Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Index Plungers Mini Indexes: Stainless Steel EH 22110

Caricato da

Ash KetchumTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Index Plungers Mini Indexes: Stainless Steel EH 22110

Caricato da

Ash KetchumCopyright:

Formati disponibili

Machine and Fixture Elements

Index Plungers / Index Bolts

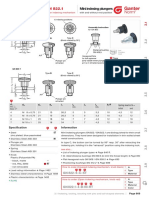

Index Plungers Mini Indexes• stainless steel

EH 22110.

Product Description

Particularly suitable for screwing into thin walled pieces.

Performance in the smallest space requirements.

Material Assembly

Body Screw in the mini index. By lifting the knob, the

• Stainless steel 1.4305 hexagon will be released for assembly.

The screw length can be adapted by distance

Locking pin collars for index plungers (EH 22120.).

• Stainless steel 1.4305

Operation

Knob When using the self-locking type the knob

• Stainless steel 1.4308 is pulled-out, turned 30° and secured by a

notched catch.

More information

Notes

Knob not removable.

Further products

• Distance Collars, for index plungers

Drawing

Order information

| | 1) |

Dimensions WS Spring load Art. No.

d1 d2 d3 d4 l1 l2 l3 F1 F2 max.

h9 min. ~ ~

[mm] [mm] [N] [°C] [g]

without locking – picture 1

4 M 8 21 15 27,5 5 6 10 4 12 250 28 22110.1102

4 M 8 x 1, 21 15 27,5 5 6 10 4 12 250 28 22110.1104

5 M10 25 18 34,0 6 8 12 6 16 250 49 22110.1106

5 M10 x 1, 25 18 34,0 6 8 12 6 16 250 50 22110.1108

6 M10 25 18 34,0 6 8 12 6 16 250 50 22110.1110

6 M10 x 1, 25 18 34,0 6 8 12 6 16 250 50 22110.1112

6 M12 28 20 40,5 7 10 14 10 23 250 74 22110.1114

6 M12 x 1,5 28 20 40,5 7 10 14 10 23 250 75 22110.1116

7 M12 28 20 40,5 7 10 14 10 23 250 75 22110.1118

7 M12 x 1,5 28 20 40,5 7 10 14 10 23 250 75 22110.1120

1)

statistical average value

Halder, Inc. www.halderusa.com Page 1 of 2

Published on: 27.11.2019

Machine and Fixture Elements

Index Plungers / Index Bolts

| | 1) |

Dimensions WS Spring load Art. No.

d1 d2 d3 d4 l1 l2 l3 F1 F2 max.

h9 min. ~ ~

[mm] [mm] [N] [°C] [g]

8 M16 33 23 47,5 10 12 17 11 34 250 110 22110.1122

8 M16 x 1,5 33 23 47,5 10 12 17 11 35 250 113 22110.1124

10 M16 33 23 47,5 10 12 17 11 35 250 113 22110.1126

10 M16 x 1,5 33 23 47,5 10 12 17 11 35 250 113 22110.1128

with locking – picture 2

4 M 8 21 15 27,5 5 6 10 4 12 250 27 22110.1130

4 M 8 x 1, 21 15 27,5 5 6 10 4 12 250 28 22110.1132

5 M10 25 18 34,0 6 8 12 6 16 250 48 22110.1134

5 M10 x 1, 25 18 34,0 6 8 12 6 16 250 49 22110.1136

6 M10 25 18 34,0 6 8 12 6 16 250 49 22110.1138

6 M10 x 1, 25 18 34,0 6 8 12 6 16 250 49 22110.1140

6 M12 28 20 40,5 7 10 14 10 23 250 72 22110.1142

6 M12 x 1,5 28 20 40,5 7 10 14 10 23 250 73 22110.1144

7 M12 28 20 40,5 7 10 14 10 23 250 73 22110.1146

7 M12 x 1,5 28 20 40,5 7 10 14 10 23 250 74 22110.1148

8 M16 33 23 47,5 10 12 17 11 35 250 110 22110.1150

8 M16 x 1,5 33 23 47,5 10 12 17 11 35 250 110 22110.1152

10 M16 33 23 47,5 10 12 17 11 35 250 112 22110.1154

10 M16 x 1,5 33 23 47,5 10 12 17 11 35 250 114 22110.1156

1)

statistical average value

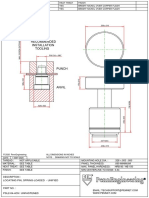

Application example

Halder, Inc. www.halderusa.com Page 2 of 2

Published on: 27.11.2019

Potrebbero piacerti anche

- STPC520 - Viti A Testa Cilindrica Con Esagono IncassatoDocumento18 pagineSTPC520 - Viti A Testa Cilindrica Con Esagono IncassatoLucaNessuna valutazione finora

- Gof-1600-Ce - 3 601 F24 000Documento10 pagineGof-1600-Ce - 3 601 F24 000Andre FilipeNessuna valutazione finora

- EH25100 1 pg838 enDocumento3 pagineEH25100 1 pg838 enEduardo FimbresNessuna valutazione finora

- SZK 40Documento1 paginaSZK 40dilipNessuna valutazione finora

- Strux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet ApplicationsDocumento2 pagineStrux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet ApplicationsneilNessuna valutazione finora

- Taper Lock BushesDocumento4 pagineTaper Lock BushesGopi NathNessuna valutazione finora

- Type 9 Ds Jan18Documento3 pagineType 9 Ds Jan18Suresh KumarNessuna valutazione finora

- Yard Piping 6-4-2011Documento2 pagineYard Piping 6-4-2011Bheema ReddyNessuna valutazione finora

- BBBarBrochure - 2011 05 30 PDFDocumento7 pagineBBBarBrochure - 2011 05 30 PDFKS LeeNessuna valutazione finora

- Delta Smart Sensors Guide to Industrial AutomationDocumento32 pagineDelta Smart Sensors Guide to Industrial AutomationchichialinNessuna valutazione finora

- BoomSupportPlus - C02 - C03 - C04 - CE01 - 90000494.0 - F.I.K. - FIKDocumento32 pagineBoomSupportPlus - C02 - C03 - C04 - CE01 - 90000494.0 - F.I.K. - FIKbaille barrelleNessuna valutazione finora

- 7 CabinDocumento48 pagine7 CabinEmrah MertyürekNessuna valutazione finora

- материалон service-manualDocumento15 pagineматериалон service-manualАндрей ГулькоNessuna valutazione finora

- Suzuki A100 KatalogDocumento47 pagineSuzuki A100 KatalogRamadhan OdeNessuna valutazione finora

- Block Roller 2Documento1 paginaBlock Roller 2Juan Ismael Grave LolNessuna valutazione finora

- Ramset Specifiers Anchoring Resource Book ANZ - DynaBolt Plus Mechanical AnchoringDocumento2 pagineRamset Specifiers Anchoring Resource Book ANZ - DynaBolt Plus Mechanical AnchoringBrian ChmeisseNessuna valutazione finora

- Hebei Shengtian Pipe-Fitting Group Co., LTD - Dimensions, Sizg Flanges PDFDocumento6 pagineHebei Shengtian Pipe-Fitting Group Co., LTD - Dimensions, Sizg Flanges PDFHamed FarajpourNessuna valutazione finora

- DTW450Documento40 pagineDTW450Eduardo Antonio Duran SepulvedaNessuna valutazione finora

- HRC Coupling PDFDocumento8 pagineHRC Coupling PDFJorge Calderon RojasNessuna valutazione finora

- Din 69002Documento3 pagineDin 69002Dule JovanovicNessuna valutazione finora

- CEI High Fidelity Spare Parts E-catalogueDocumento8 pagineCEI High Fidelity Spare Parts E-catalogueAndrei StateNessuna valutazione finora

- ER Spring Collet Chuck System: Mounting Instructions For ER Collets DIN 6499-A and DIN 6499-BDocumento10 pagineER Spring Collet Chuck System: Mounting Instructions For ER Collets DIN 6499-A and DIN 6499-BdavicocasteNessuna valutazione finora

- SAE J518 Split FlangesDocumento1 paginaSAE J518 Split Flangesmanh hung leNessuna valutazione finora

- Manual 46 STE SEDocumento7 pagineManual 46 STE SEdautroc13Nessuna valutazione finora

- Neodymium: Neodymium Shallow Pot MagnetsDocumento1 paginaNeodymium: Neodymium Shallow Pot MagnetsVladimir ParoleNessuna valutazione finora

- Manual Wedge Action Grips - 2716-01X-02X and 2736-01XDocumento3 pagineManual Wedge Action Grips - 2716-01X-02X and 2736-01XLALO MNessuna valutazione finora

- Manual Wedge Action Grips - 2716-01X-02X and 2736-01XDocumento3 pagineManual Wedge Action Grips - 2716-01X-02X and 2736-01XLALO MNessuna valutazione finora

- HRC Couplings: Maryland MetricsDocumento8 pagineHRC Couplings: Maryland MetricsnguyenhuanNessuna valutazione finora

- Wedge AnchorDocumento10 pagineWedge AnchorDoreen PohNessuna valutazione finora

- Rukovodstvo Po Ekspluatacii Makita Dga452z 18vDocumento76 pagineRukovodstvo Po Ekspluatacii Makita Dga452z 18v3278y7d3Nessuna valutazione finora

- Radiaflex: DescriptionDocumento4 pagineRadiaflex: DescriptionNawazNessuna valutazione finora

- (Customer) Doosan Diesel Operation Manual - P158LE, P180LE, P222LE, PU158TI, PU180TI, PU222TIDocumento170 pagine(Customer) Doosan Diesel Operation Manual - P158LE, P180LE, P222LE, PU158TI, PU180TI, PU222TIAngelo RuedaNessuna valutazione finora

- Type 8 Ds Jan18Documento3 pagineType 8 Ds Jan18Suresh KumarNessuna valutazione finora

- Jaw Crusher - Spare Parts ManualDocumento88 pagineJaw Crusher - Spare Parts Manualruelonepiece71% (7)

- Manual Wedge Action Grips: 2716-01x, - 02x, and 2736-01x SeriesDocumento3 pagineManual Wedge Action Grips: 2716-01x, - 02x, and 2736-01x SeriesJc GarciaNessuna valutazione finora

- Mini Ratchet Set Accessory: 2335M 5, 5.5, 6, 7, 8 1025P PH1, PH2 1025T T10, T15, T20 1025H H3, H4, H5, H6Documento1 paginaMini Ratchet Set Accessory: 2335M 5, 5.5, 6, 7, 8 1025P PH1, PH2 1025T T10, T15, T20 1025H H3, H4, H5, H6hudsonNessuna valutazione finora

- Turnbuckle - Span ScrewDocumento1 paginaTurnbuckle - Span ScrewyahsooyNessuna valutazione finora

- 2512-Z900RS Frame Slider Set PDFDocumento4 pagine2512-Z900RS Frame Slider Set PDF孙振立100% (1)

- Manual MAKITA HR2460Documento40 pagineManual MAKITA HR2460Zacek TorresNessuna valutazione finora

- LGMG CMT96 Drive Axle Parts CatalogDocumento42 pagineLGMG CMT96 Drive Axle Parts CatalogShaneNessuna valutazione finora

- BG00870511 RD106 OMM32 D28 Water Flushing PDFDocumento33 pagineBG00870511 RD106 OMM32 D28 Water Flushing PDFarmando rojo100% (2)

- BN 258Documento2 pagineBN 258Doğan ArslanNessuna valutazione finora

- Installation and Maintenance Guide for Bibby Torque LimitersDocumento13 pagineInstallation and Maintenance Guide for Bibby Torque LimitersAmirmasoudNessuna valutazione finora

- Tb4e 005FG0 359Documento3 pagineTb4e 005FG0 359Боян АнтовNessuna valutazione finora

- IP Palp-Det ENDocumento8 pagineIP Palp-Det ENAcuteNessuna valutazione finora

- Chain Saw g5200 PDFDocumento18 pagineChain Saw g5200 PDFaumaNessuna valutazione finora

- Safety Shut-Off Valve Operating ManualDocumento5 pagineSafety Shut-Off Valve Operating ManualAris SetyawanNessuna valutazione finora

- CROWN WT 3040 Lift Linkage, Part 1 - 3 PDFDocumento2 pagineCROWN WT 3040 Lift Linkage, Part 1 - 3 PDFeduardo chavezNessuna valutazione finora

- DIN 580 ISO 3266: Lifting Eye BoltsDocumento2 pagineDIN 580 ISO 3266: Lifting Eye BoltsbloggerparthiNessuna valutazione finora

- Din Standard FlangesDocumento5 pagineDin Standard FlangesMARKETING SIGMANessuna valutazione finora

- B452Documento6 pagineB452willy HNessuna valutazione finora

- Crosscut Chisels: Inch Length Weight PUDocumento2 pagineCrosscut Chisels: Inch Length Weight PURatheesh KumarNessuna valutazione finora

- Jenbacher 1902-0228E Technical Instruction Screwing TorqueDocumento6 pagineJenbacher 1902-0228E Technical Instruction Screwing TorqueArîf100% (2)

- User Manual Powertex Rigging Screw - ESDocumento5 pagineUser Manual Powertex Rigging Screw - ESIrving ChavarriaNessuna valutazione finora

- Modular Lube Lubrication Systems: Divider ValvesDocumento6 pagineModular Lube Lubrication Systems: Divider ValvesIbrahimAmroNessuna valutazione finora

- Lokotrack ST458 - R4581430 Parts ManualDocumento261 pagineLokotrack ST458 - R4581430 Parts ManualJavier Jimenez PerezNessuna valutazione finora

- Din FlangesDocumento6 pagineDin Flangestri yuda khalidNessuna valutazione finora

- Government Publications: Key PapersDa EverandGovernment Publications: Key PapersBernard M. FryNessuna valutazione finora

- Electronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionDa EverandElectronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionValutazione: 5 su 5 stelle5/5 (1)

- PDF TestDocumento1 paginaPDF TestAsh KetchumNessuna valutazione finora

- User ManualDocumento140 pagineUser ManualAsh KetchumNessuna valutazione finora

- Computers and Geotechnics: A.P. Suvorov, A.P.S. SelvaduraiDocumento10 pagineComputers and Geotechnics: A.P. Suvorov, A.P.S. SelvaduraiFebriNessuna valutazione finora

- A Simple PDFDocumento2 pagineA Simple PDFJaheer MakalNessuna valutazione finora

- Computing The Strength of Indexing Plungers: Shear LoadsDocumento2 pagineComputing The Strength of Indexing Plungers: Shear LoadsAsh KetchumNessuna valutazione finora

- Let's Get Crisping: How To Build A Sheet Pan MealDocumento2 pagineLet's Get Crisping: How To Build A Sheet Pan MealAsh KetchumNessuna valutazione finora

- Moog Animatics SmartMotor DevelopersGuide Manual enDocumento948 pagineMoog Animatics SmartMotor DevelopersGuide Manual enAsh KetchumNessuna valutazione finora

- Psychophysical Strength: Theory and Description of The Psychophysical MethodologyDocumento14 paginePsychophysical Strength: Theory and Description of The Psychophysical MethodologyAsh KetchumNessuna valutazione finora

- Digital Air Fry Oven: Please Make Sure To Read The Enclosed Ninja® Owner's Guide Prior To Using Your UnitDocumento21 pagineDigital Air Fry Oven: Please Make Sure To Read The Enclosed Ninja® Owner's Guide Prior To Using Your UnitAsh KetchumNessuna valutazione finora

- EulaDocumento1 paginaEulaDavidPonsMoroNessuna valutazione finora

- 3M VHB Tape Design Guide PDFDocumento20 pagine3M VHB Tape Design Guide PDFKundanNessuna valutazione finora

- Loctite 290-ENDocumento4 pagineLoctite 290-ENDanel SutrisnoNessuna valutazione finora

- Index 3 1 Bauarten RastbolzenDocumento6 pagineIndex 3 1 Bauarten RastbolzenAsh KetchumNessuna valutazione finora

- GN 822 GN 822.1: Mini Indexing PlungersDocumento1 paginaGN 822 GN 822.1: Mini Indexing PlungersAsh KetchumNessuna valutazione finora

- Recommended Installation Tooling: Locating Pin, Spring-Loaded - UnifiedDocumento1 paginaRecommended Installation Tooling: Locating Pin, Spring-Loaded - UnifiedAsh KetchumNessuna valutazione finora

- The Dark Triada Personality A Review PDFDocumento18 pagineThe Dark Triada Personality A Review PDFAvengingBrainNessuna valutazione finora

- Algebra and Trigonometry-OPDocumento1.218 pagineAlgebra and Trigonometry-OPDaniel Rosca Negrescu100% (1)

- F738MDocumento9 pagineF738MsnorklingmonkeyNessuna valutazione finora

- PT United Tractors TBK: On Komatsu Dump TruckDocumento21 paginePT United Tractors TBK: On Komatsu Dump Truckagus haryonoNessuna valutazione finora

- CyCon 2016 BookDocumento307 pagineCyCon 2016 Bookboranga1Nessuna valutazione finora

- Unit Testing the Date Class with JUnitDocumento34 pagineUnit Testing the Date Class with JUnitAbdo AZNessuna valutazione finora

- You Must Be Mad!: Warbirds RPG Mad Science SourcebookDocumento55 pagineYou Must Be Mad!: Warbirds RPG Mad Science SourcebookФёдор Коваль100% (2)

- PM Debug InfoDocumento156 paginePM Debug InfoCarlos garciaNessuna valutazione finora

- Data MiningDocumento10 pagineData MiningSwatiNessuna valutazione finora

- Slab Design ComputationDocumento1 paginaSlab Design ComputationgertjaniNessuna valutazione finora

- Experiment No.1:: Write A LEX Program To Scan Reserved Word & Identifiers of C LanguageDocumento4 pagineExperiment No.1:: Write A LEX Program To Scan Reserved Word & Identifiers of C LanguageRADHARAPU DIVYA PEC0% (1)

- Tackling The Universal Journal (ACDOCA) Data Challenge: White Paper (RUN Phase)Documento22 pagineTackling The Universal Journal (ACDOCA) Data Challenge: White Paper (RUN Phase)Ramesh MariyappaNessuna valutazione finora

- Lesson 1. Information and Communications TechnologyDocumento69 pagineLesson 1. Information and Communications TechnologyDaphnie Joy De la CruzNessuna valutazione finora

- Grade 12 Mathematics Important Question CollectionDocumento9 pagineGrade 12 Mathematics Important Question Collectionaashishdevkota185Nessuna valutazione finora

- From Monolith To Microservices: A Data Ow-Driven ApproachDocumento10 pagineFrom Monolith To Microservices: A Data Ow-Driven ApproachSandraNessuna valutazione finora

- LA SpecificationDocumento3 pagineLA SpecificationVino VinoNessuna valutazione finora

- Step by Step Process For Creating AdobeDocumento23 pagineStep by Step Process For Creating AdobeGL1254Nessuna valutazione finora

- Section Roll No Full Name Mobile No Option Q. No 1Documento12 pagineSection Roll No Full Name Mobile No Option Q. No 1Gazala KhanNessuna valutazione finora

- 1 1061GBDocumento8 pagine1 1061GBPatricio RojasNessuna valutazione finora

- Xcheng Poi SDK Specification v1.1Documento98 pagineXcheng Poi SDK Specification v1.1이동기Nessuna valutazione finora

- Heating Ventilation and Air ConditioningDocumento14 pagineHeating Ventilation and Air ConditioningMiahsaheb Rafeeq100% (1)

- Sophos Central Engineer ProgramDocumento3 pagineSophos Central Engineer ProgramjrosariocabreraNessuna valutazione finora

- Rexroth PSX 6Xxx.630 Timer and I/O Level: Technical InformationDocumento131 pagineRexroth PSX 6Xxx.630 Timer and I/O Level: Technical InformationMiguel ReyesNessuna valutazione finora

- Fluid Centrifugal PumpDocumento9 pagineFluid Centrifugal PumpNathan MartinezNessuna valutazione finora

- Dumitrașcu, Nicolae-Adrian Dincă, Alexandru Predincea, Nicolae. Virtual Commissioning of A Robotic Cell Using Tecnomatix Process SimulateDocumento16 pagineDumitrașcu, Nicolae-Adrian Dincă, Alexandru Predincea, Nicolae. Virtual Commissioning of A Robotic Cell Using Tecnomatix Process SimulateStephanie RiccoNessuna valutazione finora

- The Rise of Network SocietyDocumento13 pagineThe Rise of Network SocietyClauie BarsNessuna valutazione finora

- Edwin Gray Electronic Circuit PDFDocumento6 pagineEdwin Gray Electronic Circuit PDFAvram StefanNessuna valutazione finora

- Negative Effects of Social Media Thesis StatementDocumento8 pagineNegative Effects of Social Media Thesis Statementdwham6h1100% (1)

- Complete System Administrator ChecklistDocumento8 pagineComplete System Administrator Checklistيعىسسفشى نهلثىغه64% (14)

- PMU-Based Fast Sub-synchronous Oscillation DetectionDocumento7 paginePMU-Based Fast Sub-synchronous Oscillation DetectionDaniel Germán RomeroNessuna valutazione finora

- Excel Chapter - 16Documento5 pagineExcel Chapter - 16Shahwaiz Bin Imran BajwaNessuna valutazione finora

- StiffweldDocumento4 pagineStiffweldalfonso vergaraNessuna valutazione finora

- Ak21 Eun: Dynamic Operation Engine Bay Engine RunningDocumento1 paginaAk21 Eun: Dynamic Operation Engine Bay Engine Runningashjam110077Nessuna valutazione finora