Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Quality Control Checklist Excavation: Consultant: Gulf Engineering&Industrial Consultancy

Caricato da

Alvin BadzDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Quality Control Checklist Excavation: Consultant: Gulf Engineering&Industrial Consultancy

Caricato da

Alvin BadzCopyright:

Formati disponibili

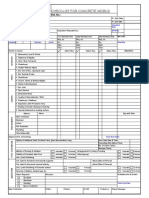

Design and Construction of 3 units FD type and 2 units FC Type

PROJECT LVQ Project -PHASE 2

CLIENT Gulf Warehousing Company Consultant: Gulf Engineering&Industrial Consultancy

Main Contractor Al Bader Construction and Steel Structure

Sub Contractor Ref. No.

Quality Control Checklist Quality Form Ref: GM/CL/004

Building Name :

Excavation ITR Ref. Number:

Description of the Activity/ Item

Discipline: (Tick Which ever applicable) Civil Mechanical Electrical Arch.

Reference Drawings: Rev.

Rev.

SI Report No/Result Results Verified By:

Inspection / Check Point SUB- Remarks

No. Date

(OK/RJ/NA) CONTRACTOR CONTRACTOR GEIC

1 Position and Marking is OK?

2 Depth of Excavation as per Contract Drawing?

Excavated formation level acceppatbale

3 (attach laboratory test report from)

4 level certified by surveyor/Site Engineer

Input Data Level

5 Ground Elevation (DATUM) Level

6 Bottom of Excavation Level:

7 Water Table Level and Presence of Water?

8 Excavated Soil Contaminated? (Yes/No)

Type of Excavate Material

9 (soil / clay / soft rock / hard rock, etc):

10 Ready for Lean Concrete / Blinding?

Bedding for U/G Piping or Cables

11 (attach test report if any)

Legend: Accepted (OK) Rejected with Remarks (RJ) Not Applicable (NA)

Comments form Main Contractor:

Comments form Client/Consultant:

Subcontractor Main Contractor Client / Consultant

Signatures Name

Register:

Signature

CheckList - GEIC Prepared By:Eng. Yousry I. Farag

Ver (0) PMP,LEED

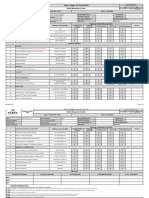

Design and Construction of 3 units FD type and 2 units FC Type

PROJECT LVQ Project -PHASE 2

CLIENT Gulf Warehousing Company Consultant: Gulf Engineering&Industrial Consultancy

Main Contractor Al Bader Construction and Steel Project Ref:

Sub Contractor Contract No.

Quality Control Checklist Quality Form Ref: GM/CL/008

Building Name:

Pre-Concrete Check Sheet ITR Ref. Number:

Description of the Activity/ Item

Discipline: (Tick Which ever applicable) Civil Mechanical Electrical Arch.

Reference Drawings: Rev.

Rev.

SI Report No/Result Results Verified By:

Inspection / Check Point SUB- Remarks

No. Date

(OK/RJ/NA) CONTRACTOR CONTRACTOR GEIC

1 Formation Level Approved?

2 AFC Drgs used & all materials approved?

3 Setting out & Layout?

4 level certified by surveyor/Site Engineer

5 Screed over w/p, Level & Grade

6 Formwork Checkpoints

Dimensions, Line, Levels & Position

Concrete Level & Charmfer

Form oil and Cleanliness

Support for Formworks

Formworks within acceptable tolerances

7 Reinforcement Check

Rebars sizes and spacings as per drgs

Rebars arrangement as per drgs

Laps position and lengths as per drgs

Dowels and starter bars as drgs

Rebars clean of dust, oil and rust

Rebars covers as per drgs

8 Ensure approval of MEP services

9 Construction joint/water bar location

10 Approval for Casting

11 Adequate & safe access

12 Final Inspection carried out

Legend: Accepted (OK) Rejected with Remarks (RJ) Not Applicable (NA)

Comments form Main Contractor:

Comments form Client/Consultant:

Subcontractor Main Contractor Client / Consultant

Signatures Name

Register:

Signature

CheckList - GEIC Prepared By:Eng. Yousry I. Farag

Ver (0) PMP,LEED

Design and Construction of 3 units FD type and 2 units FC Type

PROJECT LVQ Project -PHASE 2

CLIENT Gulf Warehousing CompGulf WareConsultant: Gulf Engineering&Industrial Consultancy

Main Contractor Al Bader Construction aAl Bader Project Ref:

Sub Contractor Contract No.

Quality Control Checklist Quality Form Ref: GM/CL/005

Building Name:

Backfilling ITR Ref. Number:

Description of the Activity/ Item

Discipline: (Tick Which ever applicable) Civil Mechanical Electrical Arch.

Reference Drawings: Rev.

Rev.

SI Report No/Result Results Verified By:

Inspection / Check Point SUB- Remarks

No. (OK/RJ/NA) Date CONTRACTOR CONTRACTOR GEIC

Confirm approval for filling / approval from

1 MEP Subcontractors (if any)

2 Filling / Backfilling Material's approved?

3 Excavation Level _______________

4 No. of Layer Required:_____________

Sand bed application (required for cables

/sleeves/trenches) and thickness as per QCS

5

Field density test been carried out as per

6 QCS requirment.

Maximum dry density of the backfill

7 material _____________________

8 FDD Standard:____________________

9 Frequency of density test ____________

Cable tiles / warning tape laid over sand

10 bedding?

11 Any other (Please specify).

Legend: Accepted (OK) Rejected with Remarks (RJ) Not Applicable (NA)

Comments form Main Contractor:

Comments form Client/Consultant:

Subcontractor Main Contractor Client / Consultant

Signatures Name

Register:

Signature

CheckList - GEIC Prepared By:Eng. Yousry I. Farag

Ver (0) PMP,LEED

Design and Construction of 3 units FD type and 2 units FC Type

PROJECT LVQ Project -PHASE 2

CLIENT Gulf Warehousing CompGulf WareConsultant: Gulf Engineering&Industrial Consultancy

Main Contractor Al Bader Construction aAl Bader Project Ref:

Sub Contractor Contract No.

Quality Control Checklist Quality Form Ref: GM/CL/009

Building Name:

Post Concrete Check Sheet ITR Ref. Number:

Description of the Activity/ Item

Discipline: (Tick Which ever applicable) Civil Mechanical Electrical Arch.

Reference Drawings: Rev.

SI

No. Inspection / Check Point

1 2 3 4 5 6 7

1 Grade of Concrete

2 Truck No.

3 Delivery Ticket No.

Volume of Batch (cu.mt)

4

5 Time of Concrete Mixer in Site

6 Concrete Temp(°C)

7 Actual Slump in Site (mm)

8 Slump in Batching Plant (mm)

9 Starting Time of Concrete

10 Finishing Time of Concrete

11 Number of Cubes Collected (Ref. nos.)

12 Curing of Concrete -------------- days

13 Finishing of Concrete Satisfactory?

Legend: Accepted (OK) Rejected with Remarks (RJ) Not Applicable (NA)

Comments form Main Contractor:

Comments form Client/Consultant:

Subcontractor Main Contractor Client / Consultant

Signatures Name

Register:

Signature

CheckList - GEIC Prepared By:Eng. Yousry I. Farag

Ver (0) PMP,LEED

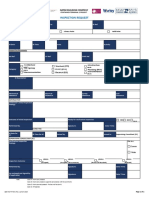

Design and Construction of 3 units FD type and 2 units FC Type

PROJECT LVQ Project -PHASE 2

CLIENT Gulf Warehousing CompaGulf WareConsultant: Gulf Engineering&Industrial Consultancy

Main Contractor Al Bader Construction an Al Bader Project Ref:

Sub Contractor Contract No.

Quality Control Checklist Quality Form Ref:

Building Name:

Pre-Pour Notice ITR Ref. Number:

Description of the Activity/ Item

Discipline: (Tick Which ever applicable) Civil Mechanical Electrical Arch.

Reference Drawings: Rev.

Rev.

Nos.of

SI Grade of QTY

Date Loction of Pour Trucks Made of Pour Remarks

No. Concrete Cumulative

Expected

1

2

3

4

5

6

7

8

9

10

11

12

13

Legend: Accepted (OK) Rejected with Remarks (RJ) Not Applicable (NA)

Comments form Main Contractor:

Comments form Client/Consultant:

Subcontractor Main Contractor Client / Consultant

Signatures Name

Register:

Signature

CheckList - GEIC Prepared By:Eng. Yousry I. Farag

Ver (0) PMP,LEED

Design and Construction of 3 units FD type and 2 units FC Type

PROJECT LVQ Project -PHASE 2

CLIENT Gulf Warehousing Company Consultant: Gulf Engineering&Industrial Consultancy

Main Contractor Al Bader Construction and Steel Structur Project Ref.

Sub Contractor Contract No.

Quality Control Checklist Quality Form Ref:

Concrete Cube Test Log

Concrete Suppliers Name: Site:

Area / Section: Date:

Structure / MemberNo. / Description:

Drawing No.: Rev.

Specified

Sample Ref. Age

Location/ Member Date Cast Date Crushed Strength Mpa @ Actual Strenght Mpa Remarks

No. (Days)

28 days

Subcontractor Main Contractor Client / Consultant

Name

Signatures

Register:

Signature

CheckList - GEIC Prepared By:Eng. Yousry I. Farag

Ver (0) PMP,LEED

Design and Construction of 3 units FD type and 2 units FC Type

PROJECT LVQ Project -PHASE 2

CLIENT Gulf Warehousing Company Consultant: Gulf Engineering&Industrial Consultancy

Main Contractor Al Bader Construction and Steel Structure Project Ref.

Sub Contractor Contract No.

Quality Control Checklist Quality Form Ref:

Cube Data Form

Concrete Suppliers Name: Site:

Area / Section: Date:

Structure / MemberNo. / Description:

Drawing No.: Rev.

Pre-Concrete Release Note No.:

Cement Type:

Concrete Class/Strength in Mpa: Stone Size:

Slump in mm: Admixture:

Date Made: Time: Temperature:

Specimen made By: Date Dispatched to Lab:

Date Tested Age in Days Mass in Kgs Dia Reading Strength in Mpa Average Strength

Note: Failure of any cube to be reported to Site Manager

Sub Contractor: Name: Signature: Date: Time:

Remarks:

Reported Reviwed by:

Name: Signature: Date: Time:

CheckList - GEIC Prepared By:Eng. Yousry I. Farag

Ver (0) PMP,LEED

Design and Construction of 3 units FD type and 2 units FC Type

PROJECT LVQ Project -PHASE 2

CLIENT Gulf Warehousing Company Consultant: Gulf Engineering&Industrial Consultancy

Main Contractor Al Bader Construction and Steel Project Ref:

Sub Contractor Contract No.

Quality Control Checklist Quality Form Ref:

Building Name:

Erection Control Form

(Sub-Main Switch Board) ITR Ref. Number:

Description of the Activity/ Item

Delivery Note No (Attached)

Discipline: (Tick Which ever applicable) Civil Mechanical Electrical Arch.

Reference Drawings: Rev.

Rev.

Report No/Result Results Verified By:

SI

Inspection / Check Point Remarks

No. Date SUB-

(OK/RJ/NA) CONTRACTOR CONTRACTOR GEIC

1 Check all Materials

2 Check Location

3 Check for any Damages

4 Check all Installation as per Drawings

5 Check Fixation of Distribution Board

6 Check for Earthing

7 Check for Cabling Arrangement

8 Check for Cable Fitting

9 Check for Cable Connection as per Drgs

10 Cleanliness

11 Check Fixing Height

Check MCB's/MCCB/ELCB Rating as per

12 Drawings

13 Check for Level

14 Duct Arrangement for Cables

Legend: Accepted (OK) Rejected with Remarks (RJ) Not Applicable (NA)

Comments form Main Contractor:

Comments form Client/Consultant:

Subcontractor Main Contractor Client / Consultant

Signatures Name

Register:

Signature

CheckList - GEIC Prepared By:Eng. Yousry I. Farag

Ver (0) PMP,LEED

Design and Construction of 3 units FD type and 2 units FC Type

PROJECT LVQ Project -PHASE 2

CLIENT Gulf Warehousing Company Consultant: Gulf Engineering&Industrial Consultancy

Main Contractor Al Bader Construction and Steel Project Ref:

Sub Contractor Contract No.

Quality Control Checklist Quality Form Ref: GM/CL/010

Building Name:

Block Work ITR Ref. Number:

Description of the Activity/ Item

Discipline: (Tick Which ever applicable) Civil Mechanical Electrical Arch.

Reference Drawings: Rev.

Rev.

SI Report No/Result Results Verified By:

Inspection / Check Point SUB- Remarks

No. (OK/RJ/NA) Date CONTRACTOR CONTRACTOR GEIC

1 Approval of all Material to be ensured

2 Layout as per approved shop Drawing?

Approved Proportion of mortar mix used and

3 obtained consistend mix?

Metal Lath provided every Alternatieve

4 Course

Wall Ties and other Accessories Provided in

5 correct Location?

6 Confirm all the MEP Services Provided

Doors and Window Openings are as per Shop

7 Drawings

All the Joints are Completely Filled with

8 Mortar

Block work Joints are Racked Uniformely

9 to 10mm (min.)

Expansion Joint b/w Bottom of Beam & Top of

10 Block Work

Confirm Final Inspection cariied out and Work

11 Under Tolerance

Legend: Accepted (OK) Rejected with Remarks (RJ) Not Applicable (NA)

Comments form Main Contractor:

Comments form Client/Consultant:

Subcontractor Main Contractor Client / Consultant

Signatures Name

Register:

Signature

CheckList - GEIC Prepared By:Eng. Yousry I. Farag

Ver (0) PMP,LEED

Design and Construction of 3 units FD type and 2 units FC Type

PROJECT LVQ Project -PHASE 2

CLIENT Gulf Warehousing Company Consultant: Gulf Engineering&Industrial Consultancy

Main Contractor Al Bader Construction and Steel Project Ref:

Sub Contractor Contract No.

Quality Control Checklist Quality Form Ref: GM/CL/017

Building Name:

Plastering Works ITR Ref. Number:

Description of the Activity/ Item

Discipline: (Tick Which ever applicable) Civil Mechanical Electrical Arch.

Reference Drawings: Rev.

Rev.

SI Report No/Result Results Verified By:

Inspection / Check Point SUB- Remarks

No. Date

(OK/RJ/NA) CONTRACTOR CONTRACTOR GEIC

1 Approval of all Material to be ensured

2 Curing of Block work?

All the Plastering accessories are fixed, Level

3 Pads are in Place and Ready to Receive Plaster

4 Plaster Beads and Stops Correctly Fixed

Confirm Mechanical Embedded Items are

5 Completed?

6 Confirm all the MEP Services Provided

7 Mixing, Application of Rush Coat

8 Curing of Rush Coat

9 Mixing,Application of Finish Coat

10 Curing for Finish Coat of Plastering

Plastered Surface is Smooth, in Plumb and away

11 from Cracks

12 Final Inspection Carried Out

Legend: Accepted (OK) Rejected with Remarks (RJ) Not Applicable (NA)

Comments form Main Contractor:

Comments form Client/Consultant:

Subcontractor Main Contractor Client / Consultant

Signatures Name

Register:

Signature

CheckList - GEIC Prepared By:Eng. Yousry I. Farag

Ver (0) PMP,LEED

Design and Construction of 3 units FD type and 2 units FC Type

PROJECT LVQ Project -PHASE 2

CLIENT Gulf Warehousing Company Consultant: Gulf Engineering&Industrial Consultancy

Main Contractor Al Bader Construction and Steel Project Ref:

Sub Contractor Contract No.

Quality Control Checklist Quality Form Ref: GM/CL/015

Building Name:

Painting - External - Internal ITR Ref. Number:

Description of the Activity/ Item

Discipline: (Tick Which ever applicable) Civil Mechanical Electrical Arch.

Reference Drawings: Rev.

Rev.

SI Report No/Result Results Verified By:

Inspection / Check Point SUB- Remarks

No. Date

(OK/RJ/NA) CONTRACTOR CONTRACTOR GEIC

1 Approval of all Material to be ensured

2 Type of application Roller/Spray

Angle of Spray/ Application as per Manufacturer

3 Recommendation

Surface Moisture is whithin Permissible Limits

4 (<4%)

Surface is Free From Cracks & Repairing done as

5 Necessary

6 Application of Primer--------------

Sufficient Curing Period Allowed as per

7 Manufacturer Recommendation

8 First Coat & Specified DFT?

9 Application of Stucco Filler--------------

Sufficient Curing Period Allowed as per

10 Manufacturer Recommendation

11 Application of First Coat & DFT------------

12 Application of Final Coat & DFT---------

13 Final Inspection?

Legend: Accepted (OK) Rejected with Remarks (RJ) Not Applicable (NA)

Comments form Main Contractor:

Comments form Client/Consultant:

Subcontractor Main Contractor Client / Consultant

Signatures Name

Register:

Signature

CheckList - GEIC Prepared By:Eng. Yousry I. Farag

Ver (0) PMP,LEED

Design and Construction of 3 units FD type and 2 units FC Type

PROJECT LVQ Project -PHASE 2

CLIENT Gulf Warehousing Company Consultant: Gulf Engineering&Industrial Consultancy

Main Contractor Al Bader Construction and Steel Project Ref:

Sub Contractor Contract No.

Quality Control Checklist Quality Form Ref: GM/CL/013

Building Name:

Flooring & Wall Tiling Works ITR Ref. Number:

Description of the Activity/ Item

Discipline: (Tick Which ever applicable) Civil Mechanical Electrical Arch.

Reference Drawings: Rev.

Rev.

SI Report No/Result Results Verified By:

Inspection / Check Point SUB- Remarks

No. Date

(OK/RJ/NA) CONTRACTOR CONTRACTOR GEIC

1 Approval of all Material to be ensured

Floor/wall is cleaned, dry & substrata is

2 ready foo to receive finishing works

3 Embedded plumbing works completed

4 Embedded electrcial works completed

5 Adhesive / mortar application & curing

Layout and locations of pedestals and

6 surfaces (for raised floors)

Fixing of pedestals over the floors with steel

7 expansion anchors (for raised floors)

Raised floor pannels are firmly fixed to the

8 pedestals

Flooring/tile works done in level & confirm PVC

9 spacers for joint are uniform

Flooring and wall tiles are completed and work is

10 satisfactory

Area is clean and protected after completion of

11 work

12 Skirting for floor & wall joint provided

Legend: Accepted (OK) Rejected with Remarks (RJ) Not Applicable (NA)

Comments form Main Contractor:

Comments form Client/Consultant:

Subcontractor Main Contractor Client / Consultant

Signatures Name

Register:

Signature

CheckList - GEIC Prepared By:Eng. Yousry I. Farag

Ver (0) PMP,LEED

Potrebbero piacerti anche

- 20-11-2019 Electrical Sleeves For Raft FoundationDocumento1 pagina20-11-2019 Electrical Sleeves For Raft Foundationfayaz khanNessuna valutazione finora

- 20-11-2019 Formwork of Raft FoundationDocumento1 pagina20-11-2019 Formwork of Raft Foundationfayaz khanNessuna valutazione finora

- Work Inspection Request (WIR)Documento2 pagineWork Inspection Request (WIR)مسابح الكهرمانNessuna valutazione finora

- Checklists 02065 - 1 - Mechanical-Work Inspection Request (WIR)Documento10 pagineChecklists 02065 - 1 - Mechanical-Work Inspection Request (WIR)AzOo AlmanabriNessuna valutazione finora

- Check List For Excavation: Company NameDocumento4 pagineCheck List For Excavation: Company NameVipin Kumar ParasharNessuna valutazione finora

- Check List Handover Rev.0Documento1 paginaCheck List Handover Rev.0Ali Mari BalochNessuna valutazione finora

- Checklist For ShutteringDocumento4 pagineChecklist For ShutteringMir Masood Shah0% (1)

- Concrete Pour Card - Checklist For Site Work - Rev. 7. Dtd. 24.08.17Documento1 paginaConcrete Pour Card - Checklist For Site Work - Rev. 7. Dtd. 24.08.17mahesh naikNessuna valutazione finora

- Inspection ChecklistDocumento2 pagineInspection Checklistgilbert cruzNessuna valutazione finora

- Material of Submittal For ApprovalDocumento1 paginaMaterial of Submittal For Approvalumar babaNessuna valutazione finora

- Inspection Request TemplateDocumento1 paginaInspection Request TemplateNoel MadesNessuna valutazione finora

- Quality Control - Works Inspection: AAC Block WallDocumento1 paginaQuality Control - Works Inspection: AAC Block WallParas100% (1)

- WIR FORM - Waterproofing MembraneDocumento1 paginaWIR FORM - Waterproofing MembraneOceNessuna valutazione finora

- Checklist For Block Work Lay Out: Project: Client: Consultant: Contractor: Trojan & NPC (J.V.)Documento1 paginaChecklist For Block Work Lay Out: Project: Client: Consultant: Contractor: Trojan & NPC (J.V.)Mani AppaNessuna valutazione finora

- Inspection Checklist Format - Excavation, Stone Dust Filling & PCCDocumento2 pagineInspection Checklist Format - Excavation, Stone Dust Filling & PCCgalfar7100% (2)

- Surveying & Setting Out ChecklistDocumento1 paginaSurveying & Setting Out ChecklistBudoy Smith100% (2)

- Check List For Concreting: Project: Doc. No.: Qa/Cl-Con/ Client: ContractorDocumento1 paginaCheck List For Concreting: Project: Doc. No.: Qa/Cl-Con/ Client: ContractorBala SubramanianNessuna valutazione finora

- Quality Control - Works Inspection: Glazed DoorsDocumento1 paginaQuality Control - Works Inspection: Glazed DoorsParasNessuna valutazione finora

- Pour CardDocumento1 paginaPour CardJohn DoeNessuna valutazione finora

- Checklist Door, Window, S&P, Plinth ProtectionDocumento7 pagineChecklist Door, Window, S&P, Plinth Protectionsoumya0% (1)

- Material Inspection Request (MIR) : Plot No. (4151)Documento2 pagineMaterial Inspection Request (MIR) : Plot No. (4151)Velmurugan Balasubramanian100% (2)

- MHSb-Std-11 Request For InformationDocumento1 paginaMHSb-Std-11 Request For InformationknabpshoNessuna valutazione finora

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Documento2 pagineET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- Plastering Checklist PDFDocumento1 paginaPlastering Checklist PDFabdelmjidNessuna valutazione finora

- C4M Aluminium Sliding WorksDocumento1 paginaC4M Aluminium Sliding WorksKishoreNessuna valutazione finora

- Work Inspection Request (Wir) : LB2 GRC Corridor Fabricated Additional Column Material Inspection & Release For ErectionDocumento2 pagineWork Inspection Request (Wir) : LB2 GRC Corridor Fabricated Additional Column Material Inspection & Release For ErectionRejoy Baby100% (1)

- Road Works Inspection ChecklistDocumento1 paginaRoad Works Inspection ChecklistSiti Rohani Isdris75% (4)

- Inspection ChecklistDocumento1 paginaInspection ChecklistMohammad Hadoumi Saldan100% (1)

- 025-ITP For Sewer & Drainage PDFDocumento6 pagine025-ITP For Sewer & Drainage PDFKöksal PatanNessuna valutazione finora

- PlumbingDocumento1 paginaPlumbingGabriel GabeNessuna valutazione finora

- Post Concrete Placement Inspection Sheet: Yes/Good No/PoorDocumento2 paginePost Concrete Placement Inspection Sheet: Yes/Good No/PoorDawit SolomonNessuna valutazione finora

- Tata Consulting Engineers Limited: Concrete Pour C ArdDocumento4 pagineTata Consulting Engineers Limited: Concrete Pour C ArdGuna Sekaran100% (1)

- Kempegowda International Airport - NSPR: Before Concreting Description Checked & Found Ok Remarks YES NO N/ADocumento2 pagineKempegowda International Airport - NSPR: Before Concreting Description Checked & Found Ok Remarks YES NO N/Adhanush gtNessuna valutazione finora

- Paver Blocks FixingDocumento1 paginaPaver Blocks FixingBharathraj RajNessuna valutazione finora

- Checklist For Pre ConcretingDocumento4 pagineChecklist For Pre ConcretingIfeanyi IwuallaNessuna valutazione finora

- 6-Interior (FalseCeiling) QCDocumento1 pagina6-Interior (FalseCeiling) QCConstruction UpdatePHNessuna valutazione finora

- Checklist For Concrete Works: Name of Work: Employer: Contract No.: ContractorDocumento1 paginaChecklist For Concrete Works: Name of Work: Employer: Contract No.: Contractormallikarjuna ketheNessuna valutazione finora

- Installation of LV Cables: Inspection and Test Plan ForDocumento1 paginaInstallation of LV Cables: Inspection and Test Plan ForHussainShabbirNessuna valutazione finora

- Grid Ceiling Checklist-R1Documento1 paginaGrid Ceiling Checklist-R1KishoreNessuna valutazione finora

- ITP-ALU Doors & Windows & Glazing WorksDocumento2 pagineITP-ALU Doors & Windows & Glazing WorksYash Sharma100% (1)

- Doc27 - Checklist For Aluminium WindowsDocumento2 pagineDoc27 - Checklist For Aluminium Windowshkshyla89100% (1)

- Checklist - PCCDocumento2 pagineChecklist - PCCajit karandikar100% (2)

- Civils - Trenching - ExcavationsDocumento2 pagineCivils - Trenching - Excavationsmitendra singhNessuna valutazione finora

- Check ListDocumento19 pagineCheck ListPanruti S SathiyavendhanNessuna valutazione finora

- QC Checklist For Block WorksDocumento1 paginaQC Checklist For Block WorksRsjBugtongNessuna valutazione finora

- Checklist For ConcretingDocumento4 pagineChecklist For ConcretingManish KapadneNessuna valutazione finora

- Earthworks-Excavation: Owner: Client: Consultant: Main Contractor: Civil ContractorDocumento1 paginaEarthworks-Excavation: Owner: Client: Consultant: Main Contractor: Civil ContractorPrasanna KumarNessuna valutazione finora

- Quality Checklist For Site Works: FlooringDocumento1 paginaQuality Checklist For Site Works: FlooringLordgie AgtucaNessuna valutazione finora

- Checklist For Granite/Marble Works: Project: Doc. No.: Client: Project LocationDocumento4 pagineChecklist For Granite/Marble Works: Project: Doc. No.: Client: Project LocationBeni N SoloNessuna valutazione finora

- Gypsum Ceiling Checklist-R1Documento1 paginaGypsum Ceiling Checklist-R1KishoreNessuna valutazione finora

- Request For InformationDocumento2 pagineRequest For InformationMarc Anthony Guno100% (1)

- Block Work CHK ListDocumento1 paginaBlock Work CHK Listhafis100% (1)

- FPM 221 Checklist Earth WorkDocumento2 pagineFPM 221 Checklist Earth WorkPrabaharan K100% (1)

- Brickandblockworkqualitycontrolchecklist 161202070038 PDFDocumento2 pagineBrickandblockworkqualitycontrolchecklist 161202070038 PDFLikopo Matiea100% (1)

- QA/Qc - Checklist Sewer LineDocumento2 pagineQA/Qc - Checklist Sewer Lineyash shah100% (2)

- Pre-Pour Inspection Checklist 0C-F027-QA-PPIC: Date SheetDocumento2 paginePre-Pour Inspection Checklist 0C-F027-QA-PPIC: Date SheetRomeo FagurelNessuna valutazione finora

- Project Title:: Checklist For Block WorkDocumento2 pagineProject Title:: Checklist For Block Workalfie100% (1)

- Electrica QC Check ListDocumento21 pagineElectrica QC Check Listmakana qc100% (1)

- Work Inspection Request: Request Ref.: KAFD-RY-RIA2-P401-ABC-ARC-IRE-00131Documento2 pagineWork Inspection Request: Request Ref.: KAFD-RY-RIA2-P401-ABC-ARC-IRE-00131Abdelrahman NabulsiNessuna valutazione finora

- Lem Res Ir Mec 034Documento2 pagineLem Res Ir Mec 034Ohaeri DarlintonNessuna valutazione finora

- Technical Submittals - HBKDocumento29 pagineTechnical Submittals - HBKAlvin BadzNessuna valutazione finora

- R00000.00-DR-385 - Daily Report (08-May-2022) (12541)Documento23 pagineR00000.00-DR-385 - Daily Report (08-May-2022) (12541)Alvin BadzNessuna valutazione finora

- D112 Wir 4211 ST 20967 - 0Documento1 paginaD112 Wir 4211 ST 20967 - 0Alvin BadzNessuna valutazione finora

- Bimak 2020 Financial Year End ReportDocumento5 pagineBimak 2020 Financial Year End ReportAlvin BadzNessuna valutazione finora

- Readymix Plant Inspection Observation (Comments)Documento9 pagineReadymix Plant Inspection Observation (Comments)Alvin BadzNessuna valutazione finora

- R00000.00-DR-384 - Daily Report (07-May-2022) (12649)Documento23 pagineR00000.00-DR-384 - Daily Report (07-May-2022) (12649)Alvin BadzNessuna valutazione finora

- R00000.00-DR-382 - Daily Report (01-May-2022) (12775)Documento23 pagineR00000.00-DR-382 - Daily Report (01-May-2022) (12775)Alvin BadzNessuna valutazione finora

- R00000.00-DR-383 - Daily Report (05-May-2022) (12724)Documento22 pagineR00000.00-DR-383 - Daily Report (05-May-2022) (12724)Alvin BadzNessuna valutazione finora

- Fans Checklist: Project Name: Project Ref. No.: Owner: Department: GroupDocumento1 paginaFans Checklist: Project Name: Project Ref. No.: Owner: Department: GroupAlvin BadzNessuna valutazione finora

- List of Activities For LSC Project - (16-May-2022)Documento16 pagineList of Activities For LSC Project - (16-May-2022)Alvin BadzNessuna valutazione finora

- CCTV System Installation ChecklistDocumento5 pagineCCTV System Installation ChecklistAlvin Badz100% (1)

- Inspection Request FormDocumento1 paginaInspection Request FormAlvin BadzNessuna valutazione finora

- Electrical Panels Installation ChecklistDocumento2 pagineElectrical Panels Installation ChecklistAlvin Badz100% (3)

- Standard Forms: Construction Supervision Department GeicDocumento1 paginaStandard Forms: Construction Supervision Department GeicAlvin BadzNessuna valutazione finora

- Reinforcement Delivered Quantity: QA/QC Weekly Report - NEW NAVAL BASE PROJECT (Reinforcement Delivery)Documento4 pagineReinforcement Delivered Quantity: QA/QC Weekly Report - NEW NAVAL BASE PROJECT (Reinforcement Delivery)Alvin BadzNessuna valutazione finora

- Aluminium Composite Panel CladdingDocumento23 pagineAluminium Composite Panel CladdingAlvin BadzNessuna valutazione finora

- D112 Wir 4211 ST 15349 - 0Documento1 paginaD112 Wir 4211 ST 15349 - 0Alvin BadzNessuna valutazione finora

- M2-05 1987 - Alice Guillermo - Chap. 2 Medium and Technique - Art and SocietyDocumento29 pagineM2-05 1987 - Alice Guillermo - Chap. 2 Medium and Technique - Art and SocietyJanessa Abastas100% (1)

- Interlocking BricksDocumento6 pagineInterlocking BricksBrian Boby ThomasNessuna valutazione finora

- 17.the Glass House Complex PDFDocumento55 pagine17.the Glass House Complex PDFNivetha KumarNessuna valutazione finora

- Translation Analysis Jeffrey EugenidesDocumento5 pagineTranslation Analysis Jeffrey EugenidesSma PopoviciNessuna valutazione finora

- Repairing Decking and JoistsDocumento3 pagineRepairing Decking and JoistsJose MartinNessuna valutazione finora

- Podium Garden (Land Scape) Waterproofing MethodologyDocumento7 paginePodium Garden (Land Scape) Waterproofing MethodologyChakradhar M100% (2)

- FemtoRV32 Piplined Processor ReportDocumento25 pagineFemtoRV32 Piplined Processor ReportRatnakarVarunNessuna valutazione finora

- Soa Vs Obpm: Oracle Business Process Management Servic E Orient ED Archit Ectur EDocumento1 paginaSoa Vs Obpm: Oracle Business Process Management Servic E Orient ED Archit Ectur EAgnia Dwi KhNessuna valutazione finora

- Methods of Analysis and Design of Boxbeams - Maisall, RollDocumento2 pagineMethods of Analysis and Design of Boxbeams - Maisall, RollkolnabNessuna valutazione finora

- Bandra Worli SealinkDocumento72 pagineBandra Worli SealinkAmar Khandve88% (40)

- Timbering Week 5Documento22 pagineTimbering Week 5FikaduKitessa0% (1)

- SATIP-Q-001-01 Portland Cement Concrete - Batch Plants ManagementDocumento2 pagineSATIP-Q-001-01 Portland Cement Concrete - Batch Plants ManagementAbdul HannanNessuna valutazione finora

- Post-Modern Classicism: Radical Eclecticism Iconic BuildingDocumento1 paginaPost-Modern Classicism: Radical Eclecticism Iconic BuildingGuerrero AlexisNessuna valutazione finora

- Pilot Devices - 3SB5Documento4 paginePilot Devices - 3SB5JeyakumarNessuna valutazione finora

- SAHIG (Flooring) BUBONG (Roof)Documento1 paginaSAHIG (Flooring) BUBONG (Roof)Zennah RodelasNessuna valutazione finora

- O1B-FB-SOUTH-049 - Rev 3Documento1 paginaO1B-FB-SOUTH-049 - Rev 3Sirapat PornthuengNessuna valutazione finora

- Test Bank For Microeconomics For Today 8th Edition by TuckerDocumento24 pagineTest Bank For Microeconomics For Today 8th Edition by TuckerEdwinNewtonczqm100% (38)

- PRAYER HALL (r1)Documento23 paginePRAYER HALL (r1)Srinivas RegulavalasaNessuna valutazione finora

- Miami-Dade County Pre-Qualified Firms As of Friday, September 10, 2021 1:09 PMDocumento55 pagineMiami-Dade County Pre-Qualified Firms As of Friday, September 10, 2021 1:09 PMGabriel AlvesNessuna valutazione finora

- Ac & Ducting Layout 1: FCU-2 Ladder Plenum Box 810 X 210Documento1 paginaAc & Ducting Layout 1: FCU-2 Ladder Plenum Box 810 X 210Abi PascuaNessuna valutazione finora

- Analisis Diseño Vigas Tipo TDocumento9 pagineAnalisis Diseño Vigas Tipo Tmery yauyoNessuna valutazione finora

- MODUL Spaceframes PDFDocumento43 pagineMODUL Spaceframes PDFAthar JantuNessuna valutazione finora

- Dharavi: Informal Settlements & Slum UpgradingDocumento42 pagineDharavi: Informal Settlements & Slum UpgradingArchiesivan22Nessuna valutazione finora

- Persian Gardens PDFDocumento16 paginePersian Gardens PDFbharath PP100% (2)

- Design Calculations For Light MastDocumento23 pagineDesign Calculations For Light Mastjobees7850Nessuna valutazione finora

- Command List-6Documento3 pagineCommand List-6Carlos ArbelaezNessuna valutazione finora

- SECTION 07 60 00 Flashing and Sheet MetalDocumento31 pagineSECTION 07 60 00 Flashing and Sheet MetalJuanPaoloYbañezNessuna valutazione finora

- History of Worms CathedralDocumento2 pagineHistory of Worms CathedralKhalid Ali Saif Al-ShamsiNessuna valutazione finora

- Price Group Updated Per 28 DES 2022Documento23 paginePrice Group Updated Per 28 DES 2022chandraNessuna valutazione finora

- Himchori ResidenceDocumento13 pagineHimchori ResidenceMohimarnob Paul Mithun100% (1)