Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Vent Size Imp For Pressure Vessels

Caricato da

thomas_v501925Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Vent Size Imp For Pressure Vessels

Caricato da

thomas_v501925Copyright:

Formati disponibili

Vent Size for Pressure Vessels

Vent sizing of pressure vessels and process equipments based on the way of usage.

Simply the presence of a Relief valve will relief the over pressure that was developed inside and

protects the reactor, Usually the reactor will be having a pressure resistance which is known as

Design pressure, if the reactor is felt with more than the design pressure, then there may be a

chance for explosion, and i said there may be a chance of explosion because after manufacturing of

reactor there will be some recommended tests that were to be done like pressure test, spark test[if

its a GLR], etc. While performing a pressure test, the vendor will cross the limit of design pressure

and gives a specification called Test Pressure, which means the pressure upto which the test was

carried out.

So, now i'll tell you when there is a need for Vent/Relief valve:

Vapour / Gas removal rate < = Vapour / Gas generation rate,

If the above condition is satisfied, then there requires a Relief valve / Vent for the system.

The major factors that will decide the Vent size were:

Maximum Vapour/Gas Generation rate,

Type of fluid inside the container, whether its a gas or liquid.

In case of Maximum generation rate, If we need to vent out Vapour / Gas that was generated, then

simply calculate the size from below equation:

V = A x S = 0.785 x D x D x S,

here, V = Volumetric flowrate in Cu.m / hr,

D is Diameter of Vent,A is Cross sectional area of the vent neck,

S is the velocity with which the vapour / gas will escape,

If the Container / Vessel is containing any gas, then there wont be any problem because if its a

solvent then there is a chance that solvent may be transform to vapours and create some vapour

pressure, but as it is a Gas then whatever the pressure that is accumulated, that will be kept off like

that.

One more important term, named as WCM [ Worst Credible Maloperation ], Which means the

highest pressure developed due to the maloperation responsible for the generation of vapour / Gas.

The calculation should obey the criteria, i.e., pressure that was developed during the WCM should

safely pass through the vent provided, or the Relief valve should respond to the WCM pressure with

a minimal response time

The approach to Relief sizing depends on 2 cases:

Fire case,

Reaction case

For a fire,

Vapour generation rate = Heat from fire / Latent heat of vaporization

For a chemical reaction,

Vapour generation rate = Reaction rate x Reaction Enthalpy / Latent heat of vaporization.

So after getting the vapour generation rate, you can go with above mentioned equation, V = A x S,

if there is any problem while calculation, then better go with a direct equation which was developed

& Proposed by Leung's Long form eqn.

A = [ m x q ] / G [ { (VxT/m)+(dP/dT)}^0.5 + {Cp x dT}^0.5 ] ^2

m - Initial mass in vessel (Kg),

q - Heat evolution rate per unit mass in vessel(Watt/Kg),

G - Vent flow capacity per unit area at set pressure(Kg/Sq.m),

V - Vessel volume(Cu.m),

T - Vessel temperature(K),

dP/dT - Rate of change of vapour pressure with temperature,

Cp - Specific heat ( J/Kg.K),

dT - difference of temperature between Maximum allowable pressure & Set pressure ( °K),

As per the Equilibrium rate model, the Value of G [ vent flow capacity] can be calculated as below,

G = (dP/dT) x SQRT(T/Cp) = hfg / [ Vfg x SQRT( Cp x T) ]

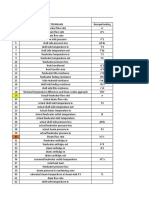

Consider a 10 KL reactor, having MOC SS316 with a design pressure of 3.2 Bar, and maximum

allowable pressure as 4.2 Bar, i.e., 30% excess to design pressure

Averag

e

Pressure Bar 3.2 4.16

Bubble point temperature

°C 110 120.5 115.3

Heat release rate ( watt/Kg) 1150 1660 1405

Liquid density ( Kg/Cu.m) 847 835 841

Vapor density (Kg/Cu.m) 3.75 4.62 4.19

Latent heat (KJ/Kg) 674.9 663.0 668.95

Liquid specific heat (KJ/Kg.K) 1.96 1.96 1.96

dP/dT 8300 9500

Vfg (Cu.m/Kg) 0.2655 0.2153 0.2404

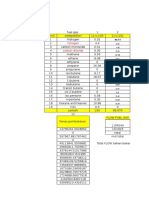

Using equation developed from Equilibrium rate model,

At 3.2 Bar pressure, G = 0.5 x (dP/dT) x SQRT(T/C) = 0.5 * 8300 * SQRT( 383/1960)

= 2385 Kg/Sq.m S.

At 4.16 Bar Pressure, G = 0.5 * 9500 * SQRT(393.15/1960) = 2128.73 Kg/Sq.m S

The average value of 2385 & 2128.73 for G gives 2256.5 Kg/Sq.m S.

Now, we need to calculate the venting area from Leung's Long form eqn.

dP/dT = ( 4.16 - 3.2 ) x 10^5 / ( 120.5 - 110 ) = 9143 N/Sq.m K

A = [ 1500 * 1405 ] / 2256.5 [ { 10 * 288.5 * 9143/1500 }^0.5 +{1960 * 10.5 }^0.5] ^2

= 0.0122 Sq.m

D = SQRT(0.0122/0.785) = 0.125 m = 5" (inch)

Potrebbero piacerti anche

- Swirling IncenDocumento42 pagineSwirling Incendrop shipNessuna valutazione finora

- Pipe Sizing Tabulation Sheet EdtDocumento9 paginePipe Sizing Tabulation Sheet EdtmaxmorekNessuna valutazione finora

- What Is %LEL / %UEL / Lower and Upper Explosive Limits For Flammable Gases and VaporsDocumento8 pagineWhat Is %LEL / %UEL / Lower and Upper Explosive Limits For Flammable Gases and VaporsSherwin Delfin CincoNessuna valutazione finora

- Boiler OEE Calculation Ver1.00Documento37 pagineBoiler OEE Calculation Ver1.00bkprodhNessuna valutazione finora

- InTech Focus Final Control Elements Sept2019Documento33 pagineInTech Focus Final Control Elements Sept2019luciaNessuna valutazione finora

- Flammability WorksheetDocumento6 pagineFlammability WorksheetshailendraNessuna valutazione finora

- CT Blowdown PhilosophyDocumento6 pagineCT Blowdown PhilosophyzamijakaNessuna valutazione finora

- Nox ModelDocumento127 pagineNox ModelClarence AG YueNessuna valutazione finora

- Boiler Efficiency by Indirect Method Coal Fired BoilerDocumento4 pagineBoiler Efficiency by Indirect Method Coal Fired BoilerM Ziaul ArifNessuna valutazione finora

- Hs DiagramDocumento32 pagineHs DiagramsubratorajNessuna valutazione finora

- Actual Pressure Head Ideal Pressure Head Velocity Head Elevation Head Actual Total Head Ideal Total HeadDocumento5 pagineActual Pressure Head Ideal Pressure Head Velocity Head Elevation Head Actual Total Head Ideal Total HeadPei IngNessuna valutazione finora

- PFD - Nitrogen Plant UTL Plaju (Cold Box)Documento1 paginaPFD - Nitrogen Plant UTL Plaju (Cold Box)Julia Dwi LestariNessuna valutazione finora

- Vent Dispersion Calc - OptionalDocumento4 pagineVent Dispersion Calc - OptionalPeddy Nesa0% (1)

- 3P04 Tutorial 4 Post 2008Documento8 pagine3P04 Tutorial 4 Post 2008Khaled KamalNessuna valutazione finora

- Natural Gas Steam Heated Natural GasDocumento10 pagineNatural Gas Steam Heated Natural GasgongweejieNessuna valutazione finora

- Hopper Heating Design GuideDocumento4 pagineHopper Heating Design GuideBadukwangNessuna valutazione finora

- High Integrity Protection Systems (HIPS) - Making SIL Calculations EffectiveDocumento4 pagineHigh Integrity Protection Systems (HIPS) - Making SIL Calculations Effective陳國政Nessuna valutazione finora

- Ows Piping Size2BLDocumento3 pagineOws Piping Size2BLreach_arindomNessuna valutazione finora

- Equilibrium LineDocumento8 pagineEquilibrium Linedhea novitaNessuna valutazione finora

- Perancangan CycloneDocumento20 paginePerancangan CycloneDavid LambertNessuna valutazione finora

- MM MM MM Kpa (Psi) Kpa (Psi) MM MM MM: Steps When D /T 10Documento3 pagineMM MM MM Kpa (Psi) Kpa (Psi) MM MM MM: Steps When D /T 10bibhansuNessuna valutazione finora

- Loop 1 Loop Loop Loop Loop Loop Loop Loop Loop: DMP-B01-B54814-2 DMP-B01-B54814-2Documento86 pagineLoop 1 Loop Loop Loop Loop Loop Loop Loop Loop: DMP-B01-B54814-2 DMP-B01-B54814-2Rakesh Karan SinghNessuna valutazione finora

- Excel As Me P T CDocumento6 pagineExcel As Me P T CNurdinHasanantoNessuna valutazione finora

- Gas Conditioning System Specification Sheet: Process InformationDocumento3 pagineGas Conditioning System Specification Sheet: Process InformationNITIN P SHAHNessuna valutazione finora

- Air CannonDocumento2 pagineAir CannonJohn FulksNessuna valutazione finora

- Nonboiling Liq Outflow F Vertical Cyl VesselDocumento26 pagineNonboiling Liq Outflow F Vertical Cyl VesselSrihari KodimelaNessuna valutazione finora

- Damper System For Gas Turbine Exhaust Gas SystemDocumento2 pagineDamper System For Gas Turbine Exhaust Gas Systemjkhan_724384Nessuna valutazione finora

- Vent Dispersion CalcDocumento9 pagineVent Dispersion CalcPeddy Nesa0% (1)

- DP Calc 1Documento3 pagineDP Calc 1Manjunath HardcheeseNessuna valutazione finora

- NFPA Pipe Sizing EXAMPLEDocumento4 pagineNFPA Pipe Sizing EXAMPLEMatt AndersonNessuna valutazione finora

- Ecuación de AntoineDocumento35 pagineEcuación de AntoineRuben PachecoNessuna valutazione finora

- Cooling Tower Calculations: I N P U TDocumento2 pagineCooling Tower Calculations: I N P U ThuangjlNessuna valutazione finora

- MX-20105ABC - Rev.1 (Stirrer - Agi Mix Tank D) - EnglishDocumento4 pagineMX-20105ABC - Rev.1 (Stirrer - Agi Mix Tank D) - EnglishidilfitriNessuna valutazione finora

- Furnace Efficiency: Fuel OilDocumento3 pagineFurnace Efficiency: Fuel OilMohamed Sayed AbdoNessuna valutazione finora

- L.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o oDocumento9 pagineL.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o omedias indah monica sariNessuna valutazione finora

- Cal. Dew PointDocumento1 paginaCal. Dew PointJuan Pablo ApazaNessuna valutazione finora

- STM Dosing and Feeding Systems For Air Pollution ControlDocumento42 pagineSTM Dosing and Feeding Systems For Air Pollution ControlJoseph RileyNessuna valutazione finora

- De Laval C-D NozzleDocumento4 pagineDe Laval C-D NozzleAravind Pradhyumnan BalajiNessuna valutazione finora

- Semi Elliptical Head Volume and AreaDocumento2 pagineSemi Elliptical Head Volume and AreaRNessuna valutazione finora

- @ 60 Degc 100 WT % H2ODocumento30 pagine@ 60 Degc 100 WT % H2OMildoggNessuna valutazione finora

- Flash CalculationsDocumento10 pagineFlash CalculationsHamza AliNessuna valutazione finora

- Fuel Gas Flow ConvDocumento3 pagineFuel Gas Flow ConvmgkvprNessuna valutazione finora

- Equal Friction MethodDocumento7 pagineEqual Friction MethodfghabboonNessuna valutazione finora

- Forced Draft BlowerDocumento108 pagineForced Draft BlowerTrevor ChandlerNessuna valutazione finora

- Can Length 6.875 6 Top: Input Data in Orange Area OnlyDocumento13 pagineCan Length 6.875 6 Top: Input Data in Orange Area Onlyionutlaur86Nessuna valutazione finora

- Perhitungan Furnace Efesiesnsi Furnace CDU 11-F-101Documento40 paginePerhitungan Furnace Efesiesnsi Furnace CDU 11-F-101Aditya PratomoNessuna valutazione finora

- Turbine Combustion Kinetics PSR-1 : CVODE Starts at Line 100 On EXCEL SheetDocumento14 pagineTurbine Combustion Kinetics PSR-1 : CVODE Starts at Line 100 On EXCEL SheetcymyNessuna valutazione finora

- Vent Sizing (61-65)Documento26 pagineVent Sizing (61-65)mieiroluiz12Nessuna valutazione finora

- Air Ingress CalculationsDocumento5 pagineAir Ingress CalculationsMallinatha PNNessuna valutazione finora

- Condensate Line SizingDocumento4 pagineCondensate Line SizingMubin Ashraf SheikhNessuna valutazione finora

- Absorption (FGD)Documento62 pagineAbsorption (FGD)Chaidir FajariNessuna valutazione finora

- Hydrogen Analysis Resource Center:: Hydrogen Compressibility (Z) at Different Temperatures (C) and Pressures (Mpa)Documento6 pagineHydrogen Analysis Resource Center:: Hydrogen Compressibility (Z) at Different Temperatures (C) and Pressures (Mpa)Ashwani KumarNessuna valutazione finora

- Counter Current Heat Exchanger CarnahanDocumento4 pagineCounter Current Heat Exchanger CarnahancymyNessuna valutazione finora

- Pipes. Maxi 1Documento1 paginaPipes. Maxi 1Nasrul AdliNessuna valutazione finora

- XyzDocumento1 paginaXyzUsman TahirNessuna valutazione finora

- Oilproperties.Xls: Γ Api +131 - 5 Ρ Γ R Γ Γ ADocumento3 pagineOilproperties.Xls: Γ Api +131 - 5 Ρ Γ R Γ Γ ATifano KhristiyantoNessuna valutazione finora

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Da EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Valutazione: 5 su 5 stelle5/5 (1)

- Practical Chemical Thermodynamics for GeoscientistsDa EverandPractical Chemical Thermodynamics for GeoscientistsNessuna valutazione finora

- International Thermodynamic Tables of the Fluid State: Propylene (Propene)Da EverandInternational Thermodynamic Tables of the Fluid State: Propylene (Propene)Nessuna valutazione finora

- 08 - Pressure Drop & Flowrate-KarmanDocumento2 pagine08 - Pressure Drop & Flowrate-Karmanthomas_v501925Nessuna valutazione finora

- Cellulose-from-Cotton ImpDocumento5 pagineCellulose-from-Cotton Impthomas_v501925Nessuna valutazione finora

- NC WW Anaerobic Wastewater Njit-Etd1996-119Documento172 pagineNC WW Anaerobic Wastewater Njit-Etd1996-119thomas_v501925Nessuna valutazione finora

- NC WW Treatment AlternativesDocumento54 pagineNC WW Treatment Alternativesthomas_v501925Nessuna valutazione finora

- NC WW Crossflow Microfiltration ADA298625Documento91 pagineNC WW Crossflow Microfiltration ADA298625thomas_v501925Nessuna valutazione finora

- Phase ChangeDocumento52 paginePhase Changethomas_v501925Nessuna valutazione finora

- 11 - TW Thermo-KineticsDocumento14 pagine11 - TW Thermo-Kineticsthomas_v501925Nessuna valutazione finora

- NC Wastewater US3939068Documento5 pagineNC Wastewater US3939068thomas_v501925Nessuna valutazione finora

- HYSYSDocumento390 pagineHYSYSEfosaUwaifoNessuna valutazione finora

- Properties of GasesDocumento3 pagineProperties of GasesImamRNNessuna valutazione finora

- NC Wastewater IJRET20170603008Documento5 pagineNC Wastewater IJRET20170603008thomas_v501925Nessuna valutazione finora

- Advanced Software Tools To Capture Heat Exchanger Cost SavingsDocumento9 pagineAdvanced Software Tools To Capture Heat Exchanger Cost Savingsthomas_v501925Nessuna valutazione finora

- NC ETP Veolia CompanyDocumento19 pagineNC ETP Veolia Companythomas_v501925Nessuna valutazione finora

- Isopropyl Alcohol Recovery by Heteroazeotropic Batch DistillationDocumento10 pagineIsopropyl Alcohol Recovery by Heteroazeotropic Batch Distillationthomas_v501925Nessuna valutazione finora

- Vogt Valves: Catalog and Application ManualDocumento77 pagineVogt Valves: Catalog and Application Manualthomas_v501925Nessuna valutazione finora

- Pres Equifase09 PDFDocumento22 paginePres Equifase09 PDFSomanath PawarNessuna valutazione finora

- A Case Study On Separation of IPA-water Mixture by Extractive Distillation Using Aspen PlusDocumento8 pagineA Case Study On Separation of IPA-water Mixture by Extractive Distillation Using Aspen Plusthomas_v501925Nessuna valutazione finora

- Isopropyl Alcohol Recovery by Heteroazeotropic Batch DistillationDocumento10 pagineIsopropyl Alcohol Recovery by Heteroazeotropic Batch Distillationthomas_v501925Nessuna valutazione finora

- Vesseldesign 120227013311 Phpapp01Documento369 pagineVesseldesign 120227013311 Phpapp01wisnu_2202Nessuna valutazione finora

- Index Funds GuideDocumento17 pagineIndex Funds GuidesambhavjoshiNessuna valutazione finora

- Solar General GuidelinesDocumento2 pagineSolar General GuidelinesRakNessuna valutazione finora

- SuratTextileMills Annual-ReportDocumento90 pagineSuratTextileMills Annual-Reportthomas_v501925Nessuna valutazione finora

- CondensingSubcooling Practical Heat Transfer PG 124Documento2 pagineCondensingSubcooling Practical Heat Transfer PG 124thomas_v501925Nessuna valutazione finora

- Sales Catalogue: Turbo-Dryer®Documento31 pagineSales Catalogue: Turbo-Dryer®thomas_v501925Nessuna valutazione finora

- Introduction of Htri XistDocumento36 pagineIntroduction of Htri Xistthomas_v501925100% (1)

- Meat-Ds - Spin Flash Dryer System-UkDocumento4 pagineMeat-Ds - Spin Flash Dryer System-Ukthomas_v501925Nessuna valutazione finora

- Rcdc1 NotesDocumento30 pagineRcdc1 NotesV.m. RajanNessuna valutazione finora

- How To Review PV Elite Report: (Specific To Forbes Marshall)Documento9 pagineHow To Review PV Elite Report: (Specific To Forbes Marshall)thomas_v501925Nessuna valutazione finora

- Tender Doc NIT 14 Jun 2019 GLR REACTOR 2019-20Documento22 pagineTender Doc NIT 14 Jun 2019 GLR REACTOR 2019-20thomas_v501925Nessuna valutazione finora

- SRSB - BPG - Heating Manual Mar 2015 BOILER PDFDocumento43 pagineSRSB - BPG - Heating Manual Mar 2015 BOILER PDFDoDuyBacNessuna valutazione finora

- Kelas 15 Oktober 2021 With AnswerDocumento5 pagineKelas 15 Oktober 2021 With Answeralia azizNessuna valutazione finora

- MTL 5017Documento1 paginaMTL 5017Jagadesh C S NadarNessuna valutazione finora

- Solution Manual Gas Dynamics 3rd Edition James E.A. John Theo G. KeithDocumento10 pagineSolution Manual Gas Dynamics 3rd Edition James E.A. John Theo G. KeithPatnala Susmitha ae17b012Nessuna valutazione finora

- Dynamics of Rigid BodiesDocumento9 pagineDynamics of Rigid BodiesJifford Rois HernanNessuna valutazione finora

- Datasheet e Inmetro-1-4Documento4 pagineDatasheet e Inmetro-1-4Fernanda MagnoNessuna valutazione finora

- MP3002/MP4012 Mechanics of Deformable Solids Tutorial 1 - Free Vibration 2009/10 Semester 2Documento8 pagineMP3002/MP4012 Mechanics of Deformable Solids Tutorial 1 - Free Vibration 2009/10 Semester 2David SaranaNessuna valutazione finora

- Lab5 Eecs2200Documento6 pagineLab5 Eecs2200Md Aminul HaqueNessuna valutazione finora

- CE Module 9 - Physics (Answer Key)Documento5 pagineCE Module 9 - Physics (Answer Key)Angelice Alliah De la CruzNessuna valutazione finora

- Consider A Two-Stage Cascade Refrigeration System .Documento5 pagineConsider A Two-Stage Cascade Refrigeration System .NaufalNessuna valutazione finora

- Problems On Performance Testing of Ic Engines: WXN BPDocumento4 pagineProblems On Performance Testing of Ic Engines: WXN BPaldrin sardillaNessuna valutazione finora

- BEEE Important Questions 16 MarksDocumento6 pagineBEEE Important Questions 16 MarkskrishnandrkNessuna valutazione finora

- Introduction To Transformer Turns Ratio TestingDocumento13 pagineIntroduction To Transformer Turns Ratio Testingridho kusumaNessuna valutazione finora

- Chapter 2Documento17 pagineChapter 2api-239026214Nessuna valutazione finora

- Lesson 3 (Componente Resistors)Documento45 pagineLesson 3 (Componente Resistors)Jhella Ochoa JuacallaNessuna valutazione finora

- Name: - Yr. & Sec: - DateDocumento3 pagineName: - Yr. & Sec: - DateJhasper ManagyoNessuna valutazione finora

- Ordinary Differential EquationDocumento34 pagineOrdinary Differential Equationalice boa0% (1)

- Outdoor Air Switches Selection and Application: 8.25 Thru 800 KV Max. Voltage 600 Thru 5000 Amperes Bulletin 2.3.1-1FDocumento18 pagineOutdoor Air Switches Selection and Application: 8.25 Thru 800 KV Max. Voltage 600 Thru 5000 Amperes Bulletin 2.3.1-1FannymagoNessuna valutazione finora

- 2 Cylinders ContactDocumento20 pagine2 Cylinders ContactGuliguli GuliNessuna valutazione finora

- TA SCAC (R410A 50,60Hz) CSA Colombia IDU CO MFL67986333 20220215Documento82 pagineTA SCAC (R410A 50,60Hz) CSA Colombia IDU CO MFL67986333 20220215Oscar Alfonso Piña PertuzNessuna valutazione finora

- Handout No. 11 (Capacitance II) by Odon M. Sanchez C. (Spring Semester 2017)Documento4 pagineHandout No. 11 (Capacitance II) by Odon M. Sanchez C. (Spring Semester 2017)AMC PureNessuna valutazione finora

- Siemens Energy Silyzer 09 - HYPOS - Dialog - WagnerDocumento20 pagineSiemens Energy Silyzer 09 - HYPOS - Dialog - WagnerFreyrVoNessuna valutazione finora

- Cqa SuspensionDocumento78 pagineCqa SuspensionSanjay MehrishiNessuna valutazione finora

- Physics Investigatory ProjectDocumento15 paginePhysics Investigatory ProjectShine Roseline100% (1)

- Manual Pss LDDocumento187 pagineManual Pss LDPhanindra Kumar JNessuna valutazione finora

- Electronics: Automatic Voltage RegulatorDocumento7 pagineElectronics: Automatic Voltage RegulatorOleksandr Cheban-Lianka50% (2)

- Icse Class-Xth-Physics Model PaperDocumento4 pagineIcse Class-Xth-Physics Model PaperUpendra Shukla100% (1)

- Q.Bank Air NavDocumento14 pagineQ.Bank Air Navsakshee gojreNessuna valutazione finora

- Rotational Motion: Sfp1001 Introductory PhysicsDocumento26 pagineRotational Motion: Sfp1001 Introductory PhysicsMuhammad FadhilNessuna valutazione finora

- DC Current Interruption in HVDC SF6 Gas MRTB by Means of Self-Excited Oscillation SuperimpositionDocumento7 pagineDC Current Interruption in HVDC SF6 Gas MRTB by Means of Self-Excited Oscillation SuperimpositionaNessuna valutazione finora

- Chapter 3 Motion and Vectors Chapter Test B With AnswersDocumento7 pagineChapter 3 Motion and Vectors Chapter Test B With AnswersLiliNessuna valutazione finora