Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tutorial MD II 2015 3

Caricato da

rip111176Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tutorial MD II 2015 3

Caricato da

rip111176Copyright:

Formati disponibili

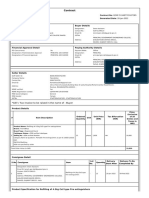

Mechanical Engineering Department

Tutorials—Bevel Gears

B E Mechanical SEM VIII 181902-Machine Design II Year 2015

1 A pair of bevel gears is transmitting 10 kW from a pinion rotating at 600 rpm to gear mounted

on a shaft which intersects the pinion shaft at an angle of 60o. The pinion has an outside pitch

diameter of 200 mm, a pressure angle of 20 o and a face width of 40 mm, and the gear shaft is

rotating at 200 rpm. Determine ( a ) the pitch angles for the gears, ( b ) the forces on the gear,

and ( c ) the torque produced about the shaft axis

2 The bevel pinion shown in Fig.14.2 rotates at 960 rev/min in the clockwise direction,

viewing from the right side and transmits 5 kW to the gear. The mounting distances, the

location of all bearings, and the radii of the pitch circles of the pinion and gear are shown in

pitch cones in the figure. Bearings A and C should take the thrust loads. Find the bearing

forces on the gear shaft.

3 A pair of bevel gear is mounted on shafts that are at 90 o apart. The set is to transmit 10 kW at

300 rpm. The pinion has 150 mm outside pitch diameter; 50 mm face width, a diametral pitch

of 6, and is 20 degree full depth. For a velocity ratio of 0.4, determine the force acting on gear

tooth.

4 Design a pair of bevel gears for two shafts whose axis are at right angles. Speed of pinion shaft

is 300 rpm, and that of gear shaft is 120 rpm. The power transmitted is 80 kW at gear shaft.

5 A pair of high grade cast iron bevel gears having shaft at right angle are to have an angular

velocity ratio of driver to driven of 2 to3. The driver is to rotate at 175 rev/min and is to

transmit 10 KW. It is 0.4 meter in pitch diameter. Take the width of face as about one third of

the length of pitch element and determine the pitch of the gear.

Potrebbero piacerti anche

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheDa EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheValutazione: 4.5 su 5 stelle4.5/5 (2)

- Gearing - ProblemsDocumento7 pagineGearing - ProblemsmanuNessuna valutazione finora

- Tutorial MD II 2015 2Documento1 paginaTutorial MD II 2015 2rip111176Nessuna valutazione finora

- Sheet No. 1 Design of GearsDocumento3 pagineSheet No. 1 Design of GearssallyNessuna valutazione finora

- Theoretical QuestionsDocumento17 pagineTheoretical Questionsanbamech50% (2)

- 01 Helical Gear ONLY ProblemsDocumento2 pagine01 Helical Gear ONLY Problemskamal0% (1)

- Tutorial MD II 2015 4Documento1 paginaTutorial MD II 2015 4rip111176Nessuna valutazione finora

- Assignment Questions MDDocumento3 pagineAssignment Questions MDTanvir NasserNessuna valutazione finora

- Assignment No. 4 Design of Shaft Date of Submission: 18/02/201 (Monday)Documento3 pagineAssignment No. 4 Design of Shaft Date of Submission: 18/02/201 (Monday)Himani VarshneyNessuna valutazione finora

- Unit I - Shafts: Single ElementDocumento7 pagineUnit I - Shafts: Single Elementchelam101100% (1)

- 12-Worm Gears PDFDocumento2 pagine12-Worm Gears PDFSarvesh MishraNessuna valutazione finora

- Anna University Exams Nov / Dec 2019 - Regulation 2017 Unit I-V 1Documento5 pagineAnna University Exams Nov / Dec 2019 - Regulation 2017 Unit I-V 1Sai KrishnaNessuna valutazione finora

- Instructions:: Gujarat Technological UniversityDocumento2 pagineInstructions:: Gujarat Technological Universitysameer_m_daniNessuna valutazione finora

- Design of Transmission System-QbDocumento5 pagineDesign of Transmission System-QbGanapathi SekaranNessuna valutazione finora

- Tutorial 01 Dynamic Force Analysis of Mechanisms - 2Documento1 paginaTutorial 01 Dynamic Force Analysis of Mechanisms - 2snafuxxspartanNessuna valutazione finora

- Mecha Assig 1Documento1 paginaMecha Assig 1tewoldemedihanit65Nessuna valutazione finora

- Bevel and Worm GearsDocumento1 paginaBevel and Worm GearsDevansh ChhajlaniNessuna valutazione finora

- Assignment No4Documento2 pagineAssignment No4Jai SharmaNessuna valutazione finora

- Sheet 1 Spur GearsDocumento2 pagineSheet 1 Spur Gearsمحمود بسيوني نصارNessuna valutazione finora

- Tutorial 3 - Gear CalculationsDocumento9 pagineTutorial 3 - Gear CalculationsMohammad AzmudinNessuna valutazione finora

- MD2 Model QuestionsDocumento2 pagineMD2 Model Questionsmanish sharmaNessuna valutazione finora

- Me 2352 - DTS Q BankDocumento5 pagineMe 2352 - DTS Q Bankpaul_jaikumarm27530% (1)

- Dts Important Ques 2 16 MarksDocumento5 pagineDts Important Ques 2 16 MarksBas RamuNessuna valutazione finora

- Tutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentDocumento12 pagineTutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentSURYA S96Nessuna valutazione finora

- Assignment 1 - Machine DesignDocumento1 paginaAssignment 1 - Machine DesignmrinalsinghrawatNessuna valutazione finora

- DMM Question BankDocumento2 pagineDMM Question Bankzubair ahmedNessuna valutazione finora

- ME6601.16 MarksDocumento6 pagineME6601.16 Markssathiskumar411Nessuna valutazione finora

- DtsDocumento11 pagineDtsSridiwakaran ParameswaranNessuna valutazione finora

- DTS Model PaperDocumento3 pagineDTS Model PaperrajkumardotcomNessuna valutazione finora

- Iat-I QPDocumento2 pagineIat-I QPBalaChandarNessuna valutazione finora

- Part B & Part C Questions - Unit WiseDocumento3 paginePart B & Part C Questions - Unit WiseShobiNessuna valutazione finora

- Designn of Tranmission SystemDocumento4 pagineDesignn of Tranmission Systemsathiskumar411Nessuna valutazione finora

- MD-II Question BankDocumento3 pagineMD-II Question BankAnonymous Pfi1bgrYNessuna valutazione finora

- TutorialDocumento1 paginaTutorialAtul GaurNessuna valutazione finora

- Tutorial Sheet No 1 On Spur GearDocumento3 pagineTutorial Sheet No 1 On Spur GearChirayuNessuna valutazione finora

- Tutorial-2 Kinematics of MachineryDocumento2 pagineTutorial-2 Kinematics of MachineryInzamam Ul HaqueNessuna valutazione finora

- Rr222105 Kinematics of MachineryDocumento11 pagineRr222105 Kinematics of MachinerySrinivasa Rao G100% (2)

- Me 1352Documento6 pagineMe 1352arunramakrishnanNessuna valutazione finora

- Dme-2 2017-18 Ist AssignmentDocumento1 paginaDme-2 2017-18 Ist Assignmentmallesh mendaNessuna valutazione finora

- Final Design Work SheetDocumento7 pagineFinal Design Work SheetKINDUNessuna valutazione finora

- Bevel Gears: Gear DrivesDocumento11 pagineBevel Gears: Gear DrivesNeil RubsNessuna valutazione finora

- UNit-2 Numerical ProblemsDocumento16 pagineUNit-2 Numerical ProblemsMarthandeNessuna valutazione finora

- Our Official Android App - REJINPAUL NETWORK FromDocumento3 pagineOur Official Android App - REJINPAUL NETWORK FromAjay KumarNessuna valutazione finora

- Design of Transmission ElementDocumento42 pagineDesign of Transmission ElementVenkatesh MohanNessuna valutazione finora

- Assignment - 2 Kinematics of MachineryDocumento1 paginaAssignment - 2 Kinematics of MachineryInzamam Ul HaqueNessuna valutazione finora

- D04FA48908744891B70ED91613E5E5ABDocumento4 pagineD04FA48908744891B70ED91613E5E5AByashvantNessuna valutazione finora

- Question Bank 2 DME 1Documento4 pagineQuestion Bank 2 DME 1Ayush KothariNessuna valutazione finora

- DOM Assignment 1 2017 18Documento2 pagineDOM Assignment 1 2017 18_hrithik_rkNessuna valutazione finora

- R8 Nov-Dec-2015Documento3 pagineR8 Nov-Dec-2015Hari VenkitNessuna valutazione finora

- Tom Assignment and TutorialDocumento6 pagineTom Assignment and TutorialAkshay MishraNessuna valutazione finora

- Krishna Engineering College, Ghaziabad Department of Mechanical Engineering Machine Design-II Assignment No: 03Documento2 pagineKrishna Engineering College, Ghaziabad Department of Mechanical Engineering Machine Design-II Assignment No: 03Vivek BajpaiNessuna valutazione finora

- 9A21506 Mechanisms & Mechanical DesignDocumento8 pagine9A21506 Mechanisms & Mechanical DesignsivabharathamurthyNessuna valutazione finora

- Question Paper Code:: (10×2 20 Marks)Documento3 pagineQuestion Paper Code:: (10×2 20 Marks)PradeepNessuna valutazione finora

- Design of Transmission System Unit IIIDocumento57 pagineDesign of Transmission System Unit IIIRaj MohanNessuna valutazione finora

- DOM2Documento7 pagineDOM2ds_shivaNessuna valutazione finora

- ME6601 QbsdfwsdfsDocumento8 pagineME6601 QbsdfwsdfsvivekzzNessuna valutazione finora

- Scientific American Supplement, No. 441, June 14, 1884.Da EverandScientific American Supplement, No. 441, June 14, 1884.Nessuna valutazione finora

- Energy-saving Principles and Technologies for Induction MotorsDa EverandEnergy-saving Principles and Technologies for Induction MotorsNessuna valutazione finora

- Gemc 511687737438095 25032022 PDFDocumento3 pagineGemc 511687737438095 25032022 PDFrip111176Nessuna valutazione finora

- GEMC-511687720852142 Invoice PDFDocumento2 pagineGEMC-511687720852142 Invoice PDFrip111176Nessuna valutazione finora

- Gemc 511687728136292 17092022Documento3 pagineGemc 511687728136292 17092022rip111176Nessuna valutazione finora

- 6-Interest Payable by The TaxpayerDocumento13 pagine6-Interest Payable by The Taxpayerrip111176Nessuna valutazione finora

- GeM Bidding 3152874 PDFDocumento4 pagineGeM Bidding 3152874 PDFrip111176Nessuna valutazione finora

- Statement Ledger PDFDocumento1 paginaStatement Ledger PDFrip111176Nessuna valutazione finora

- Gemc 511687729107385 20012022 PDFDocumento4 pagineGemc 511687729107385 20012022 PDFrip111176Nessuna valutazione finora

- ME SEM 2 CADCAM FEA Presentation MAY 2020 PDFDocumento1 paginaME SEM 2 CADCAM FEA Presentation MAY 2020 PDFrip111176Nessuna valutazione finora

- GeM Bidding 3656858 PDFDocumento4 pagineGeM Bidding 3656858 PDFrip111176Nessuna valutazione finora

- ME SEM 2 CADCAM 3720821 OT Presentation MAY 2020Documento1 paginaME SEM 2 CADCAM 3720821 OT Presentation MAY 2020rip111176Nessuna valutazione finora

- Tutorial MD II 2015 1Documento1 paginaTutorial MD II 2015 1rip111176Nessuna valutazione finora

- Finite Element 2 PDFDocumento5 pagineFinite Element 2 PDFrip111176Nessuna valutazione finora

- AMD Tutorial ME CADCAM 2022-23Documento6 pagineAMD Tutorial ME CADCAM 2022-23rip111176Nessuna valutazione finora

- Tutorial: Optimization Techniques 1Documento6 pagineTutorial: Optimization Techniques 1rip111176Nessuna valutazione finora

- Tutorial Design of Cranes 2017Documento2 pagineTutorial Design of Cranes 2017rip11117633% (3)

- 77-9 Design of CranesDocumento10 pagine77-9 Design of Cranesrip111176Nessuna valutazione finora

- Tutorial MD II 2015 4Documento1 paginaTutorial MD II 2015 4rip111176Nessuna valutazione finora

- AMD Tutorial Stress StrainDocumento3 pagineAMD Tutorial Stress Strainrip111176Nessuna valutazione finora

- Tutorial MD II 2015 5Documento1 paginaTutorial MD II 2015 5rip111176Nessuna valutazione finora

- Recent Advancements in Rapid Prototyping For Bio Medical ModelsDocumento19 pagineRecent Advancements in Rapid Prototyping For Bio Medical Modelsrip111176Nessuna valutazione finora

- Amd Tutorial Me Cadcam 2017Documento5 pagineAmd Tutorial Me Cadcam 2017rip111176Nessuna valutazione finora

- Mechanical Enginering Department: Sub:-Machine Design CODE:-2171903 Topic:-Design of Helical GearsDocumento18 pagineMechanical Enginering Department: Sub:-Machine Design CODE:-2171903 Topic:-Design of Helical Gearsrip111176Nessuna valutazione finora

- Prepared by - Vedant Vyas. (150180708011) M.E. Cad/Cam. Guided by - Prof. R. I. Patel. Place-GEC - DahodDocumento33 paginePrepared by - Vedant Vyas. (150180708011) M.E. Cad/Cam. Guided by - Prof. R. I. Patel. Place-GEC - Dahodrip111176Nessuna valutazione finora

- TUTORIAL 3 Design of Shaft Key and CouplingDocumento2 pagineTUTORIAL 3 Design of Shaft Key and Couplingrip111176100% (1)

- MD PPT 150183119005,06Documento28 pagineMD PPT 150183119005,06rip111176Nessuna valutazione finora

- Subject: Machine Design Be Sem Vii Mechanical Tutorial:02 (Helical Gear)Documento1 paginaSubject: Machine Design Be Sem Vii Mechanical Tutorial:02 (Helical Gear)rip111176Nessuna valutazione finora

- Recent Advancements in Rapid Prototyping For Bio Medical ModelsDocumento19 pagineRecent Advancements in Rapid Prototyping For Bio Medical Modelsrip111176Nessuna valutazione finora

- A PPT On Worm Gear: Presented byDocumento19 pagineA PPT On Worm Gear: Presented byrip111176Nessuna valutazione finora