Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Automatic Control (PID Etc)

Caricato da

attapapa0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

18 visualizzazioni4 pagineAutomatic Control (PID etc)

Titolo originale

Automatic Control (PID etc)

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoAutomatic Control (PID etc)

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

18 visualizzazioni4 pagineAutomatic Control (PID Etc)

Caricato da

attapapaAutomatic Control (PID etc)

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 4

aa er el

TCELAk Ma 2:07 FD

ries isa handy Bepacuction to te

closed-loop contro!

control a roportional system

shortcomings.

are ri comes the basic ole

‘of automatic control, including a simple

al

‘lee

system, common

> eo

Des arts ee gstee. wort

Ja closed loop configuration (also called

feedback or servo loop configuration), In this

article series, I'll discuss some basic aspects of,

automatic control also known as cybernetics.

Robotics, flight controls, manufacturing

processes, and many other applications

couldn't exist without it. Books on automation

have hundreds of pages, heavily loaded with

mathematics, Consequently, this series will

be an introduction to the fundamentals of

automatic control while keeping the math to

the minimum.

FEEDBACK CONTROL

Known for hundreds of years, feedback

control originated with clocks. Clock pendulum

suspensions, for example, were made of

materials expanding and contracting with

changing temperature to maintain accurate

pendulum oscillations. With the onset of

the Industrial Revolution, precise feedback

control became necessary for the new

machines. The first truly proportional closed

loop control system appeared in 1788 when

James Watt invented the flyball governor to

madify the amount of steam powering his

engine. As early as 1850, the integrating

term was introduced by Sir W. Siemens, and

by 1894, the derivative term was discovered.

In the absence of electronics, those systems

were mechanical, hydraulic, or pneumatic,

but even by our present-day standpoint

they were engineering wonders. Electronics

entered automation en mass fairly ate, simply

because devices were too cumbersome with

vacuum tubes. Thus, mechanical engineering

terminology, such as "K” for gain instead

of the "G” or “AY otherwise common in

electronics is used. One should mention that

a great deal of electronics, from oscillators

through amplifiers to power supplies depend

on feedback control. However, our current

focus is on automation with electronics

merely as the control element.

Figure 1 is a typical block diagram of a

simple closed-loop control system. A command

the set point) is issued to an electronic

controller. Let's say it is a desired speed in

an automobile cruise control. A sensor feeds

back the car's immediate speed whose value is

subtracted from the command. The difference

between the desired and the actual speed

of the vehicle is speed error. The electronic

controller pracesses the error signal according

to a control law and the resulting correction

signal drives the power converter, in our case

2 fuel control valve, to convert the relatively

‘weak electrical signal into the fuel flow to the

engine. The engine, or the plant, as referred to

in cybernetics, propels the car to a higher or

lower speed in the direction of the command

to reduce the speed error. Along the way,

disturbances—such as varying resistance of

the road due to slope, surface, load, wind.

and so forth—also affect the speed. The speed

sensor detects those variations and feeds

them back to the controller which causes the

power converter to modify the fuel flow and

thus bring the speed error to zera,

2

COMMON CONTROL LAWS

‘The common contral laws are proportional

(), proportional-integrating (PI), and

proportional-integrating-derivative | (PID).

There are also sophisticated laws such as

Fuzzy Logic, Predictive Algorithm, and others.

The widely used P, PI, and PID laws have been

around for centuries. Its unlikely they will be

made obsolete any time soon

The proportional control means that the

error signal is amplifed to drive the power

converter managing the fuel flow to the

engine, Proportional Gain (K,) of a linear

amplifier would then be equal to the Control

Gain (Ke) of the system.

Proportional systems suffer from two

shortcomings—a steady state error and

an overshoot. Let's say our cruise control

maintains the speed on a flat road, but

becomes sluggish, not completely reaching

the commanded speed, when the car’s going

uphill. Tis is called offset or a steady state

error. Assuming the fuel flow is not already

saturated and the engine can still deliver more

power, you might increase the proportional

gain Ky, but then your system will overshoot

and might become unstable, The common

fix of the steady state error is an addition

of an integrating term K;. Tt integrates the

error with time constant 1, adding it to the

control gain Kc, which then becomes Ke = Kp

+ Kj. This increases the overall gain for the

duration of the error. Having correct values of

the two terms ky and K; is critical. Incorrect

values may slow the system down or cause it

to oscillate

Power converters, plants, feedback

sensors, and all parts of the contral loop

react with finite speed, introducing a lag into

the system, By the time the speed error has

dropped to zero, the response of the power

converter and/or the plant may stil continue

to grow due to that lag. This will cause the

ABOUT THE AUTHOR

George Novacek is a professional ergineer

with 2 degree in Cybernetics and Closed-

Loop Control, Now retired, he was most

recently president of a multinational

manufacturer for embedded contrel systems

for aerospace applications. George wrote 26

feature articles for Circuit Cellar between

1999 and 2004. Contact him at gnovacek@

nexicom.net with “Circuit Cellar*in the

subject line

speed to overshoot. The system will try to

correct it, but, for the same reason, the speed

will undershoot. In the end, the total response

may be anything from a small single overshoot

to ringing to sustained oscillations. This can

be corrected by lowering the proportional

gain ky, but then the accuracy and the speed

of response may suffer. A derivative term is

the solution

The derivative term K calculates the

rate of change of the errar signal with the

derivative time constant Tj. When properly

mixed with the proportional signal, it reduces

the correction signal (i.e., the fuel flow in our

example) by anticipating the vehicle speed

response. The big overshoot no longer occurs.

Unfortunately, the derivative term makes

systems sensitive to noise and frequently

needs to be followed by 2 low-pass filter

which adds another unwelcome phase lag,

For this reason, the derivative term Ky is in

some systems omitted. The PI control law is

probably the most popular one.

PID CONTROL

Control systems and each of their

functional blacks are characterized by their

transfer functions, which are the ratio of their

‘output to the input. The transfer function of

Power Disturbance

Command | Electronic Power Response

t controller converter [Tt Plant as

' 1 Feedback |_| |

t Controller rm ‘sensor '

: it Machine ‘

ss

ens

ricuRe2

Doaeg versan of ID cartel

ciecotelbnanmycemsteral

RESOURCES

6. Ells, “Control System

Design Guide," Fourth Edition,

Butterworth-Heinemann,

2022.

Dente Gain vt

ButerSummer rT

4 Propertonal Gain x

come a x 2 on

Inept Gan

2 PID controller is mathematically expressed

by equation:

u(t) =K,e(t) +K, Jeton + =

where

e(t) ~command(t) — feedback (t)

u(t)

¢(t) = control error

correction signal

To hardware engineers, the PID control

canbe best explained’ by its analog

implementation shown in Figure 2. A.common

quad operational amplifier is all that’s needed

to make a simple PID controller. UIA subtracts

the feedback from the command signal to

generate the error signal. This is processed

by the three (.e., proportional) derivative

and integrating amplifiers—UIC, U1B, and

UID, respectively—and recombined into the

correction signal driving the power converter.

F Golnaraghi and B.C. Kuo, Automatic Contro!

Systems, Wiley, 2009,

6. Novacek, *Electro-Hydraulic Servo Velves”

Greult Cellar 253, 2011.

Figure 2 shows a parallel configuration

of a PID controller. However, the three

terms can be put in series, thus forming

2 serial controller or some other series/

parallel combination, A control law generated

by a microcontroller is typically a series

configuration. Each configuration has its

advantages and disadvantages, Many systems

contain several servo loops embedded within

each other. In Figure 2, each operational

amplifier is actually a feedback controller in

its own right.

Nowadays a microcontroller is frequently

used as the control element. Unlike nearly

instantaneous response of analog circuits,

digital circuits sample at 2 certain rate and,

consequently, introduce processing delays, i.e.

lags, which may lead to instability. In some

cases, a very fast, expensive processor might

be needed where an analog solution might be

better and more economical. An example of

the PID algorithm at constant sampling rate

is shown in Listing 1.

IMPLEMENTATION & ANALYSIS

Implementation and analysis of transfer

functions of electronic controllers is fairly

straight forward, as long as the system

‘operates within its linear range and is time

invariant (LTD). In reality, all parts of contral

systems exhibit limited linearity and when

saturated, introduce lags, and may cause

instability of the system. Our cruise control,

for example, is limited primarily by the power

of the car's engine. Transfer functions of non-

electronic components, if available at all from

their manufacturers, are not always accurate.

But they could be measured or estimated.

Therefore, the system designer needs to

plan for extensive testing and optimization.

/* Normally the integrating

The correction signal must be lim

of the power converter

gains are declared constants. */

error = setPoint - feedla

pTerm = Kp * error

Proportiona

sme 1

be limited to prevent roll-over

d to stay within linear response

, integrating and derivative

“calculate correction

17 proportion

Term += (Ki * error); 77 integral

dTerm = Kd # (error - previoustrror); // derivative

previousError = errors 77 venemoer for next Q

correctionsignal = prerm + iTerm + dTerm; =

That’ where digital controllers shine, as their programs (typically PSpice, UTSpice, and

gains and limits can be modified on the fly

Some digital controllers feature auto-tuning

capability, which, while convenient, might

be modifying the code upon every power

up. Certificating authorities frown on and

generally don’t permit self-modifying or dead

code in safety-critical applications,

Computer simulation programs (e.9.,

Simulink by MathWorks) are great tools, but,

similar to the electronic circuits simulation

others), their results are only as good as the

mathematical models of the components.

But they do get you pretty close to the goal.

The designer of the electronics should always

strive for a hefty design margin to satisfy LTT

requirements.

This has been an introduction to the

automatic systems in general. Next month,

ll take @ quick look at their analysis in

frequency domain.

dd

With this digital subscription, you have access

to all 1:

ues of Circuit Cellar 2016 from any

‘computer or tablet at anytime, Readers can

explore project ideas, bookmark pages, and

make annotations throughout each issue.

nels & Enclosures

uring custom Pa

+ Manutact

“pree CAD Soft

ipping

Free SPS gor Ro

“No Mini

“Tpuilt in 5 DAYS

Cri SUC Cenc

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Brain Waves and Biofeedback TrainingDocumento6 pagineBrain Waves and Biofeedback TrainingattapapaNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Coupling Capacitors! - AudioxpressDocumento14 pagineCoupling Capacitors! - AudioxpressattapapaNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Know Your Potatoes: From Our SelectionDocumento2 pagineKnow Your Potatoes: From Our SelectionattapapaNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Berm Rex C100Documento1 paginaBerm Rex C100attapapaNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- LSK389 Dual Monolithic JFETDocumento14 pagineLSK389 Dual Monolithic JFETattapapaNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Science Respectability ChecklistDocumento4 pagineScience Respectability ChecklistattapapaNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Nazi Rally in Buenos Aires, 1938Documento6 pagineNazi Rally in Buenos Aires, 1938attapapaNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Linear Systems Reintroduces LSK389Documento2 pagineLinear Systems Reintroduces LSK389attapapaNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

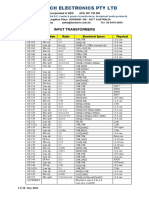

- Harbuch Electronics Pty LTD: Input TransformersDocumento4 pagineHarbuch Electronics Pty LTD: Input Transformersattapapa100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- How To Use The CNC V4 Board (Despite Its "Quirks") : InstructablesDocumento5 pagineHow To Use The CNC V4 Board (Despite Its "Quirks") : InstructablesattapapaNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Braun Multipractic 4262 2 GBDocumento11 pagineBraun Multipractic 4262 2 GBattapapaNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- ARDUINO UNO TB6560 Stepper Motor DriverDocumento4 pagineARDUINO UNO TB6560 Stepper Motor DriverattapapaNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Russel Hobbs 4461Documento21 pagineRussel Hobbs 4461attapapa100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Audible Amplifier Distortion Is Not A Mystery-Baxandall - WW-1977-11Documento4 pagineAudible Amplifier Distortion Is Not A Mystery-Baxandall - WW-1977-11attapapaNessuna valutazione finora

- Miller Coils - Catalog 59Documento36 pagineMiller Coils - Catalog 59attapapa100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Isolated High Quality Zero Crossing DetectorDocumento1 paginaIsolated High Quality Zero Crossing DetectorattapapaNessuna valutazione finora

- RX-CT980 Boombox OperationDocumento14 pagineRX-CT980 Boombox OperationattapapaNessuna valutazione finora

- 4N35 OptocouplersDocumento7 pagine4N35 OptocouplersattapapaNessuna valutazione finora

- The End of The Road by Ivor CattDocumento3 pagineThe End of The Road by Ivor CattattapapaNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)