Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Kelly Hose PDF

Caricato da

Kaleem UllahTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Kelly Hose PDF

Caricato da

Kaleem UllahCopyright:

Formati disponibili

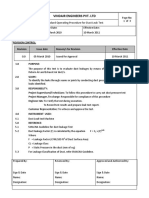

Intermediate Well Control Equipment Inspection Criteria

Equipment Group : Kelly Hose

Drilling Contractor :

Rig Unit Number – Contractor :

Rig Unit Number – PDO :

Present Well Location :

Date

Make/Brand:

Type :

Serial Number :

Year of Manufacturing

When : Conducted by :

Last Major Maintenance

Last Intermediate Maintenance

Kelly Hoses ( Yearly )

Note :

1. No heating, welding, cutting and sandblasting is allowed on any part of this equipment.

2. PTW is required for pressure tests in the field. No heating, welding, or cutting is allowed on any part of

this equipment.

3. All repair work to be executed and certified by 3rd party.

4. 3rd party is required for NDT, US and pressure testing.

5. PTW is required for pressure tests in the field.

6. Hoses to be inspected as per EP 2006-5393

Visual Done / Comments

Inspect Correct ?

ion YES NO

1 Remove, degrease and pressure clean lines and

hoses.

2 Check for any damage, deformity on lines and

the hose body.

3 Visually check outside for wear, damage,

corrosion and blisters etc.

4 Check hammer union, seals and sealing areas

5 Visual and dimensional check of male wing half

6 Visual and dimensional check of female union

thread half

7 Visual and dimensional check male hub

8 Visual and dimensional check of segment

9 Check flanges and ring grooves for wear and

corrosion.

10 Inspect the lifting and safety clamps.

11 Install hoses in place and carry out pressure test

to maximum Working pressure along with

valves.

12 Record pressure test on chart recorder.

Well Control Equipment Intermediate Inspection: Kelly Hose Generated by : WCF

Page 1 of 2

All above Name : Company : Date : Signature :

Inspections &

Tests conducted

by :

(Authorized Third

Party Inspection

Company)

Agreed by :

(Contractor Rig

Manager)

Verified by :

(PDO Site

Representative)

Authorized by :

(Contractor DS)

Seen by :

(PDO SWE)

Well Control Equipment Intermediate Inspection: Kelly Hose Generated by : WCF

Page 2 of 2

Potrebbero piacerti anche

- 2013 PACCAR MX-13: Diagnostic Service Manual EPA2013Documento373 pagine2013 PACCAR MX-13: Diagnostic Service Manual EPA2013Michał ŁusiewiczNessuna valutazione finora

- TPI For Pressure VesselDocumento10 pagineTPI For Pressure VesselBhavani Prasad100% (2)

- API Inspection Categories Drilling RIG Equipment HoistingDocumento5 pagineAPI Inspection Categories Drilling RIG Equipment Hoistingmalikpdj100% (6)

- MG-HSEQ-Q-P-0268 Rev A1 Corporate Procedure For Visual InspectionDocumento11 pagineMG-HSEQ-Q-P-0268 Rev A1 Corporate Procedure For Visual InspectionAbdelrahman Hosny100% (1)

- Daily Tool Pusher ChecklistDocumento2 pagineDaily Tool Pusher ChecklistKaleem UllahNessuna valutazione finora

- Well Testing Project Management: Onshore and Offshore OperationsDa EverandWell Testing Project Management: Onshore and Offshore OperationsNessuna valutazione finora

- Indicative Inspection & Test Plan : Project: - Iocl PanipatDocumento2 pagineIndicative Inspection & Test Plan : Project: - Iocl PanipatAshish DhokNessuna valutazione finora

- Mud Pump - High Pressure Lines PDFDocumento7 pagineMud Pump - High Pressure Lines PDFKaleem UllahNessuna valutazione finora

- Mud Pump - High Pressure Lines PDFDocumento7 pagineMud Pump - High Pressure Lines PDFKaleem UllahNessuna valutazione finora

- API 510 - Petrosync CourseDocumento301 pagineAPI 510 - Petrosync CourseThân Kha100% (15)

- CV Shoaib Anwar - Mechanical Inspector Multi Discipline - ZDocumento4 pagineCV Shoaib Anwar - Mechanical Inspector Multi Discipline - Zshoaib2scribedNessuna valutazione finora

- Engineer Maintenance and OperationsDocumento244 pagineEngineer Maintenance and OperationsMark McCord100% (2)

- Inspection and Test Plan For Shell and Tube Heat ExchangerDocumento2 pagineInspection and Test Plan For Shell and Tube Heat Exchangeralokbdas100% (1)

- Work Instruction On Tube ExpansionDocumento40 pagineWork Instruction On Tube Expansionjayaarnav100% (1)

- Section 11: Pre-Trip Vehicle Inspection TestDocumento10 pagineSection 11: Pre-Trip Vehicle Inspection TestAsad KhanNessuna valutazione finora

- THE THIRD PART INSPECTION FOR VALVES - OdtDocumento8 pagineTHE THIRD PART INSPECTION FOR VALVES - OdtVelibor StokicNessuna valutazione finora

- A1Z5L2 - Appendix VI - Valve Commissioning Checklist - USDocumento1 paginaA1Z5L2 - Appendix VI - Valve Commissioning Checklist - USAlpesh PatelNessuna valutazione finora

- Red Baron General CatalogDocumento40 pagineRed Baron General CatalogKaleem Ullah100% (1)

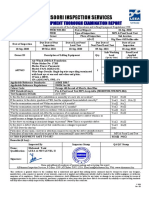

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocumento3 pagineAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNessuna valutazione finora

- RightShip Inspection and Assessment Questionnaire - Final - Questions OnlyDocumento95 pagineRightShip Inspection and Assessment Questionnaire - Final - Questions Onlymolmol88% (16)

- Fire Fighting ChecklistDocumento10 pagineFire Fighting ChecklistSrikanth Shanmugam0% (1)

- Project Information: Hazard Risk Control MeasureDocumento7 pagineProject Information: Hazard Risk Control MeasureAlejandro CampomarNessuna valutazione finora

- Inspection and Test Plan For Reciprocating CompressorDocumento21 pagineInspection and Test Plan For Reciprocating CompressorNorman Morales100% (1)

- Coflexip User Guide PDFDocumento40 pagineCoflexip User Guide PDFKaleem UllahNessuna valutazione finora

- Coflexip User Guide PDFDocumento40 pagineCoflexip User Guide PDFKaleem UllahNessuna valutazione finora

- Inspection and Test Plan For Pressure VesselDocumento2 pagineInspection and Test Plan For Pressure Vesselalokbdas50% (2)

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Documento28 pagineField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNessuna valutazione finora

- Intermediate Inspection Criteria, Well Control Equipment: Equipment Group: Shooting NippleDocumento2 pagineIntermediate Inspection Criteria, Well Control Equipment: Equipment Group: Shooting NippleKaleem UllahNessuna valutazione finora

- 510 Closed Exam A, Rev 9Documento21 pagine510 Closed Exam A, Rev 9Pamela Lee100% (1)

- 510 Final QuestionsDocumento16 pagine510 Final QuestionsSenthil Periyasamy100% (1)

- Isolated SurveyDocumento18 pagineIsolated SurveyMartin Laurence Garcia PlasabasNessuna valutazione finora

- 32-Ve-711 (Hydrostatic Test Procedure Piping - FT Gas) A11 PDFDocumento5 pagine32-Ve-711 (Hydrostatic Test Procedure Piping - FT Gas) A11 PDFMarlon TurnerNessuna valutazione finora

- Engineering Standards & Specifications: Security Level: CONFIDENTIALDocumento29 pagineEngineering Standards & Specifications: Security Level: CONFIDENTIALRod RoperNessuna valutazione finora

- Equipment Group:: Intermediate Inspection Criteria, Well Control EquipmentDocumento2 pagineEquipment Group:: Intermediate Inspection Criteria, Well Control Equipmentkaleem ullah janNessuna valutazione finora

- SAIC-A-2024 Rev 2Documento2 pagineSAIC-A-2024 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Heat Exchanger InspectionDocumento9 pagineHeat Exchanger Inspectionpstechnical_43312697Nessuna valutazione finora

- Pakinstan Glycol PresentationDocumento19 paginePakinstan Glycol PresentationKaleem UllahNessuna valutazione finora

- 11 5K 5K Annular BOPDocumento4 pagine11 5K 5K Annular BOPEdwin MP0% (1)

- Oaw 5.0 - 5 Tonne Winch User ManualDocumento46 pagineOaw 5.0 - 5 Tonne Winch User Manualtspaes67% (3)

- Third Party Inspection For Storage TankDocumento8 pagineThird Party Inspection For Storage TankGeroldo 'Rollie' L. QuerijeroNessuna valutazione finora

- Gms Ele Itp 001 HV & LV SwitchgearDocumento12 pagineGms Ele Itp 001 HV & LV Switchgearnidnitrkl051296100% (1)

- Epc P M - T - C E: Sr. Project Engineer (Project Management) - May2015-April19Documento3 pagineEpc P M - T - C E: Sr. Project Engineer (Project Management) - May2015-April19soumya19800000000Nessuna valutazione finora

- Conformity of Structural Steel Products and StructuresDocumento5 pagineConformity of Structural Steel Products and StructuresStephen HicksNessuna valutazione finora

- Work Instructions For Rolling of PlatesDocumento3 pagineWork Instructions For Rolling of PlatesPravin Patil100% (1)

- Tpi ValveDocumento6 pagineTpi ValveAlfonNessuna valutazione finora

- Pre-Hydrotest Check List-FormatDocumento1 paginaPre-Hydrotest Check List-FormatHanuman Rao0% (1)

- TUV India PRESSURE VESSEL InspectionDocumento24 pagineTUV India PRESSURE VESSEL InspectionParthiban NCNessuna valutazione finora

- TEC 093000 MET DoR 001 (Method Statement For Ceramic Tiles Wall & Floor) (K)Documento12 pagineTEC 093000 MET DoR 001 (Method Statement For Ceramic Tiles Wall & Floor) (K)Gerson FernandesNessuna valutazione finora

- VINDAIR SOP.01 Duct Pressure TestDocumento3 pagineVINDAIR SOP.01 Duct Pressure TestRamakrishna Agumbe100% (1)

- Stuck Pipe Self Learning CourseDocumento65 pagineStuck Pipe Self Learning Courseafreis29100% (2)

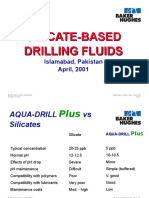

- Drilling Fluid Systems: © 2004 Baker Hughes Incorporated All Rights ReservedDocumento33 pagineDrilling Fluid Systems: © 2004 Baker Hughes Incorporated All Rights ReservedKaleem UllahNessuna valutazione finora

- IEC 62446-3 2017 Photovoltaic (PV) SystemsDocumento42 pagineIEC 62446-3 2017 Photovoltaic (PV) SystemsMarcelo Peixoto Del Peloso100% (2)

- OPERATING MANUAL Biomass BoilerDocumento23 pagineOPERATING MANUAL Biomass BoilerCORPORACION VENMATCO100% (1)

- Chapter 3 Specifying Quality For Tourism and Hospitality ServicesDocumento24 pagineChapter 3 Specifying Quality For Tourism and Hospitality ServicesMaureen AlmazarNessuna valutazione finora

- JMS For Drainage & Sewage WorksDocumento16 pagineJMS For Drainage & Sewage WorksazrulNessuna valutazione finora

- Adapters and Drilling SpoolsDocumento2 pagineAdapters and Drilling SpoolsKaleem UllahNessuna valutazione finora

- HP Hoses PDFDocumento2 pagineHP Hoses PDFKaleem UllahNessuna valutazione finora

- High Pressure Lines PDFDocumento3 pagineHigh Pressure Lines PDFKaleem UllahNessuna valutazione finora

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: Mud / Gas SeparatorDocumento2 pagineIntermediate Well Control Equipment Inspection Criteria: Equipment Group: Mud / Gas SeparatorKaleem Ullah0% (1)

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: Choke Line Coflexip Type HoseDocumento2 pagineIntermediate Well Control Equipment Inspection Criteria: Equipment Group: Choke Line Coflexip Type HoseKaleem UllahNessuna valutazione finora

- Fuid End PDFDocumento2 pagineFuid End PDFKaleem UllahNessuna valutazione finora

- Kelly Cocks PDFDocumento2 pagineKelly Cocks PDFKaleem UllahNessuna valutazione finora

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: SIDE OUTLET VALVESDocumento3 pagineIntermediate Well Control Equipment Inspection Criteria: Equipment Group: SIDE OUTLET VALVESkaleem ullah janNessuna valutazione finora

- SMPV ProformasNewDocumento20 pagineSMPV ProformasNewSanjeet Kumar SinghNessuna valutazione finora

- Hydro Test ProcedureDocumento5 pagineHydro Test ProcedureBharat BhoirNessuna valutazione finora

- Mps SDM 2014 Tp042Documento37 pagineMps SDM 2014 Tp042Janardhan Surya100% (1)

- Pneumatic Test ProcedureDocumento5 paginePneumatic Test ProcedureBharat BhoirNessuna valutazione finora

- HookDocumento5 pagineHookHarris ShehzadNessuna valutazione finora

- Piping InterviewDocumento9 paginePiping Interviewsatyammmishra0101Nessuna valutazione finora

- Valve InspectionDocumento6 pagineValve InspectionMuhammad ZainNessuna valutazione finora

- Inspection and Test Plan For Pressure Vessel - Important PointsDocumento21 pagineInspection and Test Plan For Pressure Vessel - Important PointsNorman MoralesNessuna valutazione finora

- STS QAC SOP 008 Tube Plugging ProcedureDocumento7 pagineSTS QAC SOP 008 Tube Plugging Proceduremohd as shahiddin jafriNessuna valutazione finora

- Checklist For Tank No 1Documento2 pagineChecklist For Tank No 1sathi11189Nessuna valutazione finora

- Third Party Inspection For Water Tube Boiler - ProcedureDocumento5 pagineThird Party Inspection For Water Tube Boiler - ProcedureMadhan KannanNessuna valutazione finora

- WC059 AMG Metal Non Drainable Louver Test - MSRKDocumento9 pagineWC059 AMG Metal Non Drainable Louver Test - MSRKAMG Co.Nessuna valutazione finora

- Velosi Group of Companies: FLASH REPORT - InspectionDocumento1 paginaVelosi Group of Companies: FLASH REPORT - Inspectionsathi11189Nessuna valutazione finora

- Reinforcement Inspection Record: Girder ProductionDocumento7 pagineReinforcement Inspection Record: Girder ProductionThai Hai LyNessuna valutazione finora

- TLDD 2007 1AAG Q02 2001 A1 Non Destructive Examination Procedures (NDE) PTDocumento12 pagineTLDD 2007 1AAG Q02 2001 A1 Non Destructive Examination Procedures (NDE) PTThân KhaNessuna valutazione finora

- Axial Flow For Industry 1Documento9 pagineAxial Flow For Industry 1Lipika GayenNessuna valutazione finora

- Annx-A (Inhouse Testing & Inspection Parameters of Ci Sluice Gates)Documento2 pagineAnnx-A (Inhouse Testing & Inspection Parameters of Ci Sluice Gates)BINOY DASNessuna valutazione finora

- PPM CHECK LIST - Format 1Documento26 paginePPM CHECK LIST - Format 1Conrad WaluddeNessuna valutazione finora

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocumento9 pagineAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNessuna valutazione finora

- Appendix 11F: Operational ChecklistsDocumento15 pagineAppendix 11F: Operational Checklists许爱文Nessuna valutazione finora

- FSC Trigonometric Values HandoutDocumento2 pagineFSC Trigonometric Values HandoutMuhammad AhmadNessuna valutazione finora

- Kelly Cocks PDFDocumento2 pagineKelly Cocks PDFKaleem UllahNessuna valutazione finora

- Fuid End PDFDocumento2 pagineFuid End PDFKaleem UllahNessuna valutazione finora

- Field Eng Trainee - Wellsite GuidelinesDocumento2 pagineField Eng Trainee - Wellsite GuidelinesKaleem UllahNessuna valutazione finora

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: Choke Line Coflexip Type HoseDocumento2 pagineIntermediate Well Control Equipment Inspection Criteria: Equipment Group: Choke Line Coflexip Type HoseKaleem UllahNessuna valutazione finora

- PDF - Filtration Services - 4135100 - 01 PDFDocumento42 paginePDF - Filtration Services - 4135100 - 01 PDFKaleem UllahNessuna valutazione finora

- PDF - Filtration Services - 4135100 - 01 PDFDocumento42 paginePDF - Filtration Services - 4135100 - 01 PDFKaleem UllahNessuna valutazione finora

- KCAD HBW M1 Entry TestDocumento12 pagineKCAD HBW M1 Entry TestKaleem UllahNessuna valutazione finora

- Products and ApplicationsDocumento54 pagineProducts and ApplicationsKaleem UllahNessuna valutazione finora

- Schlum-Abandon & Plugg - PresenatationDocumento33 pagineSchlum-Abandon & Plugg - PresenatationKaleem UllahNessuna valutazione finora

- B+V MANUAL TONG Type BV65 VS09 A4Documento2 pagineB+V MANUAL TONG Type BV65 VS09 A4Kaleem UllahNessuna valutazione finora

- 2-Pakistan Product Concentrations PresentationDocumento26 pagine2-Pakistan Product Concentrations PresentationKaleem UllahNessuna valutazione finora

- Pakistan Oil-Based Fluids PresentationDocumento42 paginePakistan Oil-Based Fluids PresentationKaleem UllahNessuna valutazione finora

- Solid Control Circulating SystemDocumento55 pagineSolid Control Circulating SystemKaleem UllahNessuna valutazione finora

- Pakistan Silicate-Based Fluids PresentationDocumento19 paginePakistan Silicate-Based Fluids PresentationKaleem UllahNessuna valutazione finora

- Nurture Module Scheme Rules: English Version 11.2-2 Mandatory From: 1 April 2021Documento32 pagineNurture Module Scheme Rules: English Version 11.2-2 Mandatory From: 1 April 2021KarenNessuna valutazione finora

- Vehicle Registration in AustraliaDocumento8 pagineVehicle Registration in AustraliaInarNessuna valutazione finora

- NorkaDocumento3 pagineNorkaJesus AlcarazNessuna valutazione finora

- Maintenance of A Hydroelectric Power Plant and Its ComponentsDocumento13 pagineMaintenance of A Hydroelectric Power Plant and Its Components2031 Ayush KshirsagarNessuna valutazione finora

- Exemple 8D VDADocumento8 pagineExemple 8D VDAmohamed zied jazaNessuna valutazione finora

- C708-08 Standard Specification For Nuclear-Grade Beryllium Oxide PowderDocumento4 pagineC708-08 Standard Specification For Nuclear-Grade Beryllium Oxide PowderAlabbas FadhelNessuna valutazione finora

- Fiber Inspection: Technical PosterDocumento3 pagineFiber Inspection: Technical Posterchuang xuNessuna valutazione finora

- Purchase Order Requisition R-1910-0318 Rev 0Documento27 paginePurchase Order Requisition R-1910-0318 Rev 0AnaNessuna valutazione finora

- Masonry Dam Inspection NDTDocumento2 pagineMasonry Dam Inspection NDTApurbaa SarmaNessuna valutazione finora

- 12 - Aluminium WorksDocumento16 pagine12 - Aluminium WorksTemur LomidzeNessuna valutazione finora

- Van-Beest Catalogue Complete EN PDFDocumento175 pagineVan-Beest Catalogue Complete EN PDFRuồi TrâuNessuna valutazione finora

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocumento1 paginaInspection & Testing Requirements Scope:: Test and Inspection PerSathish Kumar SelvarajNessuna valutazione finora

- Clutch System RectificationDocumento10 pagineClutch System RectificationIbu EmasNessuna valutazione finora

- B+V Manual - CLS-100-150-Rev003-08042010Documento28 pagineB+V Manual - CLS-100-150-Rev003-08042010ZEESHAN ASHRAFNessuna valutazione finora