Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

GeneQuence Salmonella reagents assay foodborne pathogens

Caricato da

Javier muñoz0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

21 visualizzazioni4 pagineTitolo originale

2007.02 Salmonella spp en alimentos selecciondos- hibridacion DNA

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

21 visualizzazioni4 pagineGeneQuence Salmonella reagents assay foodborne pathogens

Caricato da

Javier muñozCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

17.9.

34 GeneQuence Salmonella reagents are not interchangeable with

AOAC Official Method 2007.02 other GeneQuence assay reagents. Reagents should not be used

Salmonella spp. in Select Foods beyond their expiration dates.

Ò

GeneQuence Salmonella (a) Lysis reagent concentrate.—Reagent 1a, contains

DNA Hybridization with 24 H Enrichment proteinase K.

First Action 2007 (b) Lysis reagent buffer.—Reagent 1b, contains Tris, pH 7.4,

Final Action 2010 disodium EDTA, n-lauryl sarcosine, and bromphenol blue.

(Applicable to the detection of Salmonella spp. in raw turkey, (c) Hybridization solution.—Reagent 2, contains formamide.

dried, liquid, and liquid frozen pasteurized eggs, milk chocolate, and (d) Salmonella probe solution.—Reagent 3, contains

dry pet food.) HRP-labeled Salmonella-specific oligonucleotide probe and

See Table 2007.02 for the results of the interlaboratory study p o l y d e o x y a d e n y l i c a c i d - l a b e l e d S a l m o n e l l a s p e c i f ic

supporting acceptance of the method. oligonucleotide probe in Tris, pH 7.0, and cresol red.

Caution: Reagents are for laboratory use only. Use of this test (e) Wash solution, 20X concentrate.—Reagent 4, contains Tris,

should be restricted to personnel with appropriate disodium EDTA, NaCl, and Tween-20.

laboratory training in microbiology. Handle and (f) Substrate-chromogen solution.—Reagent 5, contains urea

dispose of enrichment cultures as potentially infectious peroxide and tetramethylbenzidine.

material. Use either a disposable pipet and pipeting (g) Stop solution.—Reagent 6, contains 4 N sulfuric acid.

bulb or micropipet with disposable tips to make all (h) Positive control.—Contains formaldehy de-killed

pipeting transfers. Do not mouth pipet. The preferred S. Typhimurium.

method for disposal of contaminated materials, (i) Negative control.—Contains formaldehy de-killed

including cultures, pipets, etc., is autoclaving. Stop Citrobacter freundii.

solution contains 4 N sulfuric acid. Hybridization (j) Microwell plate.—96 wells in divisible strips (coated with

solution contains formamide. Avoid contact with skin polydeoxythymidylic acid).

and mucous membranes. (k) Hybridization/probe mixture chart.

(l) High-speed blender.

A. Principle

(m) StomacherTM.

The GeneQuence Salmonella assay is a sandwich DNA

(n) Test tubes.—Glass, 12 ´ 75 mm.

hybridization (DNAH) assay for detection of Salmonella spp. in

(o) Test tubes or culture tubes.—50 mL, sterile.

select foods. Following culture enrichment of test samples, bacteria

present in the culture are lysed to release ribosomal RNA (rRNA). (p) Micropipet and tips.—To dispense 100, 150, and 400 mL

Horseradish peroxidase (HRP)-labeled detector probes and volumes.

polydeoxyadenylic acid (dA)-labeled capture probes hybridize to (q) 8-Channel pipettor and tips.—To dispense 50, 125, and

Salmonella-specific sequences of the rRNA. The dA tail on the 150 mL volumes.

capture probe facilitates binding of the hybridized complex to a (r) Repeater pipettor and syringe tips.—To dispense 100 mL

polydeoxythymidylic acid (dT)-coated microwell. Unbound probe volume, optional.

is removed by washing, and a chromogenic substrate of HRP is (s) Incubator.—35 ± 1°C.

added. After color development, the reaction is stopped by the (t) Water bath or incubator.—42 ± 0.2°C.

addition of acid, and absorbance at 450 nm is determined using a

(u) Water bath or heater block.—65 ± 1°C.

photometer. Absorbance in excess of a threshold value indicates the

presumptive presence of Salmonella spp. in the sample. A positive (v) Heater block.—45 ± 1°C, with insert for microtiter plate and

result must be confirmed by standard culture procedures such as cover.

those described in the U.S. Department of Agriculture's Food Safety (w) Microwell plate or strip washing device.—8-Well

and Inspection Service [USDA-FSIS; U.S. Department of orientation, with vacuum source.

Agriculture-Food Safety Inspection Service (2004) Microbiology (x) Microwell plate or strip reader.—450 nm with discrimination

Laboratory Guidebook, Ch. 4, http://www.fsis.usda.gov/PDF/MLG_ of 0.01 absorbance unit.

4_03.pdf] and the U.S. Food and Drug Administration's C. Media and Reagents

Bacteriological Analytical Manual [FDA/BAM; U.S. Food and

(a) Pre-enrichment media.—As appropriate for food type, per

Drug Administration (2003) Bacteriological Analytical Manual

FDA/BAM [U.S. Food and Drug Administration (2003)

Online, Ch. 5, http://www.cfsan.fda.gov/~ebam/bam-5.html]

Bacteriological Analytical Manual Online, Ch. 5,

reference methods.

http://www.cfsan.fda.gov/~ebam/bam-5.html; available from

Probes used in this test are not reactive with serovars of

Acumedia, Lansing, MI, USA, and other suppliers].

Salmonella bongori.

(b) Buffered peptone water (BPW).—Available from Acumedia

B. Apparatus and other suppliers.

Items (a)–(k) are available as GeneQuence Salmonella from (c) Rappaport-Vassiliadis broth (RV).—Available from

Neogen Corp. (Lansing, MI, USA; www.neogen.com). Each kit Acumedia and other suppliers.

contains sufficient materials and reagents for 100 tests. Store (d) Gram-negative broth (GN).—Available from Acumedia and

reagents 1a, 2, 3, and 5 at 2–8°C. Other reagents may be stored at other suppliers.

2–25°C. Alternatively, the entire kit may be stored at 2–8°C. (e) Brain heart infusion broth (BHI).—Available from

Reagents from different kit lots should not be interchanged. Acumedia and other suppliers.

ã 2010 AOAC INTERNATIONAL

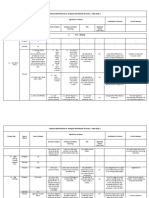

Table 2007.02. Interlaboratory study results for the detection of Salmonella spp. in foods by the GeneQuence Salmonella assay

DNAH DNAH

Total Ref. False False

a b c d 2e f g h i

Food type Serovar Lev el MPN/g s am pl es Presumptive Confirmed m e th o d c S e n s i ti v i ty , % neg. , % S p e c i fi c i ty , % pos . , %

Raw ground turkey Group E Lot 1 11 78 73 73 76 0 .6 0 9 6 .1 3 .9 — —

Group E Lot 2 1 .4 9 78 75 74 78 2 .3 1 9 4 .9 5 .1 — —

Raw ground beef 1 S. Newport High 0 .4 3 71 55 54 63 3 .1 1 8 5 .7 1 4 .3 — —

Low 0 .0 7 4 72 59 58 65 2 .0 1 8 9 .2 1 0 .8 — —

Control < 0 .0 3 71 4 2 4 0 .1 7 5 0 .0 5 0 .0 — —

ã 2010 AOAC INTERNATIONAL

Raw ground beef 2 S. Newport High 0 .4 3 66 53 51 58 1 .9 0 8 7 .9 1 2 .1 — —

Low < 0 .0 3 66 15 14 29 6 .7 6 4 8 .3 5 1 .7 — —

Control < 0 .0 3 66 0 0 0 — — — 1 0 0 .0 0 .0

Dried whole egg S. Enteritidis High 0 .2 1 66 58 58 61 0 .3 4 9 5 .1 4 .9 — —

Low 0 .1 4 66 41 41 43 0 .0 3 9 5 .3 4 .7 — —

Control < 0 .0 3 66 8 6 6 0 .0 9 1 0 0 .0 0 .0 — —

M i l k c h o c o l a te 1 S. Senftenberg High > 11 72 72 72 72 — 1 0 0 .0 0 .0 — —

Low > 11 72 72 72 72 — 1 0 0 .0 0 .0 — —

Control < 0 .0 3 72 8 0 0 — — — 8 8 .9 1 1 .1

M i l k c h o c o l a te 2 S. Senftenberg High 0 .1 5 66 51 50 52 0 .0 4 9 6 .2 3 .8 — —

Low 0 .0 9 2 66 23 23 25 0 .0 3 9 2 .0 8 .0 — —

Control < 0 .0 3 66 3 0 0 — — — 9 5 .5 4 .5

W a l n u ts S. Typhimurium High > 11 72 0 0 64 1 1 1 .6 0 .0 1 0 0 .0 — —

Low 0 .0 7 4 72 1 0 32 3 8 .6 0 .0 1 0 0 .0 — —

Control < 0 .0 3 72 0 0 0 — — — 1 0 0 .0 0 .0

Dry pet food S. Thompson High 0 .0 3 6 60 39 38 40 0 .0 4 9 5 .0 5 .0 — —

Low 0 .0 3 60 13 13 14 0 .0 0 9 2 .9 7 .1 — —

Control < 0 .0 3 60 0 0 0 — — — 1 0 0 .0 0 .0

a

MPN = Most probable number of colony-forming units (CFU)/g food.

b

Number of DNAH assay positive samples not considering subsequent confirmation.

c

Number of DNAH assay positive samples subsequently confirmed.

d

Number of samples positive by reference method (USDA-FSIS method for raw ground turkey, raw ground beef, and dried whole egg; FDA/BAM method for milk chocolate, walnuts, and dry pet food).

e 2 2

c is defined as N*{[a*d – b*c] – N/2} /[(a + b)(a + c)(c + d)(b + d)], where a = samples positive by test method, b = samples positive by reference method, c = samples negative by test method, d = samples

negative by reference method, N = total samples tested by both methods.

f

Sensitivity rate is defined as the number of DNAH confirmed positive test results divided by the number of reference method positive test results, expressed as a percentage.

g

False-negative rate = 100 – sensitivity rate.

h

Specificity rate is defined as the number of DNAH assay negative samples divided by the number of negative samples, expressed as a percentage. Calculated only for control levels with no confirmed positive

results.

i

False-positive rate = 100 – specificity rate.

D. Enrichment equilibrated to room temperature before use but should not be left

Note: All enrichment media should be prewarmed to room out unrefrigerated for long periods of time (more than 2 h).

temperature before use. Prior to starting the assay.—(1) Turn on the water bath or heater

(a) For dried, liquid, and liquid frozen pasteurized eggs.—(1) block and adjust to 65 ± 1°C. Water bath should be filled to a level of

Homogenize (Stomacher) sample in 9 volumes BPW. [Note: The ca 1.5 in. Heater block wells should be filled about 1/3 with

standard sample size as specified by USDA-FSIS is 100 g; U.S. deionized water.

Department of Agriculture-Food Safety Inspection Service (2004) (2) To reagent bottle 1a (lysis reagent concentrate), add 6 mL

Microbiology Laboratory Guidebook, Ch. 4, solution 1b (lysis reagent buffer). Dissolve contents by gentle

http://www.fsis.usda.gov/PDF/MLG_4_03.pdf.] For dried egg swirling and place the bottle on ice.

samples, add BPW to the sample gradually, and mix to produce a Note: Lysis reagent is stable in the reconstituted form for 60 days

homogeneous suspension free of lumps. Incubate 18–20 h at 35 ± when stored at –20°C. To thaw, place bottle at room temperature.

1°C. When thawed, place on ice (freeze-thawing does not adversely

(2) Remove BPW culture from incubation, and mix well. affect the reconstituted reagent).

Transfer 10 mL BPW culture to 10 mL double-strength GN broth in (3) For each sample to be tested, label a 12 ´ 75 mm glass test

50 mL tube. Incubate 6–7 h at 35 ± 1°C. tube with the appropriate sample designation and place in a rack.

(3) Remove GN culture from incubation and mix. Perform Include tubes for one positive control and one negative control per

GeneQuence Salmonella assay using 0.4 mL GN culture. Save GN experimental run.

culture at 2–8°C for possible confirmation. (4) Prepare 1X wash solution. Dilute solution 4 (20X wash

(b) For dry pet food.—(1) Blend sample in 9 volumes lactose solution concentrate) by mixing contents of bottle (25 mL) with

broth in accordance with FDA/BAM guidelines [U.S. Food and 475 mL distilled or deionized water. Fill buffer reservoir of plate

Drug Administration (2003) Bacteriological Analytical Manual washing device.

Online, Ch. 5, http://www.cfsan.fda.gov/~ebam/bam-5.html]. Note: 1X wash solution can be stored in a closed bottle at room

Incubate 18–20 h at 35 ± 1°C. temperature for up to 60 days.

(2) Remove pre-enrichment culture from incubation, and mix (5) Prepare a mixture of solution 2 (hybridization solution) and

well. Transfer 10 mL pre-enrichment culture to 10 mL solution 3 (Salmonella probe solution) in an appropriate size plastic

double-strength GN broth in 50 mL tube. Incubate 6–7 h at or glass container in a 4:1 proportion to achieve a sufficient amount

35 ± 1°C. for the number of samples to be tested. Use the formula below or

(3) Remove GN culture from incubation, and mix. Perform refer to the mixing chart available from Neogen Corp.

GeneQuence Salmonella assay using 0.4 mL GN culture. Save GN

culture at 2–8°C for possible confirmation. Volume solution 2 = [(N ´ 0.1) + 1.6] mL

(c) For milk chocolate.—(1) Blend sample in 9 volumes skim

milk medium with brilliant green in accordance with FDA/BAM Volume solution 3 = [(N ´ 0.025) + 0.4] mL

guidelines [U.S. Food and Drug Administration (2003)

Bacteriological Analytical Manual Online, Ch. 5, where N is the number of samples to be tested including controls.

http://www.cfsan.fda.gov/~ebam/bam-5.html]. Incubate 22–24 h at Note: The above formula provides for an excess volume of

2.0 mL; a different excess volume may be appropriate depending on

35 ± 1°C.

the type of container used to prepare the mixture and the type of

(2) Remove pre-enrichment culture from incubation, and mix

pipetting device used.

well. Transfer 10 mL pre-enrichment culture to 10 mL

(6) Place the appropriate number of coated microwells in the

double-strength BHI broth in 50 mL tube. Incubate 6–7 h at

plate frame, filling the frame left to right and front to back in rows of

35 ± 1°C.

8. Include wells for the reagent blank, negative control, and positive

(3) Remove BHI culture from incubation, and mix. Perform control. Avoid touching the bottoms of the wells. If the last row has

GeneQuence Salmonella assay using 0.4 mL BHI culture. Save BHI fewer than 8 wells, fill in the row as necessary with the special

culture at 2–8°C for possible confirmation. uncoated wells (colored bottoms) provided.

(d) For raw poultry.—(1) Homogenize (stomacher) sample in 9

F. Analysis

volumes RV broth. Incubate 18–20 h at 42 ± 0.2°C.

(2) Remove RV culture from incubation and mix well. Transfer (1) Mix the sample cultures (GN or BHI cultures). Add 0.4 mL of

1 mL RV culture to 10 mL GN broth. Incubate 6–7 h at 35 ± 1°C. each GN or BHI culture to the appropriate tubes. Shake the positive

control and negative control solutions by inverting the bottles

(3) Remove GN culture from incubation and mix. Perform

several times, and add 0.4 mL of each control to the appropriate

GeneQuence Salmonella assay using 0.4 mL GN culture. Save GN

tubes.

culture at 2–8°C for possible confirmation.

(2) Add 0.1 mL solution 1 (reconstituted lysis reagent) to each

Note: Samples must be tested when the final GN or BHI

tube. Shake the rack of tubes by hand for 5 s. The resulting solution

incubation period is complete. Do not hold cultures for testing at a

should be blue. If any tubes are not blue, check for proper reagent

later time.

addition. Incubate the rack of tubes in the 65°C water bath or heater

E. General Preparation block for 5 min.

General notes.—This assay should be performed in a normal (3) Remove the rack of tubes from the 65°C water bath or heater

laboratory environment with respect to humidity, lighting, etc. Steps block. Transfer 0.15 mL of each lysed sample, including the

requiring room temperature incubation should be performed at controls, to the designated microwell. The first well should be

18–30°C. Kit reagents that have been refrigerated should be reserved for the reagent blank and receives no sample. The second

ã 2010 AOAC INTERNATIONAL

well should be used for the negative control, and the third well for repeated. The absorbance value for the positive control must be

the positive control. ³1.00. Otherwise, the assay is invalid and should be repeated.

(4) Using an 8-channel pipettor, add 0.125 mL premixed solution

(b) Negative criterion.—Assays producing an absorbance value

2/3 (hybridization/probe solution) prepared in E(5) to each well

<0.10 indicate the absence of Salmonella spp. in the test sample.

except the reagent blank well. Mix the contents of the wells 5–10

times using the pipettor. (c) Positive criterion.—Assays producing an absorbance value

(5) Incubate the plate on the covered heater block at 45°C for 1 h. ³0.10 indicate the presence of Salmonella spp. in the test sample.

(6) Wash the wells 5 times at room temperature using a plate or These samples should be confirmed by standard culture procedures.

strip washing device. After the last wash, remove residual liquid by

H. Confirmation of Positive Results

inverting the plate and tapping it onto absorbent paper. Hold the

plate by gently squeezing on the sides of the frame to keep the strips For samples which produce positive hybridization assays, the

in place. result should be confirmed by streaking from the GN or BHI cultures

(7) Add 0.15 mL solution 5 (substrate-chromogen solution) to and/or the selective enrichment cultures to selective/differential

each well, including the reagent blank well. Incubate the plate at plating media (Hektoen Enteric Agar, Xylose Lysine Deoxycholate

room temperature for 20 min. Agar, and Bismuth Sulfite Agar are recommended) and continuing

(8) Add 0.05 mL solution 6 (stop solution) to each well, including with biochemical and serological identification of presumptive

the blank well. Salmonella spp. isolates using standard procedures [U.S.

(9) Read absorbance at 450 nm using a plate or strip reader Department of Agriculture-Food Safety Inspection Service (2004)

according to the manufacturer’s instructions. Blank on the reagent Microbiology Laboratory Guidebook, Ch. 4,

blank (do not blank on air). http://www.fsis.usda.gov/PDF/MLG_4_03.pdf; U.S. Food and

Drug Administration (2003) Bacteriological Analytical Manual

G. Results

Online, Ch. 5, http://www.cfsan.fda.gov/~ebam/bam-5.html].

(a) Control values.—The absorbance value for the negative

control must be £0.15. Otherwise, the assay is invalid and should be Reference: J. AOAC Int. 90, 738(2007).

ã 2010 AOAC INTERNATIONAL

Potrebbero piacerti anche

- 2004.03 Salmonella en Alimentos ELFADocumento3 pagine2004.03 Salmonella en Alimentos ELFAJavier muñozNessuna valutazione finora

- Institute Panel Use Only: Salmonella in A Variety of FoodsDocumento4 pagineInstitute Panel Use Only: Salmonella in A Variety of FoodsDogminiq GNessuna valutazione finora

- 2009.03 Salmonella en Alimentos y Superficies - GDSDocumento4 pagine2009.03 Salmonella en Alimentos y Superficies - GDSJavier muñozNessuna valutazione finora

- Institute Panel Use Only: AOAC Official Method 2013.11Documento4 pagineInstitute Panel Use Only: AOAC Official Method 2013.11Maria del Carmen RamirezNessuna valutazione finora

- Determination of Total Phenolic Content Using The Folin-C Assay: Single-Laboratory Validation, First Action 2017.13Documento7 pagineDetermination of Total Phenolic Content Using The Folin-C Assay: Single-Laboratory Validation, First Action 2017.13Naye VillalónNessuna valutazione finora

- PCR Analysis Methods For Detection and Identification of Beer-Spoilage Lactic Acid BacteriaDocumento13 paginePCR Analysis Methods For Detection and Identification of Beer-Spoilage Lactic Acid BacteriaAzriah AsisNessuna valutazione finora

- Aoac 2003.12Documento3 pagineAoac 2003.12Yesenia Borja ArroyoNessuna valutazione finora

- 16S Ribosomal DNA For: Amplification Phylogenetic StudyDocumento7 pagine16S Ribosomal DNA For: Amplification Phylogenetic StudyolamicroNessuna valutazione finora

- Sensitivity of Listeria Monocytogenes To Sanitizer PDFDocumento6 pagineSensitivity of Listeria Monocytogenes To Sanitizer PDFValentin GhenceaNessuna valutazione finora

- 1 s2.0 S221501611730033X MainDocumento25 pagine1 s2.0 S221501611730033X MainRizkaNessuna valutazione finora

- 10 1021@jf070883eDocumento7 pagine10 1021@jf070883eRocketManNessuna valutazione finora

- AOAC 2003.09 Salmonella BAXDocumento5 pagineAOAC 2003.09 Salmonella BAXGeovane Duran PadillaNessuna valutazione finora

- 2Documento8 pagine2Chorrinha ChorraNessuna valutazione finora

- Porphyromonas Gingivalis Agar MediumDocumento2 paginePorphyromonas Gingivalis Agar MediumAhmed Tawfig GamalNessuna valutazione finora

- PrimerDocumento5 paginePrimerrfsh rfshNessuna valutazione finora

- Analyzing Pesticides in FoodDocumento2 pagineAnalyzing Pesticides in FoodArifSurtonoNessuna valutazione finora

- ncm0103 Ts En-UsDocumento3 paginencm0103 Ts En-UsTabsherah AnsariNessuna valutazione finora

- Laboratory Methods _ BAM_ Detection of _i_Cyclospora__i_ and _i_Cryptosporidium__i_Documento17 pagineLaboratory Methods _ BAM_ Detection of _i_Cyclospora__i_ and _i_Cryptosporidium__i_oktaNessuna valutazione finora

- HPLC Method Quantifies Flavonoids and Antiradical Activity in Tonina fluviatilisDocumento15 pagineHPLC Method Quantifies Flavonoids and Antiradical Activity in Tonina fluviatiliscsandrasNessuna valutazione finora

- Fems Microbiology Letters - 2006 - Schoefer - A Fluorescence Quenching Test For The Detection of Flavonoid TransformationDocumento4 pagineFems Microbiology Letters - 2006 - Schoefer - A Fluorescence Quenching Test For The Detection of Flavonoid TransformationRodos LaboratoriesNessuna valutazione finora

- Determination of Bovine Lactoferrin in Food by HPLC With A Heparin Affinity Column For Sample PreparationDocumento6 pagineDetermination of Bovine Lactoferrin in Food by HPLC With A Heparin Affinity Column For Sample PreparationRusbel Andres RodriguezNessuna valutazione finora

- 18 3 2 - p.155 160Documento6 pagine18 3 2 - p.155 160Bình MinhNessuna valutazione finora

- Chemosphere: Contents Lists Available atDocumento6 pagineChemosphere: Contents Lists Available atSacra PsyntergiaNessuna valutazione finora

- Draft: Manual of Methods OF Analysis of FoodsDocumento105 pagineDraft: Manual of Methods OF Analysis of FoodsDhanushka WarnakulasooriyaNessuna valutazione finora

- The Effect of Polysorbate 20 and 80 On The Structure and Immunogenicity in Wildtype and Transgenic Mice of Recombinant Human Interferon Alpha2bDocumento20 pagineThe Effect of Polysorbate 20 and 80 On The Structure and Immunogenicity in Wildtype and Transgenic Mice of Recombinant Human Interferon Alpha2bMAHESHNessuna valutazione finora

- GB 4789.4 2010 National Food Safety Standard Food Microbiological Examination Salmonella PDFDocumento24 pagineGB 4789.4 2010 National Food Safety Standard Food Microbiological Examination Salmonella PDFmmoradi55Nessuna valutazione finora

- Quantification of Isoorientin and Total Flavonoids in Passiflora Edulis Fruit PuDocumento6 pagineQuantification of Isoorientin and Total Flavonoids in Passiflora Edulis Fruit PuRodney PerttesonNessuna valutazione finora

- Enterococcus Culture Identification Test: ReagentsDocumento4 pagineEnterococcus Culture Identification Test: ReagentsJit Mann KaursekhonNessuna valutazione finora

- Detection of Salmonella in Sludge SedimentsDocumento4 pagineDetection of Salmonella in Sludge SedimentsmegacobNessuna valutazione finora

- 2015 - Validation of A Minor Modification To The Soleris DYM Vial and Selective Supplement - AOAC PTM 051301Documento4 pagine2015 - Validation of A Minor Modification To The Soleris DYM Vial and Selective Supplement - AOAC PTM 051301jasminetsai421Nessuna valutazione finora

- 2018-Toxicity and structure-activity relationship (SAR) of α,β-dehydroamino acids against human cancer cell linesDocumento12 pagine2018-Toxicity and structure-activity relationship (SAR) of α,β-dehydroamino acids against human cancer cell linesHui Ling MaNessuna valutazione finora

- Shipra Annona PaperDocumento5 pagineShipra Annona PaperMuhammad Fattah FazelNessuna valutazione finora

- The Effect of Co-Solvents On The Antibacterial Activity of ParabenDocumento10 pagineThe Effect of Co-Solvents On The Antibacterial Activity of ParabenDamariscpNessuna valutazione finora

- Análise de Nicarbazina em RaçãoDocumento9 pagineAnálise de Nicarbazina em RaçãoCarol MicalliNessuna valutazione finora

- BAM Chapter 14. Bacillus CereusDocumento9 pagineBAM Chapter 14. Bacillus CereusremyNessuna valutazione finora

- Chen 2012Documento6 pagineChen 2012Miranti PuspitasariNessuna valutazione finora

- Anti HAV Total 30312Documento6 pagineAnti HAV Total 30312armada thamNessuna valutazione finora

- Solo 1Documento9 pagineSolo 1JOSE MIGUEL ASMAD QUINTANANessuna valutazione finora

- Brazilian Journal of MicrobiologyDocumento7 pagineBrazilian Journal of MicrobiologyHimaniNessuna valutazione finora

- 708600Documento36 pagine708600claude_badrNessuna valutazione finora

- Jurnal PenelitianDocumento8 pagineJurnal PenelitianmiminNessuna valutazione finora

- ErgovalinDocumento4 pagineErgovalinDiegoSampietroNessuna valutazione finora

- Mendez2004 PDFDocumento7 pagineMendez2004 PDFFranco SantinNessuna valutazione finora

- Método Oficial AOAC Método 991.15 Coliformes Totales y Escherichia Coli en AguaDocumento2 pagineMétodo Oficial AOAC Método 991.15 Coliformes Totales y Escherichia Coli en AguaNatalie Muñoz Gutierrez100% (1)

- RPB14150077015Documento7 pagineRPB14150077015Ijupbs IjupbsNessuna valutazione finora

- Syndecan1 (CD138) RGP009R Biovendor-3Documento20 pagineSyndecan1 (CD138) RGP009R Biovendor-3YogiHadityaNessuna valutazione finora

- HPLC PDFDocumento7 pagineHPLC PDFJorge AlisteNessuna valutazione finora

- Furtado 2012Documento6 pagineFurtado 2012Pedro Enrique DomínguezNessuna valutazione finora

- 2017 Article 286Documento9 pagine2017 Article 286Idamelis Rodríguez GarcíaNessuna valutazione finora

- PCR Amplification of Microalgal DNA For Sequencing and SpeciDocumento8 paginePCR Amplification of Microalgal DNA For Sequencing and SpeciProductos & Servicios microalgasNessuna valutazione finora

- Materials and Methods OutlineDocumento4 pagineMaterials and Methods OutlineOluwaTomi FhikunmiNessuna valutazione finora

- BAM Chapter 13B. Staphylococcal Enterotoxins Detection MethodsDocumento7 pagineBAM Chapter 13B. Staphylococcal Enterotoxins Detection MethodsremyNessuna valutazione finora

- Food control study characterizes clostridial species in foie grasDocumento6 pagineFood control study characterizes clostridial species in foie grasSebastian HerreraNessuna valutazione finora

- MLG 4Documento20 pagineMLG 4GS ShawonNessuna valutazione finora

- Deperrois Lafarge2012Documento10 pagineDeperrois Lafarge2012Cẩm Tú NguyễnNessuna valutazione finora

- Practical Handbook of Pharmaceutical Chemistry for M.PharmDa EverandPractical Handbook of Pharmaceutical Chemistry for M.PharmNessuna valutazione finora

- Experimental approaches to Biopharmaceutics and PharmacokineticsDa EverandExperimental approaches to Biopharmaceutics and PharmacokineticsNessuna valutazione finora

- Calculations for Molecular Biology and BiotechnologyDa EverandCalculations for Molecular Biology and BiotechnologyValutazione: 3 su 5 stelle3/5 (1)

- Agglutination, Complement, Neutralization, and Inhibition: Methods in Immunology and Immunochemistry, Vol. 4Da EverandAgglutination, Complement, Neutralization, and Inhibition: Methods in Immunology and Immunochemistry, Vol. 4Nessuna valutazione finora

- Aoac923 09Documento1 paginaAoac923 09Alexis Garrido Salinas100% (2)

- 44.1.01 AOAC of Fi Cial Method 920.175 Prep A Ra Tion of Test Sam PleDocumento1 pagina44.1.01 AOAC of Fi Cial Method 920.175 Prep A Ra Tion of Test Sam PlegonbioNessuna valutazione finora

- Aoac 920.108Documento1 paginaAoac 920.108Javier muñozNessuna valutazione finora

- 2005.03 Coliformes y E Coli en AlimentosDocumento4 pagine2005.03 Coliformes y E Coli en AlimentosJavier muñozNessuna valutazione finora

- 2011.17 Salmonella. E Coli y Enterobacterias VITEK Gram NegativoDocumento2 pagine2011.17 Salmonella. E Coli y Enterobacterias VITEK Gram NegativoJavier muñoz100% (1)

- Cuantificación de Almidón AOAC 920.83Documento1 paginaCuantificación de Almidón AOAC 920.83Nilo RoblesNessuna valutazione finora

- 997.02 Yeast and Mold Count in FoodsDocumento2 pagine997.02 Yeast and Mold Count in FoodsJavier muñozNessuna valutazione finora

- ASTM A106-2aDocumento13 pagineASTM A106-2aClarkFedele27Nessuna valutazione finora

- A134 PDFDocumento4 pagineA134 PDFJarbas MoraesNessuna valutazione finora

- A 53 - A 53M - 99 Qtuzltk5qg - PDFDocumento21 pagineA 53 - A 53M - 99 Qtuzltk5qg - PDFEdgardo Humberto GonzálezNessuna valutazione finora

- A 105 - A 105M - 00 Qtewns0wma - PDFDocumento4 pagineA 105 - A 105M - 00 Qtewns0wma - PDFfekihassanNessuna valutazione finora

- A 135 - 01 Qteznq - PDFDocumento9 pagineA 135 - 01 Qteznq - PDFStuartNessuna valutazione finora

- 996.08 Salmonella en Alimentos - Ensayo Inmunofluorescente Unido A Enzima VIDASDocumento3 pagine996.08 Salmonella en Alimentos - Ensayo Inmunofluorescente Unido A Enzima VIDASJavier muñozNessuna valutazione finora

- 972.45 Sporas de Bacterias Termofilas en AzucaresDocumento1 pagina972.45 Sporas de Bacterias Termofilas en AzucaresJavier muñozNessuna valutazione finora

- Crude fiber analysis using ceramic filtersDocumento3 pagineCrude fiber analysis using ceramic filtersArellanes JmzNessuna valutazione finora

- Aoac 991.07Documento7 pagineAoac 991.07Javier muñozNessuna valutazione finora

- 967.27 Salmonella en Alimentos - IdentificaciónDocumento3 pagine967.27 Salmonella en Alimentos - IdentificaciónJavier muñozNessuna valutazione finora

- 975.54 Salmonella en Alimentos - Metodo Anticuerpos Fluorescentes FADocumento2 pagine975.54 Salmonella en Alimentos - Metodo Anticuerpos Fluorescentes FAJavier muñozNessuna valutazione finora

- 990.12 Aerobic Plate Count in Foods - PetrifilmDocumento1 pagina990.12 Aerobic Plate Count in Foods - PetrifilmJavier muñozNessuna valutazione finora

- 975.54 Salmonella en Alimentos - Metodo Anticuerpos Fluorescentes FADocumento2 pagine975.54 Salmonella en Alimentos - Metodo Anticuerpos Fluorescentes FAJavier muñozNessuna valutazione finora

- 975.54 Salmonella en Alimentos - Metodo Anticuerpos Fluorescentes FADocumento2 pagine975.54 Salmonella en Alimentos - Metodo Anticuerpos Fluorescentes FAJavier muñozNessuna valutazione finora

- 967.28 Salmonella en Alimentos Test SerologicoDocumento2 pagine967.28 Salmonella en Alimentos Test SerologicoJavier muñozNessuna valutazione finora

- 33.2.27A AOAC of Fi Cial Method 2000.18 Fat Con Tent of Raw and Pas Teur Ized Whole MilkDocumento2 pagine33.2.27A AOAC of Fi Cial Method 2000.18 Fat Con Tent of Raw and Pas Teur Ized Whole MilkJavier muñoz100% (1)

- 41.1.18 AOAC Official Method 920.160 Saponification Number (Koettstorfer Number) of Oils and FatsDocumento1 pagina41.1.18 AOAC Official Method 920.160 Saponification Number (Koettstorfer Number) of Oils and FatsEmiliano García50% (2)

- 9045d EPA PDFDocumento5 pagine9045d EPA PDFMaricela Mijahuanga ValleNessuna valutazione finora

- Malaria Diagnosis and Treatment GuideDocumento63 pagineMalaria Diagnosis and Treatment Guidemiki amareNessuna valutazione finora

- Proceeding - Final DraftDocumento534 pagineProceeding - Final DraftSalmaNessuna valutazione finora

- Module 6 - Laboratory Investigation: Foodborne Disease Outbreak Investigation Team TrainingDocumento44 pagineModule 6 - Laboratory Investigation: Foodborne Disease Outbreak Investigation Team TrainingrepyNessuna valutazione finora

- Widals TestDocumento2 pagineWidals TestEdgar DumagpiNessuna valutazione finora

- Selection of A Chicken Lactobacillus Strain With Probiotic Properties and Its Application in Poultry ProductionDocumento268 pagineSelection of A Chicken Lactobacillus Strain With Probiotic Properties and Its Application in Poultry ProductionMuhamad Akhmal HakimNessuna valutazione finora

- The Role of Vaccination in Salmonella ControlDocumento51 pagineThe Role of Vaccination in Salmonella ControlDr. Aja Ogboo Chikere100% (1)

- V 6 N 5Documento126 pagineV 6 N 5Sakthivel Pillanatham CivalingamNessuna valutazione finora

- Journal of Food Hygiene and SafetyDocumento5 pagineJournal of Food Hygiene and Safetyrachel santosoNessuna valutazione finora

- Food Microbiolo (B-Ok - Xyz)Documento1.066 pagineFood Microbiolo (B-Ok - Xyz)Monika Mathur100% (2)

- Fowl Paratyphoid by DR Bhavesh ZapadiaDocumento18 pagineFowl Paratyphoid by DR Bhavesh ZapadiaBhaveshNessuna valutazione finora

- Leptospirosis, Typhoid and Other FeversDocumento37 pagineLeptospirosis, Typhoid and Other FeverskarageeNessuna valutazione finora

- Gram Negative BacilliDocumento108 pagineGram Negative Bacilliblue_blooded23100% (1)

- Enterobacteriaceae: Table 1Documento15 pagineEnterobacteriaceae: Table 1skNessuna valutazione finora

- Turtle Shell RepairDocumento2 pagineTurtle Shell RepairA Puffin LekvárNessuna valutazione finora

- Rappaport Vassiliadis Soya Broth (RVS Broth) : CompositionDocumento2 pagineRappaport Vassiliadis Soya Broth (RVS Broth) : CompositionDuyên TrầnNessuna valutazione finora

- David OnyangoDocumento16 pagineDavid OnyangoprabhasNessuna valutazione finora

- Pathophysiology of Typhoid FeverDocumento4 paginePathophysiology of Typhoid FeverIan ParrochaNessuna valutazione finora

- Food and Dairy Microbiology AnswersDocumento18 pagineFood and Dairy Microbiology AnswersPratibha PatilNessuna valutazione finora

- Aktivitas Antimikroba Ekstrak Jahe Kering Beku Terhadap Beberapa Bakteri PatogenDocumento8 pagineAktivitas Antimikroba Ekstrak Jahe Kering Beku Terhadap Beberapa Bakteri PatogenAbc BbbNessuna valutazione finora

- Suresh Pillai CVDocumento41 pagineSuresh Pillai CVxuancanhNessuna valutazione finora

- Hazard Identification & Analysis Worksheet for Cake Rusk ProcessDocumento12 pagineHazard Identification & Analysis Worksheet for Cake Rusk Processsajid waqas100% (1)

- Typhoid FeverDocumento1 paginaTyphoid FeverMarkChesterSaguidNagen100% (1)

- Typhoid Fever and Paratyphoid Fever Are Lif1Documento14 pagineTyphoid Fever and Paratyphoid Fever Are Lif1Cherry Ann DomingoNessuna valutazione finora

- Feed Mill Biosecurity HarzardDocumento39 pagineFeed Mill Biosecurity HarzardMinh PhamNessuna valutazione finora

- Enterobacteriaceae Handout (Lec & Lab)Documento15 pagineEnterobacteriaceae Handout (Lec & Lab)Lucille MarieNessuna valutazione finora

- Pathogenesis Typhoid Fever PDFDocumento7 paginePathogenesis Typhoid Fever PDFAry Nahdiyani Amalia100% (1)

- Biochemical ID of Salmonella and ShigellaDocumento46 pagineBiochemical ID of Salmonella and ShigellaNurfadillamansyurNessuna valutazione finora

- SalmonellaDocumento12 pagineSalmonellaJay Ann EmanNessuna valutazione finora

- Cundell Et Al PDA J Pharm Sci Tech March 2010 (Full Article) SfsDocumento21 pagineCundell Et Al PDA J Pharm Sci Tech March 2010 (Full Article) SfsJessica González LaraNessuna valutazione finora

- Epidemiology of Infectious Diarrhea: Basic ConceptsDocumento13 pagineEpidemiology of Infectious Diarrhea: Basic ConceptsAyu Angraeni SaputriNessuna valutazione finora