Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Structure Scope

Caricato da

AmyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Structure Scope

Caricato da

AmyCopyright:

Formati disponibili

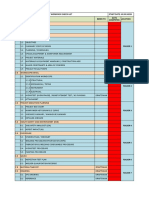

NO WHAT TO INSPECT

All topside structure components as indicated on PCSB Topside

Inspection Guidelines for Offshore Structures (Rev. 0, Oct 2013)

1.1 Primary members

1.2 Secondary members

1

1.3 Connection members

1.4 Operational & safety critical structural components

1.5 Lifting structures

1.6 Appurtenances

Conductors inspe

2.1 Conductor body from below cellar deck to splash zone

2

2.2 Conductor guide

Caisson inspec

3.1 Caisson body from below sump deck to splash zone

3

3.2 Caisson support

Jacket legs inspe

4.1

4 Jacket leg from below cellar deck to splash zone

4.2

Leg to pile connection/ crown

Flare/ vent boom in

5.1 Boom structure and braces

5

5.2 Boom base

5.3 Stair, ladder and safety cage

Telecom Tow

6.1 Tower structure and braces

6 6.2 Ladder and safety cage

6.3 Tower base, flanges and bolts

6.4 Access platforms

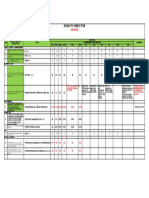

INSPECTION INTERVAL INSPECTION METHOD INSPECTION TOOLS

- Baseline inspection General Visual inspection and Welding/ pit gauge, camera/

- Periodic inspection NDT (ACFM or MPI and UTG) toughpad, measurement

(based on CIMG every 4 tape, ACFM equipment or

years) MPI yoke (with

consumables) and UT set (A

scan)

Conductors inspection

Close visual inspection and Abseiling gears, camera,

-Baseline inspection UTG at 4 direction measurement tape, UT set

'- Periodic inspection (A scan)

(based on CIMG every 4

years)

Caisson inspection

Abseiling gears, camera,

-Baseline inspection measurement tape, UT set

'- Periodic inspection Close visual inspection and (A scan)

(based on CIMG every 4 UTG at 4 direction

years)

Jacket legs inspection

Abseiling gears, camera,

measurement tape, UT set

Based on CIMG - every 4 Close visual inspection and (A scan)

years UTG at 4 direction

Flare/ vent boom inspection

Abseiling gears, camera,

Close visual inspection and measurement tape, UT set

Based on CIMG - every 4 UTG at 4 direction (A scan) and welding/ pit

years General Visual inspection gauge

General Visual inspection

Telecom Tower

Close visual inspection and Abseiling gears, camera,

- Baseline inspection UTG at 4 direction measurement tape, UT set

'- Periodic inspection (A scan) and welding/ pit

(based on CIMG every 4 gauge

years)

TYPE OF FINDING

Missing/ loose members,

variation of design, damage,

corrosion and cracks

Remaining thickness,

corrosion, cracks, damage,

variation of design, missing/

loose members

Remaining thickness,

corrosion, cracks, damage,

variation of design, missing/

loose members

Remaining thickness,

corrosion, cracks, damage,

variation of design, missing/

loose members

Remaining thickness,

corrosion, cracks, damage,

variation of design, missing/

loose members

Remaining thickness,

corrosion, cracks, damage,

variation of design, missing/

loose members

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Lab 2 ReportDocumento9 pagineLab 2 Reportsherub wangdiNessuna valutazione finora

- JX NIPPON Oil & Gas Low Voltage Cable ITRDocumento2 pagineJX NIPPON Oil & Gas Low Voltage Cable ITRAmy100% (1)

- Email Sentences and Phrases in Different SituationsDocumento11 pagineEmail Sentences and Phrases in Different SituationsOmer El-SayedNessuna valutazione finora

- Fall Protection ANSIDocumento5 pagineFall Protection ANSIsejudavisNessuna valutazione finora

- FC Bayern Munich Marketing PlanDocumento12 pagineFC Bayern Munich Marketing PlanMateo Herrera VanegasNessuna valutazione finora

- Low Voltage Switchboard Inspection Test RecordDocumento3 pagineLow Voltage Switchboard Inspection Test RecordAmyNessuna valutazione finora

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - ADocumento2 pagineJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - AAmyNessuna valutazione finora

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BDocumento2 pagineJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BAmyNessuna valutazione finora

- Closure WeldDocumento2 pagineClosure WeldAmyNessuna valutazione finora

- JX NIPPON OIL & GAS LOW VOLTAGE SWITCHBOARD INSPECTIONDocumento2 pagineJX NIPPON OIL & GAS LOW VOLTAGE SWITCHBOARD INSPECTIONAmyNessuna valutazione finora

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - CDocumento2 pagineJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - CAmyNessuna valutazione finora

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BDocumento3 pagineJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - BAmyNessuna valutazione finora

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - ADocumento2 pagineJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - AAmyNessuna valutazione finora

- Weld Efficiencies Notes PDFDocumento28 pagineWeld Efficiencies Notes PDFRamesh sivanNessuna valutazione finora

- Dayang Enterprise Sdn. BHD.: Inspection and Test Plan (Helideck Netting Frame Modification)Documento2 pagineDayang Enterprise Sdn. BHD.: Inspection and Test Plan (Helideck Netting Frame Modification)AmyNessuna valutazione finora

- WI - SummaryDocumento2 pagineWI - SummaryAmyNessuna valutazione finora

- Condy Train B ScopeDocumento2 pagineCondy Train B ScopeAmyNessuna valutazione finora

- PI SummaryDocumento2 paginePI SummaryAmyNessuna valutazione finora

- Closure WeldDocumento2 pagineClosure WeldAmyNessuna valutazione finora

- PI SummaryDocumento2 paginePI SummaryAmyNessuna valutazione finora

- Data Entry For CI Final & Prelim (Northern-2014)Documento73 pagineData Entry For CI Final & Prelim (Northern-2014)AmyNessuna valutazione finora

- Master Punchlist Tukau Revisit Phase 1 Rev.2Documento2 pagineMaster Punchlist Tukau Revisit Phase 1 Rev.2AmyNessuna valutazione finora

- Appendix 2 PDFDocumento1 paginaAppendix 2 PDFAmyNessuna valutazione finora

- Visual inspection report form updateDocumento1 paginaVisual inspection report form updateAmyNessuna valutazione finora

- Weld Defect Wall ChartDocumento6 pagineWeld Defect Wall ChartMuhammad Attaulla KhanNessuna valutazione finora

- Project Completion Checklist for 18S1 Close Out ReportDocumento3 pagineProject Completion Checklist for 18S1 Close Out ReportAmyNessuna valutazione finora

- Beryl Punchlist Clearance Project SummaryDocumento9 pagineBeryl Punchlist Clearance Project SummaryAmyNessuna valutazione finora

- DE-F-101 (B) (QAQC Close Out Report)Documento1 paginaDE-F-101 (B) (QAQC Close Out Report)AmyNessuna valutazione finora

- ITR P11A ST02 Notes on Surface Preparation RequirementsDocumento6 pagineITR P11A ST02 Notes on Surface Preparation RequirementsAmyNessuna valutazione finora

- 13S2 Punchlist Manpower & Equipment r2Documento2 pagine13S2 Punchlist Manpower & Equipment r2AmyNessuna valutazione finora

- Quality Objective - 5.02.2020Documento1 paginaQuality Objective - 5.02.2020AmyNessuna valutazione finora

- DE-F-48B (Minor T.Q's-Scope Clarification)Documento1 paginaDE-F-48B (Minor T.Q's-Scope Clarification)AmyNessuna valutazione finora

- Dayang Enterprise Inspection and Test PlanDocumento3 pagineDayang Enterprise Inspection and Test PlanAmyNessuna valutazione finora

- Liability WaiverDocumento1 paginaLiability WaiverTop Flight FitnessNessuna valutazione finora

- Proprietar Utilizator Nr. Crt. Numar Inmatriculare Functie Utilizator Categorie AutovehiculDocumento3 pagineProprietar Utilizator Nr. Crt. Numar Inmatriculare Functie Utilizator Categorie Autovehicultranspol2023Nessuna valutazione finora

- TicketDocumento2 pagineTicketbikram kumarNessuna valutazione finora

- PHASE 2 - Chapter 6 Object ModellingDocumento28 paginePHASE 2 - Chapter 6 Object Modellingscm39Nessuna valutazione finora

- fr1177e-MOTOR CUMMINS 195HPDocumento2 paginefr1177e-MOTOR CUMMINS 195HPwilfredo rodriguezNessuna valutazione finora

- VB 2Documento11 pagineVB 2Sudhir IkkeNessuna valutazione finora

- Current Affairs Q&A PDF June 9 2023 by Affairscloud 1Documento21 pagineCurrent Affairs Q&A PDF June 9 2023 by Affairscloud 1Yashika GuptaNessuna valutazione finora

- Broschuere Unternehmen Screen PDFDocumento16 pagineBroschuere Unternehmen Screen PDFAnonymous rAFSAGDAEJNessuna valutazione finora

- Lead Magnet 43 Foolproof Strategies To Get More Leads, Win A Ton of New Customers and Double Your Profits in Record Time... (RDocumento189 pagineLead Magnet 43 Foolproof Strategies To Get More Leads, Win A Ton of New Customers and Double Your Profits in Record Time... (RluizdasilvaazevedoNessuna valutazione finora

- Recommended lubricants and refill capacitiesDocumento2 pagineRecommended lubricants and refill capacitiestele123Nessuna valutazione finora

- QDA Miner 3.2 (With WordStat & Simstat)Documento6 pagineQDA Miner 3.2 (With WordStat & Simstat)ztanga7@yahoo.comNessuna valutazione finora

- Verificare Bujii IncandescenteDocumento1 paginaVerificare Bujii IncandescentemihaimartonNessuna valutazione finora

- Why Companies Choose Corporate Bonds Over Bank LoansDocumento31 pagineWhy Companies Choose Corporate Bonds Over Bank Loansতোফায়েল আহমেদNessuna valutazione finora

- PB Engine Kappa EngDocumento20 paginePB Engine Kappa EngOscar AraqueNessuna valutazione finora

- Survey Analyzes India's Toll Collection SystemsDocumento15 pagineSurvey Analyzes India's Toll Collection SystemsmohitvermakspNessuna valutazione finora

- Itec 3100 Student Response Lesson PlanDocumento3 pagineItec 3100 Student Response Lesson Planapi-346174835Nessuna valutazione finora

- Troubleshooting Edge Quality: Mild SteelDocumento14 pagineTroubleshooting Edge Quality: Mild SteelAnonymous U6yVe8YYCNessuna valutazione finora

- Organization Structure GuideDocumento6 pagineOrganization Structure GuideJobeth BedayoNessuna valutazione finora

- Mechanical PropertiesDocumento30 pagineMechanical PropertiesChristopher Traifalgar CainglesNessuna valutazione finora

- Capran+980 CM en PDFDocumento1 paginaCapran+980 CM en PDFtino taufiqul hafizhNessuna valutazione finora

- The Earthing of Zenner BarrierDocumento4 pagineThe Earthing of Zenner BarrierFatholla SalehiNessuna valutazione finora

- Trustees Under IndenturesDocumento233 pagineTrustees Under IndenturesPaul9268100% (6)

- Personal InsuranceDocumento11 paginePersonal InsuranceSumit Kumar SharmaNessuna valutazione finora

- AssDocumento9 pagineAssJane SalvanNessuna valutazione finora

- Perbandingan Sistem Pemerintahan Dalam Hal Pemilihan Kepala Negara Di Indonesia Dan SingapuraDocumento9 paginePerbandingan Sistem Pemerintahan Dalam Hal Pemilihan Kepala Negara Di Indonesia Dan SingapuraRendy SuryaNessuna valutazione finora

- Specialized Government BanksDocumento5 pagineSpecialized Government BanksCarazelli AysonNessuna valutazione finora

- ECED Lab ReportDocumento18 pagineECED Lab ReportAvni GuptaNessuna valutazione finora