Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

P126TI-II: Doosan Infracore Generator Engine

Caricato da

moisesTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

P126TI-II: Doosan Infracore Generator Engine

Caricato da

moisesCopyright:

Formati disponibili

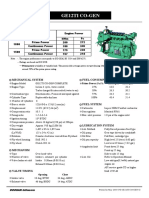

DOOSAN INFRACORE GENERATOR ENGINE

P126TI-II

Ratings Gross Engine Output Net Engine Output

( kWm/PS) Standby Prime Standby Prime

1500rpm(50Hz) 294/400 265/360 287/390 258/350

1800rpm(60Hz) 342/465 307/418 331/450 296/403

Ratings Definitions

The power ratings of Emergency Standby and Prime are in accordance with ISO 8528.

Fuel Stop power in accordance with ISO 3046.

Electric power (kWe) must be considered cooling fan loss, alternator efficiency, altitude derating and ambient temperature.

STANDBY POWER RATING is applicable for supplying emergency power for the duration of the utility power outage.

No overload capability is available for this rating. A standby rated engine should be sized for a maximum of an 80% average

load factor and 200 hours of operation per year. This includes less than 25 hours per year at the Standby Power rating.

PRIME POWER RATING is available for an unlimited number of hours per year in variable load application. Variable load

should not exceed a 70% average of the Prime Power rating during any operating period of 24 hours. The Total operating

time at 100% Prime Power shall not exceed 500 hours per year. A 10% overload capability is available for a period of 1 hour

withing a 12 hour period of operation. Total operating time at the 10% overload power shall not exceed 25 hours per year.

◎ GENERAL ENGINE DATA

ㅇEngine Model P126TI-Ⅱ

ㅇEngine Type 4-Cycle, In-line, 6-Cylinder Diesel, water cooled, Turbo charged & intercooled

ㅇBore x stroke 123 x 155 mm

ㅇDisplacement 11.051 liters

ㅇCompression ratio 17.1 : 1

ㅇRotation Counter clockwise viewed from Flywheel

ㅇFiring order 1-5-3-6-2-4

ㅇInjection timing 16˚±1˚ BTDC

ㅇDry weight 780kg(with Fan)

ㅇDimension (LxWxH) 1,384 x 1,109 x 1,195 mm

ㅇFly wheel housing SAE NO.1M

ㅇFly wheel Clutch NO.14M

ㅇNumber of teeth on flywheel 152

◎ ENGINE MOUNTING

Maximum Bending Moment at Rear Face to Block 1325 NㆍM

◎ EXHAUST SYSTEM

Maximum Back Pressure 5.9 kPa

◎ AIR INDUCTION SYSTEM

Maximum Intake Air Restriction

. With Clean Filter Element 2.16 kPa

. With Dirty Filter Element 6.23 kPa

ㅇMax. static pressure after Radiator 0.125 kPa

Printed in 2013 Large Engine Application Design Team_P126TI-II_D

◎ COOLING SYSTEM

Water circulation by centrifugal pump on engine.

ㅇCooling method Fresh water forced circulation

ㅇCoolant capacity Engine Only : Approx. 19 lit., With Radiator : Approx. 51 lit.(standard)

ㅇCoolant flow liters / min

rate

ㅇPressure Cap Max. 49 kPa

ㅇWater Temperature

- Maximum for standby and Prime 103℃

- Before start of full load 40.0℃

ㅇWater pump Centrifugal type driven by Gear

ㅇThermostat Type and Range Wax – pellet type, Opening temp. 71°C , Full open temp. 85°C

ㅇCooling fan Blower type, steel , 755 mm diameter, 7 blade

ㅇMax. external coolant system restriction Not Available

◎ LUBRICATION SYSTEM

Force-feed lubrication by gear pump, lubricating oil cooling in cooling water circuit of engine.

ㅇLub. Method Fully forced pressure feed type

ㅇOil pump Gear type driven by crank-shaft gear

ㅇOil filter Full flow, cartridge type

ㅇOil capacity Max. 23 liters , Min. 20 liters

ㅇLub oil pressure Idle Speed : Min 100 kPa

Governed Speed : Min 250 kPa

ㅇMaximum oil temperature 120℃

ㅇAngularity limit Front down 10 deg , Front up 10 deg , Side to side 22.5 deg

ㅇLubrication oil Refer to Operation Manual

◎ FUEL SYSTEM

Bosch type in-line pump with integrated, electromagnetic actuator.

ㅇInjection pump Zexel in-line "P" type

ㅇGovernor Electric type ( all speed control )

ㅇSpeed drop G3 Class ( ISO 8528 )

ㅇFeed pump Mechanical type in injpump.

ㅇInjection nozzle Multi hole type

ㅇOpening pressure 21.1 MPa

ㅇFuel filter Full flow, cartridge type with water drain valve.

ㅇMaximum fuel inlet restriction 10 kPa

ㅇMaximum fuel return restriction 60 kPa

ㅇFuel feed pump Capacity 230 liters / hr

ㅇUsed fuel Diesel fuel oil

◎ ELECTRICAL SYSTEM

ㅇBattery Charging Alternator 28.5V x 45A alternator

ㅇVoltage regulator Built-in type IC regulator

ㅇStarting motor 24V x 6.0 kW

ㅇBattery Voltage 24V

ㅇBattery Capacity 150 Ah (recommended)

ㅇStarting aid (Option) Block heater

Printed in 2013 Large Engine Application Design Team_P126TI-II_D

◎ VALVE SYSTEM

ㅇ Type Overhead valve type

ㅇ Number of valve Intake 1, exhaust 1 per cylinder

ㅇ Valve lashes at cold Intake 0.3mm , Exhaust 0.3mm

ㅇ Valve timing

Opening Close

-. Intake valve 18 deg. BTDC 34 deg. ABDC

-. Exhaust valve 46 deg. BBDC 14 deg. ATDC

◎ PERFORMANCE DATA Prime Power Standby Power

ㅇGoverned Engine speed rpm 1500 1800 1500 1800

ㅇEngine Idle Speed rpm 800 800 800 800

ㅇOver speed limit rpm 1650 1980 1650 1980

ㅇGross Engine Power Output kW 265 307 294 342

ps 360 418 400 465

ㅇBreak Mean effective pressureMpa 1.92 1.86 2.13 2.06

ㅇMean Piston Speed m/s 7.75 9.3 7.75 9.3

ㅇFriction Power kW 24 33 24 33

ps 32.63 44.87 32.63 44.87

ㅇ Specific fuel consumption

25% load liters/hr 16.9 20.6 18.3 22.2

50% load liters/hr 31.3 37.0 34.9 41.4

75% load liters/hr 47.0 56.0 51.6 61.5

100% load liters/hr 63.1 73.8 77.6 89.5

ㅇMaximum Lube oil consumptiong/h 252 292.6 280 325.5

ㅇFan Power kW 7 11 7 11

ㅇExhaust Noise at 1m Horizontally from Centerline of Exhaust Pipe distance

(without Fan) dB(A) 97.1 98.3 97.1 98.3

The all data and the specific fuel consumption are based on ISO 3046/1, Standard reference conditions are in accordance with

298 K(25˚ Celsius) air temperature, 100kPa(1000mbar) air pressure, 60% relative humidity, 110m(361ft) altitude.

Operation At Elevated Temperature And Altitude: The engine may be operated at :

1800 rpm & 1500rpm up to 750~ 1000m and 30°C without power deration

For sustained operation above these conditions, derate by 3% per 304m , and 2% per 11 °C

Engine Data with Dry Type Exhaust Manifold

ㅇ Intake Air Flow m3/min 20.68 28.23 22.33 30.22

ㅇExhaust gas temp. after turbo. °C 590 500 650 580

ㅇExhaust Gas Flow m3/min 47.4 61.6 51.2 64.2

ㅇHeat Rejection to Exhaust kW 222.4 260.1 273.5 315.4

ㅇHeat Rejection to Coolant kW 96.7 113.1 118.9 137.1

ㅇHeat Rejetion to Intercooler kW 51.6 60.3 63.4 73.1

ㅇRadiated Heat to Ambient kW 22.6 26.4 27.7 32.0

ㅇCooling water circulation liters/min 265 320 265 320

ㅇCooling fan air flow m3/min 450 530 450 530

Printed in 2013 Large Engine Application Design Team_P126TI-II_D

◆ ENGINE DIMENSION

◆ CONVERSION TABLE

in. = mm x 0.0394 lb/ft = N.m x 0.737

PS = kW x 1.3596 U.S. gal = lit. x 0.264

psi = kg/cm2 x 14.2233 kW = 0.2388 kcal/s

in3 = lit. x 61.02 lb/PS.h = g/kW.h x 0.00162

hp = PS x 0.98635 cfm = m3/min x 35.336

lb = kg x 2.20462 Mpa = Pa x 1000 = bar x 10

kW = Kcal/sec x 0.239

Doosan Infracore Co., Ltd.

21st Floor, Doosan Tower, 18-12, Euljiro 6-ga,

Jung-gu, Seoul, Korea.

TEL : +82-2-3398-8578 / FAX : +82-2-3398-8509

E-mail : enginesales@doosan.com

Web site : www.doosaninfracore.com

※ Speccifications are subject to change without prior notice

Printed in 2013 Large Engine Application Design Team_P126TI-II_D

Potrebbero piacerti anche

- Doosan P126TI Spec DatasheetDocumento4 pagineDoosan P126TI Spec DatasheetPhoenix ForceNessuna valutazione finora

- P126TI-II: Doosan Infracore Generator EngineDocumento4 pagineP126TI-II: Doosan Infracore Generator EnginehirararaNessuna valutazione finora

- Doosan P126ti Specifications PDFDocumento4 pagineDoosan P126ti Specifications PDFMuhammad rizkiNessuna valutazione finora

- Motordatenblatt DOOSAN DP158LCDocumento5 pagineMotordatenblatt DOOSAN DP158LCWILLIAM ANDRES LEONNessuna valutazione finora

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Documento4 pagineDoosan Infracore Generator Engine: Ratings (KWM/PS)Ethan KhorNessuna valutazione finora

- 09. Spec. Sheet p126ti-Ⅱ - 영문Documento4 pagine09. Spec. Sheet p126ti-Ⅱ - 영문RYUNessuna valutazione finora

- Doosan Engine: Ratings (KWM/PS)Documento4 pagineDoosan Engine: Ratings (KWM/PS)Vu DangNessuna valutazione finora

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Documento4 pagineDoosan Infracore Generator Engine: Ratings (KWM/PS)moisesNessuna valutazione finora

- Doosan Engine: Ratings (KWM/PS)Documento4 pagineDoosan Engine: Ratings (KWM/PS)Vu DangNessuna valutazione finora

- Doosan Infracore Generator Engine P222le-IiDocumento4 pagineDoosan Infracore Generator Engine P222le-IiahmedalgaloNessuna valutazione finora

- 07. SPEC. SHEET P126TI-3 - 영문Documento4 pagine07. SPEC. SHEET P126TI-3 - 영문RYUNessuna valutazione finora

- DP086TA: Doosan Infracore Generator EngineDocumento4 pagineDP086TA: Doosan Infracore Generator EngineLorena CamachoNessuna valutazione finora

- Motor P222FE PDFDocumento4 pagineMotor P222FE PDFMarco QuitoNessuna valutazione finora

- P222le SDocumento4 pagineP222le SKazim AlrefaiNessuna valutazione finora

- DP086LA: Doosan Infracore Generator EngineDocumento4 pagineDP086LA: Doosan Infracore Generator EnginehirararaNessuna valutazione finora

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Documento5 pagineDoosan Infracore Generator Engine: Ratings (KWM/PS)Jorge Eraldo Albarran PoleoNessuna valutazione finora

- DP158LCDocumento4 pagineDP158LCyah jml100% (1)

- DP158LD: Doosan Infracore Generator EngineDocumento4 pagineDP158LD: Doosan Infracore Generator EnginemoisesNessuna valutazione finora

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Documento4 pagineDoosan Infracore Generator Engine: Ratings (KWM/PS)Muhammad rizkiNessuna valutazione finora

- DP180LA: Doosan Infracore Generator EngineDocumento4 pagineDP180LA: Doosan Infracore Generator EnginehirararaNessuna valutazione finora

- DP158LDDocumento4 pagineDP158LDMichael ManzanoNessuna valutazione finora

- P222LE-S: Doosan Infracore Generator EngineDocumento4 pagineP222LE-S: Doosan Infracore Generator EngineStenlyn LayaNessuna valutazione finora

- DP180LB: Doosan Infracore Generator EngineDocumento4 pagineDP180LB: Doosan Infracore Generator EngineBrandon Atz100% (1)

- DP126LA: Doosan Infracore Generator EngineDocumento4 pagineDP126LA: Doosan Infracore Generator EnginehirararaNessuna valutazione finora

- DP180LBDocumento4 pagineDP180LBKazim AlrefaiNessuna valutazione finora

- D1146TDocumento4 pagineD1146TRaul Rojas100% (1)

- Doosan DP222LC PDFDocumento4 pagineDoosan DP222LC PDFLuisDelaHozNessuna valutazione finora

- DP222LA: Doosan Infracore Generator EngineDocumento4 pagineDP222LA: Doosan Infracore Generator EngineLuis GiraldoNessuna valutazione finora

- DP222LB: Doosan Infracore Generator EngineDocumento4 pagineDP222LB: Doosan Infracore Generator Enginehafid CJSPNessuna valutazione finora

- DP222LB: Doosan Infracore Generator EngineDocumento4 pagineDP222LB: Doosan Infracore Generator EnginemoisesNessuna valutazione finora

- Doosan Infracore Generator Engine: Ratings (KWM/PS)Documento4 pagineDoosan Infracore Generator Engine: Ratings (KWM/PS)David J SandersNessuna valutazione finora

- SPESIFIKASI TEKNIS Doosan 650 kVA - Open TypeDocumento9 pagineSPESIFIKASI TEKNIS Doosan 650 kVA - Open Typehafid CJSPNessuna valutazione finora

- Ge12ti Co Gen-GDocumento2 pagineGe12ti Co Gen-GTilok DasNessuna valutazione finora

- 2 PS Ge12tic eDocumento2 pagine2 PS Ge12tic eebow powerNessuna valutazione finora

- Dat Ge12tiDocumento2 pagineDat Ge12tiheri setyawanNessuna valutazione finora

- P158Le G-Drive: Power RatingDocumento2 pagineP158Le G-Drive: Power RatingFelipe HernándezNessuna valutazione finora

- 6KTAA25-G35 Technical DataDocumento2 pagine6KTAA25-G35 Technical DataMeme DNessuna valutazione finora

- P086ti 1Documento2 pagineP086ti 1Serhan AysanNessuna valutazione finora

- Gv180ti Co Gen-FDocumento2 pagineGv180ti Co Gen-FSilver SilverNessuna valutazione finora

- Dat Gv180tiDocumento2 pagineDat Gv180tiThomasRudyNessuna valutazione finora

- PDF Hub 6DTAA8.9-G31Documento2 paginePDF Hub 6DTAA8.9-G31Luis YupanquiNessuna valutazione finora

- D Á Ð 6DTAA8.9 G24ÀóÂ (Ëó )Documento2 pagineD Á Ð 6DTAA8.9 G24ÀóÂ (Ëó )Meme DNessuna valutazione finora

- Gv222ti - Gas Natural GLP PDFDocumento2 pagineGv222ti - Gas Natural GLP PDFdaniloreisrochaNessuna valutazione finora

- Ge08ti Co Gen-GDocumento2 pagineGe08ti Co Gen-GGuillermo OchoaNessuna valutazione finora

- D1146 G-DRIVE: Power RatingDocumento2 pagineD1146 G-DRIVE: Power RatingCesar Saavedra SaavedraNessuna valutazione finora

- D1146T G-DRIVE: Power RatingDocumento2 pagineD1146T G-DRIVE: Power RatingCesar Saavedra SaavedraNessuna valutazione finora

- 3 PS Gv158tic eDocumento2 pagine3 PS Gv158tic eebow powerNessuna valutazione finora

- Doosan Daewoo Engine P126TI CDocumento2 pagineDoosan Daewoo Engine P126TI CcassiomecNessuna valutazione finora

- SP173NA: Doosan Infracore Generator EngineDocumento4 pagineSP173NA: Doosan Infracore Generator EngineTeodoro Cornelius AltuveNessuna valutazione finora

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDa EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Marine Electrics Made Simple or How to Keep the Batteries ChargedDa EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNessuna valutazione finora

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsDa Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsValutazione: 1 su 5 stelle1/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Model HistoryDocumento3 pagineModel HistoryMario GooseNessuna valutazione finora

- Dd13 FaultDocumento6 pagineDd13 FaultSsNessuna valutazione finora

- ISUZU D-MAX 2011 4JJ1 ENGINE SERVICE MANUAL - PDF (PDFy Mirror) - Free Download, Borrow, and Streaming - Internet ArchiveDocumento3 pagineISUZU D-MAX 2011 4JJ1 ENGINE SERVICE MANUAL - PDF (PDFy Mirror) - Free Download, Borrow, and Streaming - Internet ArchivekevinNessuna valutazione finora

- Scoping Secondary Ignition Systemsvandenbrink10Documento7 pagineScoping Secondary Ignition Systemsvandenbrink10enjpetNessuna valutazione finora

- Turbine Disk (3D Printing)Documento5 pagineTurbine Disk (3D Printing)Vaibhav ShiroleNessuna valutazione finora

- Hydradrive EsiteDocumento12 pagineHydradrive EsiteMakeNessuna valutazione finora

- Diesel AssignmentDocumento12 pagineDiesel AssignmentRichard ValienteNessuna valutazione finora

- Case 1845 1845s Uni Loaders PartsDocumento5 pagineCase 1845 1845s Uni Loaders PartsBarbara100% (48)

- Chevrolet Malibu 2013Documento266 pagineChevrolet Malibu 2013Jesús Hurtado67% (3)

- Auxiliary Power Unit - Gulfstream ManualDocumento7 pagineAuxiliary Power Unit - Gulfstream ManualPerla Susana PMNessuna valutazione finora

- B737-3 71-80 B1 e (Jun2005 CMP)Documento290 pagineB737-3 71-80 B1 e (Jun2005 CMP)mehdi100% (2)

- Manual de Partes R2900G JLKDocumento1.012 pagineManual de Partes R2900G JLKCarlos Palpan ReyesNessuna valutazione finora

- Electronic Boost Controller Installation and Operation ManualDocumento11 pagineElectronic Boost Controller Installation and Operation ManualZacharias IbarraNessuna valutazione finora

- Passlniger Car Motor Oil: Iso-Vg 68 Iso-Vg 68 Iso-Vg 68Documento2 paginePasslniger Car Motor Oil: Iso-Vg 68 Iso-Vg 68 Iso-Vg 68SAFIR ULLAHNessuna valutazione finora

- New Holland TVT SERIES Service Manual PDFDocumento2.396 pagineNew Holland TVT SERIES Service Manual PDFGeorge Bogdan82% (11)

- Mercedes Tools CatalogDocumento55 pagineMercedes Tools CatalogCrescentrisingNessuna valutazione finora

- Chrysler Ball-Stud Hemi - WikipediaDocumento2 pagineChrysler Ball-Stud Hemi - WikipediaJordan4444409Nessuna valutazione finora

- Gas Turbine and Jet & Rocket Propulsion1Documento405 pagineGas Turbine and Jet & Rocket Propulsion1Kumar ArunNessuna valutazione finora

- Nissan Almera n16 2001 Electronic Repair Manual 114Documento1 paginaNissan Almera n16 2001 Electronic Repair Manual 114netifig352Nessuna valutazione finora

- TB LM42 eDocumento12 pagineTB LM42 eGianna Frola100% (1)

- 1KD FTV Injector Disassemble ReassembleDocumento7 pagine1KD FTV Injector Disassemble ReassembleAll Haul TransportNessuna valutazione finora

- Koso Honda Grom 4cyl Head Instructions MC623000Documento3 pagineKoso Honda Grom 4cyl Head Instructions MC623000Muhammad Khairul AnwarNessuna valutazione finora

- Manual de Taller Serie 900 PDFDocumento240 pagineManual de Taller Serie 900 PDFhecazorla100% (1)

- Service Manual - H6E4S123 - Valve ClearanceDocumento1 paginaService Manual - H6E4S123 - Valve ClearanceServis 1178Nessuna valutazione finora

- Bar's Head Gasket SealerDocumento2 pagineBar's Head Gasket SealerMatt CrummittNessuna valutazione finora

- Mercedes Trucks MR Fault Codes List Truckmanualshub - Com-1Documento23 pagineMercedes Trucks MR Fault Codes List Truckmanualshub - Com-1frank mutale100% (5)

- Ba CompressorDocumento78 pagineBa CompressorclintonNessuna valutazione finora

- 10-6320 For EMS - 30-6320Documento13 pagine10-6320 For EMS - 30-6320Alexandru AvrigeanuNessuna valutazione finora

- OS 140RX EngineDocumento13 pagineOS 140RX EngineJorge Andrés FeliúNessuna valutazione finora