Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

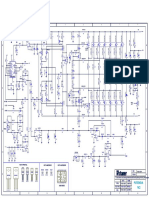

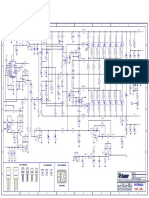

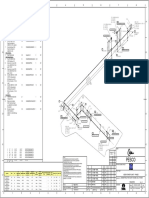

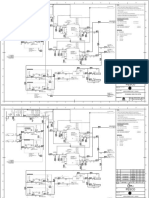

Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1

Caricato da

Valesh MonisTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1

Caricato da

Valesh MonisCopyright:

Formati disponibili

1 2 3 4 5 6 7 8

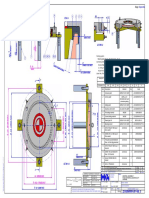

PART MATERIAL DESCRIPTION SIZE ITEM CODE QTY. SPEC

No

FABRICATION MATERIALS

N

1 Tee, Female threaded end, 50X50 MDJAWBUAEAAGABQZZUS 1 B10

Galvanized,ASME-B16.11, A105,

CL 3000

A 2 Threaded flange, CL150, 50 FACAHABZZAADABQZZUS 4 B10 A

Raised-face flanged end,

ASME-B16.5, A105, Galvanised

PIPE SUPPORTS

3 Design Pipe Assembly 50 DesignPipeH_5 1 B10

ERECTION MATERIALS

4 Pipe, MTE, Galvanized, 50 PAAZZBNAEABAABOAAZZUS 2.7 M

ASME-B36.10M, A53-B, Seamless,

19

S-40 2

5 90 degree elbow, Female 50 MCKAWBUAEAAGABQZZUS 3 B10 45

14

threaded end, 6

5

Galvanized,ASME-B16.11, A105, <1

CL 3000 >

SEE ISO 50 4

6 Spiral wound, CL150, 4.5mm, 50 GMAHAOAABFMUS 4 B10 DN

10GCF10BR001 4 45 F2 G6 B7

ASME-B16.20, SS316 (Asbestos >

E 260801 <2

Free) N 225819

B 7 Stud Bolt, ASME-B18.2.1, ASTM 5/8 BAZZZZZZAAYBFZZZUS 16 B10 EL +280 B

A193-B7, hot dip galvanized, 3 61

F2 G6 B7

With 2heavy Hex nuts A194

SCREWED END

Gr.2H and 2 washers - 95 mm F2 G6 B7

Length

8 Gate valve, CL600, Raised face 50 VAAAPBUAEAAFABQZZZZUSF 1 B10

CONN TO

flanged end, ASME-B16.10, A105 1 178 Accumulator/n1

58

50X50DN 25 11 50 mm RFFE 150

E 260801 3 E 261959

4 N 225625

>

45 <3 EL +235

CONN TO 8

COTP-TERMINAL POINTS/TP 14 7 S3

19 STEM UP

50 MM RFFE 150 10GCF10BQ042 10GCF10AA002

E 259550

N 226200

EL +505 45

C C

45

33 37

3 8

<6 45

>

F2 G6 B7 50 4

DN

45

61

5 11

EL +505 4 51

270

<4

> 12

180

<5> 4

D D

45

5

45

E E

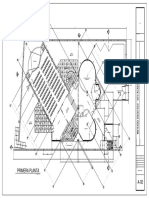

6 326 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS OWNER

5 180 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS

4 1161 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS DISTRIBUTION W/C

3 516 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS MATRIX

2 355 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS

1 140 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS NOTES:- EPC

PIECE

NO

LENGTH

MM

SIZE

MM

END PREP END PREP ITEM CODE

1. ALL DIMENSIONS AND ELEVATIONS ARE IN MILLIMETERS

2. FINISHED GROUND LEVEL (FGL) OF PLANT IS (-)0.300 WHICH

CORRESPONDS TO MSL (+)8.50M

PESCO

3. FOR PAINTING & SURFACE PREPARATION DETAILS REFER "TECHNICAL

SPECIFICATION FOR PAITING" DOC NO. TCE.11191A-SP-3903 MAIN PLANT EQUIPMENT SUPPLIER

4. FOR INSULATION DETAILS REFER "TECHNICAL SPECIFICATION FOR

INSULATION" DOC NO. TCE.11191A-SP-3902

5. ALL ELEVATIONS INDICATED ARE CENTER LINE OF PIPES UNLESS

OTHERWISE NOTED. PROJECT NAME

6. SMALL BORE PIPING (DN 50 & BELOW) ARE FIELD RUN. ISOMETRICS

ISSUED FOR THE SAME IS INDICATIVE AND MAY BE ADJUSTED TO SUIT ADEN POWER PLANT - PHASE 1

F SITE CONDITIONS. F

7. FOR SUPPORT ARRANGEMENT, REFER TYPICAL STANDARD SKETCH

DRAWING - TCE.11191A-D-4909 DRAWING TITLE ISOMETRICS FOR RAW WATER AND SERVICE

8. VICTAULIC PIPE FITTINGS SHALL NOT REST ON SUPPORTS AND SHALL

R0

WATER DISTRIBUTION SYSTEM

HAVE AMPLE CLEARANCE FROM SUPPORT.

10GCF10BR002 01 of 01

P&ID NO. ENGINEERING JOB No. DRAWING NUMBER REV

PIPING LAYOUT DRAWING NO. No. DATE REVISION DESCRIPTION BY CHK APPR Civil Mech Elect I/C PIP HSE PROS

11191A TCE.11191A-D-4916 R0

FILE NAME 10GCF10BR002.SHA DATE : DESIGNED : DRAWN : CHEF ENGR : TATA CONSULTING ENGINEERS LIMITED

1 2 3 4 5 6 7 8

Potrebbero piacerti anche

- M365 BMS NE100R-R0E: BATT - Pack - SCHDocumento2 pagineM365 BMS NE100R-R0E: BATT - Pack - SCHKoma Tozz86% (7)

- 2000 Terex T340 Elec & Hyd SchematicDocumento7 pagine2000 Terex T340 Elec & Hyd SchematicRussMahn100% (1)

- Wd11y021s10Documento28 pagineWd11y021s10cages48160Nessuna valutazione finora

- Proposed Grandview Heights SheetzDocumento9 pagineProposed Grandview Heights SheetzWSYX/WTTENessuna valutazione finora

- Fender Rumble 350 2010 Schematic Rev BDocumento2 pagineFender Rumble 350 2010 Schematic Rev Bqwe123free1231962100% (1)

- WPS Format For AWS D1.1 - WelderDocumento1 paginaWPS Format For AWS D1.1 - WelderThe Welding Inspections Community100% (1)

- SP-1097 DSS Welding Specs PDFDocumento48 pagineSP-1097 DSS Welding Specs PDFHari Prakash GrandheyNessuna valutazione finora

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Documento1 paginaPE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNessuna valutazione finora

- 17 - Guadalajara - TuDocumento1 pagina17 - Guadalajara - TuwinaaleNessuna valutazione finora

- Vendor:: Column Cell No.1 Column Cell Feed DistributorDocumento1 paginaVendor:: Column Cell No.1 Column Cell Feed DistributorJoseph Junior Jahuira TaparaNessuna valutazione finora

- Sensoren BN3300Documento1 paginaSensoren BN3300DumitrescuNessuna valutazione finora

- Scubber Seal Tank (6a25-T12) 12kl-MasterDocumento2 pagineScubber Seal Tank (6a25-T12) 12kl-MasterJayan VKNessuna valutazione finora

- 2210306WW SF1 00 - 3Documento1 pagina2210306WW SF1 00 - 3Victor PodlozovikNessuna valutazione finora

- Parts and Assemblies Simpson and Shipton Short Stroke Steam EngineDocumento2 pagineParts and Assemblies Simpson and Shipton Short Stroke Steam EngineThanh VuNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- RTC 2017Documento1 paginaRTC 2017Marco Antonio Rubiano GómezNessuna valutazione finora

- SRC 2Documento1 paginaSRC 2Marco Antonio Rubiano GómezNessuna valutazione finora

- Corrosion Loops Example 4 - Separator Template1Documento1 paginaCorrosion Loops Example 4 - Separator Template1Christian JoseNessuna valutazione finora

- ZF Ecolife K280Documento1 paginaZF Ecolife K280miltonNessuna valutazione finora

- SET P&ID - Filter Cellar - Tibasosa PDFDocumento9 pagineSET P&ID - Filter Cellar - Tibasosa PDFJairo Hernando Rojas PulidoNessuna valutazione finora

- Peta Topografi Daerah "W" Kabupaten "Z" Jawa Tengah: Disusun OlehDocumento1 paginaPeta Topografi Daerah "W" Kabupaten "Z" Jawa Tengah: Disusun OlehIntan Cahya RahmadiyaniNessuna valutazione finora

- 426-5051-00 - Turck Breakout & BoxRemote ModuleDocumento6 pagine426-5051-00 - Turck Breakout & BoxRemote ModulejNessuna valutazione finora

- Techo Corredizo Modelo 02Documento1 paginaTecho Corredizo Modelo 02orianaNessuna valutazione finora

- 03 FZQK PercussionDocumento1 pagina03 FZQK PercussionAnh Tuan PhamNessuna valutazione finora

- Uniace 100 SCHDocumento1 paginaUniace 100 SCHGabor BodnarNessuna valutazione finora

- Schematic Diagram NV-5001Documento1 paginaSchematic Diagram NV-5001Marco Kersul100% (3)

- Cover Kolom Fasade Gedung ADocumento1 paginaCover Kolom Fasade Gedung ARuang ProjectNessuna valutazione finora

- 20-08-06 Batuan Native Chicken 8-5-2020Documento15 pagine20-08-06 Batuan Native Chicken 8-5-2020julzNessuna valutazione finora

- Compound Waal-ModelDocumento1 paginaCompound Waal-Modelsri projectssNessuna valutazione finora

- B1.2 B2.1 B3 B2.2 B1.3 B1.1: Saddle Arrangement in Intermediate YardDocumento1 paginaB1.2 B2.1 B3 B2.2 B1.3 B1.1: Saddle Arrangement in Intermediate YarddeniNessuna valutazione finora

- Eec Serie KDocumento1 paginaEec Serie KmiltonNessuna valutazione finora

- TP MT5507 PC821+Schematics+DiagramDocumento12 pagineTP MT5507 PC821+Schematics+DiagramHumberto AguilarNessuna valutazione finora

- Ne02 Sas ArchitectureDocumento5 pagineNe02 Sas ArchitectureApoorva BhushanNessuna valutazione finora

- Ems VariosDocumento1 paginaEms VariosmiltonNessuna valutazione finora

- Section R-R: Issued For ConstructionDocumento1 paginaSection R-R: Issued For ConstructionjafarNessuna valutazione finora

- Pergola Design 2Documento1 paginaPergola Design 2raheemNessuna valutazione finora

- Mezzanine Floor Pour Stop Plan: The Berlin Steel Construction CompanyDocumento1 paginaMezzanine Floor Pour Stop Plan: The Berlin Steel Construction Companychandru mpNessuna valutazione finora

- CLED-40A03 (Circuit Diagram) TP - VST59.P83GDocumento7 pagineCLED-40A03 (Circuit Diagram) TP - VST59.P83GLuisMiguelCalvoNessuna valutazione finora

- 2.1. Guía de Acabados Arquitectónicos para Establecimientos de SaludDocumento4 pagine2.1. Guía de Acabados Arquitectónicos para Establecimientos de SaludCristina Quispe QuispeNessuna valutazione finora

- Vigi 003Documento1 paginaVigi 003Cashmere Joy AbutanNessuna valutazione finora

- User Guide AM400-CPU1608TP CPU Module: 5. Communication ConnectionDocumento2 pagineUser Guide AM400-CPU1608TP CPU Module: 5. Communication ConnectionManova JNessuna valutazione finora

- Piping Isometric Building:: Pengerang Cogeneration PlantDocumento1 paginaPiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNessuna valutazione finora

- Romario Red Terciaria 1 17Documento1 paginaRomario Red Terciaria 1 17Carlos Mamani CondoriNessuna valutazione finora

- 29 02 24 SH-09 GFC Beam Details SH-01Documento1 pagina29 02 24 SH-09 GFC Beam Details SH-01prasanth parthasarathyNessuna valutazione finora

- Hydraulic SchematicDocumento2 pagineHydraulic Schematicluis echevarria quispeNessuna valutazione finora

- 1K2 PotDocumento1 pagina1K2 PotcbsomtecladosNessuna valutazione finora

- To Control Unit OCS, See Circuit Diagram 2081507Documento1 paginaTo Control Unit OCS, See Circuit Diagram 2081507andrestkaNessuna valutazione finora

- RT400Documento6 pagineRT400RASMAJON100% (1)

- 2Documento1 pagina2amirul aizadNessuna valutazione finora

- Potencia: Vista Inferior Vista Frontal Vista SupeirorDocumento1 paginaPotencia: Vista Inferior Vista Frontal Vista SupeirorcbsomtecladosNessuna valutazione finora

- Section A-A: Issued For ConstructionDocumento1 paginaSection A-A: Issued For ConstructionjafarNessuna valutazione finora

- Ele Schematic With Links PDFDocumento25 pagineEle Schematic With Links PDFPeter JohnNessuna valutazione finora

- Schematic Diagrams (1/13) Input / Volume BoardDocumento13 pagineSchematic Diagrams (1/13) Input / Volume BoardWinger ZsNessuna valutazione finora

- DENON AVR-1905 SchematicDocumento13 pagineDENON AVR-1905 SchematicGuillaume HubertNessuna valutazione finora

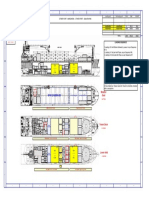

- MARGHERA Preliminary Stowage Plan MV Beautrident - Rev.11.03.2022Documento1 paginaMARGHERA Preliminary Stowage Plan MV Beautrident - Rev.11.03.2022Oleksandr ShcherbynaNessuna valutazione finora

- 13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Documento1 pagina13.8Kv U/V Load Shedding Panel-2 +uvls.2: D HA555 P 3-1313003.03 EA-383186 4400004656Anonymous BZQOJwWIh6Nessuna valutazione finora

- Casa Modelo Tipo A-ModelDocumento39 pagineCasa Modelo Tipo A-ModelJuan Pino EcheverríaNessuna valutazione finora

- 511235-1261-1542-2 - 110" Finisher Spool Piece, Finisher To PumpDocumento1 pagina511235-1261-1542-2 - 110" Finisher Spool Piece, Finisher To Pumpxuan anhNessuna valutazione finora

- Issued For Construction: Level 0 FFL 0.022Documento1 paginaIssued For Construction: Level 0 FFL 0.022Sadique PkNessuna valutazione finora

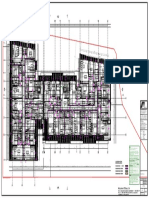

- A05 - Plan Etaj 3 - F-A1Documento1 paginaA05 - Plan Etaj 3 - F-A1Vasiliu AlexandruNessuna valutazione finora

- Instant Assessments for Data Tracking, Grade 5: Language ArtsDa EverandInstant Assessments for Data Tracking, Grade 5: Language ArtsNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaDocumento1 paginaPesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Documento1 paginaPetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisNessuna valutazione finora

- Raw Water & Service Water Distribution System: Isometric Drawing ListDocumento1 paginaRaw Water & Service Water Distribution System: Isometric Drawing ListValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10ENA01BR004 Sheet5-ModelDocumento1 pagina10ENA01BR004 Sheet5-ModelValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10ENA01BR003 Sheet3-ModelDocumento1 pagina10ENA01BR003 Sheet3-ModelValesh MonisNessuna valutazione finora

- 10END30BR001Documento1 pagina10END30BR001Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10ENA01BR003 Sheet2-ModelDocumento1 pagina10ENA01BR003 Sheet2-ModelValesh MonisNessuna valutazione finora

- PESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDDocumento4 paginePESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Asme Team QC Manager WELDING ENGINEER (Under Consideration) CO-ordinator (John) Material Engineer (Mostafa) DC (Under Consideration) Inspector (Omar)Documento2 pagineAsme Team QC Manager WELDING ENGINEER (Under Consideration) CO-ordinator (John) Material Engineer (Mostafa) DC (Under Consideration) Inspector (Omar)Valesh MonisNessuna valutazione finora

- PESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDDocumento4 paginePESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDValesh MonisNessuna valutazione finora

- Tce.11191a-D-4213 - Ldo P&id - R4 (Ur)Documento2 pagineTce.11191a-D-4213 - Ldo P&id - R4 (Ur)Valesh MonisNessuna valutazione finora

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Documento1 paginaPetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisNessuna valutazione finora

- PESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDDocumento4 paginePESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDValesh MonisNessuna valutazione finora

- 02 WordEditingTextDocumento1 pagina02 WordEditingTextValesh MonisNessuna valutazione finora

- API 5L X52 Pipe Specification (PSL1 & PSL2) - Octal SteelDocumento11 pagineAPI 5L X52 Pipe Specification (PSL1 & PSL2) - Octal SteelMULAYAM SINGH YADAVNessuna valutazione finora

- List of Drawings - Mechanical: SR No System Drawing Title Drawing Contents Drawing NoDocumento2 pagineList of Drawings - Mechanical: SR No System Drawing Title Drawing Contents Drawing NoElla CelineNessuna valutazione finora

- Sanand GIDCDocumento22 pagineSanand GIDCmaulik1621976Nessuna valutazione finora

- QCS-2010 Section 20 Part 7 Commissioning of SystemsDocumento6 pagineQCS-2010 Section 20 Part 7 Commissioning of Systemsbryanpastor106Nessuna valutazione finora

- VI XV Xvii Xix XX Xxi: This Page Has Been Reformatted by Knovel To Provide Easier NavigationDocumento15 pagineVI XV Xvii Xix XX Xxi: This Page Has Been Reformatted by Knovel To Provide Easier NavigationsebasfarsaNessuna valutazione finora

- ACO Building DrainageDocumento8 pagineACO Building DrainagepdfNessuna valutazione finora

- Minnesota Rubber and Plastics: Model: Customer: Production Ticket: JOB-BL 19Documento136 pagineMinnesota Rubber and Plastics: Model: Customer: Production Ticket: JOB-BL 19Aldebaran AlcazarNessuna valutazione finora

- Asbestos Graphite Packing RopeDocumento8 pagineAsbestos Graphite Packing RopeGnanasekar VaishniNessuna valutazione finora

- Drainage Handbook: Optional Pipe MaterialsDocumento38 pagineDrainage Handbook: Optional Pipe MaterialsedgarabrahamNessuna valutazione finora

- Venn AirDocumento24 pagineVenn AirpepeNessuna valutazione finora

- BS Iso 11922 - 1Documento21 pagineBS Iso 11922 - 1cpumangeNessuna valutazione finora

- Piping For Process Plants Part-1Documento6 paginePiping For Process Plants Part-1sriman1234Nessuna valutazione finora

- Catalouge For Cenlub ProductDocumento34 pagineCatalouge For Cenlub ProductUdaya Manju50% (2)

- Duze Cooling and Fire Extinguishing Systems For Tanks - EnglishDocumento18 pagineDuze Cooling and Fire Extinguishing Systems For Tanks - EnglishstroiebogdanNessuna valutazione finora

- Bite Type FittingsDocumento42 pagineBite Type FittingsWilson JustinoNessuna valutazione finora

- Platinumstripe™ 1800 Series Pe-Rt Pipe & FittingsDocumento2 paginePlatinumstripe™ 1800 Series Pe-Rt Pipe & Fittingsabdelkader benabdallahNessuna valutazione finora

- Group 7 Plumbing EstimateDocumento1 paginaGroup 7 Plumbing EstimateLorenz BerroyaNessuna valutazione finora

- Group Plant BrochureDocumento52 pagineGroup Plant BrochureAnonymous AdofXEYAgE100% (1)

- ENGINEERING STANDARD - Standard Piping Material SpecificationDocumento33 pagineENGINEERING STANDARD - Standard Piping Material SpecificationGanesh Eshwar100% (2)

- Nfpa 20 ReviewedDocumento6 pagineNfpa 20 Reviewedakill3rNessuna valutazione finora

- أنواع المواسير المختلفه وخواص كل نوع وإستخداماته والمميزات والعيوبDocumento60 pagineأنواع المواسير المختلفه وخواص كل نوع وإستخداماته والمميزات والعيوبMuhammad MedhatNessuna valutazione finora

- Robin Engine EH722 DS 7010Documento29 pagineRobin Engine EH722 DS 7010yewlimNessuna valutazione finora

- Road Signs: 1. - IND-2007 0137 CZ - EN - 20070322 - PROJETDocumento19 pagineRoad Signs: 1. - IND-2007 0137 CZ - EN - 20070322 - PROJETNtemou EleniNessuna valutazione finora

- Pipeline Properties Calculation WorksheetDocumento9 paginePipeline Properties Calculation WorksheetmahalakshmiNessuna valutazione finora

- SSN EPL Mechanical - ManualDocumento84 pagineSSN EPL Mechanical - ManualThejaswar TejaNessuna valutazione finora

- Air Valve Type VENTEX - Standard VersionDocumento7 pagineAir Valve Type VENTEX - Standard VersionchabibNessuna valutazione finora

- CLASS 31451: DEP 31.38.01.15-Gen Class 31451, Rev. G Page 1 of 13Documento13 pagineCLASS 31451: DEP 31.38.01.15-Gen Class 31451, Rev. G Page 1 of 13SaguesoNessuna valutazione finora

- Cost EstimateDocumento11 pagineCost Estimate8790922772Nessuna valutazione finora