Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

WPS-ASME-007-1 Rev0

Caricato da

Ahmed Lepda0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

192 visualizzazioni1 paginaTitolo originale

WPS-ASME-007-1 rev0.xls

Copyright

© © All Rights Reserved

Formati disponibili

XLS, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLS, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

192 visualizzazioni1 paginaWPS-ASME-007-1 Rev0

Caricato da

Ahmed LepdaCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLS, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

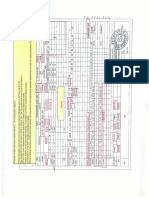

WELDING PROCEDURE SPECIFICATION(WPS)

(ASME SEC. IX)

Project : South Pars Gas Field Development(Phases 9&10) Date : 19 DEC,05

WPS No. CON-WPS-ASME-007-1 Rev. 0 JOINTS (QW-402)

PQR No. CON-PQR-ASME-010 Rev. 0 Joints Design Single V Butt Joint

Welding Process GTAW Backing ■ No for GT □ No

Types Manual □ Semi-Automatic □ Automatic Backing Material or Type N/A

BASE METALS (QW-403) For LTCS

P-No. 1 G-No. 1 to P-No. 1 G-No. 1 37.5 ± 2.5 º

Thickness Range 3 ≤ t ≤ 10.98 mm

Diameter Range All

FILLER METALS (QW-404)

F-No. 6 A-No. 1

Spec. No.(SFA) SFA : 5.28

AWS No.(Class) ER-80S-Ni1

Size of Filler Metal 2.4,3.2

Deposit Thickness Qualified GTAW: Up to 10.98 mm

3.2 ± 1.6 mm 1.6 ± 0.8mm

Trade Name OK Tigrod 13.24 Ø 2.4,3.2

Joint Details

POSITION (QW-405) ELECTRICAL CHARACTERISTICS (QW-409)

Position ALL Current AC or DC DC

Welding Progression Up Hill Polarity, Amps & Volts(Range) DCSP

Tungsten Electrode Size & Type 1.6 ~ 2.4 mm & EWTh-2

PREHEATING & INTERPASS TEMP. (QW-406) Transfer Mode N/A

Preheat Temp. Min. 10 º C Note (1) Wire Feed Speed N/A

Interpass Temp. Max. 130 º C

Preheat Maintenance N/A TECHNIQUE (QW-410)

String or Weave Bead Both

POST WELD HEAT TREATMENT (QW-407) Cleaning Method Grinding & Brushing

Temperature Range ( º C ) N/A Multi or Single pass/side Single

Time Range N/A Single or Multiple Electrodes Single

Heating Rate ( º C ) N/A

Cooling Rate ( º C ) N/A GAS (QW-408)

Percent Composition Gas Mixture Flow Rate(l/min)

Shielding Argon 99.99% (9 ~11)

Trailing N/A N/A N/A

Backing N/A N/A N/A

ELECTRODE

Welding Filler Metal Current Volt Travel Speed

Weld Layers Others

Process Class Dia(mm) Type Polar. Amp Range(A) Range(V) Range(cm/min)

1st & others GTAW ER 80S-Ni1 2.4 & 3.2 DC SP 90 ~ 130 9 ~ 12 6~7 Heat Input(2)

≤13.4 Kj/cm

Note : 1- When Moisture Removal is required (50º )

2- PQR Heat Input≥ WPS Heat input

Name

Signature

Date

SUBCONTRACTOR CONTRACTOR TPA/COMPANY

Page 1 of 1

Potrebbero piacerti anche

- What Every Engineer Should Know AboutDocumento217 pagineWhat Every Engineer Should Know AboutGurpreet Singh DhunnaNessuna valutazione finora

- Testing Rate at RUET 5-9-18Documento5 pagineTesting Rate at RUET 5-9-18tuaburgmailcom100% (4)

- Pwps Jo Wps Asme 016 Rev.001Documento2 paginePwps Jo Wps Asme 016 Rev.001Bagandi ManurungNessuna valutazione finora

- WPS GF170 As 1554.6Documento1 paginaWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- Ferrite Content ReportDocumento2 pagineFerrite Content ReportJawad MunirNessuna valutazione finora

- Solubility Behavior of Organic CompoundsDocumento7 pagineSolubility Behavior of Organic CompoundsWinston Jake Gerolaga100% (2)

- Chapter5 PDFDocumento18 pagineChapter5 PDFAli HassanNessuna valutazione finora

- Lot Inspection Report For LPG New CylindersDocumento3 pagineLot Inspection Report For LPG New CylindersJagannath MajhiNessuna valutazione finora

- Material Safety Data Sheet: Poly Cell AdhesiveDocumento8 pagineMaterial Safety Data Sheet: Poly Cell AdhesiveMinh BảoNessuna valutazione finora

- Satr Nde 2011Documento2 pagineSatr Nde 2011JaseelKanhirathinkalNessuna valutazione finora

- WPS Format For Asme Ix - Wps - Fcaw GmawDocumento1 paginaWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNessuna valutazione finora

- Oil Pantriting ProcedureDocumento5 pagineOil Pantriting ProcedureSERT-QA/QC- BUZNessuna valutazione finora

- NRP QapDocumento10 pagineNRP QapKevin Mathew100% (1)

- Er 100 S 1Documento1 paginaEr 100 S 1Oliver Quezada Inostroza100% (1)

- PDS Na GTS65 PDFDocumento2 paginePDS Na GTS65 PDFMoaatazz NouisriNessuna valutazione finora

- Welding Procedure Specification For GTAWDocumento9 pagineWelding Procedure Specification For GTAWraja reyhanNessuna valutazione finora

- Coded Marking Procedure - CM-01Documento7 pagineCoded Marking Procedure - CM-01carlosNessuna valutazione finora

- Quality Dossier - Control ValvesDocumento67 pagineQuality Dossier - Control ValvesmujeebtalibNessuna valutazione finora

- JNK Heaters Co - LTD: Ferrite Test ReportDocumento1 paginaJNK Heaters Co - LTD: Ferrite Test ReportUzorNessuna valutazione finora

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Documento17 pagineWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNessuna valutazione finora

- Field Joint Coating Installation ProcedureDocumento2 pagineField Joint Coating Installation Procedureunix manNessuna valutazione finora

- PWHTDocumento3 paginePWHTharishcsharmaNessuna valutazione finora

- SA 387 Grade 91 Class 2Documento4 pagineSA 387 Grade 91 Class 2briang-2Nessuna valutazione finora

- CPVC ChecklistDocumento1 paginaCPVC Checklistchakravarthi kanugulaNessuna valutazione finora

- Procedure Qualification Record (PQR) FormDocumento1 paginaProcedure Qualification Record (PQR) FormEarl HarbertNessuna valutazione finora

- PQR (Hdpe)Documento3 paginePQR (Hdpe)abdo elmokademNessuna valutazione finora

- Prorox WM 960 Sa PDFDocumento1 paginaProrox WM 960 Sa PDFr afriantoNessuna valutazione finora

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocumento1 paginaWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedNessuna valutazione finora

- Sample PQR Form (GTAW & SMAW - Page 1) Procedure Qualification Record (PQR)Documento2 pagineSample PQR Form (GTAW & SMAW - Page 1) Procedure Qualification Record (PQR)Luis Carlos Clericci LimonNessuna valutazione finora

- Utoc Preliminary Wps Shell Project 270807 PDFDocumento55 pagineUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNessuna valutazione finora

- SOP Pipe WeldingDocumento1 paginaSOP Pipe WeldingAndre Mars100% (1)

- Original: Mill Test CertificateDocumento3 pagineOriginal: Mill Test CertificateAhmad NafilulhudaNessuna valutazione finora

- Halliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberDocumento7 pagineHalliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberTahseen Ahmed100% (1)

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocumento1 paginaWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- BPV IX-16-3 QW-283 - ButteringDocumento1 paginaBPV IX-16-3 QW-283 - ButteringyutweldingNessuna valutazione finora

- Procedure For Ferrit TestingDocumento11 pagineProcedure For Ferrit TestingKarrar TalibNessuna valutazione finora

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocumento3 pagineN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNessuna valutazione finora

- Table of Content: SR. TitleDocumento2 pagineTable of Content: SR. TitlePratik KarekarNessuna valutazione finora

- Weld Cleaning MethodsDocumento7 pagineWeld Cleaning MethodsTrần Thùy LinhNessuna valutazione finora

- Astm A179 PDFDocumento1 paginaAstm A179 PDFgaminNessuna valutazione finora

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Documento4 paginePQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNessuna valutazione finora

- Flange Weld Testers (FWT)Documento1 paginaFlange Weld Testers (FWT)moonstar_dmeNessuna valutazione finora

- Acceptance Standards UtDocumento3 pagineAcceptance Standards UtAhmed GomaaNessuna valutazione finora

- W14-661 (0 To 40 Bar) PDFDocumento3 pagineW14-661 (0 To 40 Bar) PDFBalaji BobadeNessuna valutazione finora

- Asme WPS Demo PWHT PDFDocumento3 pagineAsme WPS Demo PWHT PDFGanesh rohitNessuna valutazione finora

- Sample WPS 1Documento13 pagineSample WPS 1waqas pirachaNessuna valutazione finora

- Materials System SpecificationDocumento15 pagineMaterials System SpecificationAwais CheemaNessuna valutazione finora

- Cold Tap Coating Report 2Documento1 paginaCold Tap Coating Report 2Jamal BakhtNessuna valutazione finora

- Engineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure SpecificationsDocumento3 pagineEngineering Standards Manual - Welding Standards M Anual - Volume 3 Welding Procedure Specificationslaz_k50% (2)

- Hot Tap ReportDocumento2 pagineHot Tap ReportCak NhassNessuna valutazione finora

- Torque Value DelmonDocumento8 pagineTorque Value DelmonKhalid HaiderNessuna valutazione finora

- Radiation Safety Distance DiagramDocumento3 pagineRadiation Safety Distance DiagramEswaranNessuna valutazione finora

- RT ProcedureDocumento18 pagineRT ProcedureLuong Ho VuNessuna valutazione finora

- 6 MM TCDocumento1 pagina6 MM TCpranesh kadamNessuna valutazione finora

- WPS Format For Asme Ix - Wps - Gtaw SawDocumento1 paginaWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNessuna valutazione finora

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocumento2 pagineBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNessuna valutazione finora

- G8s-5034-02-Bubble Leak TestDocumento4 pagineG8s-5034-02-Bubble Leak TestmaheshNessuna valutazione finora

- Spark Testing of Rubber Lining PDFDocumento2 pagineSpark Testing of Rubber Lining PDFNima Sharifi100% (1)

- Welding Consumables Issuance Record Saudi Aramco Inspection ReportDocumento1 paginaWelding Consumables Issuance Record Saudi Aramco Inspection Reportfariboy123Nessuna valutazione finora

- 1662 15Documento117 pagine1662 15RajamanikkamNessuna valutazione finora

- B H e L Limited RTDocumento13 pagineB H e L Limited RTbhavin17850% (2)

- Hardness Pro Form1Documento2 pagineHardness Pro Form1gst ajah100% (1)

- Industrial radiography A Complete Guide - 2019 EditionDa EverandIndustrial radiography A Complete Guide - 2019 EditionNessuna valutazione finora

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Documento2 pagineWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNessuna valutazione finora

- 5187901TechArticleWebDocLR PDFDocumento7 pagine5187901TechArticleWebDocLR PDFoggay94Nessuna valutazione finora

- Salary Survey: ASNT Conference Edition - Fall 2013Documento27 pagineSalary Survey: ASNT Conference Edition - Fall 2013Ahmed LepdaNessuna valutazione finora

- 8 FFDDocumento129 pagine8 FFDAhmed LepdaNessuna valutazione finora

- A Manual For Steel Detailers, Engineers & Fabricators, Containing Working Drawings & Details For Hot-Dip Galvanized StructuresDocumento24 pagineA Manual For Steel Detailers, Engineers & Fabricators, Containing Working Drawings & Details For Hot-Dip Galvanized StructuresHowo4DieNessuna valutazione finora

- 1 Updated 2159 MergedDocumento2 pagine1 Updated 2159 MergedAhmed LepdaNessuna valutazione finora

- 6.5. Bolt Installation: 5.1. What Can Be Done To Prevent The Nut From Loosening?Documento3 pagine6.5. Bolt Installation: 5.1. What Can Be Done To Prevent The Nut From Loosening?Ahmed LepdaNessuna valutazione finora

- Structural ShapesDocumento21 pagineStructural ShapesjeefryNessuna valutazione finora

- Perforated Expanded Catalog NewDocumento16 paginePerforated Expanded Catalog NewAhmed LepdaNessuna valutazione finora

- Cafco Fendolite Mii Application Guidelines PDFDocumento23 pagineCafco Fendolite Mii Application Guidelines PDFTanmay GorNessuna valutazione finora

- Cafco Fendolite Mii - Data Sheet - LRDocumento3 pagineCafco Fendolite Mii - Data Sheet - LRMohammed Ahtesham100% (1)

- Simultaneous Operations (SIMOPS)Documento156 pagineSimultaneous Operations (SIMOPS)Ahmed Lepda100% (3)

- Cafco ® Fendolite Mii: Application GuideDocumento27 pagineCafco ® Fendolite Mii: Application GuideAhmed LepdaNessuna valutazione finora

- Addressing Anchors (Steelwise Article On Anchor Bolt Fixes)Documento3 pagineAddressing Anchors (Steelwise Article On Anchor Bolt Fixes)Justin UyarNessuna valutazione finora

- Cafco Fendolite Mii - Data Sheet - LRDocumento3 pagineCafco Fendolite Mii - Data Sheet - LRMohammed Ahtesham100% (1)

- Parts of Speech Cheat Sheet: A, An, and The Are Articles That Precede Nouns. We Generally Classify Them As AdjectivesDocumento2 pagineParts of Speech Cheat Sheet: A, An, and The Are Articles That Precede Nouns. We Generally Classify Them As AdjectivesMaria AndreeaNessuna valutazione finora

- 24 Sample ChapterDocumento14 pagine24 Sample ChapterRomyMohanNessuna valutazione finora

- Astm A 153 PDFDocumento4 pagineAstm A 153 PDFmahmoud hegazy100% (5)

- Animal Signal Sheet PDFDocumento2 pagineAnimal Signal Sheet PDF유웃Nessuna valutazione finora

- 24 Sample ChapterDocumento14 pagine24 Sample ChapterRomyMohanNessuna valutazione finora

- Steel WiseDocumento5 pagineSteel WisepicottNessuna valutazione finora

- Design and MaterialDocumento40 pagineDesign and MaterialRavishankarNessuna valutazione finora

- Astm A 563 14pdf PDFDocumento18 pagineAstm A 563 14pdf PDFSathish KumarNessuna valutazione finora

- Carbon and Alloy Steel Nuts (Metric) : Standard Specification ForDocumento9 pagineCarbon and Alloy Steel Nuts (Metric) : Standard Specification ForAhmed LepdaNessuna valutazione finora

- MTC 17022021063931Documento1 paginaMTC 17022021063931Ahmed LepdaNessuna valutazione finora

- AISC - Bolts TCQ Up Side or DownDocumento1 paginaAISC - Bolts TCQ Up Side or DownAhmed LepdaNessuna valutazione finora

- Add To Favorites Contact Us SearchDocumento4 pagineAdd To Favorites Contact Us SearchAhmed LepdaNessuna valutazione finora

- A 325M - 03 PDFDocumento7 pagineA 325M - 03 PDFsergioNessuna valutazione finora

- English Math Revision KG1: Math Numbers & Shapes LinksDocumento9 pagineEnglish Math Revision KG1: Math Numbers & Shapes LinksAhmed LepdaNessuna valutazione finora

- 4th SeminarDocumento70 pagine4th SeminarVeena Goud100% (1)

- Electron Configurations of The Elements (Data Page) - WikipediaDocumento25 pagineElectron Configurations of The Elements (Data Page) - WikipediaAlex OmungaNessuna valutazione finora

- Coal LiquificationDocumento28 pagineCoal LiquificationAugust mishraNessuna valutazione finora

- Hoja Seguridad SikaboomDocumento6 pagineHoja Seguridad SikaboomcristhianNessuna valutazione finora

- Precleaning: Liquid Penetrant InspectionDocumento2 paginePrecleaning: Liquid Penetrant InspectionbalajiNessuna valutazione finora

- Tonicity Determination: Hypertonicity, Hypotonicity and IsotonicityDocumento4 pagineTonicity Determination: Hypertonicity, Hypotonicity and IsotonicityAbegailNessuna valutazione finora

- Matter and It's Properties PDFDocumento55 pagineMatter and It's Properties PDFLemuel Glenn BautistaNessuna valutazione finora

- Native Polycyclic Aromatic Hydrocarbons (PAH) in Coals - A Hardly Recognized Source of Environmental ContaminationDocumento13 pagineNative Polycyclic Aromatic Hydrocarbons (PAH) in Coals - A Hardly Recognized Source of Environmental ContaminationewpNessuna valutazione finora

- Astm A755m 15 FinalDocumento10 pagineAstm A755m 15 FinalarabsniperNessuna valutazione finora

- Diagram Worksheet: Water Molecules: Examiner's NoteDocumento2 pagineDiagram Worksheet: Water Molecules: Examiner's NotenicoleNessuna valutazione finora

- Fabcom Batteries - BrochureDocumento7 pagineFabcom Batteries - BrochureFabcom BatteriesNessuna valutazione finora

- Shot PeeningDocumento11 pagineShot Peeningdnageshm4n244Nessuna valutazione finora

- Evaporated MilkDocumento8 pagineEvaporated MilkAnuradha MarapanaNessuna valutazione finora

- WPS PQR-02Documento8 pagineWPS PQR-02Ranjan Kumar100% (1)

- Glasse FlakeDocumento18 pagineGlasse FlakeBoris CardenasNessuna valutazione finora

- Solvent Free, Low Viscosity, Epoxy Primer: Mixing DescriptionDocumento2 pagineSolvent Free, Low Viscosity, Epoxy Primer: Mixing DescriptionSameehu TVNessuna valutazione finora

- Product Catalog THFDocumento48 pagineProduct Catalog THFEdy Quispe QuentaNessuna valutazione finora

- KProselect Lubricants B GBDocumento4 pagineKProselect Lubricants B GByovannyNessuna valutazione finora

- Alcohols-Structure and Synthesis 2Documento82 pagineAlcohols-Structure and Synthesis 2Diana Cárdenas MuñozNessuna valutazione finora

- Formation of Color Complexes of CobaltDocumento4 pagineFormation of Color Complexes of Cobaltsidra tariqNessuna valutazione finora

- Lipids ExperimentDocumento3 pagineLipids ExperimentCyra LumibaoNessuna valutazione finora

- Processes: Extraction Methods of Oils and Phytochemicals From Seeds and Their Environmental and Economic ImpactsDocumento14 pagineProcesses: Extraction Methods of Oils and Phytochemicals From Seeds and Their Environmental and Economic Impactsbatiya urbanusNessuna valutazione finora

- 1.2 Exercise 4 - Empirical and Molecular FormulaeDocumento1 pagina1.2 Exercise 4 - Empirical and Molecular FormulaeNorhafiza RoslanNessuna valutazione finora

- Video 21Documento41 pagineVideo 21AssyakurNessuna valutazione finora

- Asme Section Ii A Sa-29 Sa-29m PDFDocumento26 pagineAsme Section Ii A Sa-29 Sa-29m PDFHyunjong MoonNessuna valutazione finora

- Prac - Exam - Style - Paper - 1 - MS Chmeistry OlevelDocumento2 paginePrac - Exam - Style - Paper - 1 - MS Chmeistry OlevelAhmed SadhanNessuna valutazione finora

- Iron Carbon Phase DiagramDocumento4 pagineIron Carbon Phase DiagramMizanur RahmanNessuna valutazione finora