Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Assignment: 3 Chapter: Metal Joining Process: Sr. No Questions

Caricato da

Sp Patel0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

35 visualizzazioni1 paginaTitolo originale

assignment-MP2-3.docx

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

35 visualizzazioni1 paginaAssignment: 3 Chapter: Metal Joining Process: Sr. No Questions

Caricato da

Sp PatelCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

ASSIGNMENT: 3

CHAPTER: METAL JOINING PROCESS

Sr.

QUESTIONS

No

1 Define following terms

1. Flux

2. Filler materials

3. Electrode

4. Shielding gas

5. Edge preparation

2 Describe the types of flame obtained in oxy-acetylene gas welding with neat sketch.

3 Explain electrode beam welding process and state its advantages and limitation.

4 State the function of flux in soldering and brazing.

5 Explain gas welding process with neat sketch and state its advantages and limitations.

6 Calculate the melting efficiency in the case of arc welding and resistance welding of steel with

potential of 20v and a current of 200amp. The travel speed is 5mm/s and the cross section of

the joint is 20mm2. Heat required to melt steel may be taken as 10j/mm 3 and heat transfer

efficiency as 0.85. assume resistance, r= 100 micro ohms.

7 Discuss different between MIG and TIG

8 Classify the metal joining process. Explain the principle of gas welding process with

advantages and limitation.

9 Classify the electrode used in arc welding and explain its code used to specify it.

10 Explain the principle of arc welding with neat sketch. State the parameter affecting the arc

11 Explain with sketch TIG welding process with its application, advantages and limitation.

12 Describe the explosive welding process with advantages and limitation.

13 What determine whether the certain welding process can be used for work piece in a horizontal,

vertical or an upside down position, or for all types of position? Explain with appropriate

example.

14 Two flat copper sheets of 1.2 mm thickness each are spot welded. The process parameter are

current : 5000 amp. Current flow time : 0.20 sec Dia. Of electrode: 6 mm

Estimate the heat generated in welding zone.

15 Explain the factor affected in selection of electrode in arc welding .

16 A steel tube of 76mm outer dia. And 4mm thickness is welded to a flat piece by applying

friction welding process with the following information.

Energy applied e= is 2/c, where i= moment of inertia of the flywheel, s= spindle speed in rpm,

c= proportionally constant =250, weld zone =5 mm deep and energy required to melt the

electrode= 0.14 kg-m. If the entire energy of the flywheel is used to heat the electrode, what is

the required moment of inertia of the flywheel?

17 Classify the metal joining process along with the types of welding process. Explain oxy-

hydrogen welding process with neat sketch.

18 Distinguish arc welding process and resistance welding process in brief. Explain the resistance

welding cycle.

19 What is the laser welding process? Explain the step involve in the process with its application,

merits and limitation

20 Explain with sketch MIG welding process with its application, advantages and limitation.

Potrebbero piacerti anche

- CWEng SampleQuestionsDocumento8 pagineCWEng SampleQuestionsSungJun ParkNessuna valutazione finora

- Resistance and Special WeldingDocumento24 pagineResistance and Special WeldingKBSMANITNessuna valutazione finora

- Welding Technology Two MarksDocumento20 pagineWelding Technology Two Markssai100% (1)

- 814 1991Documento32 pagine814 1991Balasubramanian Singaravelu100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Linux in Plain EnglishDocumento405 pagineLinux in Plain Englishambotlang50% (2)

- Aws A5.10Documento38 pagineAws A5.10poulmackNessuna valutazione finora

- Welding ElectrodesDocumento36 pagineWelding ElectrodesMersudin Saric100% (4)

- Mechanical Engineering - Mp-Ii Final Exam Question BankDocumento4 pagineMechanical Engineering - Mp-Ii Final Exam Question BankupenderNessuna valutazione finora

- Welded ConnectionsDocumento144 pagineWelded ConnectionsshivaniNessuna valutazione finora

- Advanced Welding TechologyDocumento6 pagineAdvanced Welding TechologydearsaswatNessuna valutazione finora

- The WPS Writers GuideDocumento129 pagineThe WPS Writers GuideGEORGEVPAUL_14565666Nessuna valutazione finora

- Subjective Questions UNIT-03 (Welding)Documento1 paginaSubjective Questions UNIT-03 (Welding)nirmalkrNessuna valutazione finora

- 1.2 Resistance and Special WeldingDocumento14 pagine1.2 Resistance and Special WeldingnikhilbathamNessuna valutazione finora

- Welding ProcessesDocumento50 pagineWelding ProcessesTg TarroNessuna valutazione finora

- Course Name: NAME 301 Shipbuilding Technology-I: Md. Omar FarukDocumento56 pagineCourse Name: NAME 301 Shipbuilding Technology-I: Md. Omar FarukMd. Omar FarukNessuna valutazione finora

- Resistance and Special Welding.0001Documento100 pagineResistance and Special Welding.0001KKNessuna valutazione finora

- The Mechanical Properties and Microstructures of 9% Chromium Steel P92 WeldmentsDocumento23 pagineThe Mechanical Properties and Microstructures of 9% Chromium Steel P92 WeldmentspkguptaqaqcNessuna valutazione finora

- Revista - Materials Science ForumDocumento5 pagineRevista - Materials Science Forum0741005518Nessuna valutazione finora

- Assignment Awt NDocumento1 paginaAssignment Awt NdearsaswatNessuna valutazione finora

- Assignment No 1Documento2 pagineAssignment No 1HarshitkumarNessuna valutazione finora

- 6 (WG11)Documento22 pagine6 (WG11)alimajdNessuna valutazione finora

- Conventional Casting WeldingDocumento190 pagineConventional Casting WeldingprabhjotbhangalNessuna valutazione finora

- Welding - GATE QuestionsDocumento1 paginaWelding - GATE QuestionsJo75% (4)

- InTech-Welding of Aluminum Alloys PDFDocumento25 pagineInTech-Welding of Aluminum Alloys PDFCortesar ManuNessuna valutazione finora

- Resistance WeldingDocumento13 pagineResistance WeldingAashishSethiNessuna valutazione finora

- Performance and Analysis of Weld Joint by Using Two Dissimilar Electrodes E6010 and E7018Documento5 paginePerformance and Analysis of Weld Joint by Using Two Dissimilar Electrodes E6010 and E7018Editor IJTSRDNessuna valutazione finora

- Temper Bead Welding of S460N Steel in Wet Welding ConditionsDocumento10 pagineTemper Bead Welding of S460N Steel in Wet Welding ConditionsNickesh ShahNessuna valutazione finora

- Eeu Final Year DiplomaDocumento7 pagineEeu Final Year Diplomakarthikrajputh03Nessuna valutazione finora

- Mig Co2 WeldingDocumento20 pagineMig Co2 WeldingAsad Bin Ala Qatari100% (1)

- Application of Plasma-MIG Hybrid Welding To Dissimilar Joint Between Copper and SteelDocumento6 pagineApplication of Plasma-MIG Hybrid Welding To Dissimilar Joint Between Copper and Steelkaliappan45490Nessuna valutazione finora

- Heavy Assembly ShopDocumento8 pagineHeavy Assembly ShoprampdwnNessuna valutazione finora

- Effect of Laser - MIG Hybrid Welding On Microstructure and Properties of Seismic Steel Plate For BuildingsDocumento6 pagineEffect of Laser - MIG Hybrid Welding On Microstructure and Properties of Seismic Steel Plate For BuildingsMarben TanegaNessuna valutazione finora

- Thermit Welding of Chromium Vanadium RailsteelDocumento8 pagineThermit Welding of Chromium Vanadium Railsteelsantu_23Nessuna valutazione finora

- Study On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelDocumento8 pagineStudy On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelIJMERNessuna valutazione finora

- (20834799 - Advances in Materials Science) A Study On The Effect of Different Activating Flux On a-TIG Welding Process of Incoloy 800HDocumento12 pagine(20834799 - Advances in Materials Science) A Study On The Effect of Different Activating Flux On a-TIG Welding Process of Incoloy 800HARUN VNessuna valutazione finora

- Describe The Ultrasonic Welding Process With Neat DiagramDocumento1 paginaDescribe The Ultrasonic Welding Process With Neat DiagramBharani KumarNessuna valutazione finora

- Study On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelDocumento8 pagineStudy On Effect of Manual Metal Arc Welding Process Parameters On Width of Heat Affected Zone (Haz) For Ms 1005 SteelAngga Pamilu PutraNessuna valutazione finora

- Question WI..Documento42 pagineQuestion WI..Indra MansyahNessuna valutazione finora

- Effect of Energy Input On Microstructure and Hardness of TIG Welded AISI 430-Ferritic Stainless SteelDocumento8 pagineEffect of Energy Input On Microstructure and Hardness of TIG Welded AISI 430-Ferritic Stainless SteelAshish Kumar AgrawalNessuna valutazione finora

- Ass#4 - Fall 2017 (Q)Documento3 pagineAss#4 - Fall 2017 (Q)Omar BahgatNessuna valutazione finora

- Optimization of MIG Welding Parameters For Improving StrengthDocumento5 pagineOptimization of MIG Welding Parameters For Improving StrengthMario Antonio Araya MorosoNessuna valutazione finora

- Shoebs ProjectDocumento20 pagineShoebs ProjectMehdiNessuna valutazione finora

- Chapter2 - Manual Metal Arc WeldingDocumento14 pagineChapter2 - Manual Metal Arc WeldingAkhil VenugopalNessuna valutazione finora

- The Effect of Current On SMAW Welding To Tensile Strength and Micro Structure of Low Carbon SteelDocumento5 pagineThe Effect of Current On SMAW Welding To Tensile Strength and Micro Structure of Low Carbon Steelmade dwi payanaNessuna valutazione finora

- Electro Mechanical PartDocumento18 pagineElectro Mechanical Partmahendra161024Nessuna valutazione finora

- Analysis of Tig Welding Weldment and Defect Identification Using Non Destructive Testing NDTDocumento48 pagineAnalysis of Tig Welding Weldment and Defect Identification Using Non Destructive Testing NDTRebecca KelleyNessuna valutazione finora

- GDocumento2 pagineGBhupendra Verma0% (1)

- Welding Technology: Department of Mechanical Engineering National Institute of Technology RaipurDocumento66 pagineWelding Technology: Department of Mechanical Engineering National Institute of Technology RaipuryashNessuna valutazione finora

- Irjet V3i2175Documento1 paginaIrjet V3i2175AbhayNessuna valutazione finora

- Aws Cwi QuestionDocumento8 pagineAws Cwi Questionfrenskiran75% (4)

- Resistance Mash Welding For Joining of Copper Conductors2Documento21 pagineResistance Mash Welding For Joining of Copper Conductors2Sulficker AliNessuna valutazione finora

- Optimization of Process Parameters of MIG Welding To Improve Tensile Strength of Fe-415 Mild SteelDocumento6 pagineOptimization of Process Parameters of MIG Welding To Improve Tensile Strength of Fe-415 Mild SteelIJRASETPublicationsNessuna valutazione finora

- Aws 517Documento22 pagineAws 517afarmaiaNessuna valutazione finora

- CH 5Documento49 pagineCH 5MuhammadMansoorGoharNessuna valutazione finora

- Assignment - 2 Section - ADocumento1 paginaAssignment - 2 Section - AAaronNessuna valutazione finora

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysDa EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNessuna valutazione finora

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesDa EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNessuna valutazione finora

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesDa EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNessuna valutazione finora

- How to prepare Welding Procedures for Oil & Gas PipelinesDa EverandHow to prepare Welding Procedures for Oil & Gas PipelinesValutazione: 5 su 5 stelle5/5 (1)

- National Level CertificateDocumento3 pagineNational Level CertificateSp PatelNessuna valutazione finora

- LETTERDocumento1 paginaLETTERSp PatelNessuna valutazione finora

- Machine Design ManualDocumento21 pagineMachine Design ManualSp PatelNessuna valutazione finora

- Cover Page: Machine Design-II Semester: 8: in This Subject Student Are Learn About Below Given PointDocumento8 pagineCover Page: Machine Design-II Semester: 8: in This Subject Student Are Learn About Below Given PointSp PatelNessuna valutazione finora

- Shivanagar Vidya Prasarak Mandal'S: Paper Presentation OnDocumento13 pagineShivanagar Vidya Prasarak Mandal'S: Paper Presentation OnSp PatelNessuna valutazione finora

- Machine Design ManualDocumento20 pagineMachine Design ManualSp PatelNessuna valutazione finora

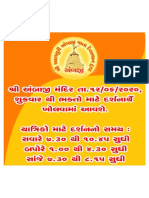

- Daily DarshanDocumento1 paginaDaily DarshanSp PatelNessuna valutazione finora

- 3310702fundamentals of Digital ElectronicsDocumento5 pagine3310702fundamentals of Digital ElectronicsSp PatelNessuna valutazione finora

- Assignment: 1 Chapter: Introduction: Sr. No QuestionsDocumento1 paginaAssignment: 1 Chapter: Introduction: Sr. No QuestionsSp PatelNessuna valutazione finora

- Webinar IKS Program ScheduleDocumento1 paginaWebinar IKS Program ScheduleSp PatelNessuna valutazione finora

- 3310702fundamentals of Digital ElectronicsDocumento5 pagine3310702fundamentals of Digital ElectronicsSp PatelNessuna valutazione finora

- 3310702fundamentals of Digital ElectronicsDocumento5 pagine3310702fundamentals of Digital ElectronicsSp PatelNessuna valutazione finora

- Assignment: 5 Chapter: Plastic Technology: Sr. No QuestionsDocumento1 paginaAssignment: 5 Chapter: Plastic Technology: Sr. No QuestionsSp PatelNessuna valutazione finora

- Design EnggDocumento4 pagineDesign EnggSp PatelNessuna valutazione finora

- Assignment: 6 Chapter: Super Finishing Process: Sr. No QuestionsDocumento1 paginaAssignment: 6 Chapter: Super Finishing Process: Sr. No QuestionsSp PatelNessuna valutazione finora

- Assignment: 2 Chapter: Foundary Technology: Sr. No QuestionsDocumento1 paginaAssignment: 2 Chapter: Foundary Technology: Sr. No QuestionsSp PatelNessuna valutazione finora

- Circular: Ref: Gtu/Central Techfest-2020/2196 Date: 25.02.2020Documento1 paginaCircular: Ref: Gtu/Central Techfest-2020/2196 Date: 25.02.2020Sp PatelNessuna valutazione finora

- Assignment-1 Noc18 Me46 86Documento2 pagineAssignment-1 Noc18 Me46 86Namita GondNessuna valutazione finora

- Assignment: 4 Chapter: Forming and Shaping Process: Sr. No QuestionsDocumento1 paginaAssignment: 4 Chapter: Forming and Shaping Process: Sr. No QuestionsSp PatelNessuna valutazione finora

- Apr 123Documento2 pagineApr 123Sp PatelNessuna valutazione finora

- DCN Mid 1 Question Paper - July 2019Documento1 paginaDCN Mid 1 Question Paper - July 2019Sp PatelNessuna valutazione finora

- Passed S.S.C. Exam 87.43 Distinction 2006 Gujarat Secondary and Higher Secondary Education B Gujarat 1 B344829Documento2 paginePassed S.S.C. Exam 87.43 Distinction 2006 Gujarat Secondary and Higher Secondary Education B Gujarat 1 B344829Sp PatelNessuna valutazione finora

- AES Mid 2 Question Bank - 2019Documento1 paginaAES Mid 2 Question Bank - 2019Sp PatelNessuna valutazione finora

- Electronics Measurements and Instrumentation PDFDocumento136 pagineElectronics Measurements and Instrumentation PDFraduseicaNessuna valutazione finora

- Notice: Laxmi Institute of Technoloy, SarigamDocumento1 paginaNotice: Laxmi Institute of Technoloy, SarigamSp PatelNessuna valutazione finora

- Braking SystemDocumento26 pagineBraking SystemShyam VimalKumar100% (1)

- Lines - Basic Concepts-1Documento3 pagineLines - Basic Concepts-1Nanda KumarNessuna valutazione finora

- C ProgramsDocumento5 pagineC ProgramsSp PatelNessuna valutazione finora

- Welding Journal 1960 5Documento157 pagineWelding Journal 1960 5AlexeyNessuna valutazione finora

- RTFI Assessment Presentation 5-23-05Documento185 pagineRTFI Assessment Presentation 5-23-05shaban100% (5)

- Fabrication Inspection ProcedureDocumento11 pagineFabrication Inspection Procedurewill_herry100% (6)

- Rererence - PIM-SC-2505-N - CS PIPING FABRICATIONDocumento14 pagineRererence - PIM-SC-2505-N - CS PIPING FABRICATIONaslam.ambNessuna valutazione finora

- Technical Specifications For PEB WorksDocumento46 pagineTechnical Specifications For PEB Worksvenugopal BedadakotaNessuna valutazione finora

- Swps Aws b2 1 X XXXDocumento6 pagineSwps Aws b2 1 X XXXDavid0% (2)

- RT Outline Training LV IIIDocumento3 pagineRT Outline Training LV IIITrung Tinh HoNessuna valutazione finora

- General Specification For Welding and Weld Inspection (EIL)Documento19 pagineGeneral Specification For Welding and Weld Inspection (EIL)Mitchel Fernandes100% (6)

- Week 1 - Introduction To Welding ProcessesDocumento85 pagineWeek 1 - Introduction To Welding ProcessesPradip GajjarNessuna valutazione finora

- ITW Cored Wire Catalogue ENG PDFDocumento70 pagineITW Cored Wire Catalogue ENG PDFPhạm Văn ĐảngNessuna valutazione finora

- Hybrid WeldingDocumento4 pagineHybrid WeldingKaushik SenguptaNessuna valutazione finora

- Lincoln Electric Svm118-A Square Wave Tig 355Documento149 pagineLincoln Electric Svm118-A Square Wave Tig 355Borbély AttilaNessuna valutazione finora

- Mild Steel Welding Handbook Vol 4Documento2 pagineMild Steel Welding Handbook Vol 4Fasil ParuvanathNessuna valutazione finora

- Accessories Catalogue WeldingDocumento104 pagineAccessories Catalogue WeldingManish MNessuna valutazione finora

- Aws ChartDocumento3 pagineAws ChartSaran KumarNessuna valutazione finora

- 02 Samss 006Documento17 pagine02 Samss 006inatt101Nessuna valutazione finora

- LNG W000370451 enDocumento37 pagineLNG W000370451 enClaude BouillotNessuna valutazione finora

- Alternate Welding Processes For In-Service WeldingDocumento103 pagineAlternate Welding Processes For In-Service WeldingJohann Alexander Caballero Bohorquez100% (2)

- 570 950mpa High Tensile Strength SteelDocumento32 pagine570 950mpa High Tensile Strength SteelAde Aidil SyuhadaNessuna valutazione finora

- Acknowledgements: Welded Connection Design & Cost EstimationDocumento20 pagineAcknowledgements: Welded Connection Design & Cost EstimationJessica JacksonNessuna valutazione finora

- Standardization of Welding ElectrodesDocumento8 pagineStandardization of Welding ElectrodesAqsa BanoNessuna valutazione finora

- Specification For Copper and Copper-Alloy Bare Welding Rods and ElectrodesDocumento24 pagineSpecification For Copper and Copper-Alloy Bare Welding Rods and ElectrodesAnshul AgarwalNessuna valutazione finora

- Unit 1 Part 3Documento163 pagineUnit 1 Part 3Kaushal MehtaNessuna valutazione finora

- Welding Electrode ProjectDocumento36 pagineWelding Electrode ProjectjswldeepNessuna valutazione finora

- Pibiviesse Cat Gen 2019Documento26 paginePibiviesse Cat Gen 2019Kasthuri Rangan KNessuna valutazione finora

- 4 - Shimelis BeyeneDocumento105 pagine4 - Shimelis BeyeneShimelis BebiNessuna valutazione finora

- 02 Samss 005 PDFDocumento16 pagine02 Samss 005 PDFayubqc.gusatNessuna valutazione finora

- CH 27Documento19 pagineCH 27marihomenonNessuna valutazione finora