Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Functional Safety The Next Edition of IEC 61511 PDF

Caricato da

weberyosDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Functional Safety The Next Edition of IEC 61511 PDF

Caricato da

weberyosCopyright:

Formati disponibili

Session Four: Functional safety: the next edition of IEC 61511

Session Four

Functional safety: the next edition of IEC 61511

Mirek Generowicz

Engineering Manager, I&E Systems Pty Ltd

Abstract

The functional safety standard IEC 61511 provides a framework for managing

instrumented safety systems in the process sector. The overall objective is to

ensure that the systems reliably deliver sufficient risk reduction to reduce risk to

acceptable levels.

The standard was first developed in the USA and originally released in 1996 as

ISA S84. It was adopted by the IEC as an international standard and released

in the form IEC 61511 in 2003. At the same time the ISA version was revised

and reissued as ANSI/ISA-84.00.01-2004. The ISA and IEC versions are

virtually identical. The Australian version AS IEC 61511 is also identical.

With almost 20 years of experience since the original ISA S84, a new edition of

IEC 61511 has now been prepared. Part 1 of the new edition was released in

February 2016. Parts 2 and 3 will follow shortly.

This paper outlines:

A brief history of the standard

An overview of how the standard works to achieve reliable risk reduction

The changes that are likely to be adopted

Why those changes are necessary.

The Legal Basis: Duty of Care

IEC 61511 is not directly referenced in legislation, though it is referenced in

some Codes of Practice. The legal requirement to apply IEC 61511 arises from

duty of care.

Everybody involved in owning, operating, designing, building or maintaining

hazardous facilities has a duty of care under occupational health and safety

legislation.

Due diligence in fulfilling our duty care requires us to:

Identify appropriate standards

Take reasonable steps to apply the standards

Monitor compliance

Demonstrate compliance

IEC 61511 is now a well-established in Australia and around the world. Failing

to comply with this standard would leave us open to being accused of

negligence.

6th Safety Control Systems Conference – Melbourne 2016 1

Session Four: Functional safety: the next edition of IEC 61511

Over the past 20 years the ISA S84 / IEC 61511 standard has been applied

widely and shown to be practicable. It is unarguably the most appropriate

standard to apply for instrumented safety systems in the process sector.

IEC 61511 applies to all of us who are in a position to influence those hazards.

It is not simply a standard for equipment suppliers or just for instrumentation

and control engineers.

The changes make the standard simpler and should improve the level of

compliance that can be readily achieved.

Regulators now expect users to demonstrate a reasonable level of compliance

to the standard. Owners, end users and EPC/EPCM contractors will need to

improve and to formalise the way they execute engineering activities in order to

comply with the standard requirements.

The Evolution of Functional Safety

Safety instrumented systems have been delivering risk reduction for at least

half a century.

In the early years of automation after the Second World War safety

instrumented functions were implemented using simple pneumatic, hydraulic or

hardwired electrical circuits. These simple functions were easy to understand

and had failure modes that were well defined. The behaviour under fault

conditions could be completely determined and predicted.

Electronic and programmable electronic systems came into use in safety

functions during the 1970s.

Electronic and programmable electronic systems have indeterminate failure

modes. They do not inherently fail into a safe state. They are subject to

hidden or latent faults that can be difficult to eliminate. Failure modes and

behaviours cannot be completely determined and predicted.

Programmable systems in particular have hidden complexity, and the

complexity has been increasing exponentially for several decades. Complex

systems are subject to the risk of systematic failures, failures caused by errors

and failures in the design and implementation of the systems.

Engineering practices evolved over decades in response to increasing

complexity.

6th Safety Control Systems Conference – Melbourne 2016 2

Session Four: Functional safety: the next edition of IEC 61511

Moore’s Law Applies to Instrumentation

Standards Evolution

Various standards were developed in the 1980s and 1990s to provide guidance

in controlling the risk of both systematic failures and random failures:

Health and Safety Executive (HSE UK) Guidelines – 1987,

‘Programmable Electronic Systems in Safety Related Application’

ISA S84 – 1996,

‘Application of Safety Instrumented Systems for the Process Industry’

IEC 61508 Ed. 1 – 1998, Ed. 2 – 2010,

‘Functional safety of electrical/electronic/programmable electronic

safety-related systems’

IEC 61511 – 2003 (ANSI/ISA – 84.00.01-2004)

‘Functional safety – Safety instrumented systems for the process

industry sector’

Risk Reduction Factor

‘Functional Safety’ refers to “Safety Instrumented Systems” (SIS) that

implement “Safety Instrumented Functions” (SIFs) as part of a company’s

overall risk management strategy.

Safety Instrumented Functions

Respond to a specific, defined hazard

Implement a specific action

Put the equipment into (or maintain) a safe state

Provide a defined degree of risk reduction

6th Safety Control Systems Conference – Melbourne 2016 3

Session Four: Functional safety: the next edition of IEC 61511

DETECT DECIDE DO

The risk reduction required from a function is characterised by the ‘Safety

Integrity Level’ or SIL.

To put it simply, each safety function is designed to deliver either 1, 2 or 3

orders of magnitude in risk reduction.

SIL 1, SIL 2 and SIL 3 correspond to Risk Reduction Factors of at least 10, 100

and 1,000.

Reliable Risk Reduction

Safety functions can fail due to

Systematic failures, caused by errors and failures in the design,

implementation, operation and maintenance of the systems

OR

Random hardware failures, those failures that can never be completely

eliminated by controlling the design, implementation, operation and

maintenance.

Systematic Integrity

IEC 61511 outlines well defined and detailed quality management practices to

avoid or to control the risk of systematic failures.

The degree of attention to detail and the level of effectiveness in the techniques

applied depend on the risk reduction required.

SIL 3 safety functions need to be 100 times as reliable as SIL 1 safety

functions. Design, checking, inspection and testing techniques need to be

proportionately more effective.

6th Safety Control Systems Conference – Melbourne 2016 4

Session Four: Functional safety: the next edition of IEC 61511

IEC 61511 defines a ‘safety lifecycle’ (similar to a quality process):

Safety requirements are defined in objective terms to achieve measurable risk

reduction. The hazard and risk assessment and the safety requirements

derived from it provide the basis for the whole system.

Management and planning provide a framework to ensure systematic integrity

and dependability.

The safety lifecycle applies traceability, verification and validation to ensure that

the requirements are fulfilled.

The owners, end users and process designers play a fundamental role in the

IEC 61511 safety lifecycle because they are ultimately accountable for the risk

management.

Hardware Integrity

To deliver a risk reduction factor of 10, the probability of failure on demand

must be less than 0.1

To deliver a risk reduction factor of 1000, the probability of failure on demand

must be less than 0.001

IEC 61511 and the related standard IEC 61508 describe techniques to evaluate

the probability of random hardware failure.

The probability of failure of a function can be reduced by increasing the

coverage and/or frequency of regular testing.

It can be reduced by selecting devices with lower failure rates.

It can also be reduced by applying a fault tolerant design – which means that

the function will continue to function successfully with one or more failed

components. For instance if two block valves are used in series the probability

that both will fail concurrently is lower than the probability of a single valve

failing.

6th Safety Control Systems Conference – Melbourne 2016 5

Session Four: Functional safety: the next edition of IEC 61511

Minimum Acceptable Fault Tolerance

When the standards were developed it was recognised that the there was a

great deal of uncertainty in the failure rate statistics and in the assumptions

made in the design.

To compensate for the uncertainty the standards set minimum levels of fault

tolerance for each part of a safety function.

The level of fault tolerance that is appropriate increases with the risk reduction

required. IEC 61511 defines minimum hardware fault tolerance (HFT)

requirements for the sensors, logic solvers and final elements that make up

each safety function.

Lessons Learned in Practice

Systematic Integrity Not Well Understood

The long history of major accident events shows that many users have failed to

understand and apply the requirements for managing quality or ‘systematic

integrity’.

The conclusions from many reports include these recurring systematic failures:

Lack of appreciation of organisational roles, responsibilities and

interfaces

Poor safety culture and a lack of leadership in safety

Inadequate attention paid to personnel competencies – and in particular

management competencies

Equipment poorly maintained

Alarms and automatic shutdown systems not working properly

Inadequate control of modifications to critical systems

Safeguards bypassed – or not even commissioned

Lack of documentation for safety systems

Minimum Acceptable Fault Tolerance Impracticable

The hardware fault tolerance required by IEC 61511 has been too onerous to

achieve in practice. Most users have found it difficult to comply with the

standard. The methods of assessing the HFT requirements are complicated

and difficult to use.

To minimise the HFT requirement to a practicable level users need to obtain

extensive evidence about the suitability of the devices being used. Users also

need to ensure that the majority of failures are to a safe state or that dangerous

failures are promptly detected and repaired.

Actuated valves are commonly used as final elements in safety functions, but

the dominant failure mode of actuated valves is dangerous. The most common

failures cause the valves to stick or jam in a dangerous state.

6th Safety Control Systems Conference – Melbourne 2016 6

Session Four: Functional safety: the next edition of IEC 61511

In the existing IEC 61511 standard a risk reduction factor of 1,000 or more (SIL

3) requires at least three block valves in series as final elements – unless

continuous automatic diagnostic functions can be implemented.

Continuous automatic diagnostic functions are not usually practicable in the

process sector.

In many cases it is impracticable to install three valves in series. Non-

compliance is widespread. The most common practice is to use only two

valves in series, either in a double block or a double block and bleed

arrangement.

Installing a third block valve not only increases the cost; it also increases the

risk of spurious trip and loss of production.

The Changes in the New Edition

The new edition of IEC 61511 will include:

New requirements for systematic capability

New requirements for formal functional safety management systems

New requirements for formal procedures to manage competence

New security risk assessments, relating to deliberate malicious

interference

More detailed requirements about planning for verification

Clarification of requirements for risk reduction is spread across multiple

SIFs

New annexes with detailed guidance

Simplified requirements for hardware fault tolerance

Requirements for better substantiation of the failure rate data and of

uncertainties in the data

Revised software development requirements

Additional requirements for bypasses

Formal review by operations and maintenance of the hazard and risk

assessments

Independent assessment of modifications to systems before

implementation.

6th Safety Control Systems Conference – Melbourne 2016 7

Session Four: Functional safety: the next edition of IEC 61511

Systematic Capability

The concept of systematic capability was introduced in the 2010 edition of IEC

61508. Systematic capability is essentially a measure of the effectiveness of

quality management techniques applied to components. Requirements for

systematic capability are included in the new edition of IEC 61511.

Functional Safety Management Systems

The purpose of a functional safety management system is to achieve

systematic integrity.

Functional safety management has been poorly understood and largely ignored

throughout the process sector, particularly by the end users or plant owners.

Any supplier with responsibility for one or more phases in the lifecycle must

now demonstrate a functional safety management system as well as a quality

management system.

The requirement for having a functional safety management system applies just

as much to end users and owners as it does to designers and suppliers.

The operation and maintenance of a safety instrumented system must be

managed under a formal system of functional safety procedures.

Competency

More emphasis has been put on competency requirements for all parties

involved in designing, developing, implementing, operating and maintaining

SIS.

The wording in the standard has been changed from describing factors that

‘should’ be addressed when considering competence to factors that ‘shall’ be

addressed.

A new sub-clause has been added requiring formal procedures to manage

competence and requiring periodic assessments of competence of individuals

with respect to their responsibilities.

There are competency requirements for those in charge too: Managers and

leaders need to have adequate knowledge, ability and experience relating to

the activities for which they are accountable.

Security Risk Assessment

In the section of the standard dealing with process hazard and risk

assessment, a new sub-clause has been added requiring a security risk

assessment.

This relates to security of the systems from deliberate malicious interference,

as distinct to the risk assessment of materials, process and equipment.

Requirements resulting from the security assessment need to be included into

the safety requirements specification.

6th Safety Control Systems Conference – Melbourne 2016 8

Session Four: Functional safety: the next edition of IEC 61511

Verification

A new sub-clause has been added with more detailed requirements about what

should be covered in planning when verification is to include testing.

A new sub-clause has been added specifically requiring verification that non-

safety functions that are integrated with safety function do not interfere with the

safety functions. Lack of separation between safety functions and non-safety

functions has been a widespread problem which compromises safety integrity.

Multiple SIFs

A new sub-clause clarifies that if risk reduction is spread across multiple SIFs

within the same SIS, then the safety integrity achieved must meet the overall

risk reduction requirement taking into account dependencies.

Risk Reduction > 10 000

The requirements for achieving four or more orders of magnitude reduction in

risk are specified in much more detail.

In IEC 61511-3 there is a new Annex J that provides very detailed guidance on

the evaluation of dependencies between multiple safety systems or functions.

This annex is particularly relevant to where high levels of risk reduction are

achieved by splitting risk reduction across multiple systems.

Hardware Fault Tolerance

The requirements for HFT have been simplified and aligned with the method

‘Route 2H’ that was introduced in the 2010 edition of IEC 61508.

The level of hardware fault tolerance required has been reduced on the basis

that ‘the reliability data used when quantifying the effect of random failures shall

be credible, traceable, documented, justified and shall be based on field

feedback from similar devices used in a similar operating environment.’

SIL 3 can now be claimed with only two block valves in series (fault tolerance of

one). The new IEC 61511 edition stops short of specifically requiring the 90%

confidence level required by IEC 61508 Route 2H, but it does require an

equivalent demonstration of confidence in the data.

Suitability of Components

IEC 61511 still allows a choice: components must either comply with IEC

61508, or else a substantial volume of evidence of ‘prior use’ must be available

to show that the components are suitable for the intended service.

For compliance to IEC 61508 the ‘systematic capability’ of components and

subsystems must be demonstrated. That means that the quality control must

be appropriate for the level of SIL claimed.

6th Safety Control Systems Conference – Melbourne 2016 9

Session Four: Functional safety: the next edition of IEC 61511

New sub-clauses have been inserted into the section on ‘Quantification of

random failure’ requiring better substantiation of the failure rate data and of

uncertainties in the data.

The calculated probability of failure will need to consider faults that might never

be detected, and failures that might be caused by periodic testing.

Application Program Software Development

The clause on application program has been completely re-written, though

there are no obvious or significant changes in requirements. The term

‘application program’ replaces the term ‘software’ which was previously used.

The new clause is shorter.

The application program development lifecycle is now integrated into the

overall safety lifecycle. In the earlier edition it was described separately.

Control of Bypasses in Operation

History has shown us that the application of bypasses and overrides has

contributed to the cause of many disasters.

A new sub-clause has been added requiring additional risk management where

SIS devices are bypassed in continuous operation.

A new sub-clause requires all bypasses to be authorised and logged.

A new sub-clause requires spare parts to be identified and made available to

minimise bypass duration.

Operations and Maintenance Review of HRA Assumptions

There has often been a lack of communication between the designers and

those responsible for operation and maintenance.

A new sub-clause requires those responsible for operations and maintenance

to review the assumptions made in hazard and risk assessment.

SIS Modification

A new sub-clause emphasises the need to update documentation affected by a

modification.

A new sub-clause requires independent assessment of the functional safety

before any modification is implemented.

Annexes

IEC 61511 parts 2 and 3 include many annexes that provide guidance on

implementing the standard.

Extensive changes, deletions and additions have been made in the annexes for

the new edition.

6th Safety Control Systems Conference – Melbourne 2016 10

Session Four: Functional safety: the next edition of IEC 61511

Summary

The changes in the new edition are primarily aimed at improving systematic

safety integrity.

The objective is to prevent the recurring systematic failures that have been

evident for many years throughout the process sector. These failures are all

preventable.

The requirements for hardware fault tolerance have been reduced, but the

failure rate data used in calculations must be more reliable. The quality and

suitability of components must be demonstrated.

The guidance and support material has been enhanced in the standard to

assist safety and design engineers, safety assessors, and operators.

Over the past 20 years the standard has been applied widely and shown to be

practicable. The changes make the standard simpler and should improve the

level of compliance that can be readily achieved.

Regulators now expect a reasonable level of compliance to the standard.

Due diligence in fulfilling our duty of care requires us to be able to demonstrate

compliance with IEC 61511.

Owners, end users and EPC/EPCM contractors will need to improve and to

formalise the way they execute engineering activities in order to comply with

the standard requirements.

For more information on functional safety visit:

http://www.iesystems.com.au/publications/

6th Safety Control Systems Conference – Melbourne 2016 11

Potrebbero piacerti anche

- Hima Fscs - Tuv Fse Sample Questions 2013Documento6 pagineHima Fscs - Tuv Fse Sample Questions 2013mnmNessuna valutazione finora

- Safety Instrumented Systems Verification – Practical Probabilistic CalculationsDa EverandSafety Instrumented Systems Verification – Practical Probabilistic CalculationsValutazione: 3.5 su 5 stelle3.5/5 (6)

- Iec 61511 PDFDocumento4 pagineIec 61511 PDFScribdSnake1230% (1)

- FSA Guidance Document - As Published 08.03.2019 1.0Documento31 pagineFSA Guidance Document - As Published 08.03.2019 1.0KevinXavierNessuna valutazione finora

- Essentials On Safety Instrumented SystemsDocumento9 pagineEssentials On Safety Instrumented Systemstibi1000Nessuna valutazione finora

- Doe STD 1195 2011 PDFDocumento55 pagineDoe STD 1195 2011 PDFMarco RangelNessuna valutazione finora

- Modelling Smoke and Gas Ingress Into Offshore Temporary RefugesDocumento93 pagineModelling Smoke and Gas Ingress Into Offshore Temporary RefugesmobilebufferNessuna valutazione finora

- White Paper Rouse 2h Sil Verification For Rosemount Type B Transmitters With Type A Components DataDocumento16 pagineWhite Paper Rouse 2h Sil Verification For Rosemount Type B Transmitters With Type A Components DataCARLOS PEREZNessuna valutazione finora

- BS60080 2020 Technical Note - Flame DetectionDocumento7 pagineBS60080 2020 Technical Note - Flame DetectionmaheshNessuna valutazione finora

- Trevor - Kletz. - An - Engineers - View - of - Human Preview PDFDocumento36 pagineTrevor - Kletz. - An - Engineers - View - of - Human Preview PDFweberyosNessuna valutazione finora

- Research Paper On KeyloggersDocumento3 pagineResearch Paper On KeyloggersRish100% (1)

- Vdocuments - MX - Industrial Robotics by Mikell P Groover Robotics by Mikell P GrooverpdfDocumento2 pagineVdocuments - MX - Industrial Robotics by Mikell P Groover Robotics by Mikell P GrooverpdfMRANessuna valutazione finora

- EnterpriseContinousTesting PDFDocumento134 pagineEnterpriseContinousTesting PDFPasttor Del AguaNessuna valutazione finora

- IEC 61508 OverviewDocumento13 pagineIEC 61508 OverviewDámaso DortaNessuna valutazione finora

- Safety Instrumented SystemDocumento19 pagineSafety Instrumented SystemK_S_Krishna0001Nessuna valutazione finora

- Functional Safety in Process IndustryDocumento10 pagineFunctional Safety in Process Industry59wilchesNessuna valutazione finora

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- FSE 1 Rev 3.3 Exercise SolutionsDocumento19 pagineFSE 1 Rev 3.3 Exercise SolutionsNestor PintoNessuna valutazione finora

- IEC-61511 Functional Safety TrainingDocumento2 pagineIEC-61511 Functional Safety TrainingMuhammad.Saim100% (1)

- Safety Instrumented Systems (SIS), Safety Integrity Levels (SIL), IEC61508, and Honeywell Field InstrumentsDocumento4 pagineSafety Instrumented Systems (SIS), Safety Integrity Levels (SIL), IEC61508, and Honeywell Field InstrumentsAhmad Adel El TantawyNessuna valutazione finora

- SIL Verification of Legacy System V3Documento12 pagineSIL Verification of Legacy System V3Anonymous H0xnVVXypgNessuna valutazione finora

- ABB Safety SIL MethodologyDocumento24 pagineABB Safety SIL MethodologybariNessuna valutazione finora

- Functional Safety: Sil Assessment & Verification: Do Proof Test Practices Affect P&Ids?Documento32 pagineFunctional Safety: Sil Assessment & Verification: Do Proof Test Practices Affect P&Ids?Muhammad.SaimNessuna valutazione finora

- SIL ObjectivesDocumento29 pagineSIL ObjectivesrkoncNessuna valutazione finora

- ISATR84Documento6 pagineISATR84checito49100% (1)

- Chastainw Advancesinlayerofprotectionanalysis PDFDocumento37 pagineChastainw Advancesinlayerofprotectionanalysis PDFanon_770350620100% (1)

- Designing and Validating A Safety Instrumented System (SIS) and Its Role in Process Safety ManagementDocumento14 pagineDesigning and Validating A Safety Instrumented System (SIS) and Its Role in Process Safety ManagementChemkhi100% (1)

- E BOOK Functional SafetyDocumento13 pagineE BOOK Functional Safetyomar alnasser100% (1)

- TR - 84.00.02 Part1Documento108 pagineTR - 84.00.02 Part1Sandra TiguaqueNessuna valutazione finora

- SIS 3 - SRS - General PDFDocumento7 pagineSIS 3 - SRS - General PDFrieza_fNessuna valutazione finora

- Basics of TripsDocumento257 pagineBasics of TripsHenryOdohNessuna valutazione finora

- CHAZOP Paper (Lite) r0.1Documento7 pagineCHAZOP Paper (Lite) r0.1Udaya Kumar KrishnanNessuna valutazione finora

- Basics of SISDocumento4 pagineBasics of SISJagath PrasangaNessuna valutazione finora

- HFT From IEC-En - 61511-1 CommentedDocumento2 pagineHFT From IEC-En - 61511-1 Commenteddijoz85Nessuna valutazione finora

- Functional Safety ManagementDocumento8 pagineFunctional Safety ManagementasimozmaNessuna valutazione finora

- PROJECT STANDARDS and SPECIFICATIONS Instrumentation Safety Requirments Rev01Documento7 paginePROJECT STANDARDS and SPECIFICATIONS Instrumentation Safety Requirments Rev01hiyeonNessuna valutazione finora

- Achieved SILDocumento4 pagineAchieved SILAkoKhaledi50% (2)

- Sil VerificationDocumento3 pagineSil Verificationavinash-mokashi0% (1)

- Comparison Chart of ISA CFSE TUVDocumento1 paginaComparison Chart of ISA CFSE TUVrlimaye0% (3)

- Best Practices: Consider These Safety-Instrumented SystemDocumento18 pagineBest Practices: Consider These Safety-Instrumented Systemardiyanto100% (1)

- Selection GuideDocumento65 pagineSelection GuideAdnan HayatNessuna valutazione finora

- Module 9 - ALARP 20150305Documento32 pagineModule 9 - ALARP 20150305Muhammad.SaimNessuna valutazione finora

- EXIDA: Estimating The Beta Factor 1Documento7 pagineEXIDA: Estimating The Beta Factor 1Kareem RasmyNessuna valutazione finora

- When Is An Independent Protection LayerDocumento9 pagineWhen Is An Independent Protection LayerChimaovu EhoroNessuna valutazione finora

- Preview ANSI+ISA+84.00.01-2004+Part+2Documento17 paginePreview ANSI+ISA+84.00.01-2004+Part+2MOZAMMIL MAHBOOBNessuna valutazione finora

- Gis 30-851Documento24 pagineGis 30-851Felix JaimesNessuna valutazione finora

- PART 2-A SIS Applications in BoilersDocumento29 paginePART 2-A SIS Applications in BoilersAdila AnbreenNessuna valutazione finora

- SIL LOPA Presentation 19th June 2016Documento38 pagineSIL LOPA Presentation 19th June 2016vasuNessuna valutazione finora

- Determining The Required Safety Integrity Level For Your Process PDFDocumento8 pagineDetermining The Required Safety Integrity Level For Your Process PDFfitasmounirNessuna valutazione finora

- LOPA and Risk Graphs For SIL DeterminationDocumento11 pagineLOPA and Risk Graphs For SIL DeterminationShweta181Nessuna valutazione finora

- Rizal Technological University College of Engineering, Architecture and TechnologyDocumento82 pagineRizal Technological University College of Engineering, Architecture and TechnologyJulius ChavezNessuna valutazione finora

- Use and Misuse of Enabling Conditions and Conditional Modifiers in Layers of Protection Analysis (LOPA)Documento22 pagineUse and Misuse of Enabling Conditions and Conditional Modifiers in Layers of Protection Analysis (LOPA)userscribd2011Nessuna valutazione finora

- Management of Functional Safety Guideline ProcessDocumento13 pagineManagement of Functional Safety Guideline ProcessLayo1230% (1)

- 17 CASS TOES For FSM Assessment From IEC 61511-1 2016 v1Documento7 pagine17 CASS TOES For FSM Assessment From IEC 61511-1 2016 v1didikpramujiNessuna valutazione finora

- CHAZOPDocumento2 pagineCHAZOPAbd ZouhierNessuna valutazione finora

- Ida E: Functional Safety Engineering II SIS Design - SIL VerificationDocumento273 pagineIda E: Functional Safety Engineering II SIS Design - SIL VerificationMarcio GranatoNessuna valutazione finora

- CDOIF Guideline Demonstrating Prior Use v7 FinalDocumento34 pagineCDOIF Guideline Demonstrating Prior Use v7 Finaldwi rakhmatullahNessuna valutazione finora

- UL Functional Safety Webinar SlidesDocumento33 pagineUL Functional Safety Webinar Slidesc208052Nessuna valutazione finora

- Fmeda1 - Exida PaperDocumento7 pagineFmeda1 - Exida PapervijayigcarNessuna valutazione finora

- SIS - Safety Instrumented Systems - A Practical View - Part 1Documento58 pagineSIS - Safety Instrumented Systems - A Practical View - Part 1mgkvprNessuna valutazione finora

- Certified Functional Safety Expert A Complete Guide - 2020 EditionDa EverandCertified Functional Safety Expert A Complete Guide - 2020 EditionNessuna valutazione finora

- Safety Critical Systems A Complete Guide - 2021 EditionDa EverandSafety Critical Systems A Complete Guide - 2021 EditionNessuna valutazione finora

- Warehouse Storage of Hazardous Chemicals Guide PDFDocumento5 pagineWarehouse Storage of Hazardous Chemicals Guide PDFweberyosNessuna valutazione finora

- 2018 05 Beacon English PDFDocumento1 pagina2018 05 Beacon English PDFweberyosNessuna valutazione finora

- Pro Smart SildeDocumento31 paginePro Smart SildeweberyosNessuna valutazione finora

- Ethanol HazComDocumento1 paginaEthanol HazComweberyosNessuna valutazione finora

- Exam MicroservicesDocumento3 pagineExam Microservicesapi-498231319Nessuna valutazione finora

- Build A Real-Time Chat Application With Socket - Io and Node - Js (With Automated Testing)Documento25 pagineBuild A Real-Time Chat Application With Socket - Io and Node - Js (With Automated Testing)John ToughNessuna valutazione finora

- Final Year Project PresentationDocumento15 pagineFinal Year Project PresentationDipu SinghNessuna valutazione finora

- Ebilling Project ReportDocumento104 pagineEbilling Project ReportRohit HazareNessuna valutazione finora

- Seven QC Tools For Process Quality ImprovementDocumento119 pagineSeven QC Tools For Process Quality ImprovementRaajha MunibathiranNessuna valutazione finora

- Introduction To Process ControlDocumento24 pagineIntroduction To Process ControlAbdelrahman GadallahNessuna valutazione finora

- OOP Through Java Question BankDocumento6 pagineOOP Through Java Question BankRocky AdityaNessuna valutazione finora

- Software Development Life CycleDocumento14 pagineSoftware Development Life CycleAzharNessuna valutazione finora

- What Is Black Box Testing?: Black Box Testing Is Done Without The Knowledge of The Internals of The System Under TestDocumento127 pagineWhat Is Black Box Testing?: Black Box Testing Is Done Without The Knowledge of The Internals of The System Under TestusitggsipuNessuna valutazione finora

- NSE 3 FortiSOAR AttemptDocumento2 pagineNSE 3 FortiSOAR AttemptLorena TavaresNessuna valutazione finora

- Silas GomezDocumento1 paginaSilas GomezAbhishek RajpootNessuna valutazione finora

- Changes in CMMI-Dev, V 1 - 3Documento2 pagineChanges in CMMI-Dev, V 1 - 3Ribhu Nath LavaniaNessuna valutazione finora

- DLL With HarbourDocumento4 pagineDLL With HarbourFabian ToroNessuna valutazione finora

- Control System Question PaperDocumento2 pagineControl System Question PaperKishor GooddayNessuna valutazione finora

- 6169 1 SMDocumento4 pagine6169 1 SMas1as2as3Nessuna valutazione finora

- Software Developer: About Me My ContactDocumento1 paginaSoftware Developer: About Me My ContactChandanNessuna valutazione finora

- Unit-7: Java Web Frameworks: Spring MVCDocumento26 pagineUnit-7: Java Web Frameworks: Spring MVCHarishNessuna valutazione finora

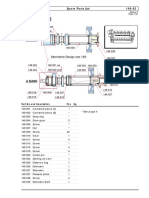

- Camshaft V32: Wärtsilä 32 Spare Parts List 148-02Documento4 pagineCamshaft V32: Wärtsilä 32 Spare Parts List 148-02Toster902Nessuna valutazione finora

- DevOps Foundations - CD - CIDocumento8 pagineDevOps Foundations - CD - CIJohn HernandezNessuna valutazione finora

- Institute of Space Technology: Submitted byDocumento12 pagineInstitute of Space Technology: Submitted byMesum IrfaniNessuna valutazione finora

- The 5 Relationships Between ClassesDocumento3 pagineThe 5 Relationships Between ClassesSaadEdinNajemNessuna valutazione finora

- CAST Solutioning Guidance - CAS V3.96Documento31 pagineCAST Solutioning Guidance - CAS V3.96Gopu GaneshNessuna valutazione finora

- EXCEL Training Course Content - ABB 800xa DCS V1.1Documento2 pagineEXCEL Training Course Content - ABB 800xa DCS V1.1Venkatesh SelvarajNessuna valutazione finora

- SLP Catalogue PDFDocumento315 pagineSLP Catalogue PDFMichael AkhramovichNessuna valutazione finora

- MaxxForce11 13SpecCardDocumento2 pagineMaxxForce11 13SpecCardJohn MkCito KINessuna valutazione finora

- Final DocumentationDocumento55 pagineFinal Documentationshakibul islamNessuna valutazione finora

- Angular-5 Training SyllabusDocumento7 pagineAngular-5 Training Syllabusmari ANessuna valutazione finora