Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Poultry House Air Leakage Calculator 2018

Caricato da

ventus130 valutazioniIl 0% ha trovato utile questo documento (0 voti)

104 visualizzazioni1 paginaair leakage poultry

Titolo originale

Poultry house air leakage calculator 2018

Copyright

© © All Rights Reserved

Formati disponibili

XLSX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoair leakage poultry

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

104 visualizzazioni1 paginaPoultry House Air Leakage Calculator 2018

Caricato da

ventus13air leakage poultry

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

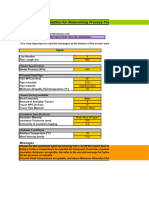

Poultry House Leakage Estimator - 2018

The University of Georgia - Department of Poultry Science

Michael Czarick (mczarick@uga.edu)

Enter "Green" Values (do not leave blank)

This spreadsheet is intended to illustrate how poultry house tightness can be estimated

though the use of a static pressure test. The spreadsheet will also illustrate how poultry

house tightness will determine the amount of fresh air brought in by minimum

ventilation fans(s) that will enter through a houses inlets relative to that entering

through cracks (unplanned openings). The spreadsheet will not provide precise values,

but rather estimates

Do you want to display equivalent metric values (yes = 1, no = 0)? 1

Poultry House Leakage Test: Metric

House length (ft) 300 91.5 m

House width (ft) 68 20.7 m 20400

Total fan capacity used in leakage test (cfm @ 0.10") 14100 23,970 cmh 34680

Static pressure measured (") 0.10 25 Pa

Relative leakage area (ft2 per 1,000 ft2 of house floor space) 0.54 0.54 m2/1000 m2

Total house leakage area (ft2) 10.9 1.0 m2

(For the best accuracy if the static pressure obtained during house testing exceeds 0.25",

consider using fewer or a lower capacity test fans.)

Minimum Ventilation Inlet Opening Requirements:

Minimum ventilation fan capacity (cfm) 14100 23,970 cmh

Number of air inlets to be used 48 48

Maximum air inlet height/opening (inches) 6.0 15.2 cm

Air inlet length (inches) 36.0 91.4 cm

Total side wall air inlet area (ft2) 72.0 6.7 m2

Total required opening area for specified fan(s) @ 0.10" (ft2) 18.8 1.75 m2

Total house leakage area (ft2) 10.9 1.01 m2

Total required inlet area @ 0.10" (ft2) 7.9 0.73 m2

Percentage of air that will entering through inlets 42% 42%

Approximate required air inlet opening size/height (inches) 0.66 1.7 cm

Potrebbero piacerti anche

- Qfarm Manual v1.21Documento161 pagineQfarm Manual v1.21ventus13100% (1)

- Created by Image2PDF Trial Version, To Remove This Mark, Please Registerthis SoftwareDocumento56 pagineCreated by Image2PDF Trial Version, To Remove This Mark, Please Registerthis SoftwareHesham HassanNessuna valutazione finora

- Pressure Drop Calculations SRN Description Value UnitDocumento34 paginePressure Drop Calculations SRN Description Value UnitSatyajit M0% (1)

- Calculation of Smoke Spilled SystemDocumento2 pagineCalculation of Smoke Spilled SystemMFaiz RHamira100% (1)

- Stair Pressurization CalculationDocumento2 pagineStair Pressurization Calculationnaruto256100% (1)

- 12 Air Inlet OperationDocumento22 pagine12 Air Inlet Operationventus13Nessuna valutazione finora

- Pullet v4.1Documento2 paginePullet v4.1Kalil RahimanNessuna valutazione finora

- Pressure Drop Calcs-VDI2081-1 (2003)Documento9 paginePressure Drop Calcs-VDI2081-1 (2003)Satyajit MNessuna valutazione finora

- ACMV CalculationDocumento12 pagineACMV Calculationazim azrulNessuna valutazione finora

- Staircase Pressurisation-1Documento11 pagineStaircase Pressurisation-1Zawhtet WinNessuna valutazione finora

- Staircase Pressurization Calculation.B+G+21Documento9 pagineStaircase Pressurization Calculation.B+G+21john philipNessuna valutazione finora

- Noise RequirementDocumento8 pagineNoise RequirementSatyajit MNessuna valutazione finora

- Rooms Pressurized Calculation - RevaDocumento2 pagineRooms Pressurized Calculation - RevaDoan Tien Do100% (1)

- Calculation of Air Duct Pressure Loss (Rectangular)Documento15 pagineCalculation of Air Duct Pressure Loss (Rectangular)Phyu Mar Thein KyawNessuna valutazione finora

- Residential Combustion Air Calcs Worksheet 3-5-12 - 201305151521424290Documento1 paginaResidential Combustion Air Calcs Worksheet 3-5-12 - 201305151521424290victor japposanNessuna valutazione finora

- Stair Case FanDocumento3 pagineStair Case FanAnonymous FHbOdLDNessuna valutazione finora

- 3-Gaseous Systems Calculations.Documento3 pagine3-Gaseous Systems Calculations.AyaEzzNessuna valutazione finora

- Calculation of Air ConditioningDocumento22 pagineCalculation of Air ConditioningPhyu Mar Thein KyawNessuna valutazione finora

- Design Calculation Sheet For Fire Lift Well Pressurisation S.NO. DescriptionDocumento1 paginaDesign Calculation Sheet For Fire Lift Well Pressurisation S.NO. DescriptionpsjjoshiNessuna valutazione finora

- Center - SPF Calculation DataDocumento1 paginaCenter - SPF Calculation DataPAul JoHn MeNdozaNessuna valutazione finora

- Q Flow Rate (CFM) K Coefficient, 0.827 A Flow Area, FTDocumento1 paginaQ Flow Rate (CFM) K Coefficient, 0.827 A Flow Area, FTKHUSHBOONessuna valutazione finora

- Instrument AirDocumento1 paginaInstrument AirBesan LaduNessuna valutazione finora

- @S V All FansDocumento23 pagine@S V All Fansamo3330Nessuna valutazione finora

- Steam TracingDocumento72 pagineSteam TracingMuzzamilNessuna valutazione finora

- Bha Calculo - Lurgi EspDocumento13 pagineBha Calculo - Lurgi EspFlavio DudaNessuna valutazione finora

- Pressurization Fans CalculationDocumento3 paginePressurization Fans CalculationamarandmoazNessuna valutazione finora

- PoultryDocumento21 paginePoultry8415533Nessuna valutazione finora

- Atrium Smoke ExhaustDocumento12 pagineAtrium Smoke ExhaustRan NNessuna valutazione finora

- SipDocumento16 pagineSipAlison LewisNessuna valutazione finora

- Stair Pressurization CalculationDocumento9 pagineStair Pressurization CalculationHaymanot BaynesagnNessuna valutazione finora

- Topic 3 Ventilation PurposesDocumento24 pagineTopic 3 Ventilation Purposessiti nasuhaNessuna valutazione finora

- Ventilation Fans All RevisedDocumento6 pagineVentilation Fans All RevisedBilal Hussein SousNessuna valutazione finora

- Control of Particle Contamination With Liquid and Air Particle Counters Durig Preparation of The TTF 1.3GHZ ResonatorsDocumento15 pagineControl of Particle Contamination With Liquid and Air Particle Counters Durig Preparation of The TTF 1.3GHZ ResonatorsvladimirNessuna valutazione finora

- Ejw ADocumento1 paginaEjw Ahudiono cahyonoNessuna valutazione finora

- Calculation of Duct SizingDocumento7 pagineCalculation of Duct SizingPhyu Mar Thein KyawNessuna valutazione finora

- En 5Documento3 pagineEn 5Shagufta AzamNessuna valutazione finora

- Septic Tank Design Program RASDocumento8 pagineSeptic Tank Design Program RASMagdy BakryNessuna valutazione finora

- Flare Modeling ParametersDocumento20 pagineFlare Modeling ParametersvartharajanNessuna valutazione finora

- Ducting Design: " Add Your Company Slogan "Documento30 pagineDucting Design: " Add Your Company Slogan "Arga BennyNessuna valutazione finora

- Steam TracingDocumento47 pagineSteam TracingPascal CustonNessuna valutazione finora

- Item No. 10 - Sow NMIF Genset Building SoundproofingDocumento12 pagineItem No. 10 - Sow NMIF Genset Building SoundproofingparangkilalakitaNessuna valutazione finora

- Process Design Calculation3 - NDDocumento14 pagineProcess Design Calculation3 - NDabhishek5810Nessuna valutazione finora

- Lift Well Pressurisation - Old - 20240317Documento1 paginaLift Well Pressurisation - Old - 20240317kundur088Nessuna valutazione finora

- Transfer Grille Free-Area-CharacteristicsDocumento6 pagineTransfer Grille Free-Area-Characteristicsfopoku2k2Nessuna valutazione finora

- Fire Water ProtectionDocumento68 pagineFire Water ProtectionZakyAlFatony100% (1)

- 3.1 + 3.2 + 3.3 Ventilation CalculationDocumento3 pagine3.1 + 3.2 + 3.3 Ventilation Calculationabuya3kubmNessuna valutazione finora

- Summer Fans: (Cubic FT of Air To Be Handled)Documento14 pagineSummer Fans: (Cubic FT of Air To Be Handled)Jùñâïd MûmtæzNessuna valutazione finora

- Min Med Max Unit Scenario Description Project DataDocumento1 paginaMin Med Max Unit Scenario Description Project DataunconformistNessuna valutazione finora

- Burner CalculationDocumento6 pagineBurner CalculationAnonymous 3ESYcrKP100% (4)

- Blower CalculationDocumento1 paginaBlower Calculationvijayamalraj67% (3)

- Ejw BDocumento1 paginaEjw Bhudiono cahyonoNessuna valutazione finora

- Ex-7 Flow Meter DemonstrationDocumento7 pagineEx-7 Flow Meter Demonstrationasefat593Nessuna valutazione finora

- Headloss CalculationDocumento1 paginaHeadloss Calculationmohamed esmatNessuna valutazione finora

- Proinert Technical Guide: Proinert Pressure Relief Venting - When Less Is Better!Documento4 pagineProinert Technical Guide: Proinert Pressure Relief Venting - When Less Is Better!Dgh TeriNessuna valutazione finora

- Design of Hvac Kiba 21-11-18Documento12 pagineDesign of Hvac Kiba 21-11-18Aparna AwasthiNessuna valutazione finora

- Duct Design Calculation Pressure DropsDocumento6 pagineDuct Design Calculation Pressure DropsngarinyagaNessuna valutazione finora

- Steam Tracing Excel 2007Documento74 pagineSteam Tracing Excel 2007cybermineNessuna valutazione finora

- Calculation For Door Room PressureDocumento2 pagineCalculation For Door Room PressureDamodar GatlaNessuna valutazione finora

- Wind Farm Noise: Measurement, Assessment, and ControlDa EverandWind Farm Noise: Measurement, Assessment, and ControlNessuna valutazione finora

- 14 Attic InletsDocumento27 pagine14 Attic Inletsventus13Nessuna valutazione finora

- 8 Negative Pressure VentilationDocumento28 pagine8 Negative Pressure Ventilationventus13Nessuna valutazione finora

- 12 Air Inlet OperationDocumento22 pagine12 Air Inlet Operationventus13Nessuna valutazione finora

- The University of Georgia: 2018 Cold Weather Management WorkshopDocumento1 paginaThe University of Georgia: 2018 Cold Weather Management Workshopventus13Nessuna valutazione finora

- 9 Air InletsDocumento22 pagine9 Air Inletsventus13Nessuna valutazione finora

- 3 House TightnessDocumento23 pagine3 House Tightnessventus13Nessuna valutazione finora

- 2018 Cold Weather Environmental QuizDocumento2 pagine2018 Cold Weather Environmental Quizventus13Nessuna valutazione finora

- 2 Broiler House Heating System DesignDocumento22 pagine2 Broiler House Heating System Designventus13Nessuna valutazione finora

- 5 Heating SystemsDocumento29 pagine5 Heating Systemsventus13Nessuna valutazione finora

- Ross Tech Note - Broiler Foot HealthDocumento5 pagineRoss Tech Note - Broiler Foot Healthventus13Nessuna valutazione finora

- Measure Nipple Drinker Flow RateDocumento4 pagineMeasure Nipple Drinker Flow Rateventus13Nessuna valutazione finora

- Optimizing Broiler Feed Conversion Ratio: July 2011Documento6 pagineOptimizing Broiler Feed Conversion Ratio: July 2011ventus13Nessuna valutazione finora

- Tech Notes - The Ross Broiler First For Performance and WeDocumento3 pagineTech Notes - The Ross Broiler First For Performance and Weventus13Nessuna valutazione finora

- Ross Tech: Leg Health in BroilersDocumento8 pagineRoss Tech: Leg Health in Broilersventus13Nessuna valutazione finora

- The Ulitimate Poultry Watering GuideDocumento12 pagineThe Ulitimate Poultry Watering Guideventus13Nessuna valutazione finora

- Poultry SignalsDocumento81 paginePoultry Signalsventus13Nessuna valutazione finora

- Connecteur IDC Hirose HIF3BA Série 2.54mm 10pin 2x5 Femelle (FR - Rs-Online - Com 2313792)Documento15 pagineConnecteur IDC Hirose HIF3BA Série 2.54mm 10pin 2x5 Femelle (FR - Rs-Online - Com 2313792)SupportNessuna valutazione finora

- Price Forecasting & Anomaly Detection For Agricultural Commodities in IndiaDocumento13 paginePrice Forecasting & Anomaly Detection For Agricultural Commodities in IndiaAction ReplayNessuna valutazione finora

- W6!7!304E Skin-Pass Mills ReferencesDocumento36 pagineW6!7!304E Skin-Pass Mills Referencesdorin serbanNessuna valutazione finora

- 7212 2022 CertificateDocumento1 pagina7212 2022 CertificateGyana SahooNessuna valutazione finora

- Log 2Documento355 pagineLog 2Wilbert WilbertNessuna valutazione finora

- 4 - An Introductory Handbook On CBTC - April 2021Documento118 pagine4 - An Introductory Handbook On CBTC - April 2021rupadhyaayNessuna valutazione finora

- Tales From The Evil Empire - Building My New Blog With Orchard - Part 2 - Importing Old ContentsDocumento8 pagineTales From The Evil Empire - Building My New Blog With Orchard - Part 2 - Importing Old ContentsActive8Nessuna valutazione finora

- Nama: Diphda Antaresada Nim: 201581294 Online 5 DPPL Sesi 10 UML Project UAS 1. Use CaseDocumento2 pagineNama: Diphda Antaresada Nim: 201581294 Online 5 DPPL Sesi 10 UML Project UAS 1. Use CaseDiphda AntaresadaNessuna valutazione finora

- Zehir PHPDocumento7 pagineZehir PHPanon-902445Nessuna valutazione finora

- Icon Line Trimmer - ICPLT26 Operator ManualDocumento10 pagineIcon Line Trimmer - ICPLT26 Operator ManualAnirudh Merugu67% (3)

- Managed IT Services RFP TemplateDocumento11 pagineManaged IT Services RFP Templateedpaala67% (3)

- Quality Assurance Kamera GammaDocumento43 pagineQuality Assurance Kamera GammawiendaintanNessuna valutazione finora

- Intern Report-3Documento77 pagineIntern Report-3manishNessuna valutazione finora

- Sap PP Configuration DocumentDocumento75 pagineSap PP Configuration DocumentRafaelCasagrandeNessuna valutazione finora

- Caterpillar Cs 551 Cs 553 CP 553 Parts ManualDocumento23 pagineCaterpillar Cs 551 Cs 553 CP 553 Parts Manualzugenkzz33% (3)

- Used The Business Model of Canvas (BMC) To Create Alternative Strategies in Business Development of The Micro Small Medium EnterprisesDocumento10 pagineUsed The Business Model of Canvas (BMC) To Create Alternative Strategies in Business Development of The Micro Small Medium EnterprisesJoven SegueraNessuna valutazione finora

- Freno Motobomba PDFDocumento136 pagineFreno Motobomba PDFEzequiel CeccarelliNessuna valutazione finora

- Research Method and Design RINGKASDocumento24 pagineResearch Method and Design RINGKASYuda ChanNessuna valutazione finora

- Narrative Profile - BEED LibraryDocumento51 pagineNarrative Profile - BEED LibraryJUNNARIENessuna valutazione finora

- Fire Prevention Week Report To The Community - Oct. 7, 2021Documento15 pagineFire Prevention Week Report To The Community - Oct. 7, 2021NBC12 RichmondNessuna valutazione finora

- Weekly Home Learning Plan: (4 Quarter: Week 1)Documento8 pagineWeekly Home Learning Plan: (4 Quarter: Week 1)JenicaEilynNessuna valutazione finora

- Advt No.311 - Intranet PDFDocumento2 pagineAdvt No.311 - Intranet PDFaabbbtNessuna valutazione finora

- Computer Project Work 2022 (Autorecovered)Documento58 pagineComputer Project Work 2022 (Autorecovered)Babloo Singh 11 SCI-BNessuna valutazione finora

- MT131 Tutorial - 2 Sets Functions Sequences and Summation - 2023-2024Documento63 pagineMT131 Tutorial - 2 Sets Functions Sequences and Summation - 2023-2024johnnader1254Nessuna valutazione finora

- Valve Control System On A Venturi To Control FiO2 A Portable Ventilator With Fuzzy Logic Method Based On MicrocontrollerDocumento10 pagineValve Control System On A Venturi To Control FiO2 A Portable Ventilator With Fuzzy Logic Method Based On MicrocontrollerIAES IJAINessuna valutazione finora

- Principles of Purchasing Nd1 Bam 117Documento36 paginePrinciples of Purchasing Nd1 Bam 117Alexander GabrielNessuna valutazione finora

- Normal Probability Distribution and Z TableDocumento4 pagineNormal Probability Distribution and Z TableAnimeliciousNessuna valutazione finora

- Huawei LTE RNP Introduction1Documento31 pagineHuawei LTE RNP Introduction1Hân Trương100% (1)

- Exstream03Content01Doc PDFDocumento108 pagineExstream03Content01Doc PDFAymen EL ARBI100% (3)

- Schools Division Office Quezon City: How To Create Quiz On Google FormDocumento31 pagineSchools Division Office Quezon City: How To Create Quiz On Google FormLove ShoreNessuna valutazione finora