Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ELASTOMERIC and POT PTFE

Caricato da

Swapnil K0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

113 visualizzazioni10 paginebearing

Copyright

© © All Rights Reserved

Formati disponibili

XLSX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentobearing

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

113 visualizzazioni10 pagineELASTOMERIC and POT PTFE

Caricato da

Swapnil Kbearing

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 10

Data

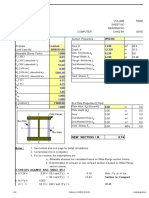

1 DIMENSIONING

a) Cover 6 mm

A 300 mm along the traffic

B 350 mm across the traffic

a 288 mm

b 338 mm

2a 576 Ok

b) a/10 28.8 and a/5 57.6

Material Symbol Value Unit Symbol Value Unit Symbol

steel hs 3 mm Ns 3 Nos Ts

elastomer hi 10 mm Ni 4 Nos Ti

h 61 mm (total thk of bearing including steel plates)

hs thickness of each layer of steel plate

hi thickness of each layer of elastomer pad

Ns Total no of steel plates

Ni Total no of layers of elastomer pad

Ts Total Thickness of steel plate

Ti Total Thickness of Elastomeric pad excluding steel plates

"Ti" should be between 28.8 and 57.6 ok

c) S 7.78 Ok calculate for individual layer (S = Shape factor)

2 LIMITS OF VERTICAL PRESSURE

Lclear 12 m girder clear span

T SW 150 Ton Total weight of single span superstructure

Tbearing 6 nos Total no of bearing per span

Pc 25 Ton slowly applied vertical load per bearing (DL)

Ltotal 13 m

Ps 30 Ton quick acting vertical load per bearing (LL)

σmin (mpa) 2.57 ok only due to DL

σmax (mpa) 5.65 ok due to DL& LL

3 NO SLIP CONDITION

TE 22.5 TON tractive effort

BF 15 TON breaking force

Hs 22.5 TON Quick acting horizontal force

Hc 4.5 TON 40% of Hs per support (Slow acting horizontal force

G 1 Mpa shear modulus

ζv 0.46 mpa shear stress

0.46 shear strain

∆strain 24.04 mm movements corresponding to shear strain

dt 30 change in temperature

∆t 7.02 temperature movement

∆creep 3 movement due to creep

T∆ 10.0 total movement due to temperature and creep

Hc 1.9

check for no slip condition

μ1 0.33 for DL

μ1 0.21 for DL+LL

F1 8.34 T safe resisting force

F2 11.34 T safe resisting force

4 BED BLOCK CONCRETE

concrete 30

fperm 7.5 mpa safe permissible stress

5 LIMIT OF DISTORTION

shear strain #REF! #REF!

6 CHECK FOR NO UPLIFT CONDITION AT EDGE OF BEARING

Assumptions

∆_DL+LL 25 mm vertical deflection under DL+LL

Ɵ_bearing 0.0038461538 radian roatation at bearing

Ɵ_DL 0.0017 radian roatation due to DL

Ɵ_DL+LL 0.0021 radian roatation due to DL

a) For DL condition

∑ei/(a/6) > tanαc

ei 0.103 mm compression of individual layer

ein 0.412 mm compression of all layer

∑ei/(a/6) 0.009 radian safe ∑ei/(a/6) > tanαc

a) For DL+LL condition

∑ei/(a/6) > tanαc+1.5tanαs

ei 0.218 mm compression of individual layer

ein 0.873 mm compression of all layer

∑ei/(a/6) 0.018 radian safe ∑ei/(a/6) > tanαc+1.5tanαs

7 Check for total shear stress

a) ζv_comp 1.39 mpa 1.5/S*(Pc+1.5Ps/(axb))

b) ζv_horz 0.65 mpa Hc/(a*b)

c) ζv_rotation 0.39 mpa G*a*a*(tanαc+1.5*tanαs)/(2*hi*Ti)

Total stess 2.43 mpa ok

8 Check suitability of steel plate

σs 140 mpa allowable stress in steel

h_required 2.05 mm safe

Value Unit

9 mm

52 mm

Pmax 4546 KN Max Vertical axial load (Including Live load)

Pmin 1012.5 KN Min Vertical axial load (Excluding Live load)

H 722.6 KN Horizontal force

s_max 63.5 mm max horizontal displacement at guided sliding end

fy 280 mpa grade of steel of pot bearing

∆_mid 116 mm deflection at center of span

0.0001 radian rotation < 0.025 all provision of IRC 83 ca

Ɵ

0.16615776 degree

A Design of elastomeric pad

Diameter Check

fz_max allow 35 mpa

fz_min allow 5 mpa

d_elastmr 406.664023 .= 490 mm <180 mm min

A_elastmr 188574.099 mm2

fz_max 24.12 mpa < 35 mpa Ok

fz_min 5.37 mpa > 5 mpa Ok

e_max 34.93 mm .= 35 mm max eccentricity due to horizontal d

Mg 159.11 kN-m .= 160 kN-m moment due to eccentricity

z_elastmr 11550164 mm3 section modulus of elastomer

fp 37.96 mpa < 40 mpa OK extreme fibre stress

Thickness Check

h_elastmr 32.67 mm > 16 Ok 35 mm

h_elastmr_final 51.25 mm 55 mm final thk of elastomer

Deflection Check

∆_perimeter 0.7105 mm < 8.25 mm Ok

B Design of PTFE pad

Option 1 Square shape of sheet

fz_max allow 40 mpa

a/b_min 337.12 mm 450 mm size of squre sheet Ok

A_ptfe 202500 mm2 area of PTFE sheet

z_ptfe 15187500 mm3

fp 32.98 mpa < 45 mpa OK extreme fibre stress

h_ptfe 5 mm > 4.5 mm Ok thickness of PTFE sheet

max protrusion above recess 2.00 mm

Option 2 Round shape of sheet

fz_max allow 40 mpa

d_min 380.40 mm 520 mm size of squre sheet Ok

A_ptfe 212371.663 mm2 area of PTFE sheet

z_ptfe 13804158 mm3

fp 32.997 mpa < 45 mpa OK extreme fibre stress

h_ptfe 5 mm > 4.5 mm Ok thickness of PTFE sheet

C Design of POT cylinder

H 722.6 KN Design horizontal force

H_min allow 454.6 KN Ok

H_max allow 1136.5 KN Ok

fluid pressure_elastmr 24.11 mpa

a)fluid pressure_cylin 324844.983 /(bp*hc) bp=thk of cylinder wall

b)hoop stress_due to H 361300 /(bp*hc) hc=height of cylinder wall

a)+b)= 168

bp*hc= 4084.19633

bp=hc= 63.91 mm 90 mm

D Design of base plate of POT

h_base plate 65 mm assumed base plate thk

d_base plate bottom 750 mm dia of base plate at bottom

A_base plate 441786.467 mm2 area of base plate

Z_base plate 41417481 mm3 section modulus of base plate

fp_max 14.15 mpa

fp_min 6.43 mpa

M_upward force 115821.946 N-mm

check for thk

taking width= 1 mm

M/Z= 184.8

Z 626.74

t_base plate 61.32 < 65 Ok

E Checks for cylinder

a)Check for shear stress

i)fluid pressure 14.73 mpa

ii)pressure_H force 24.58 mpa

fv 39.31 mpa total shear stress

b)Check for bending stress

consider 1 mm radial slice of cylinder

i)fluid pressure 27.01 mpa

ha 75.00 mm height of line of application of design horizontal force from cylinder

ii)pressure_H force 122.89 mpa

fp 149.9 mpa < 184.8 mpa Ok

b)Check for combine bending & shear stress

fpv 154.97 mpa < 252 mpa Ok

F Design of side guide for sliding of POT-PTFE

Lg 350 mm length of guide

bg 50 mm width of guide

tg 30 mm thickness of guide

a)Check for shear stress

fv 41.29 mpa < 126 mpa

b)Check for bending stress

M 21678000 N-mm

Z 145833.333 mm3

fp 148.65 mpa < 184.8 mpa

b)Check for combine bending & shear stress

fpv 164.96 mpa < 252 mpa

all provision of IRC 83 can applied

ntricity due to horizontal displacement of guided plate

due to eccentricity

odulus of elastomer

extreme fibre stress

elastomer pad thickness

extreme fibre stress

thickness of PTFE sheet

extreme fibre stress

thickness of PTFE sheet

0 6.43

750 14.15

620 12.81

zontal force from cylinder wall above base interface

Potrebbero piacerti anche

- Detailed Design of Free Pot BearingDocumento7 pagineDetailed Design of Free Pot BearingDevesh SinghNessuna valutazione finora

- Design of POT-PTFE (Fixed)Documento8 pagineDesign of POT-PTFE (Fixed)NONGTHONNessuna valutazione finora

- 2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementDocumento9 pagine2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementGaurav PatilNessuna valutazione finora

- Type FRB1. 333 Ton Free Sliding Bearing DesignDocumento8 pagineType FRB1. 333 Ton Free Sliding Bearing DesignAnkush SharmaNessuna valutazione finora

- Longitudinal BearingDocumento6 pagineLongitudinal BearingDPJAIN INFRASTRUCTURENessuna valutazione finora

- FB. 60M - Free Bearing DesignDocumento10 pagineFB. 60M - Free Bearing DesignBasava SowmyaNessuna valutazione finora

- 23m Pot Ptfe DetailsDocumento10 pagine23m Pot Ptfe DetailsAmbrishNessuna valutazione finora

- Design Calculation of Spherical MSM Slide Guide (T) Bearing - 1800 KN (GB7) PDFDocumento6 pagineDesign Calculation of Spherical MSM Slide Guide (T) Bearing - 1800 KN (GB7) PDFDusmantaKumarSahooNessuna valutazione finora

- Bearing Design-30.0m - PSCDocumento5 pagineBearing Design-30.0m - PSCSHARATH VASUPRADA100% (1)

- Design of Welded Plate GirderDocumento25 pagineDesign of Welded Plate GirderJinshad UppukodenNessuna valutazione finora

- Bearing Pot Cum 27-08-2020Documento48 pagineBearing Pot Cum 27-08-2020Hymavathi MNessuna valutazione finora

- Pot Bearing DrawingDocumento1 paginaPot Bearing DrawingMiguel Belda DiezNessuna valutazione finora

- 3bow-String Girder - Design Construction Aspects PDFDocumento12 pagine3bow-String Girder - Design Construction Aspects PDFankur mundraNessuna valutazione finora

- BOX Culvert Load DetailsDocumento7 pagineBOX Culvert Load DetailsDhimas Surya Negara100% (1)

- CribDocumento1 paginaCribskumarsrNessuna valutazione finora

- POT Design R0Documento9 paginePOT Design R0VB665Nessuna valutazione finora

- Bearing 1 PDFDocumento1 paginaBearing 1 PDFAnkit SuriNessuna valutazione finora

- Design of Elastomeric Bearing Based On IRC 083-2-1987Documento4 pagineDesign of Elastomeric Bearing Based On IRC 083-2-1987Babita SharmaNessuna valutazione finora

- Final Pot Ptfe Design Sheet - 02.01.13Documento47 pagineFinal Pot Ptfe Design Sheet - 02.01.13Sandeep Kumar75% (4)

- Bolted Splice DesignDocumento8 pagineBolted Splice DesignAnonymous sfkedkymNessuna valutazione finora

- Load Combinations Section 12Documento23 pagineLoad Combinations Section 12avikshit yNessuna valutazione finora

- Corbel DesignDocumento4 pagineCorbel DesignnonameNessuna valutazione finora

- Elastomercic Bearing DN (14+872 MNB)Documento19 pagineElastomercic Bearing DN (14+872 MNB)Ankur ChauhanNessuna valutazione finora

- Plate GirderDocumento74 paginePlate Girderarif_rubin100% (1)

- Loads On Pot - Ptfe Bearing - 3x17m SpanDocumento12 pagineLoads On Pot - Ptfe Bearing - 3x17m SpanMalayKumarDebNessuna valutazione finora

- TSR NIRMAN Bow String Girder Launching Design Note-06.05.2022Documento1 paginaTSR NIRMAN Bow String Girder Launching Design Note-06.05.2022sups madiNessuna valutazione finora

- Methodology For Stressing of PSC Girders (C)Documento2 pagineMethodology For Stressing of PSC Girders (C)HegdeVenugopalNessuna valutazione finora

- 248 T Bearing (Sliding) HDocumento32 pagine248 T Bearing (Sliding) Hmanoj_structureNessuna valutazione finora

- Design of Elastomeric BearingsDocumento6 pagineDesign of Elastomeric BearingsHarshitha GaneshNessuna valutazione finora

- Girder Stressing CalculationsDocumento11 pagineGirder Stressing CalculationsSarmad WaqasNessuna valutazione finora

- Design of Abutment BridgeDocumento15 pagineDesign of Abutment Bridge7894561230% (1)

- Is 800 2007Documento12 pagineIs 800 2007Ragavan100% (1)

- Design of Pier Pile P3Documento198 pagineDesign of Pier Pile P3designbridgeeng geo group0% (1)

- Steel Plate Girder (41.38m) - R0Documento58 pagineSteel Plate Girder (41.38m) - R0ShaileshRastogiNessuna valutazione finora

- Design of Plate GirderDocumento85 pagineDesign of Plate Girdersamirbendre1100% (2)

- 2 Span PSC Bridge - 8 - Results and Design1Documento52 pagine2 Span PSC Bridge - 8 - Results and Design1Akshay Magar PatilNessuna valutazione finora

- Free POT/PTFE BearingDocumento25 pagineFree POT/PTFE BearingZakee MohamedNessuna valutazione finora

- Bearing DesignDocumento5 pagineBearing DesignAnde BhanuNessuna valutazione finora

- Calculation of Reactions & Horizontal Loads For Pot-Ptfe BearingsDocumento12 pagineCalculation of Reactions & Horizontal Loads For Pot-Ptfe BearingsVenkat PalliNessuna valutazione finora

- Design of Elastomeric Bearing: (For Effective Span of 20.95M)Documento8 pagineDesign of Elastomeric Bearing: (For Effective Span of 20.95M)vivekNessuna valutazione finora

- Pot Bearings PDFDocumento12 paginePot Bearings PDFFurtado23Nessuna valutazione finora

- Steel Bridge DesignDocumento56 pagineSteel Bridge Designnavin263Nessuna valutazione finora

- Steel CompositeDocumento208 pagineSteel CompositeDipak BorsaikiaNessuna valutazione finora

- Design of Balanced Cantilever BridgeDocumento37 pagineDesign of Balanced Cantilever BridgeArafat RahmanNessuna valutazione finora

- Bridge Load Rating Summary FormDocumento8 pagineBridge Load Rating Summary FormiGp2013Nessuna valutazione finora

- Comment - Design of 24 M Comp Girder-R5 FINAL PDFDocumento60 pagineComment - Design of 24 M Comp Girder-R5 FINAL PDFNilay Gandhi100% (2)

- Elastomeric Bearing DesignDocumento22 pagineElastomeric Bearing DesignRudra Sharma50% (2)

- Crackwidth CheckDocumento12 pagineCrackwidth CheckSithara Ps100% (1)

- LRFD Steel Girder SuperStructure Design Example - LRFD - Design - Bridge - Structures PDFDocumento61 pagineLRFD Steel Girder SuperStructure Design Example - LRFD - Design - Bridge - Structures PDFSomi Khan100% (1)

- Bridge Bearing DesignDocumento2 pagineBridge Bearing DesignYoshua Yang100% (1)

- Plate Girder DesignDocumento8 paginePlate Girder Designkalpanaadhi100% (1)

- Transverse-Design771 TriDocumento17 pagineTransverse-Design771 TriBasava SowmyaNessuna valutazione finora

- Loading & Girder DesignDocumento21 pagineLoading & Girder DesignRameshNessuna valutazione finora

- Beam Design As Per AISC - ASD - 9thED - ModifiedDocumento6 pagineBeam Design As Per AISC - ASD - 9thED - ModifiedArif RusyanaNessuna valutazione finora

- Typical Anchor BoltsDocumento33 pagineTypical Anchor BoltslucianduNessuna valutazione finora

- Grade of Concrete Grade of Steel,: LoadsDocumento22 pagineGrade of Concrete Grade of Steel,: LoadsEr. Hisham Ajmal PCNessuna valutazione finora

- Design of Beam (Steel)Documento30 pagineDesign of Beam (Steel)jeyavaniNessuna valutazione finora

- Beam Column ConnectionDocumento2 pagineBeam Column ConnectionHAZIRACFS SURATNessuna valutazione finora

- Beams TB1Documento3 pagineBeams TB1mangeshNessuna valutazione finora

- Modal AnalysisDocumento6 pagineModal AnalysisSwapnil KNessuna valutazione finora

- Ia-Ii Re 22-23Documento2 pagineIa-Ii Re 22-23Swapnil KNessuna valutazione finora

- Thermal AnalysisDocumento3 pagineThermal AnalysisSwapnil KNessuna valutazione finora

- Buckling AnalysisDocumento7 pagineBuckling AnalysisSwapnil KNessuna valutazione finora

- Failure Data AnalysisDocumento13 pagineFailure Data AnalysisSwapnil KNessuna valutazione finora

- Non Linearity Strs ToepsDocumento4 pagineNon Linearity Strs ToepsSwapnil KNessuna valutazione finora

- Apcs 2Documento2 pagineApcs 2Swapnil KNessuna valutazione finora

- Imp 2Documento14 pagineImp 2Swapnil KNessuna valutazione finora

- Beam-Design-including torsion-IS 456Documento7 pagineBeam-Design-including torsion-IS 456Swapnil KNessuna valutazione finora

- Bursting Reinforcement DesignDocumento2 pagineBursting Reinforcement DesignSwapnil KNessuna valutazione finora

- 117 - Seismic Evaluation of Residential Building With Masonry Wall Using EtabsDocumento8 pagine117 - Seismic Evaluation of Residential Building With Masonry Wall Using EtabsSwapnil KNessuna valutazione finora

- Vibration Analysis ATC CHARTDocumento6 pagineVibration Analysis ATC CHARTSwapnil K100% (1)

- PT Method StatementDocumento6 paginePT Method StatementSwapnil KNessuna valutazione finora

- Retaining Walls - Optimal DesignDocumento10 pagineRetaining Walls - Optimal DesignSwapnil KNessuna valutazione finora

- 7th 8th Floor PT Slab Strengthening Design ReportDocumento41 pagine7th 8th Floor PT Slab Strengthening Design ReportSwapnil KNessuna valutazione finora

- Mechanical Vibrations Previous Years Questions PDFDocumento14 pagineMechanical Vibrations Previous Years Questions PDFBalamurali Gunji100% (1)

- CIE IGCSE Physics Formula SheetDocumento2 pagineCIE IGCSE Physics Formula SheetthusvigNessuna valutazione finora

- Chapter 29-Magnetic FieldsDocumento43 pagineChapter 29-Magnetic FieldsGled HysiNessuna valutazione finora

- Hydraulic Turbine IDocumento27 pagineHydraulic Turbine IRam Krishna Singh100% (3)

- أسئلة واجابات في التروسDocumento29 pagineأسئلة واجابات في التروسمحمد عصامNessuna valutazione finora

- Lecture 1Documento41 pagineLecture 1norhaslina_aa33% (3)

- 1-1 - Kinematics Motion Along Straigt LineDocumento14 pagine1-1 - Kinematics Motion Along Straigt LineJoanna LeeNessuna valutazione finora

- Example Design of Circular Beam ACI 1999Documento5 pagineExample Design of Circular Beam ACI 1999José Pablo Rosales Sánchez100% (3)

- Class 9 Sci Topic 1 - Laws of Motion - Notes - Awatade ClassesDocumento7 pagineClass 9 Sci Topic 1 - Laws of Motion - Notes - Awatade ClassesRamkrishnahari RaskarNessuna valutazione finora

- CU Quantum Social Science 1107012821 PDFDocumento306 pagineCU Quantum Social Science 1107012821 PDFBreilla ZanonNessuna valutazione finora

- ConvectionDocumento2 pagineConvectionSanith RenjalNessuna valutazione finora

- TUTORIAL Settling - 20172018 PDFDocumento15 pagineTUTORIAL Settling - 20172018 PDFHomesick TutorsNessuna valutazione finora

- Mohr Circle Hp35sDocumento3 pagineMohr Circle Hp35sAlfredo Romero GNessuna valutazione finora

- Shear Strengthening of RC Beams With Web-Bonded Continuous Steel PlatesDocumento12 pagineShear Strengthening of RC Beams With Web-Bonded Continuous Steel PlatesRachida KrachaiNessuna valutazione finora

- Ok - SDB SAP2000 v14.0.0 - License # 02 February 2016Documento2 pagineOk - SDB SAP2000 v14.0.0 - License # 02 February 2016AdyZiipNessuna valutazione finora

- Summative Test in Grade 10 ScienceDocumento2 pagineSummative Test in Grade 10 ScienceRomeo GabitananNessuna valutazione finora

- Ultrasonic DetectionDocumento8 pagineUltrasonic DetectionSaravanan ViswakarmaNessuna valutazione finora

- Aade 10 DF Ho 26Documento9 pagineAade 10 DF Ho 26Trần Anh ĐứcNessuna valutazione finora

- Department of Mechanical Engineering School of Engineering University of Management and TechnologyDocumento3 pagineDepartment of Mechanical Engineering School of Engineering University of Management and TechnologyUSMAN SARWARNessuna valutazione finora

- Advanced Fluid Mechanics: SS 2020 Prof. Dr. O. EiffDocumento6 pagineAdvanced Fluid Mechanics: SS 2020 Prof. Dr. O. EiffCamille CrnNessuna valutazione finora

- Experiment No. 2: The Conical PendulumDocumento7 pagineExperiment No. 2: The Conical PendulumHerbert James BandaNessuna valutazione finora

- Research Proposal 1 PDFDocumento5 pagineResearch Proposal 1 PDFMunem BushraNessuna valutazione finora

- Individu Assign 1 Sem 2 1718 PDFDocumento3 pagineIndividu Assign 1 Sem 2 1718 PDFafiqzeroNessuna valutazione finora

- Hydrostatic Force On Plane SurfacesDocumento3 pagineHydrostatic Force On Plane SurfaceskarthikNessuna valutazione finora

- Syllabus-NS02-Physics For Engineers (Edited 4232021)Documento16 pagineSyllabus-NS02-Physics For Engineers (Edited 4232021)Harexon StuartNessuna valutazione finora

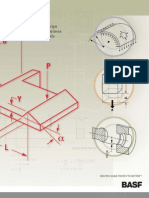

- BASF Design Solution GuideDocumento86 pagineBASF Design Solution Guideomerscheen80% (5)

- CAMENEN LARSON 2005 A General Formula For Non-Cohesive Bed Load SedimentDocumento12 pagineCAMENEN LARSON 2005 A General Formula For Non-Cohesive Bed Load SedimentFelipe AzevedoNessuna valutazione finora

- Coulomb Theory For Retaining WallDocumento11 pagineCoulomb Theory For Retaining WallTahir Ur RahmanNessuna valutazione finora

- Physics Module Form 4 Teachers' Guide Chapter 2: Force and MotionDocumento44 paginePhysics Module Form 4 Teachers' Guide Chapter 2: Force and MotionCikgu Zul Zacherry85% (13)

- Lecture 5-Electric Properties of MatterDocumento15 pagineLecture 5-Electric Properties of Matterana carolina aristizabalNessuna valutazione finora