Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

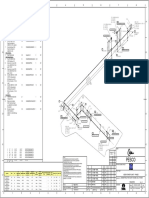

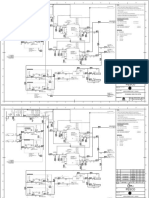

Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 Area

Caricato da

Valesh MonisTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 Area

Caricato da

Valesh MonisCopyright:

Formati disponibili

1 2 3 4 5 6 7 8

PART MATERIAL DESCRIPTION SIZE ITEM CODE QTY. SPEC

No

FABRICATION MATERIALS

N

1 Threaded flange, CL150, 25 FACAHABZZAADABQZZUS 2 B10 TO GT#11 AREA

Raised-face flanged end, E 394705

ASME-B16.5, A105, Galvanised N 265622

ERECTION MATERIALS EL +917

A A

2 Pipe, MTE, Galvanized, 25 PAAZZBNAEABAABOAAZZUS 2.8 M SCREWED END

166

ASME-B36.10M, A53-B, Seamless,

<6> 2

S-40

25DN

3 90 degree elbow, Female 25 MCKAWBUAEAAGABQZZUS 4 B10

threaded end, 127

Galvanized,ASME-B16.11, A105, F1 G4 B5

CL 3000 6

F1 G4 B5 STEM EAST

800

4 Spiral wound, CL150, 4.5mm, 25 GMAHAOAABFMUS 2 B10 11PCB57AA001

ASME-B16.20, SS316 (Asbestos

Free)

474

5 Stud Bolt, ASME-B18.2.1, ASTM 1/2 BAZZZZZZAAYBFZZZUS 8 B10

<5> 2

A193-B7, hot dip galvanized , With 2

heavy Hex nuts A194 Gr.2H and

2 washers - 75 mm Length

6 Globe valve, CL150, Raised 25 VALAHBUAEAAFABQZZZZUS 1 B10

B Face Flange end, Galvanized, B

27

ASME-B16.10, A105 27

5

27 39 1

34 3

2

>

<4

27

3

EL +117

511

458

<3> 2

C C

27 27

3

2

>

<2

59

10 06

10

D 27 D

27

3

289

EL -394

263

<1> 2

SEE ISO

11PCB50BR002

E 393252

N 265622 40DN

EL -683

E E

40X25DN

6 165 25 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS OWNER

5 474 25 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS

4 341 25 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS DISTRIBUTION W/C

3 458 25 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS MATRIX

2 1006 25 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS

1 263 25 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS NOTES:- EPC

PIECE

NO

LENGTH

MM

SIZE

MM

END PREP END PREP ITEM CODE

1. ALL DIMENSIONS AND ELEVATIONS ARE IN MILLIMETERS

2. FINISHED GROUND LEVEL (FGL) OF PLANT IS (-)0.300 WHICH

CORRESPONDS TO MSL (+)8.50M

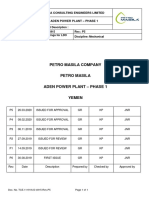

PESCO

3. FOR PAINTING & SURFACE PREPARATION DETAILS REFER "TECHNICAL

SPECIFICATION FOR PAITING" DOC NO. TCE.11191A-SP-3903 MAIN PLANT EQUIPMENT SUPPLIER

4. FOR INSULATION DETAILS REFER "TECHNICAL SPECIFICATION FOR

INSULATION" DOC NO. TCE.11191A-SP-3902

5. ALL ELEVATIONS INDICATED ARE CENTER LINE OF PIPES UNLESS

OTHERWISE NOTED. PROJECT NAME

6. SMALL BORE PIPING (DN 50 & BELOW) ARE FIELD RUN. ISOMETRICS

ISSUED FOR THE SAME IS INDICATIVE AND MAY BE ADJUSTED TO SUIT ADEN POWER PLANT - PHASE 1

F SITE CONDITIONS. F

7. FOR SUPPORT ARRANGEMENT, REFER TYPICAL STANDARD SKETCH

DRAWING - TCE.11191A-D-4909 DRAWING TITLE ISOMETRICS FOR RAW WATER AND SERVICE

8. VICTAULIC PIPE FITTINGS SHALL NOT REST ON SUPPORTS AND SHALL

R0

WATER DISTRIBUTION SYSTEM

HAVE AMPLE CLEARANCE FROM SUPPORT.

11PCB57BR001 01 of 01

P&ID NO. ENGINEERING JOB No. DRAWING NUMBER REV

PIPING LAYOUT DRAWING NO. No. DATE REVISION DESCRIPTION BY CHK APPR Civil Mech Elect I/C PIP HSE PROS

11191A TCE.11191A-D-4916 R0

FILE NAME 11PCB57BR001.SHA DATE : DESIGNED : DRAWN : CHEF ENGR : TATA CONSULTING ENGINEERS LIMITED

1 2 3 4 5 6 7 8

Potrebbero piacerti anche

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- A B C C 2: A1-Tr5m-L4-001 A1-Tr5m-Iso-004 A1-Tr5m-L4-001Documento1 paginaA B C C 2: A1-Tr5m-L4-001 A1-Tr5m-Iso-004 A1-Tr5m-L4-001faviikaujaNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Chwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)Documento1 paginaChwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)vishwas salunkheNessuna valutazione finora

- Lista de Materiales: Item Diam Cant DescripcionDocumento1 paginaLista de Materiales: Item Diam Cant DescripcionMarcia IturraNessuna valutazione finora

- Fabrication materials listDocumento1 paginaFabrication materials listthe.avishekkNessuna valutazione finora

- 6 NOS Ø17 HOLES ON 210 PCD EQUISPACED FULL GEAR COUPLINGDocumento1 pagina6 NOS Ø17 HOLES ON 210 PCD EQUISPACED FULL GEAR COUPLINGShyam J VyasNessuna valutazione finora

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocumento1 paginaFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNessuna valutazione finora

- Fabrication materials and pipe supports bill of materialsDocumento1 paginaFabrication materials and pipe supports bill of materialsValesh MonisNessuna valutazione finora

- Fabrication materials and pipe supports bill of materialsDocumento1 paginaFabrication materials and pipe supports bill of materialsValesh MonisNessuna valutazione finora

- Chwr-1021-Cs-100-Ic-40 - Sheet (1 of 1)Documento1 paginaChwr-1021-Cs-100-Ic-40 - Sheet (1 of 1)vishwas salunkheNessuna valutazione finora

- 50 10xaa1 He40 21RDCH 1016Documento1 pagina50 10xaa1 He40 21RDCH 1016uma raneNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- (09-2) - L-ZL (26) 26RG01B.001 PDFDocumento1 pagina(09-2) - L-ZL (26) 26RG01B.001 PDFRaznan RamliNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Dometic SNG 420Documento2 pagineDometic SNG 420bagasNessuna valutazione finora

- BILL OF MATERIALSDocumento1 paginaBILL OF MATERIALSABAID ULLAHNessuna valutazione finora

- 1u01 WW 9002 01Documento1 pagina1u01 WW 9002 01syslor.kimNessuna valutazione finora

- Va1048 2Documento1 paginaVa1048 2陆军Nessuna valutazione finora

- FABRICATION MATERIALS LISTDocumento1 paginaFABRICATION MATERIALS LISTSaptarshi MandalNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 50 10xaa1 He40 22RDCH 1016Documento1 pagina50 10xaa1 He40 22RDCH 1016uma raneNessuna valutazione finora

- All Piping Drawings Spec SheetsDocumento18 pagineAll Piping Drawings Spec Sheetsc.reidNessuna valutazione finora

- 150 10xaa1 H50 21RDCH 1004 1Documento1 pagina150 10xaa1 H50 21RDCH 1004 1uma raneNessuna valutazione finora

- Nozzle Schedule: General NotesDocumento1 paginaNozzle Schedule: General NotesArielNessuna valutazione finora

- Fabrication Materials ListDocumento1 paginaFabrication Materials ListSaptarshi MandalNessuna valutazione finora

- Riau GFPP (275Mw) Ipp Project: Pt. Medco Ratch Power Riau Lotte Engineering & ConstructionDocumento1 paginaRiau GFPP (275Mw) Ipp Project: Pt. Medco Ratch Power Riau Lotte Engineering & ConstructionFebri NuansaNessuna valutazione finora

- 10GHA25BR501 Sheet1 ModelDocumento1 pagina10GHA25BR501 Sheet1 ModelFebri NuansaNessuna valutazione finora

- 10ENA01BR004 Sheet5-ModelDocumento1 pagina10ENA01BR004 Sheet5-ModelValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- General Arrangement Drawing For Slug Catcher Rev.c IfaDocumento1 paginaGeneral Arrangement Drawing For Slug Catcher Rev.c IfaMe RahmanNessuna valutazione finora

- La253x.ca100v-008 R02Documento2 pagineLa253x.ca100v-008 R02Ricardo TurinNessuna valutazione finora

- 2300 52 AAA BD 280 282181 01 - RevS1Documento1 pagina2300 52 AAA BD 280 282181 01 - RevS1CosminMarianNessuna valutazione finora

- Item 3 - GA10010211 PN 400824Documento1 paginaItem 3 - GA10010211 PN 400824Pablo GarcíaNessuna valutazione finora

- 202366-VP10-DWG-002 - Rev.1 Detail Drawing For Inlet Compressor Filter Separator F-1011Documento6 pagine202366-VP10-DWG-002 - Rev.1 Detail Drawing For Inlet Compressor Filter Separator F-1011Pham LanphuongNessuna valutazione finora

- 6 Nos Ø17 Holes On 185 PCD Equispaced.: Bore CapacityDocumento1 pagina6 Nos Ø17 Holes On 185 PCD Equispaced.: Bore CapacityShyam J VyasNessuna valutazione finora

- Gate Valve Class 1500Documento1 paginaGate Valve Class 1500Hamdi Al-sarooryNessuna valutazione finora

- Ga 219585 1Documento1 paginaGa 219585 1phantuan080213Nessuna valutazione finora

- Ocr TestDocumento8 pagineOcr TestAirNessuna valutazione finora

- Material List - Fabrication: PT. Size Description QTYDocumento4 pagineMaterial List - Fabrication: PT. Size Description QTYmixmixmixNessuna valutazione finora

- For ConstructionDocumento5 pagineFor ConstructionBasem AlsaftliNessuna valutazione finora

- Material List - Fabrication: - / - A1ZA-1 2 PMDocumento2 pagineMaterial List - Fabrication: - / - A1ZA-1 2 PMMallela Sampath KumarNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Piping Isometric - 3Documento1 paginaPiping Isometric - 3CosminMarianNessuna valutazione finora

- 9100 Series - CD220628Documento6 pagine9100 Series - CD220628Eduardo TapiaNessuna valutazione finora

- PIPE AND FLANGE PART DETAILSDocumento1 paginaPIPE AND FLANGE PART DETAILSfaviikaujaNessuna valutazione finora

- 6 Nos Ø13 Holes On 155 PCD Equispaced.: Bore CapacityDocumento1 pagina6 Nos Ø13 Holes On 155 PCD Equispaced.: Bore CapacityShyam J VyasNessuna valutazione finora

- Collar Flexible Plano General-1Documento1 paginaCollar Flexible Plano General-1jarryNessuna valutazione finora

- Material List for Piping ComponentsDocumento1 paginaMaterial List for Piping Componentsvishwas salunkheNessuna valutazione finora

- Tumbler Steam Jacketed Kettle Section: ManholeDocumento1 paginaTumbler Steam Jacketed Kettle Section: ManholeDhee SulvitechNessuna valutazione finora

- So6625 218M1 218M1L So6625-Eh0d-Iso-218m1l-094 01 Er-000 01Documento1 paginaSo6625 218M1 218M1L So6625-Eh0d-Iso-218m1l-094 01 Er-000 01Humberto MatusNessuna valutazione finora

- Tal Wsa PNG Iso 1P020807 - 00 - A01 - 00Documento1 paginaTal Wsa PNG Iso 1P020807 - 00 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNessuna valutazione finora

- Fabrication and Erection Materials Bill of MaterialsDocumento1 paginaFabrication and Erection Materials Bill of MaterialsValesh MonisNessuna valutazione finora

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocumento1 paginaFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNessuna valutazione finora

- Celebrate Learning Labels and OrganizersDa EverandCelebrate Learning Labels and OrganizersNessuna valutazione finora

- 10ENA01BR003 Sheet3-ModelDocumento1 pagina10ENA01BR003 Sheet3-ModelValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pipe Support Fabrication and Erection Materials ListDocumento1 paginaPipe Support Fabrication and Erection Materials ListValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Documento1 paginaPetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisNessuna valutazione finora

- 10ENA01BR003 Sheet2-ModelDocumento1 pagina10ENA01BR003 Sheet2-ModelValesh MonisNessuna valutazione finora

- Raw Water & Service Water Distribution System: Isometric Drawing ListDocumento1 paginaRaw Water & Service Water Distribution System: Isometric Drawing ListValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Fabrication and Erection Materials Bill of MaterialsDocumento1 paginaFabrication and Erection Materials Bill of MaterialsValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10ENA01BR003 Sheet1-ModelDocumento1 pagina10ENA01BR003 Sheet1-ModelValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10ENA01BR004 Sheet5-ModelDocumento1 pagina10ENA01BR004 Sheet5-ModelValesh MonisNessuna valutazione finora

- Fabrication materials and pipe supports bill of materialsDocumento1 paginaFabrication materials and pipe supports bill of materialsValesh MonisNessuna valutazione finora

- Fabrication materials and pipe supports bill of materialsDocumento1 paginaFabrication materials and pipe supports bill of materialsValesh MonisNessuna valutazione finora

- Fabrication materials and pipe supports bill of materialsDocumento1 paginaFabrication materials and pipe supports bill of materialsValesh MonisNessuna valutazione finora

- Tce.11191a-D-4213 - Ldo P&id - R4 (Ur)Documento2 pagineTce.11191a-D-4213 - Ldo P&id - R4 (Ur)Valesh MonisNessuna valutazione finora

- TCE LDO Isometric Drawings for Aden Power Plant Phase 1Documento1 paginaTCE LDO Isometric Drawings for Aden Power Plant Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- A Comprehensive Study On IoT Based Accident Detection Systems For Smart VehiclesDocumento18 pagineA Comprehensive Study On IoT Based Accident Detection Systems For Smart VehiclesGajendra M NNessuna valutazione finora

- Expt 8a-Study and Analysis of Hidden Terminal Problem in WLAN Using NetsimDocumento5 pagineExpt 8a-Study and Analysis of Hidden Terminal Problem in WLAN Using NetsimKritika VermaNessuna valutazione finora

- MT8053iE PDFDocumento1 paginaMT8053iE PDFToth VasileNessuna valutazione finora

- 1 AsdDocumento38 pagine1 AsdGianfranco Gallegos RosilloNessuna valutazione finora

- Mathematics Syllabus PDFDocumento5 pagineMathematics Syllabus PDFLETCHUMY A/P MARIPAN MoeNessuna valutazione finora

- CQI and IRCA Certified ISO/IEC 27001:2013 Lead Auditor Training CourseDocumento6 pagineCQI and IRCA Certified ISO/IEC 27001:2013 Lead Auditor Training Coursedigi devaNessuna valutazione finora

- McFarlane Shimmy Dampner ManualDocumento6 pagineMcFarlane Shimmy Dampner ManualmidunNessuna valutazione finora

- Data Sheet 6ES7331-7KF02-0AB0: Supply VoltageDocumento5 pagineData Sheet 6ES7331-7KF02-0AB0: Supply VoltageCatalin OnofrencoNessuna valutazione finora

- Cambio de Cilindro de Dirección 988KDocumento4 pagineCambio de Cilindro de Dirección 988KMAQUINARIAS TRACTOR SHOPNessuna valutazione finora

- The Rate-Diversity Trade-Off For Linear Space-Time Codes: Badri Varadarajan and John R. BarryDocumento5 pagineThe Rate-Diversity Trade-Off For Linear Space-Time Codes: Badri Varadarajan and John R. BarryEMellaNessuna valutazione finora

- ICLTSET 24 BrochureDocumento2 pagineICLTSET 24 BrochureGopinath SNessuna valutazione finora

- What Is Batch Operating System? Advantages and Disadvantages? - Simple Explanation Using AnimationDocumento2 pagineWhat Is Batch Operating System? Advantages and Disadvantages? - Simple Explanation Using AnimationseignNessuna valutazione finora

- CEP Isolation & Normalisation ProcedureDocumento2 pagineCEP Isolation & Normalisation ProcedureVishal GuptaNessuna valutazione finora

- LTE Optimization Parameters Rollout ReportDocumento10 pagineLTE Optimization Parameters Rollout ReportMostafa AdelNessuna valutazione finora

- Enterprise™ Acute Care Beds Model 8000 Service Manual: Build Level 23 Date 22.01.07 Document Reference: 746-436Documento106 pagineEnterprise™ Acute Care Beds Model 8000 Service Manual: Build Level 23 Date 22.01.07 Document Reference: 746-436Yemel Yarbouh ContrerasNessuna valutazione finora

- PassMark - Intel Core I3-10110u at 2.10GHz - Price Performance ComparisonDocumento6 paginePassMark - Intel Core I3-10110u at 2.10GHz - Price Performance ComparisonRONNE PETSON ARAUJO DOS SANTOSNessuna valutazione finora

- AJ&Smart Design Sprint ChecklistDocumento22 pagineAJ&Smart Design Sprint ChecklistTemo GiorgadzeNessuna valutazione finora

- Scraper SiteDocumento3 pagineScraper Sitelinda976Nessuna valutazione finora

- BSBTWK502 Project PortfolioDocumento14 pagineBSBTWK502 Project PortfolioSneha JainNessuna valutazione finora

- Ymca Manila Hostel RatesDocumento2 pagineYmca Manila Hostel RatesJaydee Peregrino-Co100% (2)

- SumaDocumento84 pagineSumaOmar SalahNessuna valutazione finora

- SAP CPS Redwood Expert Seeks Consultant RoleDocumento2 pagineSAP CPS Redwood Expert Seeks Consultant RoleJagadeesh VilenNessuna valutazione finora

- Napoleon, Pompeii, and Steve Jobs: Key Figures in HistoryDocumento2 pagineNapoleon, Pompeii, and Steve Jobs: Key Figures in HistoryĐoàn Nguyễn Phước LộcNessuna valutazione finora

- Your Guide To A Perfect Self-Tape PDFDocumento24 pagineYour Guide To A Perfect Self-Tape PDFJeremy HenryNessuna valutazione finora

- Data MiningDocumento10 pagineData MiningSwatiNessuna valutazione finora

- Subsea Xmas TreeDocumento8 pagineSubsea Xmas Treemadonnite3781100% (1)

- AHRI Standard 1060 I-P 2018 PDFDocumento17 pagineAHRI Standard 1060 I-P 2018 PDFGuy BlouinNessuna valutazione finora

- Lab - Researching Network Attacks and Security Audit ToolsDocumento4 pagineLab - Researching Network Attacks and Security Audit ToolsAlvaro Avila QuirosNessuna valutazione finora

- ICT Era Living ModuleDocumento24 pagineICT Era Living ModuleJohn Chelo Rodriguez100% (9)

- BMS-T017 Issue 2 - Orion IOM Manual PDFDocumento39 pagineBMS-T017 Issue 2 - Orion IOM Manual PDFnatNessuna valutazione finora