Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

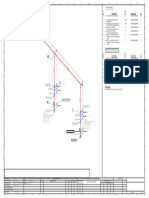

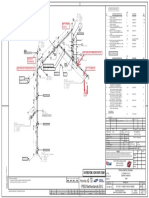

10ENA01BR004 Sheet5-Model

Caricato da

Valesh MonisTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

10ENA01BR004 Sheet5-Model

Caricato da

Valesh MonisCopyright:

Formati disponibili

1 2 3 4 5 6 7 8

PART MATERIAL DESCRIPTION SIZE ITEM CODE QTY. SPEC

No

FABRICATION MATERIALS

N

1 Pipe, BE, ASME-B36.10M, 300 PAAZZBOZZABAABSAAZZUS 24.0 M B01

A106-B, Seamless, S-STD

2 Sockolet® Size on Size, 300X25 MEUAWBVZZAEYABQZZUS 1 B01 13

13 PT10ENA01CP003

A CL3000, Beveled end, A

ASME-B36.10M, A105 12

P5

3 Sockolet® Size on Size, 300X20 MEUAWBVZZAEYABQZZUS 1 B01 STEM NORTH

161 10ENA01AA706

CL3000, Beveled end,

324

ASME-B36.10M, A105

130

4 90 degree elbow, long radius, 300 MCMZZBOZZAAEADCZZUSA 2 B01

<6> 7

, Beveled end, ASME-B16.9, 20DN

A234-WPB, S-STD

20 20

PIPE SUPPORTS

5 Design Pipe Assembly 300 DesignPipeH_5 6 B01 SEE ISO 300DN 1

ERECTION MATERIALS 10ENA01BR004 SHT 06 32 2

6 Pipe, PE, ASME-B36.10M, 25 PAAZZBPZZABAABSAAZZUS 0.4 M E 334864 12

N 347203 7

A106-B, Seamless, S-40 > 10

EL +1666 <5

7 Pipe, PE, ASME-B36.10M, 20 PAAZZBPZZABAABSAAZZUS 0.3 M 3

178

A106-B, Seamless, S-40 300X20DN

8 90 degree elbow, CL3000, 25 MCKAWBVZZAAGABQZZUS 1 B01 S5

B Socket welded end, 25 10ENA01BQ043

B

28

ASME-B16.11, A105

9 Plug, CL3000, Male threaded 25 MFIAWBNZZAAGABQZZUS 1 B01 N 347078

S5

end, ASME-B16.11, A105 10ENA01BQ044

10 90 degree elbow, CL3000, 20 MCKAWBVZZAAGABQZZUS 1 B01 50

Socket welded end, 10 00

00

ASME-B16.11, A105 2

11 Ball valve, full port, CL600, 25 VAIAPBUZZAAFABQZZBFUS 1 B01 457

Threaded end, ASME-B16.10, 20

A105 17 4

EL +1666

12 Ball valve, full port, CL600, 20 VAIAPBUZZAAFABQZZBFUS 1 B01

2654

Threaded end, ASME-B16.10,

1740

A105 457

<4> 1

INSTRUMENTS 457

13 PRESSURE TRANSMITTER 20 1 B01

C PT10ENA01CP003 38 C

15

1

108 457

2 1 4

300X25DN 01 <3

>

18 100

184

S5

10ENA01BQ032 308

0 24

600 E 333326

41

<1> 6 21 6

24 1

8

9 EL -1296

61

21

D 00 181 D

60

<2> 6 11

25DN STEM UP

9 10ENA01AA401

S5

10ENA01BQ033 TO NEAREST DRAIN PIT

0 0

60

S5

61 10ENA01BQ034

13

SEE SHT

10ENA01BR004 SHT 04

E 312164 0DN

N 337076 30

EL -988

E S5 E

10ENA01BQ042

6 130 20 SQ.CUT SCREWED PAAZZBPZZABAABSAAZZUS OWNER

5 122 20 SQ.CUT SQ.CUT PAAZZBPZZABAABSAAZZUS

4 1740 300 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS DISTRIBUTION W/C

3 22243 300 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS MATRIX

2 211 25 SQ.CUT SCREWED PAAZZBPZZABAABSAAZZUS

1 100 25 SQ.CUT SQ.CUT PAAZZBPZZABAABSAAZZUS NOTES:- EPC

PIECE

NO

LENGTH

MM

SIZE

MM

END PREP END PREP ITEM CODE

1. ALL DIMENSIONS AND ELEVATIONS ARE IN MILLIMETERS

2. FINISHED GROUND LEVEL (FGL) OF PLANT IS (-)0.300 WHICH

CORRESPONDS TO MSL (+)8.50M

PESCO

3. FOR PAINTING & SURFACE PREPARATION DETAILS REFER "TECHNICAL

SPECIFICATION FOR PAITING" DOC NO. TCE.11191A-SP-3903 MAIN PLANT EQUIPMENT SUPPLIER

4. FOR INSULATION DETAILS REFER "TECHNICAL SPECIFICATION FOR

INSULATION" DOC NO. TCE.11191A-SP-3902

5. ALL ELEVATIONS INDICATED ARE CENTER LINE OF PIPES UNLESS

OTHERWISE NOTED. PROJECT NAME

6. SMALL BORE PIPING (DN 50 & BELOW) ARE FIELD RUN. ISOMETRICS

ISSUED FOR THE SAME IS INDICATIVE AND MAY BE ADJUSTED TO SUIT ADEN POWER PLANT - PHASE 1

F SITE CONDITIONS. F

7. FOR SUPPORT ARRANGEMENT, REFER TYPICAL STANDARD SKETCH

DRAWING - TCE.11191A-D-4909 DRAWING TITLE ISOMETRICS FOR LIGHT CRUDE OIL SYSTEM

10ENA01BR004 05 of 06

P&ID NO. ENGINEERING JOB No. DRAWING NUMBER REV

PIPING LAYOUT DRAWING NO. No. DATE REVISION DESCRIPTION BY CHK APPR Civil Mech Elect I/C PIP HSE PROS

11191A TCE.11191A-D-4914 P5

FILE NAME 10ENA01BR004.SHA DATE : DESIGNED : DRAWN : CHEF ENGR : TATA CONSULTING ENGINEERS LIMITED

1 2 3 4 5 6 7 8

Potrebbero piacerti anche

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Bill of Material Fabrication: Project: Epc For Bab Facilities Upgrade Project Drg. Title: Piping Isometric & BomDocumento1 paginaBill of Material Fabrication: Project: Epc For Bab Facilities Upgrade Project Drg. Title: Piping Isometric & Bomsandeepkumarsahoo9337Nessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Ocr TestDocumento8 pagineOcr TestAirNessuna valutazione finora

- A1-TR5M-L4-003 A1-TR5M-ISO-004 A1-TR5M-L4-003: Weld SummaryDocumento1 paginaA1-TR5M-L4-003 A1-TR5M-ISO-004 A1-TR5M-L4-003: Weld SummaryfaviikaujaNessuna valutazione finora

- GroomingDocumento1 paginaGroomingIkbal AlanisNessuna valutazione finora

- Chwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)Documento1 paginaChwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)vishwas salunkheNessuna valutazione finora

- Chwr-1015-Cs-250-Ic-45 - Sheet (6 of 6)Documento1 paginaChwr-1015-Cs-250-Ic-45 - Sheet (6 of 6)vishwas salunkheNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 2300 52 AAA BD 280 282181 01 - RevS2Documento1 pagina2300 52 AAA BD 280 282181 01 - RevS2CosminMarianNessuna valutazione finora

- Piping Isometric - 3Documento1 paginaPiping Isometric - 3CosminMarianNessuna valutazione finora

- 1/1 P055AZOR-05P00-1353-51 A A-2: 3c 248 HV 10 Shop ASME B31.3Documento1 pagina1/1 P055AZOR-05P00-1353-51 A A-2: 3c 248 HV 10 Shop ASME B31.3Deshwa SaravananNessuna valutazione finora

- Issued For Construction Modular Isometrics: Piping Isometric DrawingDocumento1 paginaIssued For Construction Modular Isometrics: Piping Isometric Drawing86tejasNessuna valutazione finora

- ISO ExampleDocumento1 paginaISO Examplethe.avishekkNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- For ConstructionDocumento5 pagineFor ConstructionBasem AlsaftliNessuna valutazione finora

- H31 SW F34 2475Documento4 pagineH31 SW F34 2475Bini RanishNessuna valutazione finora

- 4103 TOYO20 92DJ 1300 052 - Rev 1 - Sht001Documento1 pagina4103 TOYO20 92DJ 1300 052 - Rev 1 - Sht001Dinesh SunderNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- D-055.011-304-15-052-R4 - RL - B (Viga Eje D)Documento1 paginaD-055.011-304-15-052-R4 - RL - B (Viga Eje D)RCarlos PTNessuna valutazione finora

- Lista de Materiales: Item Diam Cant DescripcionDocumento1 paginaLista de Materiales: Item Diam Cant DescripcionMarcia IturraNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10END30BR001Documento1 pagina10END30BR001Valesh MonisNessuna valutazione finora

- Chwr-1021-Cs-100-Ic-40 - Sheet (1 of 1)Documento1 paginaChwr-1021-Cs-100-Ic-40 - Sheet (1 of 1)vishwas salunkheNessuna valutazione finora

- TR-DM-MI-0218: Issued For ConstructionDocumento2 pagineTR-DM-MI-0218: Issued For ConstructionMarcellino YohanesNessuna valutazione finora

- 10ENA01BR003 Sheet2-ModelDocumento1 pagina10ENA01BR003 Sheet2-ModelValesh MonisNessuna valutazione finora

- Iso - Pipeline 1001 P 1Documento1 paginaIso - Pipeline 1001 P 1jameenNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 1u01 WW 9002 01Documento1 pagina1u01 WW 9002 01syslor.kimNessuna valutazione finora

- All Piping Drawings Spec SheetsDocumento18 pagineAll Piping Drawings Spec Sheetsc.reidNessuna valutazione finora

- MD 512 1a51 Iso WRW XXXX XXX 01 PDFDocumento1 paginaMD 512 1a51 Iso WRW XXXX XXX 01 PDFsarsan nedumkuzhiNessuna valutazione finora

- 4103 TOYO20 92DJ 1300 011 - Rev 1 - Sht001Documento11 pagine4103 TOYO20 92DJ 1300 011 - Rev 1 - Sht001Dinesh SunderNessuna valutazione finora

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaDocumento1 paginaPesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisNessuna valutazione finora

- 01 E02STB007-W146693-03-0 - BC - Stress UpdateDocumento1 pagina01 E02STB007-W146693-03-0 - BC - Stress Update86tejas100% (1)

- LCPRDS NRV 80NBDocumento1 paginaLCPRDS NRV 80NBPartha Sarathi PradhanNessuna valutazione finora

- 2300 52 AAA CW 280 281307 04 - RevS2Documento1 pagina2300 52 AAA CW 280 281307 04 - RevS2CosminMarianNessuna valutazione finora

- Chws-1011-Cs-250-Ic-45 - Sheet (4 of 6)Documento1 paginaChws-1011-Cs-250-Ic-45 - Sheet (4 of 6)vishwas salunkheNessuna valutazione finora

- D-000731-2-SCLP-C21BT-02049 SHT.4 Rev 1 - Line No. SCLP-C21BT-02049 ISODocumento1 paginaD-000731-2-SCLP-C21BT-02049 SHT.4 Rev 1 - Line No. SCLP-C21BT-02049 ISOneil horwoodNessuna valutazione finora

- 150 10xaa1 H50 21RDCH 1004 1Documento1 pagina150 10xaa1 H50 21RDCH 1004 1uma raneNessuna valutazione finora

- Listado de Materiales Tag ManifoldDocumento1 paginaListado de Materiales Tag ManifoldLuis Miguel Vicente ValentinNessuna valutazione finora

- Technical Manual: VanessaDocumento7 pagineTechnical Manual: VanessaAnonymous LLLK3pqNessuna valutazione finora

- Piping Material Specification: Pipe DataDocumento3 paginePiping Material Specification: Pipe DataBhaumik BhuvaNessuna valutazione finora

- Tolva 3Documento1 paginaTolva 3Quimica Sur-AndinaNessuna valutazione finora

- Piping Material Specification 3C605 Carbon Steel, Class 300 Issue Date: Feb 17, 2014Documento12 paginePiping Material Specification 3C605 Carbon Steel, Class 300 Issue Date: Feb 17, 2014azilahnazriNessuna valutazione finora

- Iso Mre S70 002Documento6 pagineIso Mre S70 002celonevesNessuna valutazione finora

- 3CM2S Piping Material Class Specification: 000-SP-PI02-0070Documento5 pagine3CM2S Piping Material Class Specification: 000-SP-PI02-0070Oswaldo GuerraNessuna valutazione finora

- Tal Wsa PNG Iso 1afl062502 - 00 - A01 - 00Documento1 paginaTal Wsa PNG Iso 1afl062502 - 00 - A01 - 00landeopauloNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Punj Lloyd: 4 See Iso ACC-5100-00015-01 5100PSV 2602Documento1 paginaPunj Lloyd: 4 See Iso ACC-5100-00015-01 5100PSV 2602Saptarshi MandalNessuna valutazione finora

- 13L00501A - 7P-A: General NotesDocumento7 pagine13L00501A - 7P-A: General NotesCLS AKNessuna valutazione finora

- Ms Trading Pipefittingcatalogue Dec2016 ElectronicDocumento44 pagineMs Trading Pipefittingcatalogue Dec2016 ElectronicANV100% (1)

- Piping Material Data SheetDocumento1 paginaPiping Material Data SheetbrunorodorNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaDocumento1 paginaPesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisNessuna valutazione finora

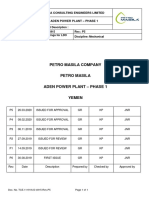

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Documento1 paginaPetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisNessuna valutazione finora

- Raw Water & Service Water Distribution System: Isometric Drawing ListDocumento1 paginaRaw Water & Service Water Distribution System: Isometric Drawing ListValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10ENA01BR003 Sheet2-ModelDocumento1 pagina10ENA01BR003 Sheet2-ModelValesh MonisNessuna valutazione finora

- 10ENA01BR003 Sheet3-ModelDocumento1 pagina10ENA01BR003 Sheet3-ModelValesh MonisNessuna valutazione finora

- Tce.11191a-D-4213 - Ldo P&id - R4 (Ur)Documento2 pagineTce.11191a-D-4213 - Ldo P&id - R4 (Ur)Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Asme Team QC Manager WELDING ENGINEER (Under Consideration) CO-ordinator (John) Material Engineer (Mostafa) DC (Under Consideration) Inspector (Omar)Documento2 pagineAsme Team QC Manager WELDING ENGINEER (Under Consideration) CO-ordinator (John) Material Engineer (Mostafa) DC (Under Consideration) Inspector (Omar)Valesh MonisNessuna valutazione finora

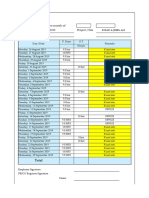

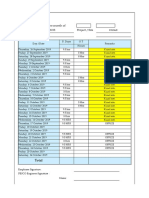

- PESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDDocumento4 paginePESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDValesh MonisNessuna valutazione finora

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Documento1 paginaPetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 10END30BR001Documento1 pagina10END30BR001Valesh MonisNessuna valutazione finora

- PESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDDocumento4 paginePESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDValesh MonisNessuna valutazione finora

- PESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDDocumento4 paginePESCO Time Sheet For The Month of Name: Rehan Monis Project / Site IDValesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Documento1 paginaPesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNessuna valutazione finora

- 02 WordEditingTextDocumento1 pagina02 WordEditingTextValesh MonisNessuna valutazione finora

- Malvaceae Shrub: GossypiumDocumento5 pagineMalvaceae Shrub: GossypiumKhushbooNessuna valutazione finora

- BIODIVERSITYDocumento40 pagineBIODIVERSITYSimran jeet KaurNessuna valutazione finora

- Lorax Lesson PlanDocumento8 pagineLorax Lesson Planapi-278032450Nessuna valutazione finora

- Cultivation of Rice in IndiaDocumento65 pagineCultivation of Rice in IndiarishabhNessuna valutazione finora

- Control Valve SizingDocumento7 pagineControl Valve SizingJojolasNessuna valutazione finora

- Cells - Basic Unit of LifeDocumento45 pagineCells - Basic Unit of Lifeapi-202349222Nessuna valutazione finora

- Gahisan - GST (Research Work)Documento2 pagineGahisan - GST (Research Work)Hannah Mae Gahisan100% (1)

- ProMec EngineeringDocumento17 pagineProMec EngineeringAnonymous 7a5KZi8MNessuna valutazione finora

- Nitrogen SourcesDocumento3 pagineNitrogen SourcesRoque VirgilioNessuna valutazione finora

- Dosage Recommendation ARBOCEL® FT 400 For Cress Growth PDFDocumento6 pagineDosage Recommendation ARBOCEL® FT 400 For Cress Growth PDFPelayo BolivarNessuna valutazione finora

- Peninsula Gardens Improves Cannabis Cultivation With Condair RS SeriesDocumento4 paginePeninsula Gardens Improves Cannabis Cultivation With Condair RS SeriesRuk RukNessuna valutazione finora

- Arabic Food Recipes, Arrabian Cousine, How To Make Hammus Zaatar, Falafil, Fatush, Exotic Dubai Tours Safaris and Hotels DubaiDocumento41 pagineArabic Food Recipes, Arrabian Cousine, How To Make Hammus Zaatar, Falafil, Fatush, Exotic Dubai Tours Safaris and Hotels Dubaideepa_sampath20Nessuna valutazione finora

- Bai Tap U12 Lop 4Documento2 pagineBai Tap U12 Lop 4Nam HảiNessuna valutazione finora

- IEO English Sample Papers For Class 10Documento24 pagineIEO English Sample Papers For Class 10Madhuri RaghuNessuna valutazione finora

- ElectroputereDocumento3 pagineElectroputeremonzer alesberNessuna valutazione finora

- Stone, Judith - Cupcake Recipes - How To Bake Cup Cakes and Fairy Cakes Like A Pro (2011) PDFDocumento44 pagineStone, Judith - Cupcake Recipes - How To Bake Cup Cakes and Fairy Cakes Like A Pro (2011) PDFLughNessuna valutazione finora

- Symbiosis Quiz PDFDocumento2 pagineSymbiosis Quiz PDFJerson NidoNessuna valutazione finora

- CH 8 Transport in Plants Worksheet 1 AnswerDocumento6 pagineCH 8 Transport in Plants Worksheet 1 Answermohammed mahdy100% (1)

- RZ 5215 1Documento2 pagineRZ 5215 1amirhosseinNessuna valutazione finora

- Adulteration of Crude DrugsDocumento10 pagineAdulteration of Crude DrugsKirankumar HullattiNessuna valutazione finora

- Field Guide 0Documento54 pagineField Guide 0AfiQah AzizNessuna valutazione finora

- How To Cultivate Curly Chilies in Pots-1Documento2 pagineHow To Cultivate Curly Chilies in Pots-1Nurul Rachman NasutionNessuna valutazione finora

- TLB SpiceDocumento13 pagineTLB SpicePT Tama Lintas BenuaNessuna valutazione finora

- GCE Biology-Human Biology-Teachers' Guide Revised 18-02-14Documento93 pagineGCE Biology-Human Biology-Teachers' Guide Revised 18-02-14mariumrana40Nessuna valutazione finora

- Hydro Electric Power Plants-GovernorDocumento19 pagineHydro Electric Power Plants-GovernorAnonymous PvzeJ38Y8Nessuna valutazione finora

- Sponges - A Coloring WorksheetDocumento2 pagineSponges - A Coloring Worksheetnearurheart1Nessuna valutazione finora

- Small-Scale Coffee Processing: Agricultural and Botanical AspectsDocumento8 pagineSmall-Scale Coffee Processing: Agricultural and Botanical Aspectsanakarylle100% (1)

- What Is Capiz ShellDocumento4 pagineWhat Is Capiz ShellIra James AbanesNessuna valutazione finora

- Career Point: Pre Foundation DivisonDocumento8 pagineCareer Point: Pre Foundation DivisonMeenakshiSundareshNessuna valutazione finora

- Cyanobacteria LabDocumento6 pagineCyanobacteria LabsenorgustoNessuna valutazione finora