Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Renderoc HB40: High-Technology Medium Weight Concrete Reinstatement Mortar Uses Design Criteria

Caricato da

sammyDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Renderoc HB40: High-Technology Medium Weight Concrete Reinstatement Mortar Uses Design Criteria

Caricato da

sammyCopyright:

Formati disponibili

Renderoc HB40 constructive solutions

High-technology medium weight concrete

reinstatement mortar

Uses

For the reinstatement of large areas of concrete and for small, Design criteria

localised patch repairs. Renderoc HB40 is alkaline in nature Renderoc HB40 can be applied in sections up to 40 mm thickness

and will protect embedded steel reinforcement. It is specifically in vertical locations and up to 30 mm thickness in overhead

designed for vertical and overhead repair work where a locations in a single application and without the use of formwork.

medium-weight mortar is required. Thicker sections should be built up in layers but are sometimes

possible in a single application depending on the actual configuration

Advantages of the repair area and the volume of exposed reinforcing steel. The

material should not be applied at less than 10 mm thickness.

Medium weight formulation enabling high build and

Greater thicknesses than those specified above can be achieved

thereby saving time and expense of multiple

by spray application or by the use of formwork. Please consult

applications

Fosroc for further information.

Obviates the need for formwork

Polymer-modification provides extremely low permeability Typical Properties

to water, carbon dioxide and chlorides The test methods used were in full accordance with the Product

Excellent bond to the concrete substrate Conformity Certification Scheme for Repair Mortar (PCCS-RM)

Exceptional system of shrinkage compensation TM1 - TM6 (2010). Specimens were stored at 27°C and 55% RH.

One component, pre-bagged to overcome site-batched The physical properties below are typical of the results obtained in

variations practice.

Contains no chloride admixtures

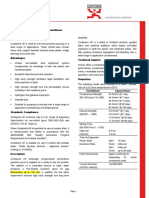

Test method Description of Test Typical result

TM1 Compressive strength 28-33 MPa @ 7days

Standards compliance

35-40 MPa @ 28 days

Renderoc HB40 has been tested and approved in accordance TM2 Tensile strength > 2 MPa @ 7 days

with the Product Conformity Certification Scheme for Repair TM3 Elastic modulus 15-25 kN/mm2 @ 28 days

Mortar (PCCS-RM) TM1 to TM6 (2010). TM4 Bond strength > 2 MPa @ 7 days

TM5 Shrinkage - No cracks @ 7 days

Description Coutinho Ring No cracks @ 28 days

Renderoc HB40 is supplied as a ready to use blend of dry TM6 Figg air permeability > 200 secs @ 35 days

powders which requires only the site addition of clean water BS6319 : Pt3:1983 Flexural strength > 5 MPa @ 7 days

to produce a highly consistent, medium weight repair mortar. HKHA/MTS Drying shrinkage < 300 Microstrains @ 7 days

(2000/2002)

The material is based on Portland cements, graded Specification

Part D CI.2.1.21

aggregates, lightweight fillers and chemical additives which

Notes:

provide a mortar with good handling characteristics, while

minimising water demand. The low water requirement ensures (i) The specimens were stored in full accordance with the

fast strength gain and long-term durability. Product Conformity Certification Scheme for Repair Mortar

(PCCS-RM) (2010).

Technical support (ii) TM1 toTM4 and Flexural strength are based on BS6319

Fosroc offers comprehensive technical support, including Part 2.

help at the design stage, application advice and on site (iii) TM1, TM2, TM3, TM4, TM5 & TM6 are requirements of the

problem solving. Specifiers and contractors are encouraged Product Conformity Certification Scheme for Repair Mortar

to contact our trained staff for answers to their questions. (PCCS-RM) (2010).

For further information please contact Fosroc. Fresh wet density: approximately 1930 kg/m3 depending on actual

consistency used.

Chemical resistance: the low permeability severely retards

chemical attack in aggressive environments. The cured mortar is

highly impermeable to acid gases, chloride ions, oxygen and

water.

As a carbon dioxide barrier, a 10mm thickness of Renderoc HB40

is equivalent to a 600mm thickness of 30MPa concrete.

Renderoc HB40

Specification clauses Mixing

The polymer modified reinstatement mortar shall be Renderoc Care should be taken to ensure that Renderoc HB40 is

HB40, a single component cement-based blend of powders thoroughly mixed. A forced-action mixer is essential. Mixing in

to which only the site-addition of clean water shall be permitted. a suitably sized drum using "Renderoc" mixing paddle in a

The reinstatement mortar shall comply fully with the Product slow speed (400/500 rpm) heavy-duty (min 1kw) drill is an

Conformity Certification Schene for Repair Mortar (PCCS-RM) acceptable alternative. Mixing of part bags should never be

TM1 to TM6 and shall exhibit a fresh wet density of 1930 kg/m3. attempted.

For normal applications, place 3.8 to 4.2 litres of clean water

Application instructions into the mixer and, with the machine in operation, add one full

Surface preparation 25 kg bag of Renderoc HB40 and mix for 3 to 5 minutes until

fully homogeneous. Note that powder must always be added

Clean the surface and remove any dust, unsound material,

to water.

plaster, oil, paint, grease, corrosion deposits or algae. Roughen

the surface and remove any laitence by light scabbling or grit- Application

blasting. Saw cut or cut back the extremities of the repair For application to all surfaces, Renderoc HB40 must be well-

locations to a depth of at least 10 mm to avoid feather-edging compacted on to the primed substrate by trowel or by gloved

and to provide a square edge. Break out the complete repair hand. Exposed steel reinforcement should be completely

area to a minimum depth of 10 mm up to the sawn edge. encapsulated by the mortar. Renderoc HB40 can be applied

Expose fully any corroded steel in the repair area and remove at a minimum thickness of 10 mm and up to 40 mm thickness

all loose scale and corrosion deposits. Steel should be in vertical locations in a single application and without the use

cleaned to a bright condition paying particular attention to the of formwork. Overhead thicknesses between 10 mm and 30

back of exposed steel bars. Grit-blasting is recommended for mm can be made in a single application, depending on the

this process. nature of the substrate and the details of the location. If the

recommended thicknesses are exceeded and sagging

Reinforcing steel priming

occurs, the affected section must be completely removed and

Apply one full coat of Nitoprime Zincrich WB and allow to dry reapplied in accordance with the procedure described above.

before continuing. If any doubt exists about having achieved Greater thicknesses than those specified above can be

an unbroken coating, a second application should be made achieved by spray application or by the use of formwork.

and, again, allowed to dry before continuing.

Where thicker sections are required by hand or trowel

Substrate priming application, the surface of the intermediate layers should be

The substrate should be thoroughly soaked with clean water scratch-keyed and cured with Nitobond AR. Application of a

(any excess being removed prior to commencement) prior to further (Nitobond SBR/cement slurry) bond coat and a further

applying a slurry primer mixed with 1 part of Nitobond SBR to application of Renderoc HB40 may proceed as soon as this

1.5 parts of cement by volume. The bond coat should be layer reached initial set (typically 2-3 hours, depending on

scrubbed into the surface of the concrete. Avoid applying too temperature and humidity).

thickly. The repair mortar should be applied as soon as the Finishing

bond coat becomes ‘tacky’. If the bond coat is too wet,

Renderoc HB40 can be finished with a steel, plastic or wood

achieving the desired build may be difficult. If the bond coat

float, or by a damp sponge technique, to achieve the desired

becomes dry, build and bond will be reduced. If a Nitobond

surface texture. The completed surface should not be

SBR / cement slurry coat dries before application of the repair

overworked.

mortar, it must be removed and the area reprimed before

continuing. High temperature working

In exceptional circumstances, for example, where a substrate/ At ambient temperatures above 35°C, the material should be

repair barrier is required or where the substrate is likely to stored in the shade and cool water used for mixing.

remain permanently damp, Nitobond EP Slowset bonding Low temperature working

aid should be used. Contact Fosroc for further information.

In cold conditions down to 5°C, the use of warm water (up to

30°C) is advisable to accelerate strength development. Normal

precautions for winter working with cementitious materials

should then be adopted.

constructive solutions page 2

Renderoc HB40

Renderoc HB40: 25 kg bags

Curing Nitoprime Zincrich WB: 1 and 4.5 litre tins

Renderoc HB40 is a cement-based repair mortar. In common Nitobond SBR: 5 and 25 litre drums

with all cementitious materials, Renderoc HB40 must be cured

Nitobond AR: 20 litre drums

immediately after finishing in accordance with good concrete

practice. The use of Nitobond AR or Concure WB, sprayed on to Nitobond EP Slowset: 4 litre packs

the surface of the finished Renderoc in a continuous film, is Coverage and yield

recommended. In harsh drying conditions, supplementary curing Renderoc HB40: Approximately 16 litres per 25 kg bag

such as polythene sheeting must be used. Concure WB must (16mm thickness per m2 per 25kg bag)

be removed before overcoating.

Nitoprime Zincrich WB: 7.4 m2/litre

Overcoating

Nitobond SBR: 2 to 5 m2/litre

The completed area of the repair can be overcoated generally (diluted as slurry bond coat)

after 24 hours. Fosroc recommends the use of the Dekguard

range of protective, anti-carbonation coatings. These products Nitobond AR: 6 to 8 m2/litre

also provide a decorative and uniform appearance as well as Nitobond EP Slowset: 10 to 11.5 m2/pack

protecting other areas of the structure which might otherwise Notes: the actual yield per bag of Renderoc HB40 will depend

be at risk from the environment. Dekguard products may be on the consistency used. The coverage figures for liquid

applied over the repair area without prior removal of the products are theoretical - due to wastage factors and the

Nitobond AR curing membrane. Other curing membranes variety and nature of possible substrates, practical coverage

must be removed prior to the application of Dekguard products. figures will be reduced.

Sampling Procedure

Fosroc standard test methods must be employed when Storage

performance testing this product. For full information please Shelf life

contact your local Fosroc office.

All products have a shelf life of 9 months if kept in a dry store

in the original, unopened bags or packs.

Limitations

Storage conditions

Renderoc HB40 should not be used when the temperature is

below 5°C and falling. Do not mix part bags. Due to the Store in dry conditions in the original, unopened bags or

medium weight nature of Renderoc HB40, the product should packs. If stored at high temperatures and/or high humidity

not be used in areas subject to traffic. Exposure to heavy conditions the shelf life may be reduced. Nitobond SBR, and

rainfall prior to the final set may result in surface scour. Nitobond AR should be protected from frost.

Estimating

Supply

Note: In accordance with Commercial or Health & Safety

requirements packaging detail may alter. Please contact your

local Fosroc office for detail.

constructive solutions page 3

Renderoc HB40

Precautions Additional information

Health and safety Fosroc manufactures a wide range of products specifically

designed for the repair and refurbishment of damaged

Renderoc HB40 contains cement powders which, during

reinforced concrete. This includes hand-placed and spray

normal use, have no harmful effect on dry skin. However, when

grade repair mortars, fluid micro-concretes, chemical-

Renderoc HB40 is mixed, or becomes damp, alkali is released

resistant epoxy mortars and a comprehensive package of

which can be harmful to the skin. During use, avoid inhalation

protective coatings. In addition, a wide range of complementary

of dust and contact with skin and eyes. Nitoprime Zincrich WB

products is available. This includes joint sealants,

and Nitobond products should not be allowed to come into

waterproofing membranes, grouting, anchoring and

contact with skin or eyes or be swallowed.

specialised flooring materials.

Wear suitable gloves, eye protection and dust masks. The

Fosroc have also produced several educational training videos

use of barrier creams is recommended. In case of contact with

which provide more detail about the mechanisms which

skin, wash with clean water. In case of contact with eyes, rinse

cause corrosion within reinforced concrete structures and the

immediately with plenty of clean water and seek medical

solutions which are available to arrest or retard these

advice. If swallowed, seek medical attention immediately - do

destructive mechanisms.

not induce vomiting.

For further information about products, training videos or

For further information see relevant Material Safety Data

publications, contact the local Fosroc office.

Sheet.

Fire

Renderoc HB40, Nitobond SBR, Nitobond AR and Nitoprime

Zincrich WB are non-flammable.

Flash points

Nitoprime Zincrich WB: 16°C

Renderoc is the trademark of Fosroc International Limited.

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard

Conditions for the Supply of Goods and Service, copies of which may be obtained on request. Whilst Fosroc endeavours

to ensure that any advice, recommendation, specification or information it may give is accurate and correct, it cannot,

because it has no direct or continuous control over where or how its products are applied, accept any liability either directly

or indirectly arising from the use of its products, whether or not in accordance with any advice, specification,

recommendation or information given by it.

SALES OFFICES IN GREATER CHINA REGION

Fosroc

Hong Kong Ltd. Fosroc Guangzhou Limited

No. 7 Hong Yuan Road, Eastern Section, Guangzhou Economic & Technological Development

2001-5A, Pacific Plaza District, Guangzhou 510760, China

410 Des Voeux Road West

Tel: +(86-20) 8226 9245 Fax: +(86-20) 8226 8010 email: china@fosroc.com

Hong Kong

Tel: (852) 2882 8662 We also have offices in the following locations :

Fax: (852) 2895 2931 Macao, Taiwan (Distributor), Beijing, Chongqing, Shanghai and Suzhou

Email: hongkong@fosroc.com For Macao & Taiwan, please contact Fosroc Hong Kong office.

www.fosroc.com For other cities in China, please contact Fosroc Guangzhou office.

FIL/JUL/12/J

Potrebbero piacerti anche

- Functional Polymer Coatings: Principles, Methods, and ApplicationsDa EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsValutazione: 1 su 5 stelle1/5 (1)

- Renderoc HB25: Constructive SolutionsDocumento4 pagineRenderoc HB25: Constructive SolutionsDoby YuniardiNessuna valutazione finora

- Corrosion: Corrosion ControlDa EverandCorrosion: Corrosion ControlL L ShreirValutazione: 5 su 5 stelle5/5 (1)

- Renderoc HB40 TDS.2018Documento5 pagineRenderoc HB40 TDS.2018Joan FosterNessuna valutazione finora

- Renderoc HB40 NewDocumento5 pagineRenderoc HB40 NewJayvee G. DignosNessuna valutazione finora

- Fosroc Renderoc HBS Mar 10Documento4 pagineFosroc Renderoc HBS Mar 10Nikola ArsovskiNessuna valutazione finora

- Renderoc S: Constructive SolutionsDocumento4 pagineRenderoc S: Constructive SolutionstalatzahoorNessuna valutazione finora

- Fosroc Renderoc HB: Technical Data SheetDocumento4 pagineFosroc Renderoc HB: Technical Data SheetRJNessuna valutazione finora

- Renderoc TG: Trowel Grade Cementitous Repair MortarDocumento2 pagineRenderoc TG: Trowel Grade Cementitous Repair Mortarmohammad khabibNessuna valutazione finora

- Renderoc TGDocumento2 pagineRenderoc TGMansoor Ali50% (2)

- Renderoc HB40 TDSDocumento4 pagineRenderoc HB40 TDSLucasNessuna valutazione finora

- Fosroc Renderoc TG: Constructive SolutionsDocumento2 pagineFosroc Renderoc TG: Constructive SolutionsVincent JavateNessuna valutazione finora

- Renderoc HS PDFDocumento2 pagineRenderoc HS PDFMuhammed KunnappillyNessuna valutazione finora

- Brushbond RFX PDFDocumento2 pagineBrushbond RFX PDFDeep GandhiNessuna valutazione finora

- Brush BondDocumento4 pagineBrush BondGibbs PerNessuna valutazione finora

- RCT-ConRep FR MortarDocumento2 pagineRCT-ConRep FR MortarfahadNessuna valutazione finora

- TDS Renderoc LAXtra India3Documento2 pagineTDS Renderoc LAXtra India3ARCHANA GUPTANessuna valutazione finora

- TDS Renderoc RG IndiaDocumento3 pagineTDS Renderoc RG IndiaBijaya RaulaNessuna valutazione finora

- Ikote CM 50X TDS (02-April-2024) V1.3Documento2 pagineIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNessuna valutazione finora

- Renderoc RGDocumento3 pagineRenderoc RGR.ThangarajNessuna valutazione finora

- TDS Renderoc LAXtra IndiaDocumento2 pagineTDS Renderoc LAXtra IndiaSHAIK ASIMUDDINNessuna valutazione finora

- RFX 1Documento3 pagineRFX 1Easwarakumar NNessuna valutazione finora

- TDS Renderoc RG IndiaDocumento3 pagineTDS Renderoc RG IndiaPrad RNessuna valutazione finora

- TDS Renderoc RG India PDFDocumento3 pagineTDS Renderoc RG India PDFrajiv_quantumNessuna valutazione finora

- TDS Renderoc RGM IndiaDocumento4 pagineTDS Renderoc RGM IndiaKishore Nayak kNessuna valutazione finora

- Fosroc Brushbond: Uses Design CriteriaDocumento4 pagineFosroc Brushbond: Uses Design CriteriaSabyasachi BangalNessuna valutazione finora

- TEC-030100.2-MET-DoR-002-Fosroc1B-Renderoc HS (High Strenght) (Shrinkage Compensated, Polymer Modified, FibreDocumento2 pagineTEC-030100.2-MET-DoR-002-Fosroc1B-Renderoc HS (High Strenght) (Shrinkage Compensated, Polymer Modified, FibreEli MatucadNessuna valutazione finora

- Renderoc HSDocumento2 pagineRenderoc HSMansoor AliNessuna valutazione finora

- TDS Renderoc TG Saudi ArabiaDocumento4 pagineTDS Renderoc TG Saudi Arabiaumn_mlkNessuna valutazione finora

- Nitomortar HBDocumento4 pagineNitomortar HBMansoor AliNessuna valutazione finora

- Premcrete Hydroseal FX - TDSDocumento3 paginePremcrete Hydroseal FX - TDSSorin TantauNessuna valutazione finora

- Fosroc Renderoc Tgxtra: Constructive SolutionsDocumento2 pagineFosroc Renderoc Tgxtra: Constructive SolutionsVincent JavateNessuna valutazione finora

- Fosroc Nitomortar HB: Constructive SolutionsDocumento4 pagineFosroc Nitomortar HB: Constructive SolutionsVincent JavateNessuna valutazione finora

- Brushbond RFXDocumento2 pagineBrushbond RFXaneesh kapaNessuna valutazione finora

- Brushbond RFXDocumento2 pagineBrushbond RFXaneesh kapaNessuna valutazione finora

- Conbextra HF: Shrinkage Compensated Cementitious Precision GroutDocumento4 pagineConbextra HF: Shrinkage Compensated Cementitious Precision GroutbinodNessuna valutazione finora

- Renderoc PlugDocumento5 pagineRenderoc PlugtalatzahoorNessuna valutazione finora

- iKOTE CM 40X (TDS) 02-APRIL-2024Documento2 pagineiKOTE CM 40X (TDS) 02-APRIL-2024nguyen hoang AnhNessuna valutazione finora

- Nitomortar ELDocumento4 pagineNitomortar ELMansoor AliNessuna valutazione finora

- Renderoc RG: Constructive SolutionsDocumento3 pagineRenderoc RG: Constructive Solutionsmohammad khabibNessuna valutazione finora

- Brushbond RFX PDFDocumento2 pagineBrushbond RFX PDFpiyu114Nessuna valutazione finora

- TDS Renderoc RG SPL India2Documento3 pagineTDS Renderoc RG SPL India2Sam WitwickyNessuna valutazione finora

- Nitomortar MHDocumento4 pagineNitomortar MHMansoor AliNessuna valutazione finora

- Fosroc Renderoc Laxtra: Constructive SolutionsDocumento2 pagineFosroc Renderoc Laxtra: Constructive SolutionsVincent JavateNessuna valutazione finora

- Rebar Primer/Bond-Ci: Cementitious Corrosion Protection and Bonding AgentDocumento2 pagineRebar Primer/Bond-Ci: Cementitious Corrosion Protection and Bonding AgentAbel BerhanemeskelNessuna valutazione finora

- Datasheet File Conbextra - HFDocumento4 pagineDatasheet File Conbextra - HFandikaNessuna valutazione finora

- TDS Renderoc HSXtra IndiaDocumento2 pagineTDS Renderoc HSXtra IndiaZulfikar A. SheriNessuna valutazione finora

- Masterbrace Adh 1406Documento3 pagineMasterbrace Adh 1406akhemraNessuna valutazione finora

- Masteremaco S 422Documento3 pagineMasteremaco S 422shahidNessuna valutazione finora

- TDS Renderoc RG SPL IndiaDocumento3 pagineTDS Renderoc RG SPL IndiaKumar SundaramNessuna valutazione finora

- TDS Renderoc RG SPL IndiaDocumento3 pagineTDS Renderoc RG SPL IndialavekushNessuna valutazione finora

- Sika Rapid Repair Mortar PDS - CE - PDFDocumento6 pagineSika Rapid Repair Mortar PDS - CE - PDFLouis BirNessuna valutazione finora

- Renderoc RGDocumento4 pagineRenderoc RGvenkatasuri999Nessuna valutazione finora

- Fosroc Renderoc RsxtraDocumento4 pagineFosroc Renderoc RsxtraVincent JavateNessuna valutazione finora

- Brushbond RFXDocumento2 pagineBrushbond RFX폴로 쥰 차Nessuna valutazione finora

- Conbextra GP TDS RE GroutingDocumento5 pagineConbextra GP TDS RE Groutingkhraieric16Nessuna valutazione finora

- Product Summary Catalogue: Creating Solutions For ConstructionDocumento46 pagineProduct Summary Catalogue: Creating Solutions For Constructionpiyu114Nessuna valutazione finora

- Renderoc FC: Single Component Polymer Modified Cementitious Fairing CoatDocumento3 pagineRenderoc FC: Single Component Polymer Modified Cementitious Fairing CoatAbdul Nazir - 11858 Hawiyah Branch - QCNessuna valutazione finora

- Renderoc HSXtraDocumento2 pagineRenderoc HSXtraPremNessuna valutazione finora

- Fosroc Brushbond PDFDocumento4 pagineFosroc Brushbond PDFnavin jollyNessuna valutazione finora

- MS-Precon + Drainage Board-R3 26.3.2020)Documento4 pagineMS-Precon + Drainage Board-R3 26.3.2020)sammyNessuna valutazione finora

- A Guide To The Air Pollution Control (Volatile Organic Compounds) RegulationDocumento63 pagineA Guide To The Air Pollution Control (Volatile Organic Compounds) RegulationsammyNessuna valutazione finora

- Plu 14Documento82 paginePlu 14sammyNessuna valutazione finora

- Drawing No. RevDocumento2 pagineDrawing No. RevsammyNessuna valutazione finora

- Drawing No. RevDocumento6 pagineDrawing No. RevsammyNessuna valutazione finora

- Drawing No. RevDocumento6 pagineDrawing No. RevsammyNessuna valutazione finora

- A-016 Phase 3 Drawing No. Rev. Drawing Title: KL48/3/BLK/A/LO-12 BDocumento4 pagineA-016 Phase 3 Drawing No. Rev. Drawing Title: KL48/3/BLK/A/LO-12 BsammyNessuna valutazione finora

- 7 - Why Is The Ocean SaltyDocumento7 pagine7 - Why Is The Ocean SaltyA dumNessuna valutazione finora

- Worksheet 25 Redox KeyDocumento7 pagineWorksheet 25 Redox KeysamareshcmondalNessuna valutazione finora

- Basic Concept in ChemistryDocumento15 pagineBasic Concept in ChemistryPrithviraj Netke0% (1)

- Phenbol ReactionDocumento3 paginePhenbol Reactionilias1973Nessuna valutazione finora

- Class 10 Science Metals and Non-Metals WorksheetDocumento2 pagineClass 10 Science Metals and Non-Metals WorksheetSiddharth SreeKumarNessuna valutazione finora

- Board of Intermediate Education: Senior Inter Model Paper ChemistryDocumento2 pagineBoard of Intermediate Education: Senior Inter Model Paper Chemistryrathod adithNessuna valutazione finora

- Basics of Methanogenesis in Anaerobic DigesterDocumento25 pagineBasics of Methanogenesis in Anaerobic DigesterErnesto AcevedoNessuna valutazione finora

- SteelDocumento1 paginaSteelgego2Nessuna valutazione finora

- Group B Erection & Commissioning of Cold Rolling MillDocumento2 pagineGroup B Erection & Commissioning of Cold Rolling MillPiyush PanchalNessuna valutazione finora

- Production of BioplasticDocumento7 pagineProduction of Bioplasticpritesh tamboliNessuna valutazione finora

- Fairfield Atlas Limited Shinoli Metallurgical Technical Delivery Specification TDS No: TDS/ P 0110790 Rev No: 02 Page No: 1 of 3Documento4 pagineFairfield Atlas Limited Shinoli Metallurgical Technical Delivery Specification TDS No: TDS/ P 0110790 Rev No: 02 Page No: 1 of 3Andras StegerNessuna valutazione finora

- Lab Activity 4 PolysaccharidesDocumento17 pagineLab Activity 4 Polysaccharidescryxx jdnNessuna valutazione finora

- RP 04 - Identification of Cations and AnionsDocumento9 pagineRP 04 - Identification of Cations and AnionsAnything Anywhere AnytimeNessuna valutazione finora

- Smart Prep Cibacron On SlavosDocumento4 pagineSmart Prep Cibacron On SlavosagnberbcNessuna valutazione finora

- A Review On Design and Fabrication of Fuel Fired Crucible FurnaceDocumento12 pagineA Review On Design and Fabrication of Fuel Fired Crucible FurnaceJamilu TankoNessuna valutazione finora

- Nickel Aluminum Bronze GuideDocumento9 pagineNickel Aluminum Bronze GuideAnoir AkkariNessuna valutazione finora

- Production of Vinyl Chloride Process SelectionDocumento58 pagineProduction of Vinyl Chloride Process SelectionAngela Clariz DulaNessuna valutazione finora

- Materials For Energy Efficiency: Thermoelectrics, Thin Films, and Phosphors - Material Matters v6n4Documento32 pagineMaterials For Energy Efficiency: Thermoelectrics, Thin Films, and Phosphors - Material Matters v6n4Sigma-AldrichNessuna valutazione finora

- Glukosa DialabDocumento2 pagineGlukosa DialabDian Ayu UtamiNessuna valutazione finora

- Hdpe PyrolysisDocumento8 pagineHdpe Pyrolysiswinifred ekpoNessuna valutazione finora

- Basic Principles of Chemistry Practicals PDFDocumento42 pagineBasic Principles of Chemistry Practicals PDFJoscobu Juma100% (1)

- BASF Oilfield-Solutions StimulationDocumento6 pagineBASF Oilfield-Solutions StimulationRonald Figo Torres Eche100% (1)

- Cathodic ProtectionDocumento12 pagineCathodic ProtectionIndhumathi BabusenanNessuna valutazione finora

- Ss Wire Properties / Orthodontic Courses by Indian Dental AcademyDocumento79 pagineSs Wire Properties / Orthodontic Courses by Indian Dental Academyindian dental academyNessuna valutazione finora

- DOST RDI Laboratory ServicesDocumento38 pagineDOST RDI Laboratory ServicesAtlas CerboNessuna valutazione finora

- TALAT Lecture 2101.01: Understanding Aluminium As A MaterialDocumento23 pagineTALAT Lecture 2101.01: Understanding Aluminium As A MaterialCORE MaterialsNessuna valutazione finora

- 19 Petrucci10e CSMDocumento52 pagine19 Petrucci10e CSMPhạm Hoàng NamNessuna valutazione finora

- Electrochemical Series: Petr VanýsekDocumento10 pagineElectrochemical Series: Petr VanýsekMycoLogist4LifeNessuna valutazione finora

- How Is Plastic Made A Simple Step-By-Step ExplanationDocumento12 pagineHow Is Plastic Made A Simple Step-By-Step Explanationsalemg82Nessuna valutazione finora

- NLC 4Documento15 pagineNLC 4vidhi parekhNessuna valutazione finora