Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sulphur in Gas Method 2

Caricato da

JesseTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sulphur in Gas Method 2

Caricato da

JesseCopyright:

Formati disponibili

DETERMINATION OF HYDROGEN SULFIDE AND TOTAL SULFUR IN NATURAL GAS

Marshall T. Schreve

Del Mar Scientific, Ltd.

4951Airport Parkway

Suite 803

Addison, Texas 75001

USA

INTRODUCTION severely stings eyes and throat

Hydrogen Sulfide (H2S) is a gas composed of one 500 ppm Immediate dizziness, breathing

Sulfur Atom and two Hydrogen Atoms. ;H2S is formed ceases in a few minutes

by the decomposition of organic matter and is 700 ppm Quick unconsciousness, death

therefore, found naturally in crude oil and natural gas results if not immediately rescued

deposits. illS is a highly toxic, trans~arent, colorless

1,000 ppm Immediate unconsciousness,

and corrosive gas. Due to the toxic and caustic

followed by death within minutes

properties of this gas and its natural presence within

natural gas, it is imperative to measure and control the

concentration levels of H2S within natural gas

CONCENTRA TION UNITS

pipelines. This paper will discuss the Properties,

PPMN = Parts Per Million by

Purpose of Measurement and Measurement

Volume PPM/W = Parts Per Million

Technologies for H2S and discuss how these

by Weight GrainsllOO ft3 = Grains

technologies can be adapted for measurement of Total

per 100 cubic feet Percent = % of

Sulfur.

total gas

Conversion Factors

TOTAL SULFUR MEASUREMENT 1 Grain/100 ft3 = -15.7 PPMN

10,000 PPMN = 1%

Total sulfur measurement is critical in processed gas for y.. Grain/IOO ft3 (quarter grain) =-4

refinery applications, pharmaceutical and beverage as PPMN

well. Additional sulfurs present in most natural gas

formations can be mercaptans, sulfides, disulfides and

WHY MEASURE?

thiophenes. The use of odorants (which may be a form Personal Safety - illS is a toxic gas and can

of mercaptans) further emphasis the need. for Total cause severe illness and/or death.

Sulfur analysis.

Corrosion Protection - illS is a caustic chemical

that can cause embrittlement of steel pipelines.

PROPERTIES Contractual Agreements - FERC requires that

H2S is also known as Sour Gas, Swamp Gas, pipeline gas be less than 4 PPMN. Most custody

Sulfuretted Hydrogen, and Hydrosulfuric Acid. H2S transfer contracts also state this limit.

has a familiar odor of rotten eggs at low concentrations. Feedstock Quality - Protection of catalysts in

At high concentrations, H2S is highly toxic and often refinery and petrochemical processes is

deadly. economically important.

Legal Requirements - Sulfur emissions can be

Physical Properties controlled by measuring concentrations ofH2S in

Boiling Point -76.60°F fuel gas prior to combustion.

Freezing Point -121.9°F

Molecular Weight 34.08 glmole MEASUREMENT TECHNOLOGIES

Specific Gravity 1.1895

Lower Explosive Limit 4.0% Many different technologies for measuring

Upper Explosive Limit 44.0% concentrations of H2S and Total Sulfur have been

used. This sections briefly describes some of the

Danger Levels more popular technologies that have been used:

10 ppm Unpleasant Odor, Safe for 8

hour exposure

100 ppm Kills sense of smell in 3-15

minutes, stings eyes and throat

200 ppm Rapidly kills sense of smell,

Lead Acetate Tape - The most widely used method UV Fluorescence - All sulfurs are converted to sulfur

available for H2S measurement over the past 30+ years. dioxide in a pyrolyzer furnace. The combustion gases

Paper tape is chemically impregnated with Lead Acetate. then flow into a fluorescence chamber where they are

When exposed to H2S, a chemical reaction on the tape exposed to ultra violet radiation. The ultra violet light

occurs forming a colored reactant, Lead Sulfide (PbS). emission provides an instrumental method for sulfur

Optics are used to measure the rate of formation of the analysis.

colored stain, which is directly proportional to the H2S

present. Chemical preparation advances and electronics

innovations have improved this technology for response Chemiluminescence - Involves the flameless combustion

times less than 10 seconds and sensitivities below 50ppb. of the sample in a reducing atmosphere of air and

Lead Acetate tape can be used to measure total sulfur by hydrogen at near vacuum conditions to produce sulfur

mixing the sample stream with hydrogen and passing it monoxide. The sulfur monoxide produced is transferred to

through a furnace (pyrolyzer) at elevated temperatures. a reaction cell where it is combined with ozone to produce

The sulfur compounds found in the sample stream are an excited form of sulfur dioxide, which releases light

converted to hydrogen sulfide and then read as total upon relaxation.

sulfur.

Conductimetric Detector - The target gas (H2S) is

Stain Tubes - Glass tubes filled with a lead acetate defused through a porous filter or membrane then contacts

impregnated substance. A measured amopnt of gas is the surface of a sensor element where a change in

pulled through the glass tube by a hand-held pump. The resistance occurs that is proportional to the concentration

lead acetate reacts with any present H2S and forms a stain of the target gas. The signal (current) is then amplified

changing the color of the substance within the tube. The and sent to a microprocessor. The sensor element could be

length of the stain through the tube is proportional to the an electrochemical cell, metal oxide cylinder or a

amount of H2S present in the known volume of gas. Stain combination ofthe two sensors.

tubes are generally ± 25% of reading and should therefore

only be used as a spot check technique. Diode Tuned Laser - Utilizes laser absorption

spectroscopy to detect the presence of one or more

Solid State Sensors - Normally this technology is used to gases in a mixture of other gases

measure different gases in ambient air, however, in recent

years this technology has been adapted for use in

pressurized systems such as pipelines. When exposed to Silver Nitrate Tape- A relatively new method,

low-pressure flow of the gas stream, this sensor outputs a developed from the above mentioned lead acetate tape.

The silver nitrate tape retains the same interferent-free

signal to an electronic controller that reports a value for

analysis capability, but also eliminates the need for a

H2S. Particular attention should be given to the potential

humidifier . The spent silver nitrate tape is EPA

interferences of other gas components that report false classified as non-hazardous, and can be disposed of

positive readings for H2S. without concern or regulation.This method does not

require scrubbers, dilution systems, pyrolyzers or

Titration - Titrators operate on the principle of the heaters.

oxidation-reduction reaction of Sulfurs free Bromine,

which is generated by electrolysis. A sample is bubbled

CALIBRATION

through a solution of Hydrobromic Acid within a reaction

cell. The amount of current required to generate enough Regardless of the technology employed, it is imperative

free Bromine to react with all sulfur present is recorded that calibration be performed periodically to insure

and is indicative of the.amount of sulfur present. accuracy. Some analyzers are susceptible to calibration

drift, zero drift, desensitizing or interferences. Periodic

calibration assures the user that the calibration of the

Flame Photometric Detector - Sulfur compounds are analyzer stays accurate. Depending on the analyzer make

thermally decomposed in a hydrogen flame with excess and model, a calibration once a month or once a quarter is

hydrogen, and light (energy) is emitted when recomposed typically sufficient.

sulfur molecules revert from its excited state into the

ground energy state. When sampling for .on-line H2S analysis, it is critical

X-Ray Absorption Detector - Radiation from the source that the gas sample containing a representative

passes through a sample to a detector where it is concentration of H2S reach the analyzer in the shortest

converted into a digital signal, which IS a measure of the period of time possible. The response time of most

sample absorption analyzers is typically many times faster than the delivery

time of the gas · sample from the sample tap to the

analyzer:

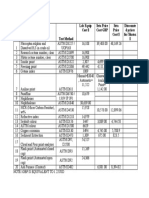

Gas Sample Lag Time Estimates:

Tube diameter Pressure Length/ft Flow/SCFH Lag Time/minutes

0.25 800# 100' 0.4 SCFH 144 minutes

0.25 200# 100' 0.4 SCFH 36 minutes

0.25 50# 100' 0.4 SCFH 9 minutes

0.25 20# 100' 0.4 SCFH 3.5 minutes

The quality of natural gas sample points range from the applications, the sample quality can be further

basic sample tap with a weldolet to sample taps improved by installing a membrane probe regulator

equipped with membrane probe regulators. assembly. The addition of the membrane will prevent

droplets of liquid traveling in the gas stream away from

Unfortunately, many of the taps through which samples the pipe walls from entering the sample line. The

are drawn for on-line H2S analysis are the basic sample regulator portion of the assembly makes the pressure

taps without a probe. The gas sampled through a basic cut inside the pipe at flowing temperature and therefore

sample tap with only a weldolet and no, probe is likely the temperature drop and resulting liquid drop out

to contain liquid contaminants as the liquids typically associated with the pressure cut is minimized.

travel along the pipe walls and may easily enter the

sample line. Much of the liquid conuiminants can be Reducing the sample pressure at the line tap will reduce

avoided simply by installing a probe through the the amount of gas packed in the sample line and

weldolet to draw the sample from near the center of decrease the time it takes for the sample to reach the

the pipe. The use of a probe will ensure a more Analyzer. The delivery time of the sample to the

representative sample of the flowing gas will be analyzer can be further improved by utilizing the

presented to the H2S analyzer. However, in many analyzer' s speed loop.

PREVENT ATIVE MAINTENANCE

Analytical instrumentation requires routine maintenance to insure proper performance. Operators responsible for maintenance

should set up their own Preventative Maintenance (PM) schedule. A checklist of services to be performed should include the

following:

Detector assembly verification, adjustment and replacement as required

Consumables replacement

Sample flow system inspection and cleaning, as required

General instrument performance evaluation

Verify certification of calibration~standards

Complete calibration using a certified known-value calibration standard

. Keep area around analyzer clean and organized

CONCLUSION

Measurement of H2S is a necessary and sometimes dangerous process. It is critical for personal safety and pipeline quality

reasons. Many technologies exist to perform this function and care should be taken to select the technology and brand of

instrument that best suits the application requirements, whether it is for safety, quality, legal, contractual, or other purposes.

Well-trained operating personnel can assure that the H2S analyzer are accurately calibrated and are maintained for optimal

performance.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Iso 17025 - Corrective Action Request Form (Completed)Documento1 paginaIso 17025 - Corrective Action Request Form (Completed)JesseNessuna valutazione finora

- Iso 17025 - Corrective Action Request Form (Completed)Documento1 paginaIso 17025 - Corrective Action Request Form (Completed)Jesse100% (1)

- WeatherfordLabs Reservoir Fluid AnalysisDocumento7 pagineWeatherfordLabs Reservoir Fluid AnalysisJesseNessuna valutazione finora

- NGA ISO 6974 ManualDocumento89 pagineNGA ISO 6974 ManualhopkhtnNessuna valutazione finora

- Activity Group 1-8thDocumento5 pagineActivity Group 1-8thcharles100% (1)

- DHC 11 12 2021Documento1 paginaDHC 11 12 2021JesseNessuna valutazione finora

- DHC 09 04 2022.Documento1 paginaDHC 09 04 2022.JesseNessuna valutazione finora

- Section 3.a Civil (3) FOR BUILDING WORKDocumento3 pagineSection 3.a Civil (3) FOR BUILDING WORKJesseNessuna valutazione finora

- Lab Equip Cost $ Seta Price Cost GBP Seta Price Cost $ Discounte D Prices For Shatox $Documento1 paginaLab Equip Cost $ Seta Price Cost GBP Seta Price Cost $ Discounte D Prices For Shatox $JesseNessuna valutazione finora

- Alto SaxophoneDocumento9 pagineAlto SaxophoneJesse100% (2)

- SPS - Technical Spec.Documento2 pagineSPS - Technical Spec.JesseNessuna valutazione finora

- PVTsimHelp 20Documento197 paginePVTsimHelp 20JesseNessuna valutazione finora

- Hydrates: by Sherry Oyagha 28 August, 2020Documento45 pagineHydrates: by Sherry Oyagha 28 August, 2020JesseNessuna valutazione finora

- Construction Quality Control Plan Draft - Rev0 - 27feb09Documento24 pagineConstruction Quality Control Plan Draft - Rev0 - 27feb09JesseNessuna valutazione finora

- General Comprehensive Quality Plan & Manual Sample: Selected Pages Sample IncludesDocumento28 pagineGeneral Comprehensive Quality Plan & Manual Sample: Selected Pages Sample IncludesJesseNessuna valutazione finora

- Challenges During Operation and Shutdown of Waxy Crude PipelinesDocumento13 pagineChallenges During Operation and Shutdown of Waxy Crude PipelinesJesseNessuna valutazione finora

- Heptanes PlusDocumento15 pagineHeptanes PlusJesseNessuna valutazione finora

- KDC HSE-IIPPManual v.2015Documento156 pagineKDC HSE-IIPPManual v.2015JesseNessuna valutazione finora

- E Nose IoTDocumento8 pagineE Nose IoTarun rajaNessuna valutazione finora

- Ipa18 202 SeDocumento15 pagineIpa18 202 SeDimas Suryo WicaksonoNessuna valutazione finora

- Equilibrium Staged Operations - SummaryDocumento15 pagineEquilibrium Staged Operations - SummarydptsenNessuna valutazione finora

- Chapter 3 f4 2019Documento36 pagineChapter 3 f4 2019Leena bsb.Nessuna valutazione finora

- JEE Mains 1 - 2024Documento16 pagineJEE Mains 1 - 2024Ronit BiswalNessuna valutazione finora

- Modeling The Oxygen Diffusion of Nanocomposite-Based Food Packaging FilmsDocumento10 pagineModeling The Oxygen Diffusion of Nanocomposite-Based Food Packaging FilmsbhuniakanishkaNessuna valutazione finora

- Primary Reservoir CharacteristicsDocumento11 paginePrimary Reservoir Characteristicszuly ortizNessuna valutazione finora

- Full Download Book Transforming Nokia The Power of Paranoid Optimism To Lead Through Colossal Change PDFDocumento41 pagineFull Download Book Transforming Nokia The Power of Paranoid Optimism To Lead Through Colossal Change PDFjohn.colvard20294% (16)

- Sounds 190728012436Documento34 pagineSounds 190728012436Mark Jay BongolanNessuna valutazione finora

- Chm3410hwk01-Soln 249211458Documento7 pagineChm3410hwk01-Soln 249211458Jerika ArceoNessuna valutazione finora

- Batang E, GheremyDocumento3 pagineBatang E, Gheremyyeng botzNessuna valutazione finora

- Pogil Boyles LawDocumento4 paginePogil Boyles LawRussel OtillaNessuna valutazione finora

- How To Calculate The Flowrate of Motive Fluid in An Ejector PDFDocumento3 pagineHow To Calculate The Flowrate of Motive Fluid in An Ejector PDFMuhammad ImranNessuna valutazione finora

- Maxon 5500 InstructionsDocumento8 pagineMaxon 5500 InstructionsdcarunchioNessuna valutazione finora

- PTFE HY538 HoerbigerDocumento1 paginaPTFE HY538 HoerbigerТатьяна ВасильеваNessuna valutazione finora

- Chapter 12Documento44 pagineChapter 12RG RAJNessuna valutazione finora

- Mununga Day Secondary School: Candidate'S Name: ClassDocumento3 pagineMununga Day Secondary School: Candidate'S Name: ClassSimon SimuntalaNessuna valutazione finora

- Phy Mid Year ExamDocumento13 paginePhy Mid Year ExamKendrickNessuna valutazione finora

- QLD Gas Pipeline Specs - Jemena PDFDocumento1 paginaQLD Gas Pipeline Specs - Jemena PDFamir_hayfaNessuna valutazione finora

- Rocket Activities 1Documento3 pagineRocket Activities 1badmintNessuna valutazione finora

- States of Matter With SolutionDocumento26 pagineStates of Matter With SolutionDevansh DubeyNessuna valutazione finora

- Imo Circulara 776 - Guidelines For The Approval of Equivalent Fixed GasDocumento18 pagineImo Circulara 776 - Guidelines For The Approval of Equivalent Fixed GasradugorjNessuna valutazione finora

- The Ultimate IGCSE Physics GuideDocumento40 pagineThe Ultimate IGCSE Physics GuideTaleen Sakayan82% (17)

- 3 2 KeytermsDocumento2 pagine3 2 Keytermsapi-291995478Nessuna valutazione finora

- Membrane Separation in Natural Gas Processing.Documento23 pagineMembrane Separation in Natural Gas Processing.CCESARPL100% (1)

- Applied ThermodynanmicsDocumento93 pagineApplied ThermodynanmicsDiana Catalina Gallo100% (1)

- IpsenDocumento8 pagineIpsenJacques GillesNessuna valutazione finora

- Fluids MT1 RevDocumento3 pagineFluids MT1 RevbmfranzNessuna valutazione finora