Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

OGASCO - ENOC Jabel Ali Refinery Expansi Technical Specification 2017-06-21

Caricato da

Renny DevassyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

OGASCO - ENOC Jabel Ali Refinery Expansi Technical Specification 2017-06-21

Caricato da

Renny DevassyCopyright:

Formati disponibili

Jotspec

Technical specification

New construction

EPC: Name:

Client: Unit ID: Sub contr: Oil & Gas Const. Co.

Cons/Eng: Version: 1 Date: 6/21/2017

Project: OGASCO - ENOC Jabel Ali Refinery Expansion Project

Prepared by: Jossy Barboza - Jotun Abu Dhabi LLC

2017-06-21 07:10:01 (UTC) Page 1 of 14

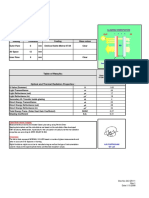

Summary

Project OGASCO - ENOC Jabel Ali Refinery Expansion Project Prepared by Jossy Barboza - Jotun Abu Dhabi LLC

Customer Oil & Gas Const. Co. Approved by Jossy Barboza Version 1

Location Date 6/21/2017

The paint specification(s) include(s) the following positions and areas

Position Area m²

ENOC System A 100

ENOC System D 100

ENOC System E 100

ENOC System F 100

ENOC System I1 100

ENOC System I2 100

ENOC System C 100

ENOC System J 100

ENOC System H 100

ENOC System A - Pipe Support 100

Total 1000

Summary of products and volumes

Product Consumption (l)

ALUMINIUM PAINT H.R.,ALUMINIUM 11

BARRIER,GREY 47

EPOXY HR,LIGHT GREY 40

EPOXY HR,ALUMINIUM 20

HARDTOP XP,COLOUR GROUP 1 16

JOTAMASTIC 87,ALUMINIUM 23

PENGUARD HB,STD 136 56

RESIST 78,NONE 31

SOLVALITT,ALUMINIUM 38

JOTUN THINNER NO. 02,CLEAR 1

JOTUN THINNER NO. 04,CLEAR 2

JOTUN THINNER NO. 07,CLEAR 2

JOTUN THINNER NO. 10,CLEAR 1

2017-06-21 07:10:01 (UTC) Page 2 of 14

JOTUN THINNER NO. 17,CLEAR 6

JOTUN THINNER NO. 23,CLEAR 3

Total 295

2017-06-21 07:10:01 (UTC) Page 3 of 14

Technical specification

Project OGASCO - ENOC Jabel Ali Refinery Expansion Project Prepared by Jossy Barboza - Jotun Abu Dhabi LLC

Customer Oil & Gas Const. Co. Approved by Jossy Barboza Version 1

Location 56- Jotun Abu Dhabi, FG Whs Date 6/21/2017

Position ENOC System A ISO 12944-2 category N/A

Substrate Carbon Steel Area 100 m² No. 1

Surface Prep. Surfaces to be coated shall be degreased to ISO 12944-4, Part 6.1.4 Alkaline Cleaning, and abrasive blast cleaned to Sa 2½ (ISO 8501-1) with a

minimum surface profile 75 µm, grade Fine to Medium G, Ry5 (ISO 8503-2).

Product Type Area to Vol. solids Filmthickness (µm) Loss Recoating intervals Thinner Consumption (l)

of paint % % (%) 15°C 23°C 40°C

coat

Dry spec. Wet spec. Min Max Min Max Min Max No. Max Theor. Practical

%

BARRIER,GREY FC 100 53 75 142 0 * * 1.5 h 1 mth40 min 7 d 17 5 14 14

PENGUARD HB,STD 136 FC 100 54 150 278 0 * * 8h 7 d 3.5 h 5 d 17 5 28 28

HARDTOP XP,COLOUR GROUP 1 FC 100 63 50 79 0 * * 7h * 4h * 10 5 8 8

Total 275

Remarks: Finish Coat Color to be advised

2017-06-21 07:10:01 (UTC) Page 4 of 14

Technical specification

Project OGASCO - ENOC Jabel Ali Refinery Expansion Project Prepared by Jossy Barboza - Jotun Abu Dhabi LLC

Customer Oil & Gas Const. Co. Approved by Jossy Barboza Version 1

Location 56- Jotun Abu Dhabi, FG Whs Date 6/21/2017

Position ENOC System D ISO 12944-2 category N/A

Substrate Carbon Steel Area 100 m² No. 2

Surface Prep. Surfaces to be coated shall be degreased to ISO 12944-4, Part 6.1.4 Alkaline Cleaning, and abrasive blast cleaned to Sa 2½ (ISO 8501-1) with a

minimum surface profile 75 µm, grade Fine to Medium G, Ry5 (ISO 8503-2).

Product Type Area to Vol. solids Filmthickness (µm) Loss Recoating intervals Thinner Consumption (l)

of paint % % (%) 15°C 23°C 40°C

coat Dry spec. Wet spec. Min Max Min Max Min Max No. Max Theor. Practical

%

RESIST 78,NONE FC 100 72 75 104 0 * NR 4 h NR 1.5 h NR 4 5 10 10

ALUMINIUM PAINT H.R.,ALUMINIUM FC 100 45 25 56 0 * * 8h * 6h * 2 5 6 6

ALUMINIUM PAINT H.R.,ALUMINIUM FC 100 45 25 56 0 * * 8h * 6h * 2 5 6 6

Total 125

Remarks:

2017-06-21 07:10:01 (UTC) Page 5 of 14

Technical specification

Project OGASCO - ENOC Jabel Ali Refinery Expansion Project Prepared by Jossy Barboza - Jotun Abu Dhabi LLC

Customer Oil & Gas Const. Co. Approved by Jossy Barboza Version 1

Location 56- Jotun Abu Dhabi, FG Whs Date 6/21/2017

Position ENOC System E ISO 12944-2 category N/A

Substrate Carbon Steel Area 100 m² No. 3

Surface Prep. Surfaces to be coated shall be degreased to ISO 12944-4, Part 6.1.4 Alkaline Cleaning, and abrasive blast cleaned to Sa 2½ (ISO 8501-1) with a

minimum surface profile 75 µm, grade Fine to Medium G, Ry5 (ISO 8503-2).

Product Type Area to Vol. solids Filmthickness (µm) Loss Recoating intervals Thinner Consumption (l)

of paint % % (%) 15°C 23°C 40°C

coat Dry spec. Wet spec. Min Max Min Max Min Max No. Max Theor. Practical

%

RESIST 78,NONE FC 100 72 75 104 0 * * 4h * 1.5 h * 4 5 10 10

SOLVALITT,ALUMINIUM FC 100 40 25 62 0 * * 4h * 3h * 7 5 6 6

SOLVALITT,ALUMINIUM FC 100 40 25 62 0 * * 4h * 3h * 7 5 6 6

Total 125

Remarks:

2017-06-21 07:10:01 (UTC) Page 6 of 14

Technical specification

Project OGASCO - ENOC Jabel Ali Refinery Expansion Project Prepared by Jossy Barboza - Jotun Abu Dhabi LLC

Customer Oil & Gas Const. Co. Approved by Jossy Barboza Version 1

Location 56- Jotun Abu Dhabi, FG Whs Date 6/21/2017

Position ENOC System F ISO 12944-2 category N/A

Substrate Carbon Steel Area 100 m² No. 4

Surface Prep. Surfaces to be coated shall be degreased to ISO 12944-4, Part 6.1.4 Alkaline Cleaning, and abrasive blast cleaned to Sa 2½ (ISO 8501-1) with a

minimum surface profile 75 µm, grade Fine to Medium G, Ry5 (ISO 8503-2).

Product Type Area to Vol. solids Filmthickness (µm) Loss Recoating intervals Thinner Consumption (l)

of paint % % (%) 15°C 23°C 40°C

coat Dry spec. Wet spec. Min Max Min Max Min Max No. Max Theor. Practical

%

SOLVALITT,ALUMINIUM FC 100 40 25 62 0 * * 4h * 3h * 7 5 6 6

SOLVALITT,ALUMINIUM FC 100 40 25 62 0 * * 4h * 3h * 7 5 6 6

Total 50

Remarks:

2017-06-21 07:10:01 (UTC) Page 7 of 14

Technical specification

Project OGASCO - ENOC Jabel Ali Refinery Expansion Project Prepared by Jossy Barboza - Jotun Abu Dhabi LLC

Customer Oil & Gas Const. Co. Approved by Jossy Barboza Version 1

Location 56- Jotun Abu Dhabi, FG Whs Date 6/21/2017

Position ENOC System I1 ISO 12944-2 category N/A

Substrate Stainless Steel Area 100 m² No. 5

Surface Prep. After pre-treatment of welds, sharp edges, removal of weld spatter and other surface contamination the surface shall be degreased with an alkaline

detergent, washed by low-pressure Water Cleaning LP WC method to ISO 8501-4 Wa 1 or higher and hand or machine abraded with non-metallic

abrasives or bonded fibre machine or hand abrasive pads to remove all polish and to impart a scratch pattern to the surface. Do not use high speed

rotational sanders.

Product Type Area to Vol. solids Filmthickness (µm) Loss Recoating intervals Thinner Consumption (l)

of paint % % (%) 15°C 23°C 40°C

coat Dry spec. Wet spec. Min Max Min Max Min Max No. Max Theor. Practical

%

EPOXY HR,ALUMINIUM FC 100 63 125 198 0 20 h 14 d 10 h 7 d 4 h 3 d 23 5 20 20

EPOXY HR,LIGHT GREY FC 100 63 125 198 0 20 h 14 d 10 h 7d 4h 3d 23 5 20 20

EPOXY HR,LIGHT GREY FC 100 63 125 198 0 20 h * 10 h * 4h * 23 5 20 20

Total 375

Remarks:

2017-06-21 07:10:01 (UTC) Page 8 of 14

Technical specification

Project OGASCO - ENOC Jabel Ali Refinery Expansion Project Prepared by Jossy Barboza - Jotun Abu Dhabi LLC

Customer Oil & Gas Const. Co. Approved by Jossy Barboza Version 1

Location 56- Jotun Abu Dhabi, FG Whs Date 6/21/2017

Position ENOC System I2 ISO 12944-2 category N/A

Substrate Stainless Steel Area 100 m² No. 6

Surface Prep. After pre-treatment of welds, sharp edges, removal of weld spatter and other surface contamination the surface shall be degreased with an alkaline

detergent, washed by low-pressure Water Cleaning LP WC method to ISO 8501-4 Wa 1 or higher and hand or machine abraded with non-metallic

abrasives or bonded fibre machine or hand abrasive pads to remove all polish and to impart a scratch pattern to the surface. Do not use high speed

rotational sanders.

Product Type Area to Vol. solids Filmthickness (µm) Loss Recoating intervals Thinner Consumption (l)

of paint % % (%) 15°C 23°C 40°C

coat Dry spec. Wet spec. Min Max Min Max Min Max No. Max Theor. Practical

%

SOLVALITT,ALUMINIUM FC 100 40 25 62 0 * * 4h * 3h * 7 5 6 6

SOLVALITT,ALUMINIUM FC 100 40 25 62 0 * * 4h * 3h * 7 5 6 6

Total 50

Remarks:

2017-06-21 07:10:01 (UTC) Page 9 of 14

Technical specification

Project OGASCO - ENOC Jabel Ali Refinery Expansion Project Prepared by Jossy Barboza - Jotun Abu Dhabi LLC

Customer Oil & Gas Const. Co. Approved by Jossy Barboza Version 1

Location 56- Jotun Abu Dhabi, FG Whs Date 6/21/2017

Position ENOC System C ISO 12944-2 category N/A

Substrate Carbon Steel Area 100 m² No. 7

Surface Prep. Surfaces to be coated shall be degreased to ISO 12944-4, Part 6.1.4 Alkaline Cleaning, and abrasive blast cleaned to Sa 2½ (ISO 8501-1) with a

minimum surface profile 75 µm, grade Fine to Medium G, Ry5 (ISO 8503-2).

Product Type Area to Vol. solids Filmthickness (µm) Loss Recoating intervals Thinner Consumption (l)

of paint % % (%) 15°C 23°C 40°C

coat Dry spec. Wet spec. Min Max Min Max Min Max No. Max Theor. Practical

%

JOTAMASTIC 87,ALUMINIUM FC 100 87 100 115 0 * * 10 h * 4h * 17 5 11 11

JOTAMASTIC 87,ALUMINIUM FC 100 87 100 115 0 * * 10 h * 4h * 17 5 11 11

Total 200

Remarks:

2017-06-21 07:10:01 (UTC) Page 10 of 14

Technical specification

Project OGASCO - ENOC Jabel Ali Refinery Expansion Project Prepared by Jossy Barboza - Jotun Abu Dhabi LLC

Customer Oil & Gas Const. Co. Approved by Jossy Barboza Version 1

Location 56- Jotun Abu Dhabi, FG Whs Date 6/21/2017

Position ENOC System J ISO 12944-2 category N/A

Substrate Galvanized Steel Area 100 m² No. 8

Surface Prep. After removal of excess zinc and surface defects the area to be coated shall be degreased to ISO 12944-4 Part 6.1.4 Alkaline Cleaning. The

galvanised surface shall be abrasive sweep blasted with the nozzle angle at 45-60° from perpendicular at reduced nozzle pressure to create a sharp,

angular uniform surface profile using approved non-metallic abrasive media.

Product Type Area to Vol. solids Filmthickness (µm) Loss Recoating intervals Thinner Consumption (l)

of paint % % (%) 15°C 23°C 40°C

coat Dry spec. Wet spec. Min Max Min Max Min Max No. Max Theor. Practical

%

BARRIER,GREY FC 100 53 50 94 0 * NR 1.5 h NR 40 min NR 17 5 9 9

BARRIER,GREY FC 100 53 50 94 0 * * 1.5 h * 40 min * 17 5 9 9

Total 100

Remarks:

2017-06-21 07:10:01 (UTC) Page 11 of 14

Technical specification

Project OGASCO - ENOC Jabel Ali Refinery Expansion Project Prepared by Jossy Barboza - Jotun Abu Dhabi LLC

Customer Oil & Gas Const. Co. Approved by Jossy Barboza Version 1

Location 56- Jotun Abu Dhabi, FG Whs Date 6/21/2017

Position ENOC System H ISO 12944-2 category N/A

Substrate Carbon Steel Area 100 m² No. 9

Surface Prep. Surfaces to be coated shall be degreased to ISO 12944-4, Part 6.1.4 Alkaline Cleaning, and abrasive blast cleaned to Sa 2½ (ISO 8501-1) with a

minimum surface profile 75 µm, grade Fine to Medium G, Ry5 (ISO 8503-2).

Product Type Area to Vol. solids Filmthickness (µm) Loss Recoating intervals Thinner Consumption (l)

of paint % % (%) 15°C 23°C 40°C

coat Dry spec. Wet spec. Min Max Min Max Min Max No. Max Theor. Practical

%

RESIST 78,NONE FC 100 72 75 104 0 * * 4h * 1.5 h * 4 5 10 10

Total 75

Remarks:

2017-06-21 07:10:01 (UTC) Page 12 of 14

Technical specification

Project OGASCO - ENOC Jabel Ali Refinery Expansion Project Prepared by Jossy Barboza - Jotun Abu Dhabi LLC

Customer Oil & Gas Const. Co. Approved by Jossy Barboza Version 1

Location 56- Jotun Abu Dhabi, FG Whs Date 6/21/2017

Position ENOC System A - Pipe Support ISO 12944-2 category N/A

Substrate Carbon Steel Area 100 m² No. 10

Surface Prep. Surfaces to be coated shall be degreased to ISO 12944-4, Part 6.1.4 Alkaline Cleaning, and abrasive blast cleaned to Sa 2½ (ISO 8501-1) with a

minimum surface profile 75 µm, grade Fine to Medium G, Ry5 (ISO 8503-2).

Product Type Area to Vol. solids Filmthickness (µm) Loss Recoating intervals Thinner Consumption (l)

of paint % % (%) 15°C 23°C 40°C

coat Dry spec. Wet spec. Min Max Min Max Min Max No. Max Theor. Practical

%

BARRIER,GREY FC 100 53 75 142 0 * * 1.5 h 1 mth40 min 7 d 17 5 14 14

PENGUARD HB,STD 136 FC 100 54 150 278 0 * * 8h 7 d 3.5 h 5 d 17 5 28 28

HARDTOP XP,COLOUR GROUP 1 FC 100 63 50 79 0 * * 7h * 4h * 10 5 8 8

Total 275

Remarks:

2017-06-21 07:10:01 (UTC) Page 13 of 14

* please refer to the relevant technical datasheets and AG application guide for recoating and curing conditions

NR: Not recommended for this exposure or generic type:

Unless otherwise agreed in writing, all product supplied and technical advice given by us are subject to our standard terms and conditions of sale. In the event that supplies are made and

technical advice is given by one of our associated companies or dealers, then such supplies and technical advice shall be subject to the standard terms of sale of that company, a copy of which

is available upon request. The given data must be considered as guidelines only, the figures in some columns may be rounded. Drying times and paint consumptions may vary depending on

actual conditions.

For updated information about our products please refer to our web site at www.jotun.com

2017-06-21 07:10:01 (UTC) Page 14 of 14

Potrebbero piacerti anche

- Rekomendasi Painting JotunDocumento1 paginaRekomendasi Painting JotunmanthoexNessuna valutazione finora

- Single Line Diagram Fire Alarm System Area Metering Akatara Project-R3Documento1 paginaSingle Line Diagram Fire Alarm System Area Metering Akatara Project-R3PandaNessuna valutazione finora

- Laminado Cool Lite KNT 164 4mm + PVB 0.76 + Incoloro 4 MMDocumento1 paginaLaminado Cool Lite KNT 164 4mm + PVB 0.76 + Incoloro 4 MMJuliana SarmientoNessuna valutazione finora

- 6mm Superlite 70 40t Clear +16as+6mm ClearDocumento1 pagina6mm Superlite 70 40t Clear +16as+6mm ClearNav JavNessuna valutazione finora

- 6mm Superlite 70 40t Clear +16as+6mm ClearDocumento1 pagina6mm Superlite 70 40t Clear +16as+6mm ClearNav JavNessuna valutazione finora

- Palazzoli Catalogu Sockets & PDFDocumento469 paginePalazzoli Catalogu Sockets & PDFBoutheyna MZOUGHUINessuna valutazione finora

- Major Projects NigeriaDocumento16 pagineMajor Projects Nigeriafle92100% (1)

- Guidance For Tenders Lca50 100 - 2014Documento4 pagineGuidance For Tenders Lca50 100 - 2014Antony SantosNessuna valutazione finora

- Emirates Glass Laboratory: Table of ResultsDocumento1 paginaEmirates Glass Laboratory: Table of ResultsNav JavNessuna valutazione finora

- Emirates Glass Laboratory: Table of ResultsDocumento1 paginaEmirates Glass Laboratory: Table of ResultsNav JavNessuna valutazione finora

- Laminado Incoloro Serigrafía Blanca 35% 4mm + Cool Lite ST 150 4mm Cara #3Documento1 paginaLaminado Incoloro Serigrafía Blanca 35% 4mm + Cool Lite ST 150 4mm Cara #3Juliana SarmientoNessuna valutazione finora

- Valve List - F-5001Documento3 pagineValve List - F-5001Ajay PrajapatiNessuna valutazione finora

- Oneal OP 5000 PDFDocumento11 pagineOneal OP 5000 PDFGuto LiberatoNessuna valutazione finora

- TGU Without CoatingDocumento1 paginaTGU Without CoatingABIRAMI K ANessuna valutazione finora

- HSE For Gas SET: Check List CuttingDocumento1 paginaHSE For Gas SET: Check List CuttingRiju Scaria/EMD/QTRNessuna valutazione finora

- Schematics-All k200 InnovetDocumento16 pagineSchematics-All k200 InnovetCantave SidnyNessuna valutazione finora

- Databook of Blowing and Auxiliary Agents 1St Edition Wypych Full ChapterDocumento51 pagineDatabook of Blowing and Auxiliary Agents 1St Edition Wypych Full Chapterheather.jones631100% (5)

- Engineering Change Order: IntentDocumento1 paginaEngineering Change Order: IntentYanethNessuna valutazione finora

- Color TV: Service ManualDocumento56 pagineColor TV: Service ManualAndré LeftNessuna valutazione finora

- Cristtal DobleDocumento1 paginaCristtal DobleDaniel GonzalezNessuna valutazione finora

- SKN 152 - RishavDocumento1 paginaSKN 152 - Rishavmiskey.is.riskyNessuna valutazione finora

- Technical Manual: Split Unit Air Conditioner Wall Mounted J & F Series - Cooling Only & Heatpump (50Hz)Documento60 pagineTechnical Manual: Split Unit Air Conditioner Wall Mounted J & F Series - Cooling Only & Heatpump (50Hz)waqas ahmedNessuna valutazione finora

- Calumen LiveDocumento1 paginaCalumen LiveCarlos Adolfo Salah FernandezNessuna valutazione finora

- Laminado Templado 6+5 Cool Lite ST120Documento2 pagineLaminado Templado 6+5 Cool Lite ST120RAUL FRANCONessuna valutazione finora

- Technical Service Information: Automatic Transmission Service GroupDocumento5 pagineTechnical Service Information: Automatic Transmission Service GroupwaggcasNessuna valutazione finora

- APX-CE 16089C Wiring DiagramDocumento80 pagineAPX-CE 16089C Wiring Diagramnorin1994Nessuna valutazione finora

- Features Applications: 1981 Burr-Brown Corporation PDS-454K Printed in U.S.A. July, 1998Documento6 pagineFeatures Applications: 1981 Burr-Brown Corporation PDS-454K Printed in U.S.A. July, 1998mosheliosaNessuna valutazione finora

- ESC Marine Fenders Catalogue 2020Documento48 pagineESC Marine Fenders Catalogue 2020Marco SharpNessuna valutazione finora

- PDF Products Catalogue ENG COELBO ItalyDocumento278 paginePDF Products Catalogue ENG COELBO ItalyEmad ArafaNessuna valutazione finora

- Airmax RM Solenoid ValveDocumento6 pagineAirmax RM Solenoid ValveManoj DoshiNessuna valutazione finora

- Print 1Documento1 paginaPrint 1danino234Nessuna valutazione finora

- Cavity Plug XEOA - Full - en - Us - LetterDocumento1 paginaCavity Plug XEOA - Full - en - Us - LetterHassan KhattabNessuna valutazione finora

- Brochure Full Line Product GuideDocumento51 pagineBrochure Full Line Product GuideRobert GardnerNessuna valutazione finora

- Flame Arrestor TBEDocumento8 pagineFlame Arrestor TBEsudjonoNessuna valutazione finora

- Painting Scheme Manufacturer Paint ComparizonDocumento1 paginaPainting Scheme Manufacturer Paint ComparizonHanindyo ArdhiNessuna valutazione finora

- Subject: Memory Input To REKES Models: Musso and Korando With The REKES ConditionDocumento6 pagineSubject: Memory Input To REKES Models: Musso and Korando With The REKES ConditionGuio MartinezNessuna valutazione finora

- HT-151202 WD PDFDocumento2 pagineHT-151202 WD PDFDianNessuna valutazione finora

- Development of A High Stability L-Band Radiometer For Ocean Salinity MeasurementsDocumento8 pagineDevelopment of A High Stability L-Band Radiometer For Ocean Salinity MeasurementsJoh IgnacioNessuna valutazione finora

- Sixth-Generation V-Series IGBT Module Application Note - Basic Concept and FeaturesDocumento11 pagineSixth-Generation V-Series IGBT Module Application Note - Basic Concept and FeaturesNA MENessuna valutazione finora

- Capacity SheetDocumento1 paginaCapacity Sheetable.ankit.94Nessuna valutazione finora

- Model Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11ADocumento2 pagineModel Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11AErasmo LimaNessuna valutazione finora

- 6mm Solite Neutre Clear+12AS+6mm ClearDocumento1 pagina6mm Solite Neutre Clear+12AS+6mm ClearNav JavNessuna valutazione finora

- Luminous Factors Energy Factors: Planiclear 3 MM PVB Standard 0.76 MM Planiclear 3 MMDocumento1 paginaLuminous Factors Energy Factors: Planiclear 3 MM PVB Standard 0.76 MM Planiclear 3 MMAna PopoviciNessuna valutazione finora

- 42GasElectro mechanicalValvesAPDocumento7 pagine42GasElectro mechanicalValvesAPSakahi SharmaNessuna valutazione finora

- Natural Stone Fixing Systems: Product CatalogueDocumento58 pagineNatural Stone Fixing Systems: Product CataloguenagiA ahmed0% (1)

- List of Required Documents - Iocl ParadipDocumento1 paginaList of Required Documents - Iocl ParadippavanNessuna valutazione finora

- Constantes LIO HILLDocumento6 pagineConstantes LIO HILLRoberto Vega FloresNessuna valutazione finora

- Fault Codes PDFDocumento204 pagineFault Codes PDFIzz Bahar100% (1)

- 2r3 BC Bay ReportDocumento2 pagine2r3 BC Bay ReportBharath SaiNessuna valutazione finora

- Qsun Xenon Test ChamberDocumento2 pagineQsun Xenon Test Chamberlamcong197Nessuna valutazione finora

- ESC Marine Fenders Catalogue 2018 - 2019 PDFDocumento46 pagineESC Marine Fenders Catalogue 2018 - 2019 PDFDiguinho PiresNessuna valutazione finora

- Data Sheet - Specifications Glazing - 8mmDocumento1 paginaData Sheet - Specifications Glazing - 8mmLeonel SulcaNessuna valutazione finora

- Zanden Model 1000 Stereo Equalizer AmplifierDocumento2 pagineZanden Model 1000 Stereo Equalizer AmplifierEnrique PalacioNessuna valutazione finora

- Quotation CCT Proposed JFE Shoji Steel Phils Inc. Loading Dock Structural Rev 2Documento30 pagineQuotation CCT Proposed JFE Shoji Steel Phils Inc. Loading Dock Structural Rev 2Julius Dean DumaguingNessuna valutazione finora

- Gallien Krueger Backline 210 Combo Service ManualDocumento10 pagineGallien Krueger Backline 210 Combo Service ManualpavelscribdNessuna valutazione finora

- IOCL Painting Schedule - AELDocumento1 paginaIOCL Painting Schedule - AELZuber KhanNessuna valutazione finora

- Brochure SDMO Generation 2000 EnglishDocumento20 pagineBrochure SDMO Generation 2000 EnglishAlex Ortega100% (6)

- IQ OptimaDocumento8 pagineIQ OptimaDilon FernandoNessuna valutazione finora

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDa EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsValutazione: 5 su 5 stelle5/5 (1)

- Responsibility Matrix For Shop Piping WorksDocumento5 pagineResponsibility Matrix For Shop Piping WorksRenny DevassyNessuna valutazione finora

- WPS Alloy 625 Strip With Flux EST 236Documento1 paginaWPS Alloy 625 Strip With Flux EST 236Renny DevassyNessuna valutazione finora

- Price List For Painting Works - Destination Greenfield: Project #Unit Document Code Serial #RevDocumento67 paginePrice List For Painting Works - Destination Greenfield: Project #Unit Document Code Serial #RevRenny DevassyNessuna valutazione finora

- Soudokay Strip Cladding - PrincipesDocumento31 pagineSoudokay Strip Cladding - PrincipesRenny DevassyNessuna valutazione finora

- Lincoln Strip Cladding Presentation April 2011Documento26 pagineLincoln Strip Cladding Presentation April 2011Renny DevassyNessuna valutazione finora

- 1250 kVA Genset Specifications PDFDocumento8 pagine1250 kVA Genset Specifications PDFRenny DevassyNessuna valutazione finora

- Cummins C350D5 Diesel Generator Data SheetDocumento3 pagineCummins C350D5 Diesel Generator Data SheetasdthuNessuna valutazione finora

- Garnet IDocumento3 pagineGarnet IRenny DevassyNessuna valutazione finora

- 0400GF Amerlock 400 GF PDS PDFDocumento4 pagine0400GF Amerlock 400 GF PDS PDFRenny DevassyNessuna valutazione finora

- 0400GF Amerlock 400 GF PDSDocumento4 pagine0400GF Amerlock 400 GF PDSRenny DevassyNessuna valutazione finora

- Ratnamani - Manufacturing RangeDocumento2 pagineRatnamani - Manufacturing RangeRenny DevassyNessuna valutazione finora

- Cummins C350D5 Diesel Generator Data SheetDocumento3 pagineCummins C350D5 Diesel Generator Data SheetasdthuNessuna valutazione finora

- Cummins C350D5 Diesel Generator Data SheetDocumento3 pagineCummins C350D5 Diesel Generator Data SheetasdthuNessuna valutazione finora

- Grinding Training Rev 1Documento46 pagineGrinding Training Rev 1Hrvoje TeskeraNessuna valutazione finora

- Systemised Turbo Power. Our Range of Accessories For Angle GrindersDocumento25 pagineSystemised Turbo Power. Our Range of Accessories For Angle Grindersابو احمد نوفل100% (1)

- Denso Protal 7125 Brush Application SpecDocumento2 pagineDenso Protal 7125 Brush Application Specd00g3n_656010017Nessuna valutazione finora

- DSH 700 900 Leaflet en W3810Documento4 pagineDSH 700 900 Leaflet en W3810Srđan MilićevićNessuna valutazione finora

- Abrasive ProcessesDocumento63 pagineAbrasive ProcessesmohdhmNessuna valutazione finora

- Presentation On GrindingDocumento36 paginePresentation On GrindingPragyan Agrawal100% (3)

- Basic Mechanism and Model of Multi-Wire SawingDocumento13 pagineBasic Mechanism and Model of Multi-Wire SawingUnggul Teguh PrasetyoNessuna valutazione finora

- SSWW 018 Derevyannoe Kruzhevo PDFDocumento104 pagineSSWW 018 Derevyannoe Kruzhevo PDFSergio Larraguibel100% (2)

- Abrasive Belt GrinderDocumento44 pagineAbrasive Belt Grindersaad40% (5)

- Optimization of Surface Roughness in Honing of Engine Cylinder Liners With Sic Honing StonesDocumento7 pagineOptimization of Surface Roughness in Honing of Engine Cylinder Liners With Sic Honing StonesHoang LamNessuna valutazione finora

- Effect of Hydrofluoric Acid Concentration and Etching Duration On Select Surface Roughness Parameters For ZirconiaDocumento7 pagineEffect of Hydrofluoric Acid Concentration and Etching Duration On Select Surface Roughness Parameters For ZirconiaJulio Torres OrtodonciaNessuna valutazione finora

- Abrasive MaterialsDocumento148 pagineAbrasive MaterialsMartin OngNessuna valutazione finora

- Astm E1806-23Documento22 pagineAstm E1806-23zuqin bianNessuna valutazione finora

- JHC Catfines PackDocumento24 pagineJHC Catfines PackRoshan D'silva100% (2)

- Seccion 2 Surface Preparation - SSPC Good PracticesDocumento130 pagineSeccion 2 Surface Preparation - SSPC Good PracticesniineeNessuna valutazione finora

- A Report On Gems & Jewellery SectorDocumento27 pagineA Report On Gems & Jewellery SectorSaksham Jain100% (1)

- Fingerjoint Heads and Cutters: Bulletin 700 HDocumento13 pagineFingerjoint Heads and Cutters: Bulletin 700 HAdi ATMNessuna valutazione finora

- Process Industry Practices Coatings: PIP CTSE1000 Application of External CoatingsDocumento84 pagineProcess Industry Practices Coatings: PIP CTSE1000 Application of External CoatingsabcNessuna valutazione finora

- GMA Garnet™ SpeedBlast 2013Documento2 pagineGMA Garnet™ SpeedBlast 2013Srinivasan RNessuna valutazione finora

- Global Economics 13th Edition Robert Carbaugh Test BankDocumento25 pagineGlobal Economics 13th Edition Robert Carbaugh Test BankCraigVelasquezmcot100% (52)

- Gear Cutting For Production EngineeringDocumento8 pagineGear Cutting For Production Engineeringprithvi shettyNessuna valutazione finora

- Whitehall WhirlpoolDocumento23 pagineWhitehall WhirlpooljmlameirasNessuna valutazione finora

- Abrasive ManufacturingDocumento10 pagineAbrasive Manufacturinggirish19Nessuna valutazione finora

- FT - Amercoat 3279Documento5 pagineFT - Amercoat 3279Rodrigo Sánchez BautistaNessuna valutazione finora

- PFI ES 29 - 2006 EditionDocumento5 paginePFI ES 29 - 2006 EditionArcadio DuranNessuna valutazione finora

- The Scalpel Finishing Technique: A Tooth-Friendly Way To Finish Dental Composites in Anterior TeethDocumento18 pagineThe Scalpel Finishing Technique: A Tooth-Friendly Way To Finish Dental Composites in Anterior TeethSoraya BouchammaNessuna valutazione finora

- Basics of Metallographic Specimen PreparationDocumento13 pagineBasics of Metallographic Specimen PreparationFlop ShowNessuna valutazione finora

- APCS-20A HempelDocumento10 pagineAPCS-20A HempelarjunmohananNessuna valutazione finora

- Manual Hoffman PropellerDocumento20 pagineManual Hoffman PropellerJuan G CorreaNessuna valutazione finora

- Air PolishingDocumento9 pagineAir PolishingGonçalo Cunha-CoutinhoNessuna valutazione finora