MPI Report 002 Mast 002 R.1Documento1 paginaMPI Report 002 Mast 002 R.1John DolanNessuna valutazione finora

- MPI Report 011 3 and A Half DP Elevator B109-3Documento1 paginaMPI Report 011 3 and A Half DP Elevator B109-3John DolanNessuna valutazione finora

- MPI - DPI Report NewDocumento2 pagineMPI - DPI Report NewJohn DolanNessuna valutazione finora

- Liquid Penetrant Inspection Report: Industrial Proforma FormDocumento1 paginaLiquid Penetrant Inspection Report: Industrial Proforma FormJohn DolanNessuna valutazione finora

- MPI Report 004 Mast Axis 002Documento1 paginaMPI Report 004 Mast Axis 002John DolanNessuna valutazione finora

- MPI Report 013 5inch DP Elevator A109-2Documento1 paginaMPI Report 013 5inch DP Elevator A109-2John DolanNessuna valutazione finora

- MPI Report 005 Monkeyboard 001Documento1 paginaMPI Report 005 Monkeyboard 001John DolanNessuna valutazione finora

- MPI Report 010 3 and A Half DP Elevator B109-4Documento1 paginaMPI Report 010 3 and A Half DP Elevator B109-4John DolanNessuna valutazione finora

- MPI Report 012 5inch DP Elevator A109-1Documento1 paginaMPI Report 012 5inch DP Elevator A109-1John DolanNessuna valutazione finora

- INDIN 078 - HWDP Proforma R.1Documento2 pagineINDIN 078 - HWDP Proforma R.1John DolanNessuna valutazione finora

- MPI Report 006 Swivel 531-12-19Documento1 paginaMPI Report 006 Swivel 531-12-19John DolanNessuna valutazione finora

- MPI Report 009 Sub Structure B668Documento1 paginaMPI Report 009 Sub Structure B668John DolanNessuna valutazione finora

- Exhibit I - SOWDocumento5 pagineExhibit I - SOWJohn DolanNessuna valutazione finora