Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Welded Pipes Made of Thermomechanically Rolled Materials 12 PDF

Caricato da

qc_5310406550 valutazioniIl 0% ha trovato utile questo documento (0 voti)

24 visualizzazioni1 paginaThe document discusses non-destructive testing of pipes, including how to handle areas of pipes classified as questionable. Questioned areas may be leveled, cut out, or cause the pipe to fail testing. If leveled, the area must be re-tested and may require repair welding. Test reports for pipes must include specifications followed, test date, conformity declaration, product details, testing technique, deviations, image quality, operator information. Pipe manufacturing is growing due to new pipeline construction and requires high quality materials and modern testing solutions.

Descrizione originale:

Titolo originale

welded_pipes_made_of_thermomechanically_rolled_materials_12.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThe document discusses non-destructive testing of pipes, including how to handle areas of pipes classified as questionable. Questioned areas may be leveled, cut out, or cause the pipe to fail testing. If leveled, the area must be re-tested and may require repair welding. Test reports for pipes must include specifications followed, test date, conformity declaration, product details, testing technique, deviations, image quality, operator information. Pipe manufacturing is growing due to new pipeline construction and requires high quality materials and modern testing solutions.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

24 visualizzazioni1 paginaWelded Pipes Made of Thermomechanically Rolled Materials 12 PDF

Caricato da

qc_531040655The document discusses non-destructive testing of pipes, including how to handle areas of pipes classified as questionable. Questioned areas may be leveled, cut out, or cause the pipe to fail testing. If leveled, the area must be re-tested and may require repair welding. Test reports for pipes must include specifications followed, test date, conformity declaration, product details, testing technique, deviations, image quality, operator information. Pipe manufacturing is growing due to new pipeline construction and requires high quality materials and modern testing solutions.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

sified as questioned.

Questioned pipes should velopment owing to new gas pipelines under

be dealt with in one of the following manners: construction both in Poland and abroad. The

a) A questioned area should be levelled by production of these pipes requires the use of

means of an appropriate method. In order materials characterised by the highest me-

to ensure that the imperfection has been chanical properties in a given material group.

removed entirely, after checking that the NDT devices are usually provided with mod-

remaining thickness is still within a toler- ern and recently developed technical solu-

ance range, the area should undergo anoth- tions. Investment-related expectations for

er check using magnetic particle testing or the years to come make the manufacture of

penetration testing. Afterwards, the pipe welded pipes the area of interest for inves-

should be classified as passing the test. If tors and manufacturers all over the world.

the recommended removal of the faulty

area has decreased the thickness below References

the acceptable value, the questioned area1. Michałowski, W., and Trzop, S., et al.

should be repaired by welding carried out (2006). Rurociągi dalekiego zasięgu. War-

in accordance with an approved welding saw: Wydawnictwo Fundacja Odysseum.

2. PN-EN 10208-2:2011 Steel pipes for

procedure specification. After that, the re-

paired area should undergo radiographic pipelines for combustible fluids - Techni-

testing following the requirements of PN- cal delivery conditions - Part 2: Pipes of

EN 10246-10 or PN-EN ISO 10893-6; requirement class B

b) A questioned area should be cut out. The 3. PN-EN 10246-9:2004 Non-destructive

manufacturer should ensure that the whole testing of steel tubes - Part 9: Automat-

questioned section has been cut out; ic ultrasonic testing of the weld seam of

c) A pipe should be classified as failing to submerged arc welded steel tubes for the

meet the requirements. detection of longitudinal and/or trans-

In required cases the manufacturer should verse imperfections

4. PN-EN 10246-10:2004 Non-destructive

write a test report containing at least the fol-

lowing information: testing of steel tubes - Part 10: Radio-

a) reference to PN-EN 10246-10 or PN-EN graphic testing of the weld seam of au-

ISO 10893-6 and PN-EN 10208-2; tomatic fusion arc welded steel tubes for

b) test report date; the detection of imperfections

c) declaration of conformity; 5. Presentation of Salzgitter Mannesmann

d) designation of a product providing grade Grossrohr GmBH - Salzgitter 2012.

and dimensions; 6. PN-EN 10246-15:2002 Non-destructive

e) type of and detailed information about the testing of steel tubes - Part 15: Automat-

testing technique used; ic ultrasonic testing of strip/plate used in

f) each deviation from specified procedures, the manufacture of welded steel tubes for

agreed or not agreed; the detection of laminar imperfections

g) image quality class; 7. PN-EN 10246-16:2002 Non-destructive

h) operator’s name, signature and certificate testing of steel tubes - Part 16: Automatic

number [4, 10]. ultrasonic testing of the area adjacent to

the weld seam of welded steel tubes for

Conclusion the detection of laminar imperfections

In recent years the manufacture of heli- 8. PN-EN 10246-17:2002 Non-destructive

cally welded pipes has seen an intensive de- testing of steel tubes - Part 17: Ultrason-

48 BIULETYN INSTYTUTU SPAWALNICTWA No. 3/2013

Potrebbero piacerti anche

- Tender - Codes For Non-Metalic PipingDocumento2 pagineTender - Codes For Non-Metalic PipingsoumenhazraNessuna valutazione finora

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Root Cause Techniques PresentationDocumento17 pagineRoot Cause Techniques Presentationqc_531040655Nessuna valutazione finora

- Project: EXPO 2020 - OV016 - USA PAVILION Inspection and Test Plan (Itp)Documento5 pagineProject: EXPO 2020 - OV016 - USA PAVILION Inspection and Test Plan (Itp)qc_531040655Nessuna valutazione finora

- Cathodic Protection For PipelinesDocumento18 pagineCathodic Protection For Pipelineskaushikgreat100% (3)

- Api-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Documento4 pagineApi-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Ahmed ElsharkawNessuna valutazione finora

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionDa EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionValutazione: 4.5 su 5 stelle4.5/5 (16)

- Bolt Torque - Astm & IsoDocumento2 pagineBolt Torque - Astm & Isoqc_53104065550% (4)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDa EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerValutazione: 5 su 5 stelle5/5 (1)

- ISCC EU 205 Greenhouse-Gas-Emissions-v4.0Documento61 pagineISCC EU 205 Greenhouse-Gas-Emissions-v4.0juan carlos100% (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- GRP Pipe For SeawaterDocumento22 pagineGRP Pipe For Seawatersethu1091100% (2)

- Post Tensioning ManualDocumento11 paginePost Tensioning Manualimzee25100% (7)

- Ultrasonic Testing of Austenitic and Austenitic Ferritic Stainless Steel ForgingsDocumento17 pagineUltrasonic Testing of Austenitic and Austenitic Ferritic Stainless Steel ForgingsAlvice Max100% (1)

- Space WeatherDocumento36 pagineSpace WeatherMat MinNessuna valutazione finora

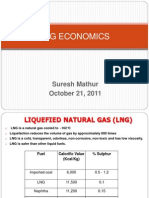

- LNG EconomicsDocumento19 pagineLNG EconomicsCal67% (3)

- Is 3589 - 2001Documento21 pagineIs 3589 - 2001Aara MeghNessuna valutazione finora

- Overview of Part 2 Failure AnalysisDocumento12 pagineOverview of Part 2 Failure AnalysisAnonymous S9qBDVkyNessuna valutazione finora

- E9d0' R""o .: Indian StandardDocumento26 pagineE9d0' R""o .: Indian Standards_samirkumar1008100% (1)

- Non-destructive Testing and Evaluation of Civil Engineering StructuresDa EverandNon-destructive Testing and Evaluation of Civil Engineering StructuresJean-Paul BalayssacNessuna valutazione finora

- CBT Questions: (2) Peel TestDocumento18 pagineCBT Questions: (2) Peel TestMOHAMEDNessuna valutazione finora

- NDT of PipingDocumento1 paginaNDT of PipingVu Tung LinhNessuna valutazione finora

- Project Standards and Specifications Pipeline Construction Rev01Documento15 pagineProject Standards and Specifications Pipeline Construction Rev01hiyeonNessuna valutazione finora

- IS 3589 - 2003-10 - With Amd 1 To 4Documento25 pagineIS 3589 - 2003-10 - With Amd 1 To 4hhr2412Nessuna valutazione finora

- A) 1.7 To 4.0 B) 2.55 To 3.9 C) 2.0 To 4.0 D) None of TheseDocumento17 pagineA) 1.7 To 4.0 B) 2.55 To 3.9 C) 2.0 To 4.0 D) None of TheseAshish Patel100% (1)

- NDT PDFDocumento13 pagineNDT PDFAaron QuinnNessuna valutazione finora

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingDa EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNessuna valutazione finora

- Auto UT PIpe InspectionDocumento16 pagineAuto UT PIpe InspectionMohd Azrul AzmanNessuna valutazione finora

- API 570 DEC 2009 ClosedDocumento17 pagineAPI 570 DEC 2009 ClosedMohammedBujairNessuna valutazione finora

- IS 3589-2001 MS PipesDocumento21 pagineIS 3589-2001 MS Pipesiampatanjali100% (5)

- Microbiology With Diseases by Body System 5th Edition Bauman Test BankDocumento25 pagineMicrobiology With Diseases by Body System 5th Edition Bauman Test BankRhondaHogancank100% (50)

- API 510 Exam May 2016Documento5 pagineAPI 510 Exam May 2016abdoNessuna valutazione finora

- Bolt Torque - Astm & IsoDocumento2 pagineBolt Torque - Astm & Isoqc_531040655100% (1)

- ASME Standard & Code ListingDocumento7 pagineASME Standard & Code ListingMyron CampbellNessuna valutazione finora

- NDT of WeldsDocumento4 pagineNDT of WeldsVu Tung Linh100% (2)

- 77.040.20 - Non-Destructive Testing of MetalsDocumento4 pagine77.040.20 - Non-Destructive Testing of MetalsIsmailNessuna valutazione finora

- Non-Destructive Testing of Drilling Oil and Gas Equipment and ToolsDocumento10 pagineNon-Destructive Testing of Drilling Oil and Gas Equipment and Toolsflasher_for_nokiaNessuna valutazione finora

- Astm A 106 - 08Documento9 pagineAstm A 106 - 08Alvin Irfani AzharNessuna valutazione finora

- Stachurski Non-Destructive Testing of Helically Welded Pipes Made of Thermomechanically Rolled Materials Used For Sending of CombustiblesDocumento13 pagineStachurski Non-Destructive Testing of Helically Welded Pipes Made of Thermomechanically Rolled Materials Used For Sending of Combustibles_ARCUL_Nessuna valutazione finora

- AC-VRF Statment MethodDocumento4 pagineAC-VRF Statment MethodHassan ShamsNessuna valutazione finora

- Annexure To SOW 3 STD Specification For Welding and NDT PipingDocumento15 pagineAnnexure To SOW 3 STD Specification For Welding and NDT PipingASHISH GORDENessuna valutazione finora

- High Density Polyethylene - HDPE - Pipe and FittingsDocumento8 pagineHigh Density Polyethylene - HDPE - Pipe and Fittingsnilesh_erusNessuna valutazione finora

- Laminar Imperfections in Strip Area Adjacent To Welded JointDocumento1 paginaLaminar Imperfections in Strip Area Adjacent To Welded Jointqc_531040655Nessuna valutazione finora

- DOC. NO:3392-00-69-00-0011 Field Application of Fusion Bonded Epoxy (FBE) Coating On The External Girth Weld Areas of Line PipesDocumento8 pagineDOC. NO:3392-00-69-00-0011 Field Application of Fusion Bonded Epoxy (FBE) Coating On The External Girth Weld Areas of Line PipesMarianne SmithNessuna valutazione finora

- HARDWARE Tech SpecificationsDocumento5 pagineHARDWARE Tech SpecificationsravisimonNessuna valutazione finora

- CW9 Part 1Documento9 pagineCW9 Part 1Steve CowanNessuna valutazione finora

- 1113 DWSDWSDDocumento53 pagine1113 DWSDWSDenjoygurujiNessuna valutazione finora

- Electrical Raceway SystemDocumento19 pagineElectrical Raceway Systemwafikmh4Nessuna valutazione finora

- Is 3589Documento22 pagineIs 3589Otavio123100% (1)

- Duct For Corrosive Fumes ExhaustDocumento8 pagineDuct For Corrosive Fumes ExhaustTS WongNessuna valutazione finora

- IGS-M-PL-027 (0) 1388 : ApprovedDocumento9 pagineIGS-M-PL-027 (0) 1388 : ApprovedMamadNessuna valutazione finora

- Section 02717 - Concrete Sewer Rehabilitation by Machine-Wound PVC PipeDocumento6 pagineSection 02717 - Concrete Sewer Rehabilitation by Machine-Wound PVC Pipefahren_de2015Nessuna valutazione finora

- Tubing and CasingDocumento10 pagineTubing and CasingEnd LabNessuna valutazione finora

- Unfired RefDocumento6 pagineUnfired RefDhakshina KNessuna valutazione finora

- PipingDocumento8 paginePipingRajkumar ANessuna valutazione finora

- 2007 Section ViiiDocumento3 pagine2007 Section ViiiMiriam LopezNessuna valutazione finora

- X3Documento23 pagineX3MOHAMEDNessuna valutazione finora

- Cathodic Protection Specification - Takoradi Oil Terminal 27.02.2018 rv1 PDFDocumento12 pagineCathodic Protection Specification - Takoradi Oil Terminal 27.02.2018 rv1 PDFRaynus Arhin100% (1)

- AUT Ss Welds 71Documento16 pagineAUT Ss Welds 71nathgsurendraNessuna valutazione finora

- NDE of BoilersDocumento6 pagineNDE of Boilersshabbir626100% (1)

- Api Exam (Ix, V, 571, 577)Documento9 pagineApi Exam (Ix, V, 571, 577)eng.ahmed.elsayed.mahmoudNessuna valutazione finora

- Specification - Pipes FlangesDocumento3 pagineSpecification - Pipes FlangesAco CvijeticNessuna valutazione finora

- 44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTDocumento8 pagine44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNessuna valutazione finora

- API 570 DEC 2009 ClosedDocumento17 pagineAPI 570 DEC 2009 ClosedAshish PatelNessuna valutazione finora

- Guide To Quality Control Inspection Duties: EchnologyDocumento3 pagineGuide To Quality Control Inspection Duties: EchnologyThanhTaiVoNessuna valutazione finora

- Fire Supperssion StandpipesDocumento15 pagineFire Supperssion StandpipesMohammad Sadik0% (1)

- Offshore Mooring Chain Cables and AccessoriesDocumento8 pagineOffshore Mooring Chain Cables and Accessoriesscofiel1Nessuna valutazione finora

- PS 3103Documento9 paginePS 3103JayeshNessuna valutazione finora

- MZLN-EL-XSPDS-00-290105 - Upstream Line Pipe - API5LDocumento38 pagineMZLN-EL-XSPDS-00-290105 - Upstream Line Pipe - API5LPaul NieNessuna valutazione finora

- Tuv Rheinland Application Iso 3834 enDocumento2 pagineTuv Rheinland Application Iso 3834 enqc_531040655Nessuna valutazione finora

- ASTM D1621 Compression Testing of Expanded Plastics and FoamsDocumento2 pagineASTM D1621 Compression Testing of Expanded Plastics and Foamsqc_531040655Nessuna valutazione finora

- Weld Root Erosion - Determine and Assess Degradation of Weld RootsDocumento2 pagineWeld Root Erosion - Determine and Assess Degradation of Weld RootsDiego AlonsoNessuna valutazione finora

- Tuv Rheinland Application Iso 3834 enDocumento2 pagineTuv Rheinland Application Iso 3834 enqc_531040655Nessuna valutazione finora

- NDT For Fabrication IndustriesDocumento2 pagineNDT For Fabrication IndustriesvivekdhavanNessuna valutazione finora

- Intercure 99 Application Guidelines UkDocumento14 pagineIntercure 99 Application Guidelines Ukqc_531040655Nessuna valutazione finora

- Establishment of Soluble Salt Criterion & Salt Measurement Method For Coating Performance PDFDocumento28 pagineEstablishment of Soluble Salt Criterion & Salt Measurement Method For Coating Performance PDFoggay94100% (1)

- Alutec PaintingDocumento1 paginaAlutec Paintingqc_531040655Nessuna valutazione finora

- General InformationDocumento8 pagineGeneral Informationqc_531040655Nessuna valutazione finora

- 35untitled Extract PagesDocumento1 pagina35untitled Extract Pagesqc_531040655Nessuna valutazione finora

- Final Quality Inspection ChecklistDocumento1 paginaFinal Quality Inspection Checklistqc_531040655Nessuna valutazione finora

- Sample: Material Shortage / Over / Damage/Return ReportDocumento1 paginaSample: Material Shortage / Over / Damage/Return Reportqc_531040655Nessuna valutazione finora

- 39untitled Extract PagesDocumento1 pagina39untitled Extract Pagesqc_531040655Nessuna valutazione finora

- Flowtech Company Profile Full Line Catalogue 2018Documento16 pagineFlowtech Company Profile Full Line Catalogue 2018qc_531040655Nessuna valutazione finora

- Revision Test-Consent FormDocumento1 paginaRevision Test-Consent Formqc_531040655Nessuna valutazione finora

- Flowtech Company Profile Full Line Catalogue 2018Documento16 pagineFlowtech Company Profile Full Line Catalogue 2018qc_531040655Nessuna valutazione finora

- 37untitled Extract PagesDocumento1 pagina37untitled Extract Pagesqc_531040655Nessuna valutazione finora

- Symbol Section: Merican Nstitute of Teel OnstructionDocumento1 paginaSymbol Section: Merican Nstitute of Teel Onstructionqc_531040655Nessuna valutazione finora

- 38untitled Extract PagesDocumento1 pagina38untitled Extract Pagesqc_531040655Nessuna valutazione finora

- Pre Qulified JointsDocumento6 paginePre Qulified Jointsqc_531040655Nessuna valutazione finora

- 40untitled Extract PagesDocumento1 pagina40untitled Extract Pagesqc_531040655Nessuna valutazione finora

- 32untitled Extract PagesDocumento1 pagina32untitled Extract Pagesqc_531040655Nessuna valutazione finora

- 34untitled Extract PagesDocumento1 pagina34untitled Extract Pagesqc_531040655Nessuna valutazione finora

- 28untitled Extract PagesDocumento1 pagina28untitled Extract Pagesqc_531040655Nessuna valutazione finora

- 33untitled Extract PagesDocumento1 pagina33untitled Extract Pagesqc_531040655Nessuna valutazione finora

- 31untitled Extract PagesDocumento1 pagina31untitled Extract Pagesqc_531040655Nessuna valutazione finora

- Basic Fire FightingDocumento44 pagineBasic Fire FightingDeming Villanueva100% (2)

- CH 21Documento32 pagineCH 21Indro ParmaNessuna valutazione finora

- Stable Glow Plasma at Atmospheric PressureDocumento4 pagineStable Glow Plasma at Atmospheric PressureproluvieslacusNessuna valutazione finora

- Mathematics Arithmetic and Number Sense Algebra Geometry: (Answer Many Word Problems As Possible)Documento5 pagineMathematics Arithmetic and Number Sense Algebra Geometry: (Answer Many Word Problems As Possible)DarleneNessuna valutazione finora

- Practical Physical Chemistry (II) Laboratory ManualDocumento25 paginePractical Physical Chemistry (II) Laboratory Manualabdu30esNessuna valutazione finora

- LIB (Lithium Ion Battery)Documento27 pagineLIB (Lithium Ion Battery)Ericke Nandita MaharaniNessuna valutazione finora

- Aquaculture: Wu-Jie Xu, Lu-Qing PanDocumento8 pagineAquaculture: Wu-Jie Xu, Lu-Qing PanmarioNessuna valutazione finora

- UAV WingDocumento5 pagineUAV WingSUNDARAMAHALINGAM ANessuna valutazione finora

- Introduction To Micro/Nano ElectronicsDocumento51 pagineIntroduction To Micro/Nano ElectronicsLIAKMANNessuna valutazione finora

- Activity 1.3.3 Thermodynamics Answer KeyDocumento11 pagineActivity 1.3.3 Thermodynamics Answer KeyLary BagsNessuna valutazione finora

- Bpharm 5 Sem Industrial Pharmacy 1 bp502t 2020Documento1 paginaBpharm 5 Sem Industrial Pharmacy 1 bp502t 2020Amol TupeNessuna valutazione finora

- Evs MCQDocumento8 pagineEvs MCQraj kundraNessuna valutazione finora

- BNR Process BendigoDocumento6 pagineBNR Process Bendigobansa79Nessuna valutazione finora

- Surface Tension Article 1Documento3 pagineSurface Tension Article 1Dr-Aqsa KhannNessuna valutazione finora

- Electrolysis O LevelDocumento17 pagineElectrolysis O LevelInnocent EbilNessuna valutazione finora

- Crude Oil Desalter and Electrostatic Dehydrator MarketDocumento7 pagineCrude Oil Desalter and Electrostatic Dehydrator MarketAnonymous bHh1L1Nessuna valutazione finora

- Shrimp: In: Use of Sodium Metabisulfite, AlternativesDocumento3 pagineShrimp: In: Use of Sodium Metabisulfite, Alternativesvalerie rosalind angkawidjajaNessuna valutazione finora

- Duncan Sobre EsmaltesDocumento9 pagineDuncan Sobre EsmaltesLeland StanfordNessuna valutazione finora

- Phy Cet Wei 23Documento4 paginePhy Cet Wei 23endtimes066xNessuna valutazione finora

- Pre-Lab 8Documento1 paginaPre-Lab 8SaulS.DiazNessuna valutazione finora

- Effect of The Varying Levels of Wood Vinegar On SunflowerDocumento7 pagineEffect of The Varying Levels of Wood Vinegar On SunflowerYamaguchi KumikoNessuna valutazione finora

- Specific Gravity and Absorption of Fine Aggregates Aashto T 84Documento7 pagineSpecific Gravity and Absorption of Fine Aggregates Aashto T 84jaipalNessuna valutazione finora

- Phys 1241Documento4 paginePhys 1241ChrisNessuna valutazione finora

- Opportunities and Limits of 2k Injection MouldingDocumento22 pagineOpportunities and Limits of 2k Injection Mouldingsa_arunkumarNessuna valutazione finora

- Omnirad 819 - EN PDS 2Documento3 pagineOmnirad 819 - EN PDS 2brausenpaulNessuna valutazione finora