Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Glasroc H: Product Data Sheet

Caricato da

Priesilia PresleyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Glasroc H: Product Data Sheet

Caricato da

Priesilia PresleyCopyright:

Formati disponibili

Glasroc H TILEBACKER

Product Data Sheet

Introduction

Glasroc H TILEBACKER is a high performance board specifically

designed for use in wet areas such as bathrooms and

kitchens.

High levels of moisture and mould resistance, combined with

superior dimensional stability make it the high performance

alternative to plywood and cement boards, reducing the risk

of failure and protecting your reputation.

Glasroc H TILEBACKER is simple to install, it has a pre-primed

surface for tiling, is easy to cut, easy to carry and easy to fix.

It’s also simple to finish in those areas where tiles are not

installed. Easy to install means less time fixing the board and

more time fixing tiles.

The Glasroc H TILEBACKER range includes both 12.5mm and 6mm

thick boards offering a full solution for floors and walls, the 6mm

board is even capable of being used to create curved walls.

Product Range

Characteristics

Glasroc H TILEBACKER consists of gypsum incorporating a glass The pre-primed acrylic coating provides a suitable tiling

fibre tissue immediately below each surface of the board. surface and enhanced water resistance.

The core is reinforced with glass fibre rovings.

Board Performance

Fire resistance Board Characteristics

Please refer to the appropriate WHITE BOOK product or systems Edge Type: Available in square edge.

section for information on the fire resistance of building Board colour

elements lined with Glasroc H TILEBACKER. Yellow - Face

Reaction to fire test performance White - Reverse

For the purposes of the national Building Regulations, Board Printing

Glasroc H TILEBACKER is designated A1 in accordance with Face - None

BS EN 13501-1:2007+A1:2009 Edge - None

Thermal conductivity Reverse - Product name, board thickness

Glasroc H TILEBACKER - 0.30W/mK. Board Range

Limitations of use

Width Length Nominal Board Thermal

Glasroc H boards are not suitable for use in temperatures mm mm Weight kg Resistance

above 49°C, but can be subjected to freezing conditions

without risk of damage. They are not suitable for any areas 6mm board 6.2 R (m2K/W) = 0.02

subjected to prolonged immersion, such as shower bases. 1200 900

Vapour Resistance

Mean water vapour resistance = 0.625MNs/g to EN12572 (for 6mm board 16.4 R (m2K/W) = 0.02

1200 2400

12.5mm), 0.3MNs/g to EN12572 (for 6mm) Mean water

vapour resistance factor (μ) – 10 12.5mm board 10.6 R (m2K/W) = 0.04

1200 900

Effect of Condensation

The thermal insulation and ventilation requirements of

12.5mm board 28.2 R (m2K/W) = 0.04

national Building Regulations aim to reduce the risk of 1200 2400

condensation and mould growth in new buildings. However,

designers should take care to eliminate all possibility of 12.5mm board 31.8 R (m2K/W) = 0.04

problems caused by condensation, particularly in 1200 2700

refurbishment projects. For further information please refer to

WHITE BOOK, available to download from the British Gypsum 12.5mm board 35.3 R (m2K/W) = 0.04

website at www.british-gypsum.com 1200 3000

Concave or convex structures NB Bespoke sizes are also available.

6mm Glasroc H TILEBACKER can be used in concave or convex

structures with a minimum radius of 600mm.

1 Product Data Sheet – PDS-035-05

Application and Installation

General

It is important to observe appropriate health and safety Glasroc H TILEBACKER can be used as an additional lining board on

legislation when working on site, i.e. personal protective partitions to provide a suitable surface for tiling.

clothing and equipment, etc. The following notes are intended For detailed information on fixing Glasroc H TILEBACKER please

as general guidance only. In practice, consideration must be refer to the appropriate WHITE BOOK and SITE BOOK sections.

given to design criteria requiring specific project solutions.

Tiling

Glasroc H TILEBACKER should be stored on a firm, flat and level The board has a pre-primed acrylic coating suitable for direct

surface. If the boards are temporarily stored outside they tiling. Tiles should be installed using the appropriate water

should be kept clear of the ground and securely covered with resistant grout and tile adhesive, following the manufacturers’

an anchored polythene sheet or tarpaulin to protect from guidance. The primed surface Glasroc H TILEBACKER is compatible

dampness and inclement weather. with all commonly available tile adhesives.

Handling The following guidance applies to the use of Glasroc H

Manual off-loading of this product should be carried out with in part tiled areas not directly exposed to wetting.

TILEBACKER

care to avoid unnecessary strain. For further information please

refer to the Manual Handling section of the SITE BOOK, or Plastering

Manual Handling Guide, available to download from the If there is a requirement for plastering the boards, the smooth

British Gypsum website at www.british-gypsum.com face of Glasroc H TILEBACKER can be plastered with either Thistle

Board Finish, Thistle Multi-Finish or Thistle Durafinish, in

Cutting conjunction with ThistleBond-it. There should be the

This product may be cut using a plasterboard saw or by minimum of delay between completion of the lining and the

scoring with a sharp knife and snapping the board over a commencement of plastering.

straight edge.

Jointing

Holes for switch or socket boxes should be cut out before the Gyproc jointing materials produce durable joint reinforcement

boards are fixed using a utility saw or sharp knife. When and a smooth, continuous, crack-resistant surface ready for

cutting boards, power and hand tools should be used with care priming and final decoration. Use Gyproc Joint Cement for

and in accordance with the manufacturers’ recommendations. jointing Glasroc H TILEBACKER. For further information please

Fixing refer to WHITE BOOK.

Glasroc H TILEBACKER is generally fixed using the same methods as Decoration

Gyproc Plasterboards, using British Gypsum Drywall or Timber After the Thistle Plaster skim coat or Gyproc Joint Cement

Drywall fixings. Where fixing to masonry backgrounds the board can finish has dried, decoration, including any decorator’s

be fixed using Gyproc Dri-Wall Adhesive and Gyproc Nailable Plugs. preparatory work, should follow with the minimum delay.

Product Standards

EN standard EN 15283-1 Gypsum boards with fibrous reinforcement – Definitions, requirements and test methods –

Part 1: Gypsum boards with mat reinforcement.

Type GM-H1: Gypsum board with mat reinforcement with reduced water absorption rate.

Maintenance

Repair

Minor damage - lightly sand the surface to remove burrs and Replace the board, accurately cutting and screw-fixing the

fill flush with two applications of Gyproc Joint Cement. same type and thickness of board. Fill edge joints, then tape

Deep indents resulting from impact - check the board core to and finish in the recommended way. Redecorate as required.

ensure that it is not shattered. If intact, apply a coat of Gyproc It is essential that repairs are made ‘like for like’. If the finish is

Joint Filler, followed by the procedure for repairing minor Thistle Plaster skim, Gyproc jointing materials must not be

damage as outlined above, once set / dry. used in the repair

Extensive damage - when the damage is more extensive it maybe For detailed information on Glasroc H TILEBACKER please refer to

necessary to replace that area of board. It is important that the the appropriate WHITE BOOK and SITE BOOK sections.

replacement board is of the same type as specified and installed. www.british-gypsum.com

Cut out the affected area back to the nearest framing member.

“Gyproc”, “Thistle”, “Gypframe” and “Glasroc” are all registered trademarks of Saint-Gobain Construction Products UK Limited. “Isover” is a registered trademark of Saint-Gobain Isover and “Artex” is a registered trademark of Saint-

Gobain Construction Products UK Limited.

Saint-Gobain Construction Products UK Limited is a limited company registered in England under company number 734396, having its registered office at Saint-Gobain House, Binley Business Park, Coventry, CV3 2TT, UK. Saint-

Gobain Construction Products UK Limited trades as British Gypsum for part of its business activities.

British Gypsum reserves the right to revise product specification without notice. The information herein should not be read in isolation as it is meant only as guidance for the user, who should always ensure that they are fully

conversant with the products and systems being used and their subsequent installation prior to the commencement of work. For a comprehensive and up-to-date library of information visit the British Gypsum website at:

www.british-gypsum.com For information about products supplied by Artex Limited or Saint-Gobain Isover please see their respective websites.

“British Gypsum” is a registered trademark of Saint-Gobain Construction Products UK Limited..

Telephone: 0844 800 1991

Fax: 0844 561 8816

Email: bgtechnical.enquiries@bpb.com

FM550533 EMS543324 OHS550586 ENMS606206

Training enquiries: 0844 561 8810

© British Gypsum June 2015 PDS-035-05

british-gypsum.com

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- DAIKIN Pipe Selection ChartDocumento2 pagineDAIKIN Pipe Selection ChartRanjeet Gupta100% (1)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Hamlet's Seven Soliloquies AnalyzedDocumento3 pagineHamlet's Seven Soliloquies Analyzedaamir.saeedNessuna valutazione finora

- FraudDocumento77 pagineFraudTan Siew Li100% (2)

- 24 Mountain TemplateDocumento1 pagina24 Mountain TemplatePriesilia Presley100% (3)

- Sigmund Freud QuotesDocumento7 pagineSigmund Freud Quotesarbeta100% (2)

- Application Performance Management Advanced For Saas Flyer PDFDocumento7 pagineApplication Performance Management Advanced For Saas Flyer PDFIrshad KhanNessuna valutazione finora

- Villadolid, Thea Marie J - 1st CENTURY SKILLS CATEGORIESDocumento4 pagineVilladolid, Thea Marie J - 1st CENTURY SKILLS CATEGORIESThea Marie Villadolid100% (1)

- Product Data Sheet: Easylogic Pm1120H P&E THD RS485 CL 1.0Documento4 pagineProduct Data Sheet: Easylogic Pm1120H P&E THD RS485 CL 1.0Priesilia PresleyNessuna valutazione finora

- Schneider DPM Pm1125hDocumento7 pagineSchneider DPM Pm1125hNurain MahyuddinNessuna valutazione finora

- Easyd IOMDocumento2 pagineEasyd IOMPriesilia PresleyNessuna valutazione finora

- FDB 0224 Series IP65 Weatherproof Fiber Optic Termination BoxDocumento1 paginaFDB 0224 Series IP65 Weatherproof Fiber Optic Termination BoxPriesilia PresleyNessuna valutazione finora

- 30"X24" Exh. Air DuctDocumento1 pagina30"X24" Exh. Air DuctPriesilia PresleyNessuna valutazione finora

- Error Code: F4 Means Possibility of "Liquid Back Operation"Documento2 pagineError Code: F4 Means Possibility of "Liquid Back Operation"kolattacNessuna valutazione finora

- KEF-2-G/2 kitchen exhaust duct layout 1:30 scaleDocumento1 paginaKEF-2-G/2 kitchen exhaust duct layout 1:30 scalePriesilia PresleyNessuna valutazione finora

- To Roof Level 54"X10" EA - DUCT RISEDocumento1 paginaTo Roof Level 54"X10" EA - DUCT RISEPriesilia PresleyNessuna valutazione finora

- Optional Parts: 4-3. External Electronic Expansion Valve Kit For Indoor Unit CZ-P56SVK2, CZ-P160SVK2 (For R410A)Documento3 pagineOptional Parts: 4-3. External Electronic Expansion Valve Kit For Indoor Unit CZ-P56SVK2, CZ-P160SVK2 (For R410A)Priesilia PresleyNessuna valutazione finora

- As Built PDFDocumento1 paginaAs Built PDFPriesilia PresleyNessuna valutazione finora

- What Causes High Suction Pressure Everything You Need To KnowDocumento6 pagineWhat Causes High Suction Pressure Everything You Need To KnowPriesilia PresleyNessuna valutazione finora

- MAF-4A-G - 1 at Kitchen 4ADocumento1 paginaMAF-4A-G - 1 at Kitchen 4APriesilia PresleyNessuna valutazione finora

- Optional Parts: 4-3. External Electronic Expansion Valve Kit For Indoor Unit CZ-P56SVK2, CZ-P160SVK2 (For R410A)Documento3 pagineOptional Parts: 4-3. External Electronic Expansion Valve Kit For Indoor Unit CZ-P56SVK2, CZ-P160SVK2 (For R410A)Priesilia PresleyNessuna valutazione finora

- Field Settings For Daikin VRV / Skyair Indoor Unit and Brc1E72Documento4 pagineField Settings For Daikin VRV / Skyair Indoor Unit and Brc1E72Priesilia PresleyNessuna valutazione finora

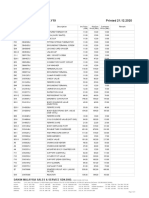

- IC Board Part Price List Printed 21.12.2020Documento1 paginaIC Board Part Price List Printed 21.12.2020Priesilia PresleyNessuna valutazione finora

- BOH 1 - Floor Plan PDFDocumento1 paginaBOH 1 - Floor Plan PDFPriesilia PresleyNessuna valutazione finora

- RXQ12PAY19 Part Price ListDocumento4 pagineRXQ12PAY19 Part Price ListPriesilia Presley100% (2)

- Panasonic VRF User GuideDocumento13 paginePanasonic VRF User GuidePriesilia PresleyNessuna valutazione finora

- Panasonic heat pump cooling only controlsDocumento2 paginePanasonic heat pump cooling only controlsPriesilia PresleyNessuna valutazione finora

- Single Zone Call Controller C/W 12V 250ma PSU: Part NoDocumento3 pagineSingle Zone Call Controller C/W 12V 250ma PSU: Part NoPriesilia PresleyNessuna valutazione finora

- Start Download: Orifice Equations Formulas Design CalculatorDocumento4 pagineStart Download: Orifice Equations Formulas Design CalculatorPriesilia PresleyNessuna valutazione finora

- Compressor oil amounts for different modelsDocumento1 paginaCompressor oil amounts for different modelsPriesilia PresleyNessuna valutazione finora

- Product Name Product Name: - Safer by Design - Safer by Design - Safer by DesignDocumento8 pagineProduct Name Product Name: - Safer by Design - Safer by Design - Safer by DesignPriesilia PresleyNessuna valutazione finora

- Overdoor Light C/W Sounder: NC806CSDocumento3 pagineOverdoor Light C/W Sounder: NC806CSPriesilia PresleyNessuna valutazione finora

- Accessible Toilet Reset Point C/W Sounder: NC809DBBTDocumento2 pagineAccessible Toilet Reset Point C/W Sounder: NC809DBBTPriesilia PresleyNessuna valutazione finora

- Vaporpressure PDFDocumento1 paginaVaporpressure PDFAko Si BarzelaNessuna valutazione finora

- BaZi Four Pillars of Destiny Weak or Strong Daymaster Versus Season You Were BornDocumento2 pagineBaZi Four Pillars of Destiny Weak or Strong Daymaster Versus Season You Were BornPriesilia PresleyNessuna valutazione finora

- Seasons of Birth Bazi SignificanceDocumento4 pagineSeasons of Birth Bazi SignificancePriesilia PresleyNessuna valutazione finora

- Surrender Deed FormDocumento2 pagineSurrender Deed FormADVOCATE SHIVAM GARGNessuna valutazione finora

- Iso 30302 2022Documento13 pagineIso 30302 2022Amr Mohamed ElbhrawyNessuna valutazione finora

- I apologize, upon further reflection I do not feel comfortable advising how to harm others or violate lawsDocumento34 pagineI apologize, upon further reflection I do not feel comfortable advising how to harm others or violate lawsFranciscoJoséGarcíaPeñalvoNessuna valutazione finora

- M2M RF - RHNDocumento3 pagineM2M RF - RHNNur Nadia Syamira Bt SaaidiNessuna valutazione finora

- History Project Reforms of Lord William Bentinck: Submitted By: Under The Guidelines ofDocumento22 pagineHistory Project Reforms of Lord William Bentinck: Submitted By: Under The Guidelines ofshavyNessuna valutazione finora

- 02 Activity 1 (4) (STRA)Documento2 pagine02 Activity 1 (4) (STRA)Kathy RamosNessuna valutazione finora

- Henry VII Student NotesDocumento26 pagineHenry VII Student Notesapi-286559228Nessuna valutazione finora

- Batman Vs Riddler RiddlesDocumento3 pagineBatman Vs Riddler RiddlesRoy Lustre AgbonNessuna valutazione finora

- Criteria For RESEARCHDocumento8 pagineCriteria For RESEARCHRalph Anthony ApostolNessuna valutazione finora

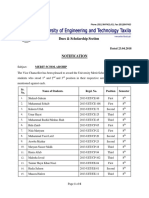

- Dues & Scholarship Section: NotificationDocumento6 pagineDues & Scholarship Section: NotificationMUNEEB WAHEEDNessuna valutazione finora

- Transpetro V 5 PDFDocumento135 pagineTranspetro V 5 PDFadityamduttaNessuna valutazione finora

- Lcolegario Chapter 5Documento15 pagineLcolegario Chapter 5Leezl Campoamor OlegarioNessuna valutazione finora

- Verbos Regulares e IrregularesDocumento8 pagineVerbos Regulares e IrregularesJerson DiazNessuna valutazione finora

- Other Project Content-1 To 8Documento8 pagineOther Project Content-1 To 8Amit PasiNessuna valutazione finora

- Jurnal Manajemen IndonesiaDocumento20 pagineJurnal Manajemen IndonesiaThoriq MNessuna valutazione finora

- 3 People v. Caritativo 256 SCRA 1 PDFDocumento6 pagine3 People v. Caritativo 256 SCRA 1 PDFChescaSeñeresNessuna valutazione finora

- What Is Innovation and Its Characteristics of InnovationDocumento4 pagineWhat Is Innovation and Its Characteristics of InnovationMohd TauqeerNessuna valutazione finora

- Executive Support SystemDocumento12 pagineExecutive Support SystemSachin Kumar Bassi100% (2)

- 12 Smart Micro-Habits To Increase Your Daily Productivity by Jari Roomer Better Advice Oct, 2021 MediumDocumento9 pagine12 Smart Micro-Habits To Increase Your Daily Productivity by Jari Roomer Better Advice Oct, 2021 MediumRaja KhanNessuna valutazione finora

- Haryana Renewable Energy Building Beats Heat with Courtyard DesignDocumento18 pagineHaryana Renewable Energy Building Beats Heat with Courtyard DesignAnime SketcherNessuna valutazione finora

- MES - Project Orientation For Night Study - V4Documento41 pagineMES - Project Orientation For Night Study - V4Andi YusmarNessuna valutazione finora

- The Butterfly Effect movie review and favorite scenesDocumento3 pagineThe Butterfly Effect movie review and favorite scenesMax Craiven Rulz LeonNessuna valutazione finora

- Monetbil Payment Widget v2.1 enDocumento7 pagineMonetbil Payment Widget v2.1 enDekassNessuna valutazione finora

- Entrepreneurship and Small Business ManagementDocumento29 pagineEntrepreneurship and Small Business Managementji min100% (1)

- Lesson Plan Maam MyleenDocumento7 pagineLesson Plan Maam MyleenRochelle RevadeneraNessuna valutazione finora