Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Civil in The Process Plant-Earthing PDF

Caricato da

Nityanand ChaudharyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Civil in The Process Plant-Earthing PDF

Caricato da

Nityanand ChaudharyCopyright:

Formati disponibili

Civil Engineer in the process plant © Matthias Hartmann

Embedded Parts – Earthing and Lightning Protection

The Earthing is one of the first technical Installations on site and requires in the

process plant a particular attention and an early finalization of the design. It is a

challenge for the designer to recognize and receive in a early stage the position

of the earthing connection points of electrical powered equipment, vessels or the

steel construction in order to forward it on time to the civil contractor whilst the

mechanical engineering is busy with preparing tendering documents and

awarding and the arrangement of machines- and electro technical equipments

isn’t defined yet.

Earthing in the plant construction is essentially in use as a functional earthing

and lightning protection. The earthing resistance is the electrical resistance

between the connection terminal and the ground earth. The earthing resistance is

the characteristic value of the earthing system and shall be in general minimized.

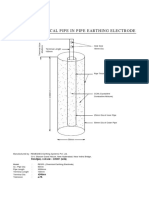

Pic. 1 Conduction of round erthing bar Ø

Types of earthing wires 10mm to a deep foundation pile

1) Galvanized band iron strap 30x3,5 mm is delivered on a spool and is

connected with clamps

2) Flat round bars dm 10-12 mm delivered in bundles is employed within the

concrete foundation. The bars will be cut on site to fit, bended and welded with

each other. This type of earthing wire is often conducted to earthing connection

plates (Pic.1-3)

3) Copper wires have a seven times higher conductibility (or a seventh of the

resistance) than iron based wires, are easier to place but also manifold more

expensive than galvanized band iron strap or round bars (Pic.4).

Pic. 2 welding connection of flat steel Pic. 3 Round earthing bar Ø 10mm welded Pic. 4 Earthing connection of copper with

earthing rods Ø 10mm at an earthing plate earthing plate and connecting lug

Characteristics in the plant Construction

Earthing

As the foundations in the plant construction are carried in most of the cases by

deep foundations piles the earthing system has already in this phase to be taken

into consideration. To install a deep earthing system conductive earthing rod

then will be embedded in the reinforcement cage or the earthing will be

connected directly with the reinforcement by welding.

If foundation piles are not used, bronze bars instead have to be driven into the

soil. How deep a rod has to be placed depends on the conductivity of the ground.

In practice on site the bronze bars will be driven into the ground until the

required conductivity has been reached. If a deep earthing system is due to

ground conditions not to realize the ground electrode has to be arranged at the

surface in grids. The conductivity will be measures constantly. The ideal

earthing system of a building is arranged horizontal and vertical in mesh grids of

smaller than 10m. Within the concrete foundation structure an inner earthing

grid is designed horizontally and connected with rising structures, the outer grid

and the deep conductor. The vertical connections are following the columns or

walls and are then rising within the concrete or are conducted to steel columns at

the bottom and the top Fig X and XI.

page 1 / 3 1st release 10.08.2012

Civil Engineer in the process plant © Matthias Hartmann

Embedded Parts – Earthing and Lightning Protection

Fig. X Extract from an earthing plan with visible inner and outer Fig. XI Legend of a earthing plan

grid, risers and arrangement of earthing plates.

Lightning protection

The lightning protection system design requires a calculation in which the

location and the height of the building have influence. Practically the lightning

protection is collected with certified antennas and then routed in a grid outside at

the building to the ground (Pic. 5.1 and 5.2). In order to avoid the lightning

entering the inner of the building the lightning protection grid is conducted to

the outer earthing grid not to the inner earthing grid.

Pic. 5.1 Lightning protection grid

on top of a roof

Pic. 5.2 Lightning protection antenna

nearby equipment

page 2 / 3 1st release 10.08.2012

Civil Engineer in the process plant © Matthias Hartmann

Embedded Parts – Earthing and Lightning Protection

Execution

Monitoring the execution and regular inspections of the good workmanship are

essential. In the focus of inspections are connections between following

structures, foundations with machines and equipment (Pic. 6.1), foundation slabs

with steel members (Pic. 6.2), pre-cast concrete elements with each other and at

least the outer and inner grid. In practice a connection between a concrete slab

with a following concrete column or wall is realized by placing a starter rod or

earthing bar.

Clear connection points to conduct the grids have to be defined by using

earthing plates from steel or bronze with recessed threads. It is recommendable

to measure and document regularly in defined sections the earthing resistance.

The resistance measure shall approve that the grid is built so far without

interruption. Pic. 6.1 Earthing connection between

equipment and foundation upstand

Pic. 6.2 connection foundation

with steel column

release Date Item Name

1st release 10.08.2012 M. Hartmann

page 3 / 3 1st release 10.08.2012

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- GTP-80 MM 2 MeterDocumento4 pagineGTP-80 MM 2 MeterNityanand ChaudharyNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Corona Essentioal Supplies GKMINDADocumento6 pagineCorona Essentioal Supplies GKMINDANityanand ChaudharyNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- GTP - RESPL-G803 (PURVI) - 50 KGDocumento1 paginaGTP - RESPL-G803 (PURVI) - 50 KGNityanand ChaudharyNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- MR. ARI F 2nd Oor, Al - Fazal Encl Ave, Khur Am Nagar, Ri NG Road, Lucknow-226022 +91 522 2751600 +91 9198989899Documento1 paginaMR. ARI F 2nd Oor, Al - Fazal Encl Ave, Khur Am Nagar, Ri NG Road, Lucknow-226022 +91 522 2751600 +91 9198989899Nityanand ChaudharyNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Remedies Earthing Systems Pvt. Ltd. PDFDocumento1 paginaRemedies Earthing Systems Pvt. Ltd. PDFNityanand ChaudharyNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Augured Hole Length 10 Feet With 100 To 150 MMDocumento1 paginaAugured Hole Length 10 Feet With 100 To 150 MMNityanand ChaudharyNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- U-Bold Clamp 14.2Documento1 paginaU-Bold Clamp 14.2Nityanand ChaudharyNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- 50 PDFDocumento1 pagina50 PDFNityanand ChaudharyNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Remedies Chemical Pipe in Pipe Earthing Electrode Remedies Chemical Pipe in Pipe Earthing ElectrodeDocumento1 paginaRemedies Chemical Pipe in Pipe Earthing Electrode Remedies Chemical Pipe in Pipe Earthing ElectrodeNityanand ChaudharyNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Comparison of Austempering and Quench-And-Tempering Processes ForDocumento103 pagineComparison of Austempering and Quench-And-Tempering Processes FornihalsinghNessuna valutazione finora

- Science 9 - 4th Quarter Long QuizDocumento1 paginaScience 9 - 4th Quarter Long QuizMik CapiliNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Practical Wet Test Acid Radical-1Documento5 paginePractical Wet Test Acid Radical-1psyxs4tsv9Nessuna valutazione finora

- Hellenistic Core Formed Glass From EpirusDocumento11 pagineHellenistic Core Formed Glass From EpirusGeorgianna LaviniaNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Part S15 Driven Piles (2012)Documento5 paginePart S15 Driven Piles (2012)CK TangNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- External Corrosion Modeling For An Underground Natural Gas Pipeline Using COMSOL MultiphysicsDocumento15 pagineExternal Corrosion Modeling For An Underground Natural Gas Pipeline Using COMSOL MultiphysicsMalika AchouriNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Evaporative Cooling Design Spreadsheet 2014 - MetricDocumento1 paginaEvaporative Cooling Design Spreadsheet 2014 - MetricCristian MoratayaNessuna valutazione finora

- Lab 4 - Kirchhoffs LawsDocumento4 pagineLab 4 - Kirchhoffs LawsAnuradha ItwaruNessuna valutazione finora

- Substance and AccidentsDocumento2 pagineSubstance and AccidentsJAN DIRK DOROQUEZNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- ConversionDocumento1 paginaConversionGOMEZ, AICHAELSON C.Nessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Problem B: Standard:Hs-Ps2-1 Determining Net Force ProblemDocumento2 pagineProblem B: Standard:Hs-Ps2-1 Determining Net Force ProblemMona Mohamed SafwatNessuna valutazione finora

- Optimum Design of Wide Span Cable-Stayed Roof StructuresDocumento13 pagineOptimum Design of Wide Span Cable-Stayed Roof StructuresAndrés Juárez SánchezNessuna valutazione finora

- 9th Class Physics Notes For Chapter 2Documento27 pagine9th Class Physics Notes For Chapter 2ali abbasNessuna valutazione finora

- Sem NotesDocumento39 pagineSem NotesN NandiniNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hamilton's Principle PDFDocumento16 pagineHamilton's Principle PDFDebkanta DasNessuna valutazione finora

- First Use of The Double Steel and Concrete Andwich Lining For Keeping High Pressure Ate Out of A Potash ShaftDocumento8 pagineFirst Use of The Double Steel and Concrete Andwich Lining For Keeping High Pressure Ate Out of A Potash ShaftCraig ThomasNessuna valutazione finora

- Review1 ScheduleDocumento3 pagineReview1 Schedulejayasuryam.ae18Nessuna valutazione finora

- Lecture03 PDFDocumento14 pagineLecture03 PDFrene erlin castilloNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Crosby Grade 100 Eye Sling HooksDocumento1 paginaCrosby Grade 100 Eye Sling HooksKonstantinos SynodinosNessuna valutazione finora

- Chapter 2Documento28 pagineChapter 2nurul najwaNessuna valutazione finora

- Project: EXPO 2020 - OV016 - USA PAVILION Inspection and Test Plan (Itp)Documento5 pagineProject: EXPO 2020 - OV016 - USA PAVILION Inspection and Test Plan (Itp)qc_531040655Nessuna valutazione finora

- Calibration of Thermometers SP250-23Documento128 pagineCalibration of Thermometers SP250-23Anonymous zdCUbW8HfNessuna valutazione finora

- Prediction of Soil Hydraulic Conductivity From Particle Size DistributionDocumento5 paginePrediction of Soil Hydraulic Conductivity From Particle Size DistributionGELBER GUTIERREZNessuna valutazione finora

- Refractive Index of Different Liquids Using Hollow PrismDocumento17 pagineRefractive Index of Different Liquids Using Hollow PrismPorkodi VendhanNessuna valutazione finora

- BA001CENDocumento21 pagineBA001CENCristian Del Alamo100% (1)

- ScamperDocumento63 pagineScamperanggreniluh64Nessuna valutazione finora

- BD44Documento42 pagineBD44Siobhan VaughanNessuna valutazione finora

- Transpo Printable Lecture1 PDFDocumento22 pagineTranspo Printable Lecture1 PDFJabin Sta. TeresaNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Propulsive PowerDocumento13 paginePropulsive PowerWaleedNessuna valutazione finora

- The Design of Optical DiodesDocumento15 pagineThe Design of Optical DiodesyassinebouazziNessuna valutazione finora