Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

UD01-Modelo de Gestión Del Equipo Pesado-2019-2

Caricato da

gilmer flores mamaniCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

UD01-Modelo de Gestión Del Equipo Pesado-2019-2

Caricato da

gilmer flores mamaniCopyright:

Formati disponibili

COURSE: Gestión de Equipo Pesado

CAREER: Gestión y Mantenimiento de Maquinaria

Pesada

6to Semestre

PROFESSOR: Darío Frías

TECSUP - 2019

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 1

UNIT ONE

FUNDAMENTALS OF MODEL TO MANAGEMENT THE

HEAVY EQUIPMENT

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 4

FINAL CAPABILITY

• Diseñar y optimizar sistemas de gestión de la producción y

disponibilidad del Equipo Pesado; planificando, controlando y

administrando los equipos con el objetivo de lograr su máxima

productividad al menor coste.

• Elaborar el planeamiento eficaz del ciclo operacional de los equipos

pesados, proyectando los costos derivados de la operación.

• Evaluar la factibilidad técnica y económica para la adquisición y

reemplazo del equipo pesado.

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 5

SPECIFIC COMPETENCE

• This presentation provides a general overview of the 5 elements

of Mining Equipment Management, what is included and what

should be our role through out the entire life cycle of the

equipment.

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 6

CONTENTS

• WHAT IS MINING EQUIPMENT MANAGEMENT?

• YOUR CHALLENGE

• LIFE CYCLE

• SELECTION

• OPERATION AND PROJECT MANAGEMENT

• REPAIR & MAINTENANCE MANAGEMENT

• BUSINESS MANAGEMENT

• REPLACEMENT, REBUILD, DISPOSAL

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 7

WHAT IS MINING EQUIPMENT MANAGEMENT?

• Mining Equipment Management is the overall management of site-

specific processes and activities involved through the entire lifecycle

of the machine. Selection:

What do I need to efficiently get the job done?

Operations & Project Management:

How can I achieve more productivity and efficiency?

Repair and Maintenance Management:

How can I develop capabilities that will lower my risk to

obtain optimum life, availability, and utilization?

Business Management:

How do I get data to manage my business that will enable

proactive fleet management decisions?

Rebuild/Resale/Disposal:

Which do we analyze? What is the most cost effective lifecycle plan for my asset[s]?

How often we analyze?

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 8

YOUR CHALLENGE – “COST PER TON”

Owning Cost Operating Cost

Purchase Price Operator

Interest

Insurance

Depreciation

+ Tires / UC

Fuel

Maintenance

Tax Repairs

Productivity

Payload

Cycle Time

Usage

Availability

Utilization

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 9

SELECTION

What do I need to efficiently get the job done?

Mining Project Existing Mining Operation

(Stages in the Life of a Mine) (Stages)

▪ Exploration ▪ Extraction

▪ Project Evaluation (Feasibility Study) ▪ Drill + Blast + Load + Haul

▪ Development & Construction ▪ Processing

▪ Production or Exploitation ▪ Smelting

• Understand in what phase the mining ▪ Closure & Reclamation ▪ Refinement

operation / project is.

• Consider all factors for acquisition

• Determine key driver for purchase

• Define best options – best solutions

• Balance O&O Costs over Productivity

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 10

OPERATION AND PROJECT MANAGEMENT

Load & Dump

Drill & Blast

Area

Lower cost

Increase

productivity

Load Haul Road

Management Management

Continua…..

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 11

How can I achieve more productivity and efficiency?

Cost / Hour Cost / Ton Tons / Hour

(minimize) (optimize) (maximize)

Minimize Optimize Manage MAINTENANCE

EQUIPMENT costs PRODUCTION to improve availability

Rebuild Costs Component Lives Application M&R Processes

% A/F Repairs Design Defects Pit Depth Planning & Scheduling

Parts Reuse Application Haul Distance Preventive Maintenance

Parts Price Maintenance Grades Condition Monitoring

Repair Quality Operation Backlog management

Operator Skill Parts Management

Payload Mgmt Repair Management

Cycle Times Component Management

HR/People Development

Performance Evaluation

What areas do we affect ? Continuous Improvement

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 12

REPAIR & MAINTENANCE MANAGEMENT

How can I develop capabilities that will lower my risk to obtain

optimum life, availability and utilization?

Cost / Hour Cost / Ton Tons / Hour

(minimize) (optimize) (maximize)

Minimize Optimize Manage MAINTENANCE

EQUIPMENT costs PRODUCTION to improve availability

Rebuild Costs Component Lives Application

% A/F Repairs Design Defects Pit Depth

Parts Reuse Application Haul Distance

Parts Price Maintenance Grades

Repair Quality Operation

Operator Skill

Payload Mgmt

Cycle Times

Continua…..

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 13

We Must be

Repair & Maintenance Management First PCR Equipment aligned with the

Cycle Disposal customer to

Optimum Fleet

Machine Life Cycle

Management

(Based on PCR) Strategy

Planned

Scheduled

Downtime Detection Unscheduled Periodic

Repairs

Component

Reasons Routines Repairs Services Replacement

(Major & Minor)

(PCR)

• Vital to minimize/prevent • Who’s in control? • Fixed frequency • Planning window to keep • Frequency determined by

unscheduled stops • Must be minimized • Well known routine condition of machine at component life targets and

• Normally performed in • Negative influence on defined level health

parallel with other MTBS, MTTR and • Frequency determined by • Window used for restoring

maintenance activities Availability planning machine to standard

• Starting point of a new

component life cycle

Ability to

Ability to build MTBS, MTTR &

maintain the

Impact On a preventive Maintenance Availability Costs ($)

maintenance

plan Plan Cost ($)

plan

All events reduce asset utilization.

Continua…..

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 14

Corrective Preventive Predictive Proactive

With What

Tools

Who will Do it

People Functions &

Responsibilities Model

What & How to Do

Processes

Everything starts with the Process …

What are we going to Do and How are

we going to Do It.

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 15

BUSINESS MANAGEMENT

What data do I need to manage my business?

Availability Productivity Costs

Reliable delivery of required Performance as sold from What are the areas that

or budgeted hours to meet the fleet. Meeting these both impact and drive the

your production targets / production targets. cost to the customer to

goals. Payload / Speed on move material.

Physical / Mechanical grade TCO

Availability Material / Tons Component life

Utilization moved / BCM’s Ore Production hours

MTBS through the crusher Fleet utilization

MTTR Cost / Ton Maintenance Ratio

Strip to Production

Ratio

Yard/Meters Drilled

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 16

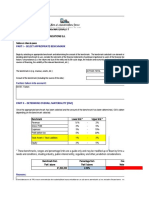

REPLACEMENT, REBUILD, DISPOSAL

What should I do with my assets?

Hourly owning cost goes Hourly operating cost goes

down with age. up with age.

It depends on the rate at which residual It depends on the rate at which

market value decreases and the expenditure on repair parts and labor

number of hours worked in a year. increases as the machine ages.

120

100

80

Total cost / total hours

60

C*

40

20

0

0 1 2 3 4 L* 5 6 7 8 9

Total hours Continua…..

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 17

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 18

SUMMARY

• Selection:

What do I need to efficiently get the job done?

• Operations & Project Management:

How can I achieve more productivity and efficiency?

• Repair and Maintenance Management:

How can I develop capabilities that will lower my risk to obtain optimum

life, availability, and utilization?

• Business Management:

How do I get data to manage my business that will enable proactive fleet

management decisions?

• Rebuild/Resale/Disposal:

What is the most cost effective lifecycle plan for my asset[s]?

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 19

TEST

• Responda a las preguntas

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 20

NEXT SESSION

UNITY:

• MANAGEMENT OF OPERATIONAL ENVIRONMENT

REFERENCE MATERIAL:

• AEXQ0686, SURFACE MINING PRIMARY LOADING TOOL – GUIDE

• https://mining.cat.com

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 21

COURSE: Gestión de Equipo Pesado

CAREER: Gestión y Mantenimiento de Maquinaria

Pesada

6to Semestre

PROFESSOR: Darío Frías

TECSUP - 2019

GESTION Y MANTENIMIENTO DE EQUIPO PESADO 22

Potrebbero piacerti anche

- TPM-Total Productive MaintananceDocumento51 pagineTPM-Total Productive MaintananceMohammad KamruzzamanNessuna valutazione finora

- ITS-Vibration Analysis v2 APR20Documento62 pagineITS-Vibration Analysis v2 APR20muara jawaNessuna valutazione finora

- 16m PDFDocumento20 pagine16m PDFDennis LuqueNessuna valutazione finora

- 14 H Electr Sistem PDFDocumento11 pagine14 H Electr Sistem PDFJoseAntonioQuintanillaPoncedeLeonNessuna valutazione finora

- 14 H Electr Sistem PDFDocumento11 pagine14 H Electr Sistem PDFJoseAntonioQuintanillaPoncedeLeonNessuna valutazione finora

- Cia Review: Part 1 Study Unit 3: Control Frameworks and FraudDocumento14 pagineCia Review: Part 1 Study Unit 3: Control Frameworks and FraudjorgeNessuna valutazione finora

- EnterpriseAssetManagement MikellapitanDocumento43 pagineEnterpriseAssetManagement MikellapitanAmit100% (1)

- TPM AwarenessDocumento51 pagineTPM AwarenessDeepak kumarNessuna valutazione finora

- Selecting the Right Manufacturing Improvement Tools: What Tool? When?Da EverandSelecting the Right Manufacturing Improvement Tools: What Tool? When?Valutazione: 5 su 5 stelle5/5 (2)

- CoCoS MaintenanceDocumento8 pagineCoCoS MaintenanceKamal WanniarachchiNessuna valutazione finora

- Increasing Reliability and Availability of Assets With Asset Performance Management APMDocumento22 pagineIncreasing Reliability and Availability of Assets With Asset Performance Management APMAhmed Abd ElmegeedNessuna valutazione finora

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Documento12 pagineInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768gilmer flores mamaniNessuna valutazione finora

- 1 Introduction To Mining Equipment ManagementDocumento40 pagine1 Introduction To Mining Equipment ManagementHenry Sullca Ccorahua100% (1)

- KK PillarDocumento117 pagineKK PillarMAngesh Gade100% (1)

- 1-Production and Operations Management and Competitive AdvantageDocumento29 pagine1-Production and Operations Management and Competitive AdvantageJayant ChoudhariNessuna valutazione finora

- 00 Meridium Presentation 2015-12-15Documento66 pagine00 Meridium Presentation 2015-12-15Saad100% (1)

- 2 Inspirage - Emir Musabasic OTM Case StudiesDocumento32 pagine2 Inspirage - Emir Musabasic OTM Case StudiesSatyanarayana NekkantiNessuna valutazione finora

- Asset ManagementDocumento39 pagineAsset Managementfoued dridi100% (1)

- Best Practices OverviewDocumento23 pagineBest Practices OverviewDAniel100% (1)

- 814K PDFDocumento31 pagine814K PDFgilmer flores mamaniNessuna valutazione finora

- Alex Thomson PAS55Documento48 pagineAlex Thomson PAS55groovercm15Nessuna valutazione finora

- TEF - Awareness - Mining ForumDocumento18 pagineTEF - Awareness - Mining ForumTC BengalonNessuna valutazione finora

- 420 Sistema Electrico de Una Retroxcavadora Marca CaterpillarDocumento17 pagine420 Sistema Electrico de Una Retroxcavadora Marca CaterpillarNeftali FuentesNessuna valutazione finora

- CMMI AwarenessDocumento14 pagineCMMI Awarenessmadan1981Nessuna valutazione finora

- Ann Handley Everybody Writes 250Documento17 pagineAnn Handley Everybody Writes 250Sonu Kumar100% (1)

- 962H Wheel Loader N4a-Electrical PDFDocumento18 pagine962H Wheel Loader N4a-Electrical PDFMujtba OsmanNessuna valutazione finora

- Feco BHPL PresentDocumento49 pagineFeco BHPL PresentSafety TMRB2023Nessuna valutazione finora

- Lean in MRO 2017 PDFDocumento78 pagineLean in MRO 2017 PDFMikail CoskunNessuna valutazione finora

- D 6Documento47 pagineD 6gilmer flores mamaniNessuna valutazione finora

- All Pillar OverviewDocumento29 pagineAll Pillar OverviewSIVAKUMAR SHANMUGASUNDARAMNessuna valutazione finora

- TPM - Methodolgy (Implementation)Documento5 pagineTPM - Methodolgy (Implementation)king master50% (2)

- VGB PDFDocumento16 pagineVGB PDFbajrangNessuna valutazione finora

- TPM IntroductionDocumento14 pagineTPM IntroductionAntonio Moncayo100% (4)

- Introduction To OPMAN and Operations StrategyDocumento6 pagineIntroduction To OPMAN and Operations StrategyMargie GonzalesNessuna valutazione finora

- Capacity UtilisationDocumento21 pagineCapacity UtilisationTyler IlesNessuna valutazione finora

- Klüberefficiencysupport.: Klüber Lubrication Services - Success For You From One Tool Box!Documento16 pagineKlüberefficiencysupport.: Klüber Lubrication Services - Success For You From One Tool Box!Velibor KaranovicNessuna valutazione finora

- FactoryTalk Metrics Customer Presentation PPT (v10.0)Documento49 pagineFactoryTalk Metrics Customer Presentation PPT (v10.0)Christian GarciaNessuna valutazione finora

- Pitch FALCON For SME 31230320Documento8 paginePitch FALCON For SME 31230320Baskaren RamachandranNessuna valutazione finora

- Service 01Documento123 pagineService 01Bruno TelesNessuna valutazione finora

- UIA Case StudyDocumento8 pagineUIA Case StudyRaduNessuna valutazione finora

- Getting The Most From Your Mining Eet: What You May Not KnowDocumento2 pagineGetting The Most From Your Mining Eet: What You May Not KnowRobbyNessuna valutazione finora

- TPM - Key To EfficiencyDocumento14 pagineTPM - Key To EfficiencyahmedNessuna valutazione finora

- TPM It Works: A Smart Way of Managing Productive ResourcesDocumento2 pagineTPM It Works: A Smart Way of Managing Productive ResourcesrkramnathNessuna valutazione finora

- Warehouse Management: Andrey Druzhinin Solution ArchitectDocumento19 pagineWarehouse Management: Andrey Druzhinin Solution ArchitectmanitenkasiNessuna valutazione finora

- On The Rig Drilling SystemsDocumento10 pagineOn The Rig Drilling Systemscippolippo123Nessuna valutazione finora

- Tugas 03 - Kel 03 - MMT - STIDocumento11 pagineTugas 03 - Kel 03 - MMT - STIGresia SilalahiNessuna valutazione finora

- TCI Operations Training Program - GET: A Production & Equipment Management ToolDocumento59 pagineTCI Operations Training Program - GET: A Production & Equipment Management Toolminingnova2Nessuna valutazione finora

- Capacity Management: ©the Mcgraw-Hill Companies, Inc., 2004Documento31 pagineCapacity Management: ©the Mcgraw-Hill Companies, Inc., 2004Surender SinghNessuna valutazione finora

- Lean MeasureableDocumento39 pagineLean MeasureableAkankshaNessuna valutazione finora

- Caterpillar Cat Loaders Spec d18520Documento12 pagineCaterpillar Cat Loaders Spec d18520Ulvis ZaķisNessuna valutazione finora

- Recap: Smurfit-Stone Container Operational Excellence Boot CampDocumento111 pagineRecap: Smurfit-Stone Container Operational Excellence Boot CampK TNessuna valutazione finora

- Module 3 - Capacity Planning PDFDocumento37 pagineModule 3 - Capacity Planning PDFMhmd Karam100% (1)

- Process Design: Weeks 4 (Chapter 7)Documento17 pagineProcess Design: Weeks 4 (Chapter 7)Faizal Akbar100% (1)

- LEAN - A Competitive Edge For Business ImprovementDocumento20 pagineLEAN - A Competitive Edge For Business ImprovementashwinshettymNessuna valutazione finora

- Operations & Material ManagementDocumento142 pagineOperations & Material ManagementMohit MalhotraNessuna valutazione finora

- Product IV I DadDocumento16 pagineProduct IV I DadRobertoNessuna valutazione finora

- What's OEE ??Documento47 pagineWhat's OEE ??Rabindra Kumar SahuNessuna valutazione finora

- Capacity Planning1 (L)Documento38 pagineCapacity Planning1 (L)seifNessuna valutazione finora

- Finops Foundation PosterDocumento1 paginaFinops Foundation PosterCilantaro BearsNessuna valutazione finora

- 17 VCC How To Optimal Manning ConfigurationDocumento24 pagine17 VCC How To Optimal Manning ConfigurationKory SantiagoNessuna valutazione finora

- OPMAN ReviewerDocumento12 pagineOPMAN ReviewerJericho PadillaNessuna valutazione finora

- TransTRACK - ID Overview 2022.11Documento29 pagineTransTRACK - ID Overview 2022.11M Reza Agung PramudiNessuna valutazione finora

- Introduction To Operational ExcellenceDocumento14 pagineIntroduction To Operational ExcellenceK TNessuna valutazione finora

- Capturing The Next Frontier of Value Operating Models For Oil and Gas Fields of The FutuDocumento15 pagineCapturing The Next Frontier of Value Operating Models For Oil and Gas Fields of The FutuQaiser HafeezNessuna valutazione finora

- CH 2Documento38 pagineCH 2msoNessuna valutazione finora

- Chap 011Documento35 pagineChap 011tb7976skNessuna valutazione finora

- Total Productive Maintenance: Submitted By-Sakshi Singh Jayant KumarDocumento26 pagineTotal Productive Maintenance: Submitted By-Sakshi Singh Jayant KumarSakshi SinghNessuna valutazione finora

- Production Planning and Control (PPC) : MD Rakibul IslamDocumento12 pagineProduction Planning and Control (PPC) : MD Rakibul IslamAE06 AvionicsNessuna valutazione finora

- Consulting Frameworks 3Documento26 pagineConsulting Frameworks 3Eduardo El Khouri BuzatoNessuna valutazione finora

- Effective Maint Manag2006Documento8 pagineEffective Maint Manag2006satriapratamaNessuna valutazione finora

- Acy Upa Nqu I: de Ustu ADocumento1 paginaAcy Upa Nqu I: de Ustu Agilmer flores mamaniNessuna valutazione finora

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Documento12 pagineInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768gilmer flores mamaniNessuna valutazione finora

- Cargador 950 G PDFDocumento14 pagineCargador 950 G PDFEdison Pfoccori Barrionuevo100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Documento10 pagineInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768gilmer flores mamaniNessuna valutazione finora

- Jir?n 70Documento1 paginaJir?n 70gilmer flores mamaniNessuna valutazione finora

- T05 - Reusabilidad de Engranajes PDFDocumento88 pagineT05 - Reusabilidad de Engranajes PDFBrayan Noa ZapanaNessuna valutazione finora

- Renr5369renr5369-01 Sis PDFDocumento2 pagineRenr5369renr5369-01 Sis PDFEdgard MarroquinNessuna valutazione finora

- PlanoDocumento8 paginePlanogilmer flores mamaniNessuna valutazione finora

- Uenr7613uenr7613-01 SisDocumento6 pagineUenr7613uenr7613-01 SisFabrizio JesúsNessuna valutazione finora

- D 11 RDocumento21 pagineD 11 RryanNessuna valutazione finora

- cs563c PDFDocumento1 paginacs563c PDFMoises Carrera AnguloNessuna valutazione finora

- 450f Retoescabadora PDFDocumento17 pagine450f Retoescabadora PDFRembertoNessuna valutazione finora

- PlanoDocumento8 paginePlanogilmer flores mamaniNessuna valutazione finora

- Tablas Estadistico de Smirnov - KolgomorovDocumento12 pagineTablas Estadistico de Smirnov - KolgomorovJaair SaalazarNessuna valutazione finora

- Untuk Cocokan Data Dengan AmihDocumento6 pagineUntuk Cocokan Data Dengan Amihpotek officialNessuna valutazione finora

- DPO-BCO - OOS EnergyDocumento5 pagineDPO-BCO - OOS EnergyNicolae HickeyNessuna valutazione finora

- Mas 03 Cost Volume Profit Analysis - CompressDocumento6 pagineMas 03 Cost Volume Profit Analysis - CompressKhemgee EspedosaNessuna valutazione finora

- UntitledDocumento369 pagineUntitledAlicia Nyberg ErikssonNessuna valutazione finora

- Manufacturing Planning and Control: MPC 6 EditionDocumento24 pagineManufacturing Planning and Control: MPC 6 EditionKhaled ToffahaNessuna valutazione finora

- Revised - (C) Chapter 2Documento12 pagineRevised - (C) Chapter 2Jade LucasNessuna valutazione finora

- Muhammad Shoaib CSCP CLTD 21..2Documento4 pagineMuhammad Shoaib CSCP CLTD 21..2MudasserAliKhanNessuna valutazione finora

- Abdul Hamid Amini PG 09 002Documento2 pagineAbdul Hamid Amini PG 09 002hamidfarahiNessuna valutazione finora

- Inception Cheat SheetDocumento1 paginaInception Cheat SheetAntonny JaramilloNessuna valutazione finora

- Exercise of Chapter 67Documento3 pagineExercise of Chapter 67Jean TanNessuna valutazione finora

- Case Study Kraljics' MatrixDocumento2 pagineCase Study Kraljics' MatrixMEHDINessuna valutazione finora

- Baxter Business Excellence ModelDocumento34 pagineBaxter Business Excellence ModelshekharbiswasNessuna valutazione finora

- Aging 6.17.2021Documento81 pagineAging 6.17.2021Ricardo DelacruzNessuna valutazione finora

- MATH11 - ADM - Org&Man - Q2 - Module14 - Different Controlling... (22 Pages)Documento22 pagineMATH11 - ADM - Org&Man - Q2 - Module14 - Different Controlling... (22 Pages)Aldrin Sarge TayagNessuna valutazione finora

- Module 6 - Elevator Pitch and SubmissionDocumento13 pagineModule 6 - Elevator Pitch and SubmissionIbrahim HabibNessuna valutazione finora

- Idea To Business Model Koe060Documento1 paginaIdea To Business Model Koe060viku9267Nessuna valutazione finora

- Continual Service ImprovementDocumento4 pagineContinual Service ImprovementJosh AlmasiNessuna valutazione finora

- Activity 15: Individual: Activities/AssessmentsDocumento2 pagineActivity 15: Individual: Activities/AssessmentsJoshua LokinoNessuna valutazione finora

- Organizational Effectiveness Management Consultant in San Francisco CA Resume Shuli GoodmanDocumento1 paginaOrganizational Effectiveness Management Consultant in San Francisco CA Resume Shuli GoodmanShuliGoodmanNessuna valutazione finora

- Adevertising TestDocumento2 pagineAdevertising Testmahmoud ababsaNessuna valutazione finora

- 01Documento24 pagine01deepakkumar20002Nessuna valutazione finora

- 1-Powerpoint Chapter 1Documento57 pagine1-Powerpoint Chapter 1Nathalie DeduqueNessuna valutazione finora

- Managing Conflict and The Art of NegotiationhhDocumento45 pagineManaging Conflict and The Art of NegotiationhhKamal AldeenNessuna valutazione finora

- 600 - Materiality AvayaDocumento19 pagine600 - Materiality AvayaBrayan Nicolás Martínez RomeroNessuna valutazione finora

- Black SwanDocumento16 pagineBlack SwanNishant SolankiNessuna valutazione finora

- Master Thesis FINAL-LUP VersionDocumento82 pagineMaster Thesis FINAL-LUP VersionWAQAS AHMEDNessuna valutazione finora

- Marketing Shampoo Industry StudyDocumento5 pagineMarketing Shampoo Industry StudyHillNessuna valutazione finora