Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cromalin System Publication Specifications: Dupont Color Proofing-Cromalin

Caricato da

inzanerTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cromalin System Publication Specifications: Dupont Color Proofing-Cromalin

Caricato da

inzanerCopyright:

Formati disponibili

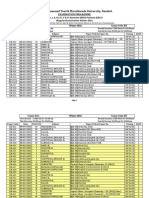

Cromalin® System Publication Specifications

Film C/P, C/N Receptor Stock CR/5 Toners SOP, SON Proof Finish C/TC

Exposure 150 lines/inch Comguide

ColorTrax® C/P C/P C/N

Layer Color Microlines Microlines Dot Gain C/N Dots Dot Gain

1 K Hold 8, Scum 6 Hold 11, Scum 8 24 ± 3% 2%–Partial 97% 23 ± 3%

2 C Hold 8, Scum 6 Hold 11, Scum 8 24 ± 3% 2%–Partial 97% 23 ± 3%

3 M Hold 8, Scum 6 Hold 11, Scum 8 24 ± 3% 2%–Partial 97% 23 ± 3%

4 Yt5 Hold 8, Scum 6 Hold 11, Scum 8 22 ± 3% 2%–Partial 97% 22 ± 3%

Note: SWOP densities should be read off of publication SWOP toner reference guide target density patch. There are

separate guides for CN and CP.

Laminator

Temperature Torque NIP Pressure*

C/N (T1179) 240°F ± 5°F 10 in/lb Orange Top 0.25 in

C4/CP 245°F ± 5°F 10 in/lb Red Top 0.20 in

CP 215°F ± 5°F 10 in/lb

C/TC 230°F ± 5F° 10 in/lb *Between stop pin on stop collar and stop adjustment screw

Toning Machines

ATM 2900 ATM II & III

Positive Negative Positive Negative CAT

Hopper Throat Gap 0.195–0.225 in 0.195 in 0.140 in 0.120 in No gap

Hopper Gap 0.160 ± .005 in 0.160 ± .005 in 0.160 ± .005 in 0.160 ± .005 in adjustment

Clean-up Bar — — 0.180–0.200 in 0.180–0.200 in required

Entrance Guide Gap — — 0.030 min 0.030 min

Toning Bars 0.175–0.205 in 0.175–0.195 in — —

Speed Range 3–7 ft/min 36–72 in/min 25–90 in/min

Exposure Equipment Exposure Equipment Approved by DuPont as of 9/27/89

Light Source Bulb # Peak 365 NM

Theimer 5 KW Ths5027 800 Microwatts/CM2 minimum

Theimer 6 KW Ths6027

Theimer 8 KW Ths8027 #400 Kokomo filter

Olec 5 KW AL53 L1250, L1261

Nuarc 6 KW System 631 EXP SYS LY33 Recommended using “low power”

Burgess 2 KW-4252VS System B1406-03/754-18025 setting for ColorTrax®

Vacuum Frame

Douthitt Option X 42 in (may go higher for higher KW light sources) distance between Kokomo

Teaneck Fast Draw filter and vacuum frame glass for 5 KW

Light Integrator

GTI Expo 19 Minimum 10 channel

OLEC AL985 Probe equipped with Schott UG-11 or Hoya 350 filter mounted at 45 degree angle towards light source

Miscellaneous

Room humidity 55% ± 5% RH; ColorTrax® room humidity 55% ± 15% RH

Room temperature 72°F ± 2°F

Use bleeder strips: thickness 0.004–0.007 in; place 1/8 in from film; run to matte

Vacuum drawdown ≥ 120 seconds used with chipboard

Use UV absorber over room light fixtures

*Peel table at 80°F ± 2°F, on table 30 seconds minimum before peel

*Use the Stouffer/UGRA wedge as a troubleshooting guide

*Hold solid 4 on Stouffer, solid 3 on UGRA *C/N only

DuPont Color Proofing—Cromalin®

Potrebbero piacerti anche

- LEDs Magazine Mar 2009Documento142 pagineLEDs Magazine Mar 2009inzanerNessuna valutazione finora

- LEDs Magazine Feb 2009Documento60 pagineLEDs Magazine Feb 2009inzanerNessuna valutazione finora

- LEDs Magazine June 2009Documento42 pagineLEDs Magazine June 2009inzanerNessuna valutazione finora

- How Do Current Circadian Metrics Relate To Physiology?Documento7 pagineHow Do Current Circadian Metrics Relate To Physiology?inzanerNessuna valutazione finora

- SSL rd21 Trott ToolsDocumento17 pagineSSL rd21 Trott ToolsinzanerNessuna valutazione finora

- LEDs Magazine Apr 2009Documento56 pagineLEDs Magazine Apr 2009inzanerNessuna valutazione finora

- Caliper For New Technologies?: Ruth TaylorDocumento30 pagineCaliper For New Technologies?: Ruth TaylorinzanerNessuna valutazione finora

- OLED Manufacturing Challenges: Jeff SpindlerDocumento16 pagineOLED Manufacturing Challenges: Jeff SpindlerinzanerNessuna valutazione finora

- What Is Considered A Circadian Phase Shift?: Phase T Phase TDocumento4 pagineWhat Is Considered A Circadian Phase Shift?: Phase T Phase TinzanerNessuna valutazione finora

- Discovering The Mindset: ImpossibleDocumento20 pagineDiscovering The Mindset: ImpossibleinzanerNessuna valutazione finora

- What Is Ideal Light?: The Office EnvironmentDocumento14 pagineWhat Is Ideal Light?: The Office EnvironmentinzanerNessuna valutazione finora

- Sustainable Manufacturing: Presented by Aaron Smith VP of Technology and R&DDocumento18 pagineSustainable Manufacturing: Presented by Aaron Smith VP of Technology and R&DinzanerNessuna valutazione finora

- Electrophosphorescence For Solid-State LightingDocumento15 pagineElectrophosphorescence For Solid-State LightinginzanerNessuna valutazione finora

- A Look Into Diffuse Luminaires and How To Characterize GlareDocumento17 pagineA Look Into Diffuse Luminaires and How To Characterize Glareinzaner100% (1)

- Oled Manufacturing Challenges - Some Input by Fraunhofer FepDocumento18 pagineOled Manufacturing Challenges - Some Input by Fraunhofer FepinzanerNessuna valutazione finora

- Phosphors For Next Generation Solid-State Lighting/Displays: Jim MurphyDocumento6 paginePhosphors For Next Generation Solid-State Lighting/Displays: Jim MurphyinzanerNessuna valutazione finora

- IES Economic Committee Value of Lighting / Quality Metrics: Michael MyerDocumento11 pagineIES Economic Committee Value of Lighting / Quality Metrics: Michael MyerinzanerNessuna valutazione finora

- Key Findings From The 2020 LED Manufacturing Supply Chain ReportDocumento15 pagineKey Findings From The 2020 LED Manufacturing Supply Chain ReportinzanerNessuna valutazione finora

- SSL rd21 Miller FutureDocumento15 pagineSSL rd21 Miller FutureinzanerNessuna valutazione finora

- Horticultural Lighting Value Metrics: Leora RadetskyDocumento13 pagineHorticultural Lighting Value Metrics: Leora RadetskyinzanerNessuna valutazione finora

- Light That Is Right: Ideal Light - With The Help of OpticsDocumento17 pagineLight That Is Right: Ideal Light - With The Help of OpticsinzanerNessuna valutazione finora

- DOE Workshop - Ask Me Session Retinal Physiology & Individual DifferencesDocumento7 pagineDOE Workshop - Ask Me Session Retinal Physiology & Individual DifferencesinzanerNessuna valutazione finora

- SSL Rd21 Koerner SustainabilityDocumento38 pagineSSL Rd21 Koerner SustainabilityinzanerNessuna valutazione finora

- Host Strategy For Blue Organic Light-Emitting DiodesDocumento22 pagineHost Strategy For Blue Organic Light-Emitting DiodesinzanerNessuna valutazione finora

- High Performance Green Leds For Solid State LightingDocumento11 pagineHigh Performance Green Leds For Solid State LightinginzanerNessuna valutazione finora

- Glare and Diffuse SourcesDocumento25 pagineGlare and Diffuse SourcesinzanerNessuna valutazione finora

- Internal Light Extraction Technology For OLED Lighting: 2021 DOE-IES Lighting R&D WorkshopDocumento12 pagineInternal Light Extraction Technology For OLED Lighting: 2021 DOE-IES Lighting R&D WorkshopinzanerNessuna valutazione finora

- The Visual Experience of Fine Art Under Low IlluminanceDocumento10 pagineThe Visual Experience of Fine Art Under Low IlluminanceinzanerNessuna valutazione finora

- Material Development For OLED Lighting Panels: Made by Vacuum DepositionDocumento13 pagineMaterial Development For OLED Lighting Panels: Made by Vacuum DepositioninzanerNessuna valutazione finora

- Advances & Challenges For Algan-Based Uv-Led Technologies: Michael KneisslDocumento13 pagineAdvances & Challenges For Algan-Based Uv-Led Technologies: Michael KneisslinzanerNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 10th Maths (EM)Documento352 pagine10th Maths (EM)Murali MohanNessuna valutazione finora

- 12 National Certification Examination - October, 2011 FOR Energy Managers & Energy AuditorsDocumento8 pagine12 National Certification Examination - October, 2011 FOR Energy Managers & Energy AuditorssamirNessuna valutazione finora

- Forces in Our Solar System Lab Report: Problem: HypothesisDocumento2 pagineForces in Our Solar System Lab Report: Problem: HypothesisDevonFwNessuna valutazione finora

- Theme 1 ChemistryDocumento71 pagineTheme 1 Chemistrydanielle.brinkcateNessuna valutazione finora

- Bachelor Level Anatomy PhysiologyDocumento23 pagineBachelor Level Anatomy PhysiologyKarun BhattaraiNessuna valutazione finora

- CHAPTER 3 PAIR OF LINEAR EQUATION IN TWO VARIABLES - Google FormsDocumento5 pagineCHAPTER 3 PAIR OF LINEAR EQUATION IN TWO VARIABLES - Google FormsPranjalNessuna valutazione finora

- 4D Analogue Modelling of Transtensional Pull-Apart Basins - Wu - Etal - 2009 - 4D - Modelling - Transtension - BasinsDocumento16 pagine4D Analogue Modelling of Transtensional Pull-Apart Basins - Wu - Etal - 2009 - 4D - Modelling - Transtension - BasinsconsupitNessuna valutazione finora

- Entropy Changes in Reversible Processes PDFDocumento9 pagineEntropy Changes in Reversible Processes PDFZenghu HanNessuna valutazione finora

- The Laws of Thermodynamics, A Very Short - Peter AtkinsDocumento121 pagineThe Laws of Thermodynamics, A Very Short - Peter Atkinsae. xandp100% (1)

- Mechanical EngineeringDocumento21 pagineMechanical EngineeringmayurNessuna valutazione finora

- UNIT-5 Introduction To Statistical Thermodynamics: Dr. Uttam Mohan Assistant Professor D.H.S.K. College, Dibrugarh AssamDocumento33 pagineUNIT-5 Introduction To Statistical Thermodynamics: Dr. Uttam Mohan Assistant Professor D.H.S.K. College, Dibrugarh Assamyamanappagouda gudagaladinnyNessuna valutazione finora

- Retirement ThicknessDocumento7 pagineRetirement ThicknessKamal UddinNessuna valutazione finora

- Probabilistic and Deterministic Slope Stability Analysis by Random Finite ElementsDocumento23 pagineProbabilistic and Deterministic Slope Stability Analysis by Random Finite ElementsDanu SaputroNessuna valutazione finora

- Magnet Quiz 3Documento2 pagineMagnet Quiz 3AYLEEN HAIDERNessuna valutazione finora

- 440N-Z21US2JN9 User Manual PDFDocumento8 pagine440N-Z21US2JN9 User Manual PDFLizbeth Soto CastilloNessuna valutazione finora

- Esdd DrawingsDocumento75 pagineEsdd DrawingsDivyam RajNessuna valutazione finora

- 2018midterm1 SolutionDocumento7 pagine2018midterm1 Solution김명주Nessuna valutazione finora

- Swami Ramanand Teerth Marathwada University, NandedDocumento19 pagineSwami Ramanand Teerth Marathwada University, NandedsmpopadeNessuna valutazione finora

- Lec 1 Introduction 19 Series EEE 2205Documento22 pagineLec 1 Introduction 19 Series EEE 2205Nasif TahmidNessuna valutazione finora

- Lec # 7 Storage SystemsDocumento22 pagineLec # 7 Storage SystemsEman ShahidNessuna valutazione finora

- Lab2 Control SystemDocumento43 pagineLab2 Control Systemعبدالملك جمالNessuna valutazione finora

- ATEX - BM XX - Operating Instructions (Rev.1.4 - Sept 2016)Documento55 pagineATEX - BM XX - Operating Instructions (Rev.1.4 - Sept 2016)Vali PopescuNessuna valutazione finora

- Composite Beam IDocumento30 pagineComposite Beam IWr Ar100% (1)

- Encyclopedia of Early Modern Philosophy and The SciencesDocumento2.267 pagineEncyclopedia of Early Modern Philosophy and The SciencesThe Literary BudNessuna valutazione finora

- ElectrostaticsDocumento64 pagineElectrostaticsTushar Sarkar0% (1)

- Emission and Absorption - Principles of Structural ChemistryDocumento2 pagineEmission and Absorption - Principles of Structural ChemistryLeon MpalsNessuna valutazione finora

- Температура ЕЕАDocumento13 pagineТемпература ЕЕААнастасия ФилимоненкоNessuna valutazione finora

- Volume BolaDocumento14 pagineVolume BolaLyfia SilitongaNessuna valutazione finora

- Jurin Ma, Et - Al. (2013) - (Prosedur Free Oil)Documento10 pagineJurin Ma, Et - Al. (2013) - (Prosedur Free Oil)Muhammad Wildan FathullahNessuna valutazione finora

- List of Publications: Dhanpat Rai Publications (P) LTDDocumento8 pagineList of Publications: Dhanpat Rai Publications (P) LTDSai VigneshNessuna valutazione finora