Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

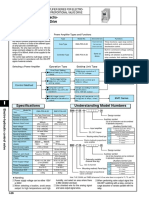

MMA2920SDFM MMA2920SDC HTM02 01 HTM2022 Spec Sheet

Caricato da

umair186Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MMA2920SDFM MMA2920SDC HTM02 01 HTM2022 Spec Sheet

Caricato da

umair186Copyright:

Formati disponibili

Unit 7, Catherine Street West, Denton, Manchester, M34 3SY

Telephone: 0161-221-1880 Fax: 0161-221-1881

Website: www.mmpl.uk.com Email: sales@mmpl.uk.com

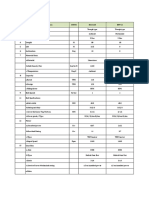

PLANT SPECIFICATION FOR 10 BAR DUPLEX MEDICAL AIR PLANT (Compliant to HTM02-01 and HTM2022)

MMA2920SDFM Floor mounted Compressor Length 6650mm x Width 1285mm x Height 2200mm Weight 1800kg.

MMA2920SDC Compact Vessel mounted Compressors Length 5200mm x Width 2000mm x Height 2200mm Weight 1870kg.

COMPRESSORS

2 Atlas Copco oil lubricated screws (22 kW) 1 compressor running as duty with the 2nd compressor as standby.

VESSELS

MMA2920SDFM 2 x Vertical Vessel 800 litres, MMA2920SDC 1 x Vertical Vessel 500 litres + 2 x Horizontal Vessels 500 litres,

each vessel is fitted with a pressure relief valve, a fusible plug, a manual drain, an automatic drain and a pressure gauge. Built to

BS 5169-75-3-E/EN 286.

DUPLEX FILTER/DRYER ASSEMBLY

Comprising; water separation filters, oil mist separation filters, desiccant dryers, carbon odour filters, sterile filters, line pressure

regulators and line pressure relief valves. All filters are fitted with pressure differential indicators.

CONTROLS AND MONITORING

Pressure sensors to monitor the following; each compressor on/off load (producing air), low vessel pressure, duty and standby

compressor control, dryer fault (pressure drop), high and low pressure fault. Monitoring sensors for each compressor; control

circuit failure, motor overload, output air temperature high. Monitoring sensor for dryer, Dewpoint failure (dryers will automatically

change over in the event of either a pressure or Dewpoint failure).

ELECTRICAL REQUIREMENTS AIR QUALITY SPECIFICATION

Each Compressor requires Nett Plant output after dryer losses – 2920 l/m.

3 Phase + Neutral + Earth supply Meets the requirement of the European Pharmacopoeia

Fused at 50 amps Motor Rated. Particulates as per ISO 8573-1 (Class 0)

Start Current –80 amps. Oil Aerosols as per ISO 8573-1 (Class 0)

Run Current –40 amps Atmospheric Dewpoint > -46 °C

Starter type – Star/Delta.

NOISE RATING

ALARM OUTPUTS 69dB(A)

Clean contacts closed in Normal;

1. PLANT FAULT Any compressor fault or dryer pressure fault.

2. PLANT EMERGENCY Either dryers Dewpoint failed or low vessel pressure.

3. RESERVE MANIFOLD BELOW 50% Monitored by input from backup cylinder manifold if fitted.

4. LINE PRESSURE FAULT Either high or low pipeline pressure fault.

5. BMS OUTPUTS Repeat of all conditions 1-4 above.

Individual indicators provided for all faults including output alarms to enable easy fault diagnosis.

RECOMMENDED SPARES PART NUMBER

25 Ltr compressor oil. ASPA1010

1 off Unloader kit. GA22 (Serial No. Required)

2 off air intake filter elements GA22 (Serial No. Required)

1 off compressor pressure relief valve. GA22 (Serial No. Required)

1 off regulator pressure relief valve for 4 Bar Line Pressure PLP1030-5.3

1 off regulator pressure relief valve for 7 Bar Line Pressure PLP1030-9.0

1 off compressor operating /low pressure switch. ASPA1033

1 off compressor high pressure switch. ASPA1032

2 off pre filter elements. FILTN110/E

2 off carbon filter elements. FILTN111/E

2 off sterile filter elements. FILTN112/E

1 off different pressure gauge. FILTN105

1 off filter bowl auto drain. FILTN106

1 off regulator overhaul kit. ASPA1081

1 off 4 pole 230V relay. ELE2052

1 off 230V timer relay. ELE2053

M.M.P. Ltd Manchester TEL; 0161-221-1880

THE RIGHT IS RESERVED TO CHANGE THE SPECIFICATION OF THE ITEMS DESCRIBED HEREIN AT ANY TIME.

Potrebbero piacerti anche

- M46 F.O. Supply Unit Main Eng and Aux. EngineDocumento440 pagineM46 F.O. Supply Unit Main Eng and Aux. EngineAjit PrabhakaranNessuna valutazione finora

- Price List Spare Part Tdar 2522: No CodeDocumento2 paginePrice List Spare Part Tdar 2522: No Codemacis garisNessuna valutazione finora

- MT050 Series Dehydrator User ManualDocumento32 pagineMT050 Series Dehydrator User ManualSalvador López Arranz100% (1)

- VacPumpReq TSB007Documento6 pagineVacPumpReq TSB007zosuryantoNessuna valutazione finora

- Proportional Reducing ValveDocumento8 pagineProportional Reducing ValvediabalziabNessuna valutazione finora

- 3-En2200-B - 4VP01Documento15 pagine3-En2200-B - 4VP01najafali1Nessuna valutazione finora

- PB-05479 v00 PB300 Compact Flex OPDocumento463 paginePB-05479 v00 PB300 Compact Flex OPMichail AleksandrovNessuna valutazione finora

- O&M Manual - Reciprocating System - MTD075Documento26 pagineO&M Manual - Reciprocating System - MTD075jeyson villafuerteNessuna valutazione finora

- 315 - SVP3000 Alphaplus S HART Protokolom PDFDocumento12 pagine315 - SVP3000 Alphaplus S HART Protokolom PDFJuan Carlos Nodner RiosNessuna valutazione finora

- Manual - 289RC Exhaust BoosterDocumento8 pagineManual - 289RC Exhaust BoosterRoberto RuedaNessuna valutazione finora

- FAIRCHILD T6000 Electro-Pneumatic Transducers Standard and Extended Ranges Installation InstructionsDocumento4 pagineFAIRCHILD T6000 Electro-Pneumatic Transducers Standard and Extended Ranges Installation InstructionsALEJANDRO IPATZINessuna valutazione finora

- PureBallast System Alfa LavalDocumento621 paginePureBallast System Alfa LavalIgorNessuna valutazione finora

- Aiwa CX-NT99LH PDFDocumento45 pagineAiwa CX-NT99LH PDFMarcyo Lima100% (1)

- PB-07655 v00 PB500 Compact Flex OPDocumento516 paginePB-07655 v00 PB500 Compact Flex OPRusHostel TVNessuna valutazione finora

- AVR 450T and 450 MDocumento20 pagineAVR 450T and 450 Mjadi purwonoNessuna valutazione finora

- 2057200101-02, Ptu2 27-27 Pv-E1mDocumento18 pagine2057200101-02, Ptu2 27-27 Pv-E1mAlexander TeixeiraNessuna valutazione finora

- Irrigation Asset Survey Interchange AreaDocumento50 pagineIrrigation Asset Survey Interchange Areadencioanova02Nessuna valutazione finora

- Power Transformer by HK RajputDocumento109 paginePower Transformer by HK RajputRajeevAgrawal75% (4)

- Models A & B Automatic Pressure Maintenance DevicesDocumento4 pagineModels A & B Automatic Pressure Maintenance DevicesHIDRUCOL SASNessuna valutazione finora

- Duplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPDocumento2 pagineDuplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPEng.Gihad EladlNessuna valutazione finora

- Denison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01Documento12 pagineDenison Hydraulics Proportional Pressure Control Valves: Series P2 & 4VP01abuzer1981Nessuna valutazione finora

- Relay AP Suat DanfossDocumento16 pagineRelay AP Suat DanfossVo Ngoc DucNessuna valutazione finora

- Manual Trident Klasik 200 - CompressDocumento12 pagineManual Trident Klasik 200 - CompressAleš FejglNessuna valutazione finora

- Transductor FLOWSERVE NT3000Documento20 pagineTransductor FLOWSERVE NT3000Xavier EspinozaNessuna valutazione finora

- Sequential Controller: SpecificationsDocumento1 paginaSequential Controller: SpecificationsscribdkhatnNessuna valutazione finora

- Buchholz RelayDocumento18 pagineBuchholz RelaysvismaelNessuna valutazione finora

- Ael6 PDFDocumento9 pagineAel6 PDFCarlos Rafael Pereyra SegoviaNessuna valutazione finora

- Manual Servomex Xendos 1800Documento20 pagineManual Servomex Xendos 1800Josh MoralesNessuna valutazione finora

- LT1019 Datasheet (1019fd)Documento12 pagineLT1019 Datasheet (1019fd)gblackweNessuna valutazione finora

- SD 16 eDocumento20 pagineSD 16 eseaqu3stNessuna valutazione finora

- QB3 Installation Guide - 1 1Documento4 pagineQB3 Installation Guide - 1 1Brandon TrocNessuna valutazione finora

- 200711111524631291Documento16 pagine200711111524631291Navneet GuptaNessuna valutazione finora

- Bhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC BoilersDocumento41 pagineBhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC Boilersrashm006ranjanNessuna valutazione finora

- IRM-3 DUO Manual EnglishDocumento33 pagineIRM-3 DUO Manual EnglishThiago Takumi TanNessuna valutazione finora

- Cs800 ManualDocumento32 pagineCs800 ManualSaadullah SiddiquiNessuna valutazione finora

- Transistor Inverter: TOSVERT™ Inverter Dedicated To Fan and Pump For HVACDocumento2 pagineTransistor Inverter: TOSVERT™ Inverter Dedicated To Fan and Pump For HVACMaitry ShahNessuna valutazione finora

- H1000e I Ema-Emc PDFDocumento4 pagineH1000e I Ema-Emc PDFNguyen Van ChungNessuna valutazione finora

- V-300 10 - 20 V-300 Max 10 - 20 Maintenance Manual (TK 50978-1-MS USA 06 - 01)Documento10 pagineV-300 10 - 20 V-300 Max 10 - 20 Maintenance Manual (TK 50978-1-MS USA 06 - 01)Juan Miguel Marin Quintero0% (1)

- Bard UP03Documento12 pagineBard UP03Alan VazquezNessuna valutazione finora

- SM 592.2 Caja de Control ElectromagneticaDocumento6 pagineSM 592.2 Caja de Control ElectromagneticaHectorI.GoCaNessuna valutazione finora

- 3439 SPEC and DRAWINGDocumento32 pagine3439 SPEC and DRAWINGManisha KharwarNessuna valutazione finora

- Mpdi K3000Documento2 pagineMpdi K3000Juan JuanNessuna valutazione finora

- The Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410ADocumento12 pagineThe Wall-Mount™ Air Conditioners - 9.0 Eer, (60Hz) : G R R-410AcarlosNessuna valutazione finora

- Avf7000v1 1Documento4 pagineAvf7000v1 1keykakyNessuna valutazione finora

- Specifications: DaikinDocumento17 pagineSpecifications: DaikinyoyokNessuna valutazione finora

- Advanced Monolithic Systems: Rohs CompliantDocumento9 pagineAdvanced Monolithic Systems: Rohs CompliantRobertoJavierANessuna valutazione finora

- SD 11 eDocumento12 pagineSD 11 eseaqu3stNessuna valutazione finora

- Wall Mount Aire AcondicionadoDocumento8 pagineWall Mount Aire AcondicionadoJose SaldarriagaNessuna valutazione finora

- Aiwa Z Ht730Documento46 pagineAiwa Z Ht730Kaspars KruminsNessuna valutazione finora

- (1X Erma First Fit 400) : Technical OfferDocumento23 pagine(1X Erma First Fit 400) : Technical OfferVikas Singh100% (1)

- 027-System Manual PB 03626 v0Documento634 pagine027-System Manual PB 03626 v0Mustafa Yıldırım50% (2)

- Supplemental Guide: Pressure Switch ProductsDocumento12 pagineSupplemental Guide: Pressure Switch Productsing_vic1Nessuna valutazione finora

- Electronic Flow SwitchDocumento4 pagineElectronic Flow SwitchwilfredoNessuna valutazione finora

- Dixell: XV105D Fan Speed ControllerDocumento2 pagineDixell: XV105D Fan Speed ControllerdbricchiNessuna valutazione finora

- CDL138 Test Report QA & QCDocumento11 pagineCDL138 Test Report QA & QCNZNessuna valutazione finora

- Mahlepi270 GBDocumento5 pagineMahlepi270 GBHassanNessuna valutazione finora

- Pompa Dragon 1Documento10 paginePompa Dragon 1Angelica DragulescuNessuna valutazione finora

- Purifier LO AND FO PDFDocumento81 paginePurifier LO AND FO PDFSanusi AbdullahNessuna valutazione finora

- 110 Waveform Generator Projects for the Home ConstructorDa Everand110 Waveform Generator Projects for the Home ConstructorValutazione: 4 su 5 stelle4/5 (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- Service-Catalog LGGLDocumento21 pagineService-Catalog LGGLumair186Nessuna valutazione finora

- GROHE Specification Sheet 27513001Documento1 paginaGROHE Specification Sheet 27513001umair186Nessuna valutazione finora

- Bronze Gate Valve Non Rising Stem PN20: Features & BenefitsDocumento1 paginaBronze Gate Valve Non Rising Stem PN20: Features & Benefitsumair186Nessuna valutazione finora

- Naffcom PMP SubmittalDocumento150 pagineNaffcom PMP Submittalumair186Nessuna valutazione finora

- Sau989 en 1 1Documento41 pagineSau989 en 1 1umair186Nessuna valutazione finora

- Avk Gate Valve, Flanged, Pn16 02/21-003: EN558/3 (BS), AISI316 Stem, A4 Bolts, 500 M EP Coating, DN50-400Documento2 pagineAvk Gate Valve, Flanged, Pn16 02/21-003: EN558/3 (BS), AISI316 Stem, A4 Bolts, 500 M EP Coating, DN50-400umair186Nessuna valutazione finora

- Pocket Guide: Full Product LineDocumento188 paginePocket Guide: Full Product Lineumair186Nessuna valutazione finora

- Company Profile 2017-18Documento123 pagineCompany Profile 2017-18umair186100% (2)

- AVK SEries 05 Support Bush Supa Plus Bolt Torque IOM ManualDocumento5 pagineAVK SEries 05 Support Bush Supa Plus Bolt Torque IOM Manualumair186Nessuna valutazione finora

- ASME A112 18 1 CSA B125 1 Rev 7 1 2018 ED 11 9 2019Documento8 pagineASME A112 18 1 CSA B125 1 Rev 7 1 2018 ED 11 9 2019umair186Nessuna valutazione finora

- 1602Documento6 pagine1602umair186Nessuna valutazione finora

- Standards Update Notice (SUN) : Standard InformationDocumento3 pagineStandards Update Notice (SUN) : Standard Informationumair186Nessuna valutazione finora

- QR0308 Fire Pump TypesDocumento1 paginaQR0308 Fire Pump Typesumair186Nessuna valutazione finora

- Underground Chilled Water System August 132014Documento12 pagineUnderground Chilled Water System August 132014umair186Nessuna valutazione finora

- IS Idealspray Multiproduct SparesL NN B0595Documento1 paginaIS Idealspray Multiproduct SparesL NN B0595umair186Nessuna valutazione finora

- 1606Documento4 pagine1606umair186Nessuna valutazione finora

- Ford C Max 2011 UKDocumento25 pagineFord C Max 2011 UKDumitru PopescuNessuna valutazione finora

- Sense Furnishings Beyond Touch - HDPO - 23-24 - 54Documento2 pagineSense Furnishings Beyond Touch - HDPO - 23-24 - 54Shivam DadhichNessuna valutazione finora

- MWM Gas Engine Tcg2020 enDocumento8 pagineMWM Gas Engine Tcg2020 enPankaj Kamble100% (1)

- Probation Period ReportDocumento17 pagineProbation Period ReportMiranti Puspitasari0% (1)

- Activity 3 - 2nd QRTRDocumento3 pagineActivity 3 - 2nd QRTRdagamacvincentjade10Nessuna valutazione finora

- Cordex HP 1.2kW: 1RU Integrated Shelf System With GMT DistributionDocumento2 pagineCordex HP 1.2kW: 1RU Integrated Shelf System With GMT DistributionJohn WikieNessuna valutazione finora

- BTS3203E V100R012C10SPH116 ENodeBFunction Performance Counter ReferenceDocumento3.955 pagineBTS3203E V100R012C10SPH116 ENodeBFunction Performance Counter ReferenceYasir Adin SaputroNessuna valutazione finora

- ACO 3901manual EditionEDocumento104 pagineACO 3901manual EditionEs1234tNessuna valutazione finora

- 5000 Watt BLDC Electric Motor Heavy Duty BLDC MotorDocumento3 pagine5000 Watt BLDC Electric Motor Heavy Duty BLDC MotorabhayuietNessuna valutazione finora

- Fire-Lite ACM-16ATF Data SheetDocumento4 pagineFire-Lite ACM-16ATF Data SheetJMAC SupplyNessuna valutazione finora

- Flexible Pneumatic Actuator For PV Solar Tracking ApplicationsDocumento4 pagineFlexible Pneumatic Actuator For PV Solar Tracking ApplicationsHilmi Dhiya UlhaqNessuna valutazione finora

- Praat ProsodyDocumento17 paginePraat Prosodydivdix1Nessuna valutazione finora

- Syllabus Booklet ElectronicsDocumento15 pagineSyllabus Booklet ElectronicsZuraizNawazNessuna valutazione finora

- ReliefVent FinalDocumento16 pagineReliefVent FinalHAZEL JEAN BIGCASNessuna valutazione finora

- Computer Organization and Assembly Language: Laboratory ManualDocumento25 pagineComputer Organization and Assembly Language: Laboratory ManualMohd ShahNessuna valutazione finora

- Lift Monitor Manual PDFDocumento10 pagineLift Monitor Manual PDFReza KühnNessuna valutazione finora

- Simple Interest - Aptitude Questions and AnswersDocumento6 pagineSimple Interest - Aptitude Questions and Answerssachinsaboo3Nessuna valutazione finora

- Data SheetDocumento24 pagineData Sheetbashok20Nessuna valutazione finora

- STR BnderDocumento6 pagineSTR Bnderhemanthkumar67008Nessuna valutazione finora

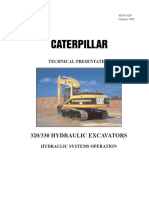

- 320/330 Hydraulic Excavators: Technical PresentationDocumento104 pagine320/330 Hydraulic Excavators: Technical Presentationramon hidalgo100% (3)

- Kpaw, LLC v. Apple, IncDocumento19 pagineKpaw, LLC v. Apple, IncLucas NolanNessuna valutazione finora

- FALCON: Smart Portable Solution: Condition Monitoring Has Never Been So Easy!!Documento21 pagineFALCON: Smart Portable Solution: Condition Monitoring Has Never Been So Easy!!Lê Xuân HậuNessuna valutazione finora

- NMA 5V, 12V & 15V Series: Isolated 1W Dual Output DC/DC ConvertersDocumento6 pagineNMA 5V, 12V & 15V Series: Isolated 1W Dual Output DC/DC ConvertersJoel Eljo Enciso SaraviaNessuna valutazione finora

- An Efficient Power Flow Algorithm For Distribution Systems With Polynomial LoadDocumento16 pagineAn Efficient Power Flow Algorithm For Distribution Systems With Polynomial Loadishak789Nessuna valutazione finora

- APL V80 SP2-Readme enDocumento16 pagineAPL V80 SP2-Readme enGrant DouglasNessuna valutazione finora

- QX Brochure PDFDocumento16 pagineQX Brochure PDFBibhas Kumar SamantaNessuna valutazione finora

- School Management System: A Synopsis Submitted in Partial Fulfillment of The Requirements For The Degree of inDocumento12 pagineSchool Management System: A Synopsis Submitted in Partial Fulfillment of The Requirements For The Degree of inankush rathorNessuna valutazione finora

- LB2-UCxx-x Premium-Sound Cabinet Loudspeaker Range Data Sheet EnUSDocumento6 pagineLB2-UCxx-x Premium-Sound Cabinet Loudspeaker Range Data Sheet EnUSvtcuongNessuna valutazione finora

- Maverick Standard SpecsDocumento1 paginaMaverick Standard SpecsRishabh PathaniaNessuna valutazione finora

- F FC FC JG DDocumento9 pagineF FC FC JG DRAJANessuna valutazione finora