Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pages From TU01 - Addendum - 2

Caricato da

ShanMugam0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

12 visualizzazioni1 paginannn

Titolo originale

Pages from TU01_Addendum_2

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentonnn

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

12 visualizzazioni1 paginaPages From TU01 - Addendum - 2

Caricato da

ShanMugamnnn

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

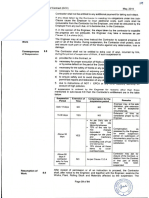

Addendum - 2

Chennai Metro Rail Project Phase 2 Corridor 3 Part-2 Section VII

TENDER No. CP30/TU01 Employer’s Requirements

(12) Inspection & Testing

Every bar shall be inspected by the Contractor before assembling on the Works

and any defective, brittle, rusted or burnt bars shall be removed. Cracked ends of

bars shall be cut out.

Reinforcement steel shall be fresh, free from corrosion. Corroded steel will not

be incorporated into the Work. If there are traces of corrosion, then the

Contractor have to give the following treatment to steel.

· Cleaning of steel by wire brush for removal of dust and rust.

No work shall be commenced without the Engineer’s Notice of No Objection.

Manufacturer's Certificate shall be supplied for each lot of supply.

Specimens sufficient for three Tensile Tests for each different size of bar for

each consignment delivered shall be sampled and tested by the Contractor.

Batches shall be rejected if the average results of each batch are not in

accordance with the specifications and shall be removed from Site, without

delay.

All manufacturer's test certificates, batch reference labels and quality control

certificates shall be retained by the Contractor and noted against each bar mark

number at the time of cutting and bending. This information shall be submitted to

the Engineer.

(13) Coupler Specifications

Only cold-forged, parallel threaded mechanical coupler system are

recommended. All mechanical couplers shall be of Type 2 (or Class H as

specified in IS-16172) and should be simple to install and which can be

confirmed by quick visual inspection to have been correctly installed and to have

achieved the required full strength connection. Any other types of mechanical

coupler systems are not permitted provided the same meet the specification

indicated in Appendix – B.

Section –VII -Outline Construction Specification SS1-73 February 2020

Sub-Section – 1 -Civil &Structural Works Rev. C

Potrebbero piacerti anche

- General Specification For Welding and Weld Inspection (EIL)Documento19 pagineGeneral Specification For Welding and Weld Inspection (EIL)Mitchel Fernandes100% (6)

- Central Business District CBD EAST - Phase 1 of The New Administrative CapitalDocumento20 pagineCentral Business District CBD EAST - Phase 1 of The New Administrative CapitalLi LiuNessuna valutazione finora

- Acsr Conductor: Engineering DepartmentDocumento8 pagineAcsr Conductor: Engineering DepartmentpvenkyNessuna valutazione finora

- 220 & 132 KV SF6 CB - GetcoDocumento36 pagine220 & 132 KV SF6 CB - GetcoVenkatNessuna valutazione finora

- Total Technical Specs PDFDocumento259 pagineTotal Technical Specs PDFBhavesh KeraliaNessuna valutazione finora

- AHU Design GuideDocumento37 pagineAHU Design Guidesachin100% (1)

- Volume-3a-Financial BidDocumento13 pagineVolume-3a-Financial BidBrijesh RavalNessuna valutazione finora

- Particular Specifications 8307Documento22 pagineParticular Specifications 8307alok bharadwajNessuna valutazione finora

- General SpecificationDocumento5 pagineGeneral SpecificationSABEASNNessuna valutazione finora

- 6-66 KV SF6 BKR R3 May12Documento26 pagine6-66 KV SF6 BKR R3 May12PB MehtaNessuna valutazione finora

- AnnexuresDocumento29 pagineAnnexuresammarashraf91Nessuna valutazione finora

- WMS JOB Procedure FOR PIPING WORKDocumento9 pagineWMS JOB Procedure FOR PIPING WORKsatyamech1_395565923Nessuna valutazione finora

- Technical SpecificationDocumento90 pagineTechnical Specificationsofianina05Nessuna valutazione finora

- Technical Specification - PlumbingDocumento6 pagineTechnical Specification - PlumbingRabin ShresthaNessuna valutazione finora

- QCS 2014Documento34 pagineQCS 2014Asad Raza QureshiNessuna valutazione finora

- SS 845 Field Metallizing of Structural Steel 1. SpecificationDocumento1 paginaSS 845 Field Metallizing of Structural Steel 1. Specificationl_aguilar_mNessuna valutazione finora

- System Study of 220Kv Switchyard For Phase - Iiib Project: Petronet LNG, DahejDocumento14 pagineSystem Study of 220Kv Switchyard For Phase - Iiib Project: Petronet LNG, DahejBrijesh BhadauriaNessuna valutazione finora

- DG BusductDocumento16 pagineDG BusductanandpurushothamanNessuna valutazione finora

- Volume - III C (I) Technical Specification For HVAC Systems PDFDocumento85 pagineVolume - III C (I) Technical Specification For HVAC Systems PDFCh Saif Ullah JuraaNessuna valutazione finora

- Hamad International Airport Jet Fuel System Expansion: 00 31/01/2019 Issued For Construction Ms LW LW DPDocumento29 pagineHamad International Airport Jet Fuel System Expansion: 00 31/01/2019 Issued For Construction Ms LW LW DPsrp. mohammedNessuna valutazione finora

- Saes L 470Documento10 pagineSaes L 470abaanNessuna valutazione finora

- sf6 CBDocumento24 paginesf6 CBNaushad AliNessuna valutazione finora

- SECTION 20710 Flash Butt Rail Welding: Caltrain Standard SpecificationsDocumento8 pagineSECTION 20710 Flash Butt Rail Welding: Caltrain Standard SpecificationsminchanmonNessuna valutazione finora

- Breaker SpecifiDocumento27 pagineBreaker SpecifiankitrajNessuna valutazione finora

- 1 ScopeDocumento11 pagine1 ScopeMichael SkrableNessuna valutazione finora

- Irst 19 2012Documento65 pagineIrst 19 2012krischaever100% (1)

- Saep 323Documento8 pagineSaep 323brecht1980100% (1)

- ARAMCO Material SpecificationDocumento21 pagineARAMCO Material Specificationkhorzoo83% (6)

- (ERECTION PROCEDURE Mech Equipment) - BiddingDocumento7 pagine(ERECTION PROCEDURE Mech Equipment) - BiddingnuntaricherdchaiNessuna valutazione finora

- M72 Certification of Engine Components M72Documento7 pagineM72 Certification of Engine Components M72aakhyar_2Nessuna valutazione finora

- Bs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Documento57 pagineBs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Vvs RayuduNessuna valutazione finora

- Liquid Penetrant TestingDocumento13 pagineLiquid Penetrant Testingishfaqurrehmanpk100% (2)

- HVAC - Equipment and Ductwork-Installation and Testing: Technical StandardDocumento15 pagineHVAC - Equipment and Ductwork-Installation and Testing: Technical Standardd r hardyNessuna valutazione finora

- Annexure To SOW 3 STD Specification For Welding and NDT PipingDocumento15 pagineAnnexure To SOW 3 STD Specification For Welding and NDT PipingASHISH GORDENessuna valutazione finora

- Erection Testing and CommissioningDocumento30 pagineErection Testing and CommissioningEngr Muhammad Abu BakrNessuna valutazione finora

- 05 12 00 Structural Steel FramingDocumento15 pagine05 12 00 Structural Steel FramingAbdul RafiqueNessuna valutazione finora

- G I Strip Technical SpecDocumento2 pagineG I Strip Technical SpecRitaban R. BanerjeeNessuna valutazione finora

- Technical Specification of 245Kv Single Pole Live Tank Sf6 Circuit BreakerDocumento41 pagineTechnical Specification of 245Kv Single Pole Live Tank Sf6 Circuit BreakerkaaisNessuna valutazione finora

- 3834 1Documento39 pagine3834 1Achuthan KannankuttyNessuna valutazione finora

- 1515-50-S002 Specification For Plant PipeDocumento7 pagine1515-50-S002 Specification For Plant PipeEr PrasannaNessuna valutazione finora

- Eaton Guidespec Metal Enclosed Non Segregated Bus Duct MV 26 18 29Documento6 pagineEaton Guidespec Metal Enclosed Non Segregated Bus Duct MV 26 18 29JeyakumarNessuna valutazione finora

- 16 - Specification of Work - Part 22Documento161 pagine16 - Specification of Work - Part 22Yadunath RavikumarNessuna valutazione finora

- Norma CCH70Documento81 pagineNorma CCH70jefersonjajNessuna valutazione finora

- LTA Specs For CouplersDocumento4 pagineLTA Specs For CouplerssawwahwahNessuna valutazione finora

- Vol III (B) Technical Specification For Mech and Instru Works - L2P4 PDFDocumento55 pagineVol III (B) Technical Specification For Mech and Instru Works - L2P4 PDFKumar AbhishekNessuna valutazione finora

- Welding InspectionDocumento7 pagineWelding Inspectionzahid_497100% (1)

- TDG 0026 Rev 4 - Final 23042014Documento20 pagineTDG 0026 Rev 4 - Final 23042014SunilKumarNessuna valutazione finora

- Tamilnadu Water Supply and Drainage Board: Name of WorkDocumento88 pagineTamilnadu Water Supply and Drainage Board: Name of WorkSriSushruthaNessuna valutazione finora

- Technical Bid-2 RSO Navsari-52Documento248 pagineTechnical Bid-2 RSO Navsari-52Sampath Kumar KandasamyNessuna valutazione finora

- Drill Stem Test (DST) Tools: General RequirementsDocumento4 pagineDrill Stem Test (DST) Tools: General Requirementsislam atifNessuna valutazione finora

- Technical Specifications For Reduction Retort Bottom SectionDocumento5 pagineTechnical Specifications For Reduction Retort Bottom SectionSharat ChandraNessuna valutazione finora

- Mechanical Specifications-9-10Documento2 pagineMechanical Specifications-9-10AMER SALEEMNessuna valutazione finora

- System Study of 220Kv Switchyard For Phase - Iiib Project: Petronet LNG, DahejDocumento34 pagineSystem Study of 220Kv Switchyard For Phase - Iiib Project: Petronet LNG, DahejBrijesh BhadauriaNessuna valutazione finora

- SPCC PTM P Ts 001 Rev BDocumento27 pagineSPCC PTM P Ts 001 Rev BDan MorganNessuna valutazione finora

- Sample Busduct SpecsDocumento15 pagineSample Busduct SpecsONILEDA1970Nessuna valutazione finora

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Design Guidelines for Surface Mount TechnologyDa EverandDesign Guidelines for Surface Mount TechnologyValutazione: 5 su 5 stelle5/5 (1)

- Pocket Guide to Preventing Process Plant Materials Mix-upsDa EverandPocket Guide to Preventing Process Plant Materials Mix-upsNessuna valutazione finora

- UAA04 Ledger DataDocumento51 pagineUAA04 Ledger DataShanMugamNessuna valutazione finora

- Minimum Wages - Area ADocumento1 paginaMinimum Wages - Area AShanMugamNessuna valutazione finora

- Parashara'S Light 6.1 (C) Geovision Software, Inc., Licensed To TSRHDocumento8 pagineParashara'S Light 6.1 (C) Geovision Software, Inc., Licensed To TSRHShanMugamNessuna valutazione finora

- MW-Central Revision Notification 01.10.2019Documento10 pagineMW-Central Revision Notification 01.10.2019Manish ShahNessuna valutazione finora

- Sfs PDFDocumento1 paginaSfs PDFShanMugamNessuna valutazione finora

- USD TO INR FORECAST 2020, 2021, 2022, 2023, 2024 - Long ForecastDocumento7 pagineUSD TO INR FORECAST 2020, 2021, 2022, 2023, 2024 - Long ForecastShanMugamNessuna valutazione finora

- FGDocumento1 paginaFGShanMugamNessuna valutazione finora

- Form EQUDocumento2 pagineForm EQUShanMugamNessuna valutazione finora

- Form EQUDocumento2 pagineForm EQUShanMugamNessuna valutazione finora

- Vitiligo (Leucoderma) - Krishnamurthy S - MediumDocumento6 pagineVitiligo (Leucoderma) - Krishnamurthy S - MediumShanMugamNessuna valutazione finora

- DJFSHFDocumento1 paginaDJFSHFShanMugamNessuna valutazione finora

- Suspensionof WorkDocumento1 paginaSuspensionof WorkShanMugamNessuna valutazione finora

- Excel Crash Course PDFDocumento2 pagineExcel Crash Course PDFmanoj_yadav735Nessuna valutazione finora

- Validación Española ADHD-RSDocumento7 pagineValidación Española ADHD-RSCristina Andreu NicuesaNessuna valutazione finora

- IFN 554 Week 3 Tutorial v.1Documento19 pagineIFN 554 Week 3 Tutorial v.1kitkataus0711Nessuna valutazione finora

- History Homework Help Ks3Documento8 pagineHistory Homework Help Ks3afetnjvog100% (1)

- Case Paul Foster Highlights of TarotDocumento76 pagineCase Paul Foster Highlights of TarotTraditionaltarot100% (6)

- Dimmable Bulbs SamplesDocumento11 pagineDimmable Bulbs SamplesBOSS BalaNessuna valutazione finora

- Quemador BrahmaDocumento4 pagineQuemador BrahmaClaudio VerdeNessuna valutazione finora

- Electronics 12 00811Documento11 pagineElectronics 12 00811Amber MishraNessuna valutazione finora

- 13 SK Kader Pendamping PGSDocumento61 pagine13 SK Kader Pendamping PGSrachman ramadhanaNessuna valutazione finora

- Case Study III - MichelinDocumento15 pagineCase Study III - MichelinfreitzNessuna valutazione finora

- Corometrics 170 Series BrochureDocumento3 pagineCorometrics 170 Series BrochureCesar MolanoNessuna valutazione finora

- Question BankDocumento3 pagineQuestion BankHimanshu SharmaNessuna valutazione finora

- Handbook+for+Participants+ +GCC+TeenDocumento59 pagineHandbook+for+Participants+ +GCC+Teenchloe.2021164Nessuna valutazione finora

- Lifecycle of A Butterfly Unit Lesson PlanDocumento11 pagineLifecycle of A Butterfly Unit Lesson Planapi-645067057Nessuna valutazione finora

- Grimm (2015) WisdomDocumento17 pagineGrimm (2015) WisdomBruce WayneNessuna valutazione finora

- Creative LibrarianDocumento13 pagineCreative LibrarianulorNessuna valutazione finora

- BS 07533-3-1997Documento21 pagineBS 07533-3-1997Ali RayyaNessuna valutazione finora

- Electric PotentialDocumento26 pagineElectric PotentialGlitchNessuna valutazione finora

- DLP - CO#1-for PandemicDocumento4 pagineDLP - CO#1-for PandemicEvelyn CanoneraNessuna valutazione finora

- Demonstration of Preprocessing On Dataset Student - Arff Aim: This Experiment Illustrates Some of The Basic Data Preprocessing Operations That Can BeDocumento4 pagineDemonstration of Preprocessing On Dataset Student - Arff Aim: This Experiment Illustrates Some of The Basic Data Preprocessing Operations That Can BePavan Sankar KNessuna valutazione finora

- PhotometryDocumento2 paginePhotometryHugo WNessuna valutazione finora

- Num Sheet 1Documento1 paginaNum Sheet 1Abinash MohantyNessuna valutazione finora

- DSynchronize (ENG)Documento3 pagineDSynchronize (ENG)Rekha Rajarajan100% (1)

- ADAMS/View Function Builder: Run-Time FunctionsDocumento185 pagineADAMS/View Function Builder: Run-Time FunctionsSrinivasarao YenigallaNessuna valutazione finora

- Hooke's LawDocumento1 paginaHooke's LawAnan BarghouthyNessuna valutazione finora

- 01 IntroductionDocumento15 pagine01 IntroductionAli FarhatNessuna valutazione finora

- Tools of Persuasion StudentsDocumento4 pagineTools of Persuasion StudentsBelén Revilla GonzálesNessuna valutazione finora

- Guia Instalacion APP Huawei Fusion HmeDocumento4 pagineGuia Instalacion APP Huawei Fusion Hmecalinp72Nessuna valutazione finora

- 37270a QUERCUS GBDocumento6 pagine37270a QUERCUS GBMocanu Romeo-CristianNessuna valutazione finora

- Phase DiagramDocumento3 paginePhase DiagramTing TCNessuna valutazione finora