Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Conductance Tester: With DIY Sensor

Caricato da

rosaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Conductance Tester: With DIY Sensor

Caricato da

rosaCopyright:

Formati disponibili

TEST & MEASUREMENT

conductance tester

with DIY sensor

Conductivity in the sense

it is used in this article is

the ability of a substance

such as water to conduct

electric current. It is

expressed in terms of

current per unit of applied

voltage. It is the reciprocal

of resistivity. Conduc-

tance is the reciprocal of

resistance and is mea-

sured in siemens. It is

therefore the ratio of the

current through a sub-

stance to the potential dif-

ference at its ends.The INTRODUCTION CONDUCTIVITY AND

Water with a very high pH is not good CONDUCTANCE

tester described in this for fish, plants or making tea or coffee. Conductivity (or specific conductance),

This is the reason that many aquarium being the reciprocal of resistivity, is

article is intended for owners, orchid growers, horticulturists, measured in the same way as resis-

assessing the quality of and many others use distilled or fil- tance and expressed in S m–1 (siemens

tered water. Water filters are very pop- per metre); its symbol is σ. At constant

water, based on the acid- ular in domestic use, where the quality temperature, the value of conductance,

ity or alkalinity (pH), by of tap water is suspect. However, water

filters themselves present a risk of ger-

symbol G, of a substance depends on

the cross-sectional area, A, in m2 , the

means of a measurement mination, requiring good attention to length, l, in m, and the conductivity, σ,

cleanliness (bottle needs thorough in S m–1:

of the conductance of the washing at least once a week).

water. A very environment-friendly way G= σ A/ l. S (siemens)

of obtaining low-pH water is the use of

rainwater, but this depends heavily on This equation can be used with a solid

the area where the rainwater is col- as well as with a liquid substance.

lected. Such water may be tested for The sensor used in the present

low pH, that is, low conductivity, with tester consists of two annular elec-

the present tester. trodes having a cross-sectional area of

The pH of water is a logarithmic 1 cm which are spaced 1 cm apart.

index of the hydrogen-ion concentra- These dimensions make the calculation

tion in the water. It is given by of the conductance of the water being

tested straightforward.

pH=log 10 (1/[H + ]) Pure water, sold as distilled water, as

used, for instance, in electric irons, lead-

where [H+] is the hydrogen-ion con- acid batteries and for horticultural pur-

centration. A pH below 7 indicates acid- poses, has a conductivity of 1×10 –3

Design by P. Baer ity and one above 7, alkalinity, at 25 °C. S m–1, so that the present meter would

Elektor Electronics 1/99

30

Probe

1

9V

LCD1 8 12 16 3.5 DIGIT 9V

DP3 DP2 DP1

R7 D3

BT1 C6

20k

C11 37

AC

9V 38

OF 100n

28

100n 39 2P T4

X

2 1

Y BP

3 K 40 R8

BAT C2 C4

BC557B

22k

C3 330n T3

10µ

G3

G2

G1

E3

D3

C3

B3

A3

E2

D2

C2

B2

A2

E1

D1

C1

B1

A1

F3

F2

F1

63V

9V 32 31 9 10 11 29 30 27 26 13 14 15 24 25 23 22 17 18 19 20 21 220n

BC547B

1M

R1 R3

R6

21 20 19 22 17 18 15 24 16 23 25 13 14 9 10 11 12 7 6 8 2 3 4 5 D2

470k

10k

R2

G3

F3

E3

D3

C3

B3

A3

G2

F2

E2

D2

C2

B2

A2

G1

F1

E1

D1

C1

B1

A1

BP

POL

AB

1 1M

31 V T1

IN HI 36 C5 T2

REF HI 330n R5

P1 IC1 C1

100k

37 ICL7106

TEST 35

100n BF

10k REF LO

4M7

32 245A BC547B

30 COMM R4

OSC 1

OSC 2

OSC 3

C REF

C REF

BUFF

IN LO 26 D1

A/Z

INT

V

40 39 38 34 33 29 28 27

R9 R10

1N4148

C7 C8 C9 C10

100k

47k

100p 100n 470n 220n

980104 - 11

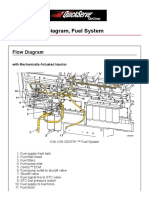

Figure 1. Circuit diagram of the

measure 10 µS (equivalent to a resis- The test voltage is taken from across conductance meter.

tance of 100 kΩ). When the water R2-R3-C3. During the negative half-

becomes less pure, the resistance period of the backplane voltage, tran-

between the electrodes drops, and the sistor T1 links the test voltage to earth.

value of conductance rises. Normal tap In essence, therefore, this FET operates is the test voltage, and Uref is the refer-

water has a conductance of about as a clocked synchronous rectifier with- ence voltage). Preset P1 provides com-

1 mS, and sea water, 100 mS or more. out a threshold voltage and conse- pensation for component and sensor

quent non-linearity. tolerances.

THE TESTER The direct test voltage so obtained

From the above, it is clear that the is directly proportional to the resis- THE SENSOR

tester must be capable of measuring tance of the water. It must, however, be To make the sensor, two rings of brass

resistance or conductance. This seems inverted to provide a test display in or other easily soldered metal, a 15 cm

simple enough: take a constant current siemens. In the present circuit this is length of RG58U coaxial cable, and a

source, insert the sensor in a potential achieved by applying the test voltage heavy-duty soldering iron are needed.

divider and apply the voltage across to the reference voltage input (REF. The brass rings should have an inner

the sensor via an analogue-to-digital HI)of IC1 and a constant voltage to the

converter (ADC) to a suitable display. test input pins (IN HI and IN LO). This

Unfortunately, the reality is not so results in the display showing UC/UT,

simple, since the resistance of a fluid instead of, as normal, U/Uref. (UC is the Figure 2. Parts required for con-

must be measured with an alternating constant voltage across pins 30, 31, UT structing the sensor.

instead of a direct current. This is

because a direct current would cause

electrolysis which after a while would

distort the sensor electrodes. 2

The tester, whose circuit diagram is RG 58 U

shown in Figure 1, therefore uses a rec-

tangular current. This enables the ADC

to drive the liquid-crystal display

(LCD) via pin 21, the backplane voltage

terminal.

The backplane voltage is used to solder braid

cover with

silicon cement

switch, via transistor T2, constant-cur- here

rent sink T3-D2-R6, which is combined

with constant-current source T4-D3-R7.

Capacitor C4 is charged and discharged

in rhythm with the backplane voltage at disc of brass

a rate of 100 mA. Because of this or other easily d = 10 mm

soldered metal

arrangement, the 100 µA current from

the source is absorbed by the sink when

the capacitor is being discharged. Con-

sequently, an alternating current of solder conductor cover with

±100 µA flows through the tester, which of coax cable here 6 mm silicon cement

causes a potential drop of ±100 µV Ω–1 13 mm

980104 - 12

across the resistance, that is, the water.

Elektor Electronics 1/99 31

+9V 0 Parts list

3

H1

FIX2

Probe Resistors:

R7

LCD1 C2 C3

C11 R1 = 470 kΩ

980104-1

1 D3 R2, R3 = 1 MΩ

R3

T4 R4 = 4.7 MΩ

R5, R9 = 100 kΩ

IC1

R1

R6 = 10 kΩ

R6

R8

D2 R7 = 20 kΩ

R2

R4

C1 C4 T3 R8 = 22 kΩ

ROTKELE )C(

1-401089

T1

R10 = 47 kΩ

P1 = 10 kΩ preset potentiometer

C5 T2

1

C8

C7

R5 Capacitors:

C10 C9

R10 R9

FIX3

C1, C6, C8, C11 = 0.1 µF

FIX4

D1

C6 P1

C2 = 10 µF, 63 V, radial

C3, C10 = 0.22 µF

C4, C5 = 0.33 µF

C7 = 100 pF

C9 = 0.47 µF

(C) ELEKTOR

980104-1

Semiconductors:

D1 = 1N4148

D2, D3 = LED, green, 3 mm

T1 = BF254A

T2, T3 = BC547B

T4 = BC557B

Integrated circuits:

IC1 = ICL7106CPL (Maxim)

Miscellaneous:

LCD1 = 3.5 digit liquid-crystal dis-

play (note that IC1 and LCD1 are

available as a set)

Figure 3. The printed- BT1 = 9 V dry battery with clip

diameter of 6 mm and circuit board for the ing each other) should 1 off switch with on contact

an outer one of 13 mm conductance tester. then be covered with Enclosure as appropriate

to give them an effec- silicon cement. PCB Order no. 980104-1 (see Read-

tive area of just under ers Services towards the end of

1 cm2. The inner diameter allows them CONSTRUCTION this issue)

to just fit over the inner conductor of The remainder of the tester is best con-

the coaxial cable, whose outer insula- structed on the printed-circuit board

tion must be removed over a length of shown in Figure 3. Mind the polarity

about 15 mm from one end and 10 mm of the diodes and electrolytic capaci- Conductivity at 20 °C

of the exposed braid cut off. The tors. The IC should be soldered directly

remaining 5 mm of braid must be to the board to allow the display to be Silver 1.6 × 10–8 S m–1

folded back over the outer insulation fitted directly above it.

Copper 1.7

of the cable. This ensures that the two Connect a standard potentiometer

brass rings are about 1 cm apart (see across the test inputs and check that the Aluminium 2.8

Figure 2). The inner core of the coaxial display shows corresponding conduc- Tungsten 5.6

cable is then soldered to the outer brass tance values when the potentiometer is Nickel 6.8

ring and the braid to turned from, say, 10 kΩ Iron 10

the inner ring. The Figure 4. The com- to 1 kΩ. Steel 18

outer surfaces of the pleted prototype When all is well, fit Manganin 44

rings (but not those fac- board. the completed board Carbon 3500

into a suitable enclosure in which a

cut-out for the display has been pro-

vided. Connect the sensor to the probe

terminals as shown in Figure 4. Do not

forget an on/off switch.

F I N A L LY …

The tester has a range of 50 µS, which

corresponds to a resistance of 20 kΩ

and a maximum test voltage at IC1 of

2 V. This value will be displayed when

the tester, or rather, the sensor, is dry.

The upper limit of the test range

(1999 µS) is set by the characteristics of

IC1. Note also that the basic error of 5

per cent increases slightly when the

test range is given an upper limit of

more than 1000 µS. [980104]

Elektor Electronics 1/99 33

Potrebbero piacerti anche

- Greenberg 1962Documento5 pagineGreenberg 1962TET2005Nessuna valutazione finora

- Chapter 9Documento16 pagineChapter 9muftahgloriaNessuna valutazione finora

- Automatic Water Level Indicator: Oyndrila Roy, Aranyak Roy, DR - Debasis RoyDocumento4 pagineAutomatic Water Level Indicator: Oyndrila Roy, Aranyak Roy, DR - Debasis RoyPeterNessuna valutazione finora

- Licensed To Arun Kumar Das: (Reaffirmed 2017)Documento4 pagineLicensed To Arun Kumar Das: (Reaffirmed 2017)Indira MukherjeeNessuna valutazione finora

- PH Measurement and Control - Che Aug 2010Documento8 paginePH Measurement and Control - Che Aug 2010hwang2Nessuna valutazione finora

- Water Level Indicator CircuitDocumento3 pagineWater Level Indicator CircuitMuhammad SalmanNessuna valutazione finora

- Conductivimetro DDS 12DWDocumento6 pagineConductivimetro DDS 12DWPaola CardozoNessuna valutazione finora

- Water Level Indicator: Project Report ONDocumento22 pagineWater Level Indicator: Project Report ONAditi MahendraNessuna valutazione finora

- Adec Project ReportDocumento3 pagineAdec Project ReportUsama WarisNessuna valutazione finora

- 03 - ResistivityDocumento45 pagine03 - ResistivityBashirNessuna valutazione finora

- Class 8 Pressure MeasurementDocumento33 pagineClass 8 Pressure MeasurementMaher Abu-ElolaNessuna valutazione finora

- PendahuluanDocumento15 paginePendahuluan045 Johannes KevinNessuna valutazione finora

- Cavalcante PESC05 PDFDocumento7 pagineCavalcante PESC05 PDFbacuoc.nguyen356Nessuna valutazione finora

- 2520 Salinity PDFDocumento3 pagine2520 Salinity PDFGloria JimenzNessuna valutazione finora

- Basic Sensor and PrincipleDocumento60 pagineBasic Sensor and Principleyeshwanth reddy RachumallaNessuna valutazione finora

- Automatic Water Level Controller": A Project Report OnDocumento7 pagineAutomatic Water Level Controller": A Project Report OnUpendra KumarNessuna valutazione finora

- MI 3295 Test Conditions v1Documento10 pagineMI 3295 Test Conditions v1Soofi AthamNessuna valutazione finora

- Resilite Red-Green Purity LightsDocumento2 pagineResilite Red-Green Purity LightsGonzalo RodríguezNessuna valutazione finora

- Liquid ConductivityDocumento4 pagineLiquid ConductivityCasey ChengNessuna valutazione finora

- Physics RecordDocumento11 paginePhysics RecordM. Mohamed SahalNessuna valutazione finora

- Mosfets As Current Sources: Analog ElectronicsDocumento22 pagineMosfets As Current Sources: Analog ElectronicsPARTH RAMANUJNessuna valutazione finora

- Asad Ahmed Khan Muhammad AliDocumento9 pagineAsad Ahmed Khan Muhammad AliAyush AgarwalNessuna valutazione finora

- Eee3352 L3Documento34 pagineEee3352 L3Desmond CheweNessuna valutazione finora

- Experiment 7 AC Circuits: ObjectivesDocumento6 pagineExperiment 7 AC Circuits: ObjectivesMujtabaAliNessuna valutazione finora

- Test 777888 PPPQQQDocumento3 pagineTest 777888 PPPQQQLeonard GržetićNessuna valutazione finora

- Full Wave Rectifier: ObjectiveDocumento18 pagineFull Wave Rectifier: ObjectiveRajesh UpadhyayNessuna valutazione finora

- Puentes AC - UnlockedDocumento21 paginePuentes AC - Unlockededmevacu1996Nessuna valutazione finora

- De Sauty BridgeDocumento3 pagineDe Sauty BridgeMalluri Veera BrahmamNessuna valutazione finora

- Lec 4 - Sensor Principles Part 2Documento30 pagineLec 4 - Sensor Principles Part 2Mohsin SarfrazNessuna valutazione finora

- Zelio Control - Liquid Level Control Relays RM4LDocumento4 pagineZelio Control - Liquid Level Control Relays RM4LbvdbNessuna valutazione finora

- Assignment 1 Summer Session 2009 10Documento5 pagineAssignment 1 Summer Session 2009 10asdf2121Nessuna valutazione finora

- Lab Iv. Silicon Diode Characteristics: 1. ObjectiveDocumento9 pagineLab Iv. Silicon Diode Characteristics: 1. ObjectiveRaja MariyappanNessuna valutazione finora

- Formation Evaluation Based On Logging DataDocumento136 pagineFormation Evaluation Based On Logging DataNizar AliNessuna valutazione finora

- Finding The Minimum Input Impedance of A Second-Order Twofold-Gain Sallen-Key Low-Pass Filter Without CalculusDocumento9 pagineFinding The Minimum Input Impedance of A Second-Order Twofold-Gain Sallen-Key Low-Pass Filter Without CalculusFederico BordonNessuna valutazione finora

- Water Level IndicatorDocumento5 pagineWater Level IndicatorAYUSH PANDEY100% (1)

- Closed Conduit Measurement Techniques: Pipeline SystemsDocumento22 pagineClosed Conduit Measurement Techniques: Pipeline SystemsPramod RathoaNessuna valutazione finora

- Electrical Resistivity Logs: NotesDocumento59 pagineElectrical Resistivity Logs: Notesdeyaa SadoonNessuna valutazione finora

- 3rd Semester Lab 201Documento36 pagine3rd Semester Lab 201Noor HussainNessuna valutazione finora

- A Full Wave RectifierDocumento17 pagineA Full Wave RectifierAnonymous xoQWeF4Nessuna valutazione finora

- WBR ReceiverDocumento5 pagineWBR ReceiverFW De LangenNessuna valutazione finora

- Experiment 1: Identification, Specifications and Testing of R, L, C Components (Color Codes), Bread BoardsDocumento36 pagineExperiment 1: Identification, Specifications and Testing of R, L, C Components (Color Codes), Bread BoardsMontiNessuna valutazione finora

- ProposalDocumento4 pagineProposaljawadmalik6467Nessuna valutazione finora

- Supplement For HashemiDocumento9 pagineSupplement For HashemiDeepak KumarNessuna valutazione finora

- Ibersensor 119Documento5 pagineIbersensor 119Jorge AndradeNessuna valutazione finora

- Standard CapacitorsDocumento2 pagineStandard CapacitorsDeepen SharmaNessuna valutazione finora

- Experiment 1Documento9 pagineExperiment 1Kenneth SablayNessuna valutazione finora

- TubesDocumento1 paginaTubesEnggarDwiKusumaNessuna valutazione finora

- SD7000 InstructionsDocumento8 pagineSD7000 InstructionsMarcelo CheloNessuna valutazione finora

- Indigo ElectrolysisDocumento5 pagineIndigo Electrolysismazahir razaNessuna valutazione finora

- Rain Alarm ProjectDocumento28 pagineRain Alarm Projectrinkoo067% (6)

- Department of Electronics Engineering: Salinity TestmeterDocumento13 pagineDepartment of Electronics Engineering: Salinity TestmeterShinthu Bargavi VenkatesanNessuna valutazione finora

- Water Level Indicator Review PaperDocumento9 pagineWater Level Indicator Review PaperNaseem KhanNessuna valutazione finora

- Sea Border Limit DetectorDocumento22 pagineSea Border Limit DetectorRavi RaoNessuna valutazione finora

- 1 The Wheat Stone BridgeDocumento4 pagine1 The Wheat Stone BridgeShem Japheth EscalonaNessuna valutazione finora

- Chemistry Investigatory Electrochemical CellDocumento10 pagineChemistry Investigatory Electrochemical CellPriyansh ShuklaNessuna valutazione finora

- Water Level ControllerDocumento35 pagineWater Level ControllerSonaliShukla100% (1)

- Experimental Techniques For Conductivity Measurement and A Brief Review of Earlier LiteratureDocumento33 pagineExperimental Techniques For Conductivity Measurement and A Brief Review of Earlier LiteratureedeinsteinNessuna valutazione finora

- Convection Heat Transfer 3 Forced Internal FlowDocumento23 pagineConvection Heat Transfer 3 Forced Internal FlowMohit JaniNessuna valutazione finora

- Four Channel Energy Measurement IC: & DescriptionDocumento66 pagineFour Channel Energy Measurement IC: & DescriptionrosaNessuna valutazione finora

- IDT Wireless-Power PRB 20150415 PDFDocumento4 pagineIDT Wireless-Power PRB 20150415 PDFrosaNessuna valutazione finora

- 1509 00940Documento40 pagine1509 00940Shibu JohnsonNessuna valutazione finora

- Wireless Charge Module: Model: PW-WCG-01 / PW-WCG-02Documento4 pagineWireless Charge Module: Model: PW-WCG-01 / PW-WCG-02rosaNessuna valutazione finora

- TPS212x 2.8-V To 22-V Priority Power MUX With Seamless SwitchoverDocumento35 pagineTPS212x 2.8-V To 22-V Priority Power MUX With Seamless SwitchoverrosaNessuna valutazione finora

- 00960a PDFDocumento20 pagine00960a PDFrosaNessuna valutazione finora

- Ultra-Low On-Resistance and Compact Bidirectional Battery SwitchDocumento8 pagineUltra-Low On-Resistance and Compact Bidirectional Battery SwitchrosaNessuna valutazione finora

- SachinDocumento3 pagineSachinMahendraNessuna valutazione finora

- A Survey On Security and Privacy Issues of Bitcoin-1Documento39 pagineA Survey On Security and Privacy Issues of Bitcoin-1Ramineni HarshaNessuna valutazione finora

- Assignment of Chemistry For B.sc-B.ed First Semester Session 2019-2023-1Documento2 pagineAssignment of Chemistry For B.sc-B.ed First Semester Session 2019-2023-1Payal sahaNessuna valutazione finora

- Julia Dito ResumeDocumento3 pagineJulia Dito Resumeapi-253713289Nessuna valutazione finora

- DLP - Light Science 7Documento6 pagineDLP - Light Science 7Samara M. SalacayanNessuna valutazione finora

- Safety Procedures in Using Hand Tools and EquipmentDocumento12 pagineSafety Procedures in Using Hand Tools and EquipmentJan IcejimenezNessuna valutazione finora

- Obligatoire: Connectez-Vous Pour ContinuerDocumento2 pagineObligatoire: Connectez-Vous Pour ContinuerRaja Shekhar ChinnaNessuna valutazione finora

- Quarter 1-Week 2 - Day 2.revisedDocumento4 pagineQuarter 1-Week 2 - Day 2.revisedJigz FamulaganNessuna valutazione finora

- Sample Resume For Supply Chain Logistics PersonDocumento2 pagineSample Resume For Supply Chain Logistics PersonAmmar AbbasNessuna valutazione finora

- Implementation of E-Governance To Improve The Civil Administration Service Quality in Public SectorDocumento11 pagineImplementation of E-Governance To Improve The Civil Administration Service Quality in Public SectorChristie YohanaNessuna valutazione finora

- Buried PipelinesDocumento93 pagineBuried PipelinesVasant Kumar VarmaNessuna valutazione finora

- Guyana and The Islamic WorldDocumento21 pagineGuyana and The Islamic WorldshuaibahmadkhanNessuna valutazione finora

- PSA Poster Project WorkbookDocumento38 paginePSA Poster Project WorkbookwalliamaNessuna valutazione finora

- English Homework 10 Grammar Focus 2: Lecturer: Mr. Dr. H. Abdul Hamid, M.SiDocumento4 pagineEnglish Homework 10 Grammar Focus 2: Lecturer: Mr. Dr. H. Abdul Hamid, M.SiMutiara siwa UtamiNessuna valutazione finora

- Biography Thesis ExamplesDocumento7 pagineBiography Thesis Examplesreneewardowskisterlingheights100% (2)

- Hướng Dẫn Chấm: Ngày thi: 27 tháng 7 năm 2019 Thời gian làm bài: 180 phút (không kể thời gian giao đề) HDC gồm có 4 trangDocumento4 pagineHướng Dẫn Chấm: Ngày thi: 27 tháng 7 năm 2019 Thời gian làm bài: 180 phút (không kể thời gian giao đề) HDC gồm có 4 trangHưng Quân VõNessuna valutazione finora

- 2016 Closing The Gap ReportDocumento64 pagine2016 Closing The Gap ReportAllan ClarkeNessuna valutazione finora

- KsDocumento5 pagineKsnurlatifahNessuna valutazione finora

- Bullshit System v0.5Documento40 pagineBullshit System v0.5ZolaniusNessuna valutazione finora

- India TeenagersDocumento3 pagineIndia TeenagersPaul Babu ThundathilNessuna valutazione finora

- Final Project Strategic ManagementDocumento2 pagineFinal Project Strategic ManagementMahrukh RasheedNessuna valutazione finora

- Economic Review English 17-18Documento239 pagineEconomic Review English 17-18Shashank SinghNessuna valutazione finora

- Latched, Flip-Flops, and TimersDocumento36 pagineLatched, Flip-Flops, and TimersMuhammad Umair AslamNessuna valutazione finora

- Cummin C1100 Fuel System Flow DiagramDocumento8 pagineCummin C1100 Fuel System Flow DiagramDaniel KrismantoroNessuna valutazione finora

- Resume: Mr. Shubham Mohan Deokar E-MailDocumento2 pagineResume: Mr. Shubham Mohan Deokar E-MailAdv Ranjit Shedge PatilNessuna valutazione finora

- Training For Humans Guide: FAQ's How Many Sets/reps Should I Do Per Exercise?Documento28 pagineTraining For Humans Guide: FAQ's How Many Sets/reps Should I Do Per Exercise?Paulo Pires100% (1)

- Delonghi Esam Series Service Info ItalyDocumento10 pagineDelonghi Esam Series Service Info ItalyBrko BrkoskiNessuna valutazione finora

- Advanced Chemical Engineering Thermodynamics (Cheg6121) : Review of Basic ThermodynamicsDocumento74 pagineAdvanced Chemical Engineering Thermodynamics (Cheg6121) : Review of Basic ThermodynamicsetayhailuNessuna valutazione finora

- Baseline Scheduling Basics - Part-1Documento48 pagineBaseline Scheduling Basics - Part-1Perwaiz100% (1)

- Antena TelnetDocumento4 pagineAntena TelnetMarco PiambaNessuna valutazione finora