Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Specification For Approval: CUSTOMERS:深圳长城开发科技股份有限公司

Caricato da

William JimenezDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Specification For Approval: CUSTOMERS:深圳长城开发科技股份有限公司

Caricato da

William JimenezCopyright:

Formati disponibili

CUSTOMERS:深圳长城开发科技股份有限公司

SPECIFICATION FOR APPROVAL

SHEET NO:WM-SO8-012

DESCRIPTION: NTC THERMISITORS

CUSTOMER P/N:

PART NO: WTR08D050MD2BW

TYPE: WTR TYPE

DATE: 2012/04/28

Ii ISSUE DEPARTMENT CUSTOMERS APPROVED

廈 門 萬 明 電 子 有 限 公 司

地址:廈門杏林工業區日新路 2 號 電話:0592-6220571 傳真:0592-6220570

ADDRESS:No 2 RiXin Road XingLin District XiaMen,FuJian,China

TEL:86-592-6220571/572/573 FAX:86-592-6220570

NTC Thermistors

For Inrush Current Suppression Lead Type

WTR Series

Features

1. Lead is not contained in the ceramic element, the

terminations, the solder for inner connection and

the coating resin.

2. Most suitable for power supplies of less than 100W

3.Excellent recovery characteristics due to resin

coating with excellent heat characteristics

4. Wide resistance range

5. Highly reliable

Applications

1. Swith mode power supplies

2. Electric motors

3. Transformer.

4. Adapter

5. CRT monitors

6. Other power circuits

Explanation of part Number

Examples: WTR 08D 100 M H 2 B

Product ID Resistance Tolerance

Product ID Contents Code Resistance Tolerance

L 15%

WTR Inrush Current Limiters NTC Thermistors

M 20%

Series Lead style

Code Dimensions Code Lead Style

05D 5.0 mm Straight Lead (Long)

A

08D 8.0 mm B Straight Lead (Short)

10D 10 mm G Vertical Crimped (Short)

13D 13 mm H Vertical Crimped (Long)

15D 15mm

Lead Spacing

20D 20 mm

Code Lead Spacing( 1.0)

25D 25 mm

2 5.0mm

30D 30 mm

3 7.50mm

Resistance

4 10.0mm

Expressed by three figures. The unit is ohm ( ). The first and

second figures are significant digits, and the third figure Packaging

expresses the number of zeros which follow the two figures.

If there is a decimal point, it is expressed by the capital letter Code Packaging

"R". In this case, all figures are significant digits.

B Bulk

Ex.) Code Resistance A Taping Ammo Pack

5R0 5

R Taping Reel Pack

100 10

Internal Code

WANMING ELECTRONICS CO.,LTD.

94

NTC Thermistors

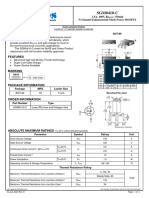

Dimensions

<Fig. 1> <Fig. 2> <Fig. 1> <Fig. 2>

D max. T max. T max. D max. T max. T max.

4.0max.

4.0max.

e e

1.0

1.0

d

5.0

5.0

20.0 min.

20.0 min.

F

F

d

(in mm) (in mm)

Lead code Coating Extension e Style Lead code Coating Extension e Style

G2 up to the end of crimp Fig. 1 H2 up to the end of crimp Fig. 1

G3 ,G4 up to the end of crimp Fig. 1 H3 ,H4 up to the end of crimp Fig. 1

A2 4.0 max. Fig. 2 A2 4.0 max. Fig. 2

A3,A4 4.0 max. Fig. 2 A3,A4 4.0 max. Fig. 2

(in mm)

Series Disc Size D max. F T max. d

05D 5.0 8.5 5.0 1.0 5.0 0.55 0.05

08D 8.0 10.5 5.0 1.0/7.5 1.0 5.0 0.55 0.05/0.8 0.05

10D 10 12.5 7.5 1.0 5.0 0.8 0.05

13D 13 15.0 7.5 1.0 5.0 0.8 0.05

15D 15 17.5 7.5 1.0 5.0 0.8 0.05

20D 20 23.0 10.0 1.0 5.0 1.0 0.05

25D 25 29.0 10 1.0 5.0 1.0 0.05

30D 30 36.0 10 1.0 5.0 1.0 0.05

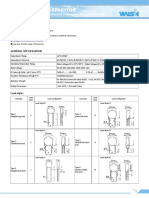

Specification

Zero power Max. Steady Max. Steady Thermal Thermal Operating Lead

Lead Lead

resistance state current power rating dissipation time thmperature Package Package

Part Number (25 ) Package

(25 ) (25 ) constant constant range

(ohm) Long Bulk Short Bulk Taping

(A) (w) (mw/ ) (sec.) ( )

WTR05D050M 5 2

WTR05D080M 8 1

WTR05D100M 10 1

WTR05D120M 12 0.7 1.8 14 18 -40~+150 G2B H2B G2A

WTR05D160M 16 0.7

WTR05D200M 20 0.3

WTR08D030M 3 4

WTR08D040M 4 3

WTR08D050M 5 3 2.3 15 30 -40~+170 G2B H2B G2A

WTR08D060M 6 2

WTR08D080M 8 2

WTR08D100M 10 2

Continued on the following page.

WANMING ELECTRONICS CO.,LTD.

99

NTC Thermistors

Continued from the preceding page.

Zero power Max. Steady Max. Steady Thermal Thermal Operating Lead Lead Lead

resistance state current power rating dissipation time thmperature Package Package

Part Number Package

(25 ) (25 ) (25 ) constant constant range Long Bulk Short Bulk Taping

(ohm) (A) (w) (mw/ ) (sec.) ( )

WTR08D120M 12 2

WTR08D160M 16 2

WTR08D200M 20 1

WTR08D220M 22 1 2.3 16 38 -40 ~ +170 G2B H2B G2A

WTR08D300M 30 0.5

WTR08D330M 33 0.5

WTR08D500M 50 0.5

WTR10D010M 1 5

WTR10D1R5M 1.5 5

WTR10D2R5M 2.5 5

WTR10D030M 3 5

WTR10D040M 4 4

WTR10D050M 5 4

WTR10D060M 6 3

WTR10D070M 7 3

WTR10D080M 8 3

WTR10D100M 10 3 2.4 17 43 -40 ~ +170 G2B H2B G2A

WTR10D120M 12 2

WTR10D160M 16 2

WTR10D200M 20 2

WTR10D250M 25 2

WTR10D300M 30 2

WTR10D500M 50 1.5

WTR10D600M 60 1.5

WTR10D800M 80 1

WTR10D121M 120 1

WTR13D1R3M 1.3 7

WTR13D1R5M 1.5 7

WTR13D2R5M 2.5 6

WTR13D030M 3 6

WTR13D040M 4 5

WTR13D050M 5 5

WTR13D060M 6 4

WTR13D070M 7 4

WTR13D080M 8 4 3.1 18 66 -40 ~ +200 G3B H3B G3A

WTR13D100M 10 4

WTR13D120M 12 4

WTR13D150M 15 3

WTR13D160M 16 3

WTR13D200M 20 3

WTR13D300M 30 2.5

WTR13D470M 47 2.0

WTR13D121M 120 1.5

Continued on the following page.

WANMING ELECTRONICS CO.,LTD.

2

NTC Thermistors

Continued from the preceding page.

Zero power Max. Steady Max. Steady Thermal Thermal Operating Lead Lead Lead

resistance state current power rating dissipation time thmperature Package Package

Part Number Package

(25 ) (25 ) (25 ) constant constant range Long Bulk Short Bulk Taping

(ohm) (A) (w) (mw/ ) (sec.) ( )

WTR15D1R3M 1.3 8

WTR15D1R5M 1.5 8

WTR15D2R5M 2.5 8

WTR15D030M 3 7

WTR15D040M 4 6

WTR15D050M 5 6

WTR15D060M 6 5

WTR15D070M 7 5

WTR15D080M 8 5

3.6 21 75 -40 ~ +200 G3B H3B G3A

WTR15D100M 10 5

WTR15D120M 12 4

WTR15D150M 15 4

WTR15D160M 16 4

WTR15D200M 20 4

WTR15D250M 25 3

WTR15D400M 40 3

WTR15D470M 47 3

WTR15D800M 80 2.5

WTR15D121M 120 2

WTR20D0R7M 0.7 12

WTR20D1R3M 1.3 9

WTR20D020M 2 8

WTR20D2R5M 2.5 8

WTR20D030M 3 8

WTR20D040M 4 8

WTR20D050M 5 7

4.9 28 113 -40 ~ +200 G4B H4B G4A

WTR20D060M 6 6

WTR20D070M 7 6

WTR20D080M 8 6

WTR20D100M 10 6

WTR20D120M 12 5

WTR20D150M 15 5

WTR20D160M 16 5

WTR20D200M 20 4

Application Circuit

NTC

+

-

WANMING ELECTRONICS CO.,LTD.

3

NTC Thermistors

Resistance VS.Temperature Characteristic

WTR05D WTR08D

WTR10D WTR13D

WTR15D WTR20D

WANMING ELECTRONICS CO.,LTD.

4

NTC Thermistors

Curent vs.Voltage Characteristic

WTR05D WTR08D

WTR10D WTR13D

WTR15D WTR20D

WANMING ELECTRONICS CO.,LTD.

5

NTC Thermistors

! Caution/Notice

! Caution (Storage and Operating Conditions)

1. This product is designed for the Switching Power all these factors can deteriorate the

Supply with smoothing capacitors. product characteristics cause failure and burn-out.

Other applications of this product may result in fire. (1) Corrosive gas or deoxidizing gas.

2. Use this product within the specified maximum (Chlorine gas, Hydrogen sulfide gas, Ammonia

current. Otherwise it may catch fire in the worst case. gas, Sulfuric acid gas, Nitric oxide gas, etc.)

3. Use this product with smoothing capacitor within (2) Volatile or flammable gas

the specified maximum capacitance value. Otherwise (3) Dusty conditions

it may catch fire in the worst case. (4) Under high or low pressure

4. This product is designed for application in (5) Wet or humid conditions

an ordinary environment (normal room temperature, (6) Near with salt water, oils, chemical liquids or

humidity and atmospheric pressure). organic solvents

Do not use under the following conditions because (7) Strong vibrations

(8) Other places where similar hazardous conditions

exist.

! Caution (Others)

Be sure to provide an appropriate fail-safe function

on your product to prevent secondary damages that may

be caused by the abnormal function or the failure of

our product.

Notice (Storage and Operating Conditions)

To keep solderability of product from declining, the

following storage condition is recommended.

1. Storage condition: 3. Handling after unpacking:

Temperature -10 to +40 degree C After unpacking, reseal product promptly or store it

Humidity less than 75%RH (not dewing condition) in a sealed container with a drying agent.

2. Storage term: 4. Storage place:

Use this product within 6 months after delivery by Do not store this product in corrosive gas

first-in and first-out stocking system. (sulfuric acid gas, chlorine gas, etc.) or in

direct sunlight.

Notice (Rating)

Use this product within the specified temperature range.

Higher temperature may cause deterioration of the

characteristics or the material quality of this

product.

Notice (Soldering and Mounting)

1. Be sure that the preheat-up does not melt the

soldering of this product. Excessive heat may

cause failure to open, short or insulation break

down.

2. Do not touch the body with soldering iron.

The soldering point should be min. 5mm away from

the root of lead wire.

WANMING ELECTRONICS CO.,LTD.

6

NTC Thermistors

Notice (Handling)

1. When this product is operated, temperature of some 3. The ceramic element of this product is fragile, and

area may be about 160 (degree C). care must be taken not to load an excessive

Use proper surrounding parts and material which with press-force or not to give a shock at handling.

stand such temperature. If they are inadequate and Such forces may cause cracking or chipping to

kept at high temperature for long time, they may be the element.

deteriorated or may produce harmful gas. And, such 4. Do not apply an excessive force to the lead wire.

harmful gas may deteriorate the element of this product. Otherwise, it may cause break off junction between

2. This product does not have waterproof construction. lead wire and element, or may crack element.

Splashed water may cause failure mode such as So, fix lead wire of element side when lead wire is

deterioration of characteristics or current leak. So, do bent or cut.

not apply cleaning to immerse it into water or any solvent.

Notice (Others)

1. This products need sufficient cool off time to

recover high resistance. Repeated ON-OFF

may cause over specified current rating.

Make sure inrush current do not exceed the

specified ratings even at the worst condition.

(maximum ambient temperature and the shortest

off time.)

2. The resin coating of this product does not

guarantee insulating. Keep an adequate insulating

distance to surrounding parts.

WANMING ELECTRONICS CO.,LTD.

7

Potrebbero piacerti anche

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesDa EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesValutazione: 4.5 su 5 stelle4.5/5 (7)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- 0900766b8063531d PDFDocumento14 pagine0900766b8063531d PDFmrscribdNessuna valutazione finora

- Quick Reference Data: PILKOR ElectronicsDocumento8 pagineQuick Reference Data: PILKOR ElectronicsAnonymous CGk2roNessuna valutazione finora

- pcx2 337Documento8 paginepcx2 337JOSE RODRÍGUEZNessuna valutazione finora

- Panasonic - Micro Chip FuseDocumento5 paginePanasonic - Micro Chip FuseJuan HernándezNessuna valutazione finora

- Cathodic Calculation (ICCP) Single ShalloWellDocumento11 pagineCathodic Calculation (ICCP) Single ShalloWellArif RusyanaNessuna valutazione finora

- PMR209, Metallized Impregnated Paper, Class X2, 250 VAC: ApplicationsDocumento13 paginePMR209, Metallized Impregnated Paper, Class X2, 250 VAC: ApplicationsMkt ConNessuna valutazione finora

- Metal Oxide Varistor-TVR-M SeriesDocumento21 pagineMetal Oxide Varistor-TVR-M SeriesJhonatan Samuel Fernandez ChaconNessuna valutazione finora

- SVC Varistors Type: SVC 471 D-14A FF 7Documento31 pagineSVC Varistors Type: SVC 471 D-14A FF 7DavidPereiraNessuna valutazione finora

- SVC 471 D-14A FF 7: Ceramic Surge Absorbers (Varistors)Documento17 pagineSVC 471 D-14A FF 7: Ceramic Surge Absorbers (Varistors)Andres PolancoNessuna valutazione finora

- Specification For Approval: Page 1 of 8Documento8 pagineSpecification For Approval: Page 1 of 8RDNessuna valutazione finora

- pcx2 339Documento8 paginepcx2 339ReialexNessuna valutazione finora

- Inductors: Data Sheet Data SheetDocumento9 pagineInductors: Data Sheet Data SheetDanna PerezNessuna valutazione finora

- SMBJ 1Documento8 pagineSMBJ 1Omar MelchorNessuna valutazione finora

- Zinc Oxide Varistor: FeaturesDocumento20 pagineZinc Oxide Varistor: FeaturesDragoslav DjorovicNessuna valutazione finora

- Disc CapDocumento33 pagineDisc CapShibu Kumar SNessuna valutazione finora

- HCCK 80G FMCW Radar HCDAR-80SDocumento1 paginaHCCK 80G FMCW Radar HCDAR-80SRoLopNessuna valutazione finora

- NIC Components NSRN SeriesDocumento5 pagineNIC Components NSRN SeriesNICCompNessuna valutazione finora

- Varistores PDFDocumento20 pagineVaristores PDFDaniel SantosNessuna valutazione finora

- Metallized Polypropylene Film Capacitors: TMPP & FMPPDocumento1 paginaMetallized Polypropylene Film Capacitors: TMPP & FMPPoscarNessuna valutazione finora

- Panasonic-Ezjpzv6r8ga C424360Documento5 paginePanasonic-Ezjpzv6r8ga C424360GiggiuNessuna valutazione finora

- Atc Q-Bridge Thermal ConductorDocumento4 pagineAtc Q-Bridge Thermal ConductorwjsynNessuna valutazione finora

- NPN Low VoltageDocumento8 pagineNPN Low VoltageNANessuna valutazione finora

- PJ EliteDocumento2 paginePJ Elitemarina anastasovaNessuna valutazione finora

- SGM0410 C SeCoSDocumento4 pagineSGM0410 C SeCoSJaqueline Valenzuela CidNessuna valutazione finora

- TKS TVR Series Metal Oxide Varistor en TVRDocumento32 pagineTKS TVR Series Metal Oxide Varistor en TVRMeh SNessuna valutazione finora

- Metal Oxide Varistor TVR Series: Disc Type Varistor For Surge ProtectionDocumento32 pagineMetal Oxide Varistor TVR Series: Disc Type Varistor For Surge ProtectionThiago HukuchimaNessuna valutazione finora

- Jameco Part Number 1539139: Distributed byDocumento4 pagineJameco Part Number 1539139: Distributed bySergio ChicNessuna valutazione finora

- CC Class I CapacitoresDocumento5 pagineCC Class I CapacitoresCicero MelloNessuna valutazione finora

- sjpw-t4 Ds enDocumento8 paginesjpw-t4 Ds enPalinda BandaraNessuna valutazione finora

- Mb-0301-4e DX07 PlugDocumento4 pagineMb-0301-4e DX07 PlugSHYAM THILLAINATHANNessuna valutazione finora

- PTS 820 Series Microminiature SMT Top Actuated: Features/Benefits Typical ApplicationsDocumento4 paginePTS 820 Series Microminiature SMT Top Actuated: Features/Benefits Typical Applicationsmarcoteran007Nessuna valutazione finora

- TCRT5000, TCRT5000L: Vishay SemiconductorsDocumento12 pagineTCRT5000, TCRT5000L: Vishay SemiconductorsRamazan ÖzenNessuna valutazione finora

- Switch LR Series 193Documento2 pagineSwitch LR Series 193Cristian Leonicio AlmeidaNessuna valutazione finora

- 12F0011X0 Stainless Steel Fastener Mechanical PropertiesDocumento2 pagine12F0011X0 Stainless Steel Fastener Mechanical PropertiespkdscdubaiNessuna valutazione finora

- Quick Reference Data: Pilkor ComponentsDocumento8 pagineQuick Reference Data: Pilkor ComponentsPozo Do CabaloNessuna valutazione finora

- Coding System of Strain Gauges-AGS-TECH VersionDocumento8 pagineCoding System of Strain Gauges-AGS-TECH VersionsergiojgsNessuna valutazione finora

- AWA0000C1Documento34 pagineAWA0000C1AB-S ELECTRO MECHANICAL INDUSTRIAL AUTOMATIONNessuna valutazione finora

- NIC Components NLQ SeriesDocumento4 pagineNIC Components NLQ SeriesNICCompNessuna valutazione finora

- Part Numbering: Chip Emifilr Capacitor Type/Capacitor Array TypeDocumento11 paginePart Numbering: Chip Emifilr Capacitor Type/Capacitor Array TypeDhaval PatelNessuna valutazione finora

- MF52 Pin Wire Coating High Precision NTC Thermistor: FeaturesDocumento3 pagineMF52 Pin Wire Coating High Precision NTC Thermistor: FeaturesJohn DoeNessuna valutazione finora

- NIC Components NFI SeriesDocumento5 pagineNIC Components NFI SeriesNICCompNessuna valutazione finora

- Type Fca: Features ApplicationsDocumento1 paginaType Fca: Features ApplicationsHari Sita RukminiNessuna valutazione finora

- Digital Timer: V0Ddts1, V0Ddts V0Ddtd1, V0Ddtd Cat. NoDocumento2 pagineDigital Timer: V0Ddts1, V0Ddts V0Ddtd1, V0Ddtd Cat. NoLuis Manuel100% (1)

- Safety Standard Recognized, C900, Encapsulated, AC Type, X1 400 VAC/Y2 250 VAC (Industrial Grade)Documento17 pagineSafety Standard Recognized, C900, Encapsulated, AC Type, X1 400 VAC/Y2 250 VAC (Industrial Grade)cacalot93Nessuna valutazione finora

- Rubycon-25YXA2200MEFCCE12-5X25 C365705Documento4 pagineRubycon-25YXA2200MEFCCE12-5X25 C365705Rajesh SuraNessuna valutazione finora

- MMST3904Documento7 pagineMMST3904zigmund zigmundNessuna valutazione finora

- Metal Film Thermosensitive Chip Resistors 0402, 0603, 0805 Eraw, V, SDocumento5 pagineMetal Film Thermosensitive Chip Resistors 0402, 0603, 0805 Eraw, V, SManu MathewNessuna valutazione finora

- "ZNR" Transient/Surge Absorbers (Type D)Documento4 pagine"ZNR" Transient/Surge Absorbers (Type D)Eduard BuseNessuna valutazione finora

- Instrumentation Screened CablesDocumento5 pagineInstrumentation Screened Cablespriyanka236Nessuna valutazione finora

- NTC Thermistor-SCK SeriesDocumento22 pagineNTC Thermistor-SCK SeriesDavid SalaNessuna valutazione finora

- Specification For Approval: Xiamen Faratronic Co. LTDDocumento15 pagineSpecification For Approval: Xiamen Faratronic Co. LTDVăn Trọng ĐàmNessuna valutazione finora

- SMDC01005 ElectronicDocumento10 pagineSMDC01005 ElectronicMariaNessuna valutazione finora

- Varistor para Luminarias Cree 20d - 1-3003069Documento16 pagineVaristor para Luminarias Cree 20d - 1-3003069Gabriel SanjurNessuna valutazione finora

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocumento2 pagineAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNessuna valutazione finora

- Connector: 3.5mm Pitch/disconnectable Crimp Style Wire-To-Wire ConnectorsDocumento2 pagineConnector: 3.5mm Pitch/disconnectable Crimp Style Wire-To-Wire ConnectorsJamesNessuna valutazione finora

- Metal Film Chip Resistors, High Reliability Type 0402, 0603, 0805, 1206 ERA 2A, 3A, 6A, 8ADocumento4 pagineMetal Film Chip Resistors, High Reliability Type 0402, 0603, 0805, 1206 ERA 2A, 3A, 6A, 8AaaaaaaaaNessuna valutazione finora

- RTD 0124Documento15 pagineRTD 0124Nguyễn Hải ĐăngNessuna valutazione finora

- Uninterruptib Le Power Supply Unit For Universal Use QUINT-DC-UPS/24DC/40Documento9 pagineUninterruptib Le Power Supply Unit For Universal Use QUINT-DC-UPS/24DC/40ARITOSOUL341Nessuna valutazione finora

- Hoist MonitorDocumento105 pagineHoist MonitorJoss Maykol Mundaca VasquezNessuna valutazione finora

- km8112356 Section 13Documento24 paginekm8112356 Section 13luis eduardo corzo enriquezNessuna valutazione finora

- 5399 TTG Rev 12Documento168 pagine5399 TTG Rev 12Márcio TakitaNessuna valutazione finora

- Precision Thermistor Measurement For ThermometryDocumento26 paginePrecision Thermistor Measurement For ThermometryDanielle CardiñoNessuna valutazione finora

- NTC Otpornik 47kDocumento24 pagineNTC Otpornik 47kmikcomiNessuna valutazione finora

- Engineering Note NTC and PTC Thermistors: Vishay DaleDocumento3 pagineEngineering Note NTC and PTC Thermistors: Vishay DaleDiabloNessuna valutazione finora

- 22 Ohm ResistorDocumento11 pagine22 Ohm ResistorDwp BhaskaranNessuna valutazione finora

- FCA Engine Mangement Operation and DiagDocumento272 pagineFCA Engine Mangement Operation and DiagCristobal MedinaNessuna valutazione finora

- Lithium Ion Charge Management IC With Integrated Switching ControllerDocumento26 pagineLithium Ion Charge Management IC With Integrated Switching ControllerValy D ValyNessuna valutazione finora

- Aurubis Copper Technical Brochure CuOFEDocumento2 pagineAurubis Copper Technical Brochure CuOFEBrian DohertyNessuna valutazione finora

- Current Developments in Wearable Thermometers: Advanced Biomedical Engineering April 2018Documento13 pagineCurrent Developments in Wearable Thermometers: Advanced Biomedical Engineering April 2018Soham MethulNessuna valutazione finora

- MESB 333 Lab Temperature MeasurementDocumento9 pagineMESB 333 Lab Temperature Measurementhezree hilmanNessuna valutazione finora

- Elektor 2019-11-12 PDFDocumento116 pagineElektor 2019-11-12 PDFNick Maniacup100% (5)

- Datos Técnicos RefrigeradorDocumento25 pagineDatos Técnicos RefrigeradorMiguel Mancilla100% (2)

- TTC 103 NTC ThermistorDocumento7 pagineTTC 103 NTC ThermistorBilly SilvaNessuna valutazione finora

- NTC Thermistor Linearity ReportDocumento6 pagineNTC Thermistor Linearity Reportميسرة0% (1)

- DishwasherDocumento37 pagineDishwashersnovovi10% (1)

- TMP61 ±1% 10-kΩ Linear Thermistor With 0402 and 0603 Package OptionsDocumento32 pagineTMP61 ±1% 10-kΩ Linear Thermistor With 0402 and 0603 Package Optionsmauricio alfonsoNessuna valutazione finora

- RT8802ADocumento29 pagineRT8802Anishatiwari82Nessuna valutazione finora

- HAKKO T12 English ManualDocumento3 pagineHAKKO T12 English Manualreza yousefiNessuna valutazione finora

- Elecolit 327 English Tds Panacol AdhesiveDocumento4 pagineElecolit 327 English Tds Panacol Adhesivegrasia77Nessuna valutazione finora

- Te Sensor Solutions Catalog PDFDocumento88 pagineTe Sensor Solutions Catalog PDFDao Thanh HuongNessuna valutazione finora

- Current ElectricityDocumento36 pagineCurrent ElectricityAmaan RizviNessuna valutazione finora

- Electronic Diesel Control: Eng. Fu'ad DaoudDocumento23 pagineElectronic Diesel Control: Eng. Fu'ad DaoudNimesh SilvaNessuna valutazione finora

- G482 Mod 2 2.2.3 and 2.2.4 Resistance and ResistivityDocumento10 pagineG482 Mod 2 2.2.3 and 2.2.4 Resistance and ResistivityAmberNessuna valutazione finora

- L-02 Temperature SensorDocumento18 pagineL-02 Temperature SensorAli Raza KhanNessuna valutazione finora

- Thermister WordDocumento41 pagineThermister WordVineet AgrawalNessuna valutazione finora

- Transducer Up To 4500 MM Touchless Absolute Series TLM With Start/ Stop-, Ssi-, Dymos-, Analog-InterfaceDocumento4 pagineTransducer Up To 4500 MM Touchless Absolute Series TLM With Start/ Stop-, Ssi-, Dymos-, Analog-Interfacelabtlm ikasariNessuna valutazione finora

- Digital Voltage Regulator: Installation and MaintenanceDocumento80 pagineDigital Voltage Regulator: Installation and MaintenanceAnkadi Sikari ReddyNessuna valutazione finora

- Medical Physics 4Documento61 pagineMedical Physics 4omar.luay.111Nessuna valutazione finora