Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Methods of Pumping Concrete As Per ACI 304.2R-17

Caricato da

Joseph Marriott AndersonTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Methods of Pumping Concrete As Per ACI 304.2R-17

Caricato da

Joseph Marriott AndersonCopyright:

Formati disponibili

Project : ACE Medical Center General Santos City

Owner : Allied Care Experts Medical Center – General Santos, Inc.

Location : National Highway, Brgy. Lagao, General Santos City

METHODS OF PUMPING CONCRETE AS PER ACI 304.2R-17

This periodic publication of references, guidelines and construction methods is intended to

enlighten the reader and clarify some issues under discussion, to achieve acceptability of works in

accordance to specifications and standards. These documents form an essential part in the

execution of the Quality Assurance and Control processes for the Project.

This article shall be discussed in meetings, toolbox talks and posted in bulletin boards.

Figure 1: Concrete Pumping Operations

METHODS OF POURING CONCRETE AS PER ACI 304R-00 Page 1 of 3

Introduction

Pumping concrete through metal pipelines by piston pumps was introduced to the United States in

Milwaukee, WI, in 1933 (Ball 1933). This concrete pump used mechanical linkages to operate, and

usually pumped through pipelines 6 in. (150 mm) or larger in diameter. Figure 1 is an example of

the operations on a big project.

Many new developments have since been made in the concrete pumping field. These include new

and improved pumps, truck-mounted and stationary placing booms, and pipelines and hoses that

withstand higher pumping pressures. Pumps are available with maximum theoretical output

capacities of over 250 yd3/h (190 m3/h). As a result of these innovations, concrete placement by

pumps has become one of the most widely used practices of the construction industry.

The construction industry recognizes that concrete pumping is useful when space for construction

equipment is limited. Cranes and hoists are freed up and other crafts can work unhampered while

pumping is in progress. Concrete pumps are designed to deliver the best combination of volume

output and concrete line pressure possible.

Basic Concepts

Pumped concrete moves as a cylinder riding on a thin lubricating film of grout or mortar on the

inside diameter of the pipeline. Before pumping begins, the entire pipeline’s interior diameter must

be coated with either grout or a specialized commercial primer using the methods for 100 percent

coating of the pipe walls as recommended by the manufacturer. Once concrete flow through the

pipeline is established, the lubrication will be maintained as long as pumping continues with a

properly proportioned and consistent mixture. A steady supply of pumpable concrete, defined as a

mixture that is capable of being pumped through a hose or pipe, is necessary for satisfactory

pumping (U.S. Bureau of Reclamation 1981). A pumpable concrete, such as conventional

concrete, requires good quality control; that is, it is uniform, has properly graded aggregate, and its

materials are uniformly batched and mixed thoroughly.

Boundary Layer – thin coating of mortar fraction that lines the inner pipeline wall during pumping.

Degree of Pumpability – the amount of resistance of a specific concrete mixture to being pumped

through a delivery pipeline.

Pumpability – capability of a specific concrete mixture to being pumped through a delivery

pipeline.

Relative Movement – ability of concrete components to navigate small distances within the

mixture and to position differently compared to the other components.

Stable Concrete – concrete mixture that resists the tendency to segregate.

METHODS OF POURING CONCRETE AS PER ACI 304R-00 Page 2 of 3

END OF ARTICLE

METHODS OF POURING CONCRETE AS PER ACI 304R-00 Page 3 of 3

Potrebbero piacerti anche

- Deformed and Plain Low-Alloy Steel Bars For Concrete ReinforcementDocumento7 pagineDeformed and Plain Low-Alloy Steel Bars For Concrete ReinforcementSantosh Ramakrishna KandalaNessuna valutazione finora

- Compression Testing of Concrete - Cylinder Vs Cube StrengthDocumento30 pagineCompression Testing of Concrete - Cylinder Vs Cube StrengthTNT100% (1)

- Constructability A Complete Guide - 2021 EditionDa EverandConstructability A Complete Guide - 2021 EditionNessuna valutazione finora

- Supervising Highway Engineer: Passbooks Study GuideDa EverandSupervising Highway Engineer: Passbooks Study GuideNessuna valutazione finora

- Thermal Stresses and Temperature Control of Mass ConcreteDa EverandThermal Stresses and Temperature Control of Mass ConcreteNessuna valutazione finora

- Construction Procedures and Internal Quality ControlDocumento17 pagineConstruction Procedures and Internal Quality ControlbienndcNessuna valutazione finora

- A New Design To Prevent Progressive Collapse of Re PDFDocumento7 pagineA New Design To Prevent Progressive Collapse of Re PDFKoresh KhalpariNessuna valutazione finora

- JIS K6741-2016 - e - Ed10 - I4-Hitachi - ENDocumento38 pagineJIS K6741-2016 - e - Ed10 - I4-Hitachi - ENvan binh NguyenNessuna valutazione finora

- 2014 Volume 1 PDFDocumento230 pagine2014 Volume 1 PDFDidik JunaidiNessuna valutazione finora

- Thermal Engineering For The Construction of Large Concrete Arch DamsDocumento10 pagineThermal Engineering For The Construction of Large Concrete Arch DamsOscar LopezNessuna valutazione finora

- Steel and Composite StructuresDocumento372 pagineSteel and Composite StructuresTATATAHER100% (1)

- R0030 Manual of Aggregate and Concrete Testing1Documento34 pagineR0030 Manual of Aggregate and Concrete Testing1Z MNessuna valutazione finora

- ACI 315R-94: Reported by ACI Committee 315Documento1 paginaACI 315R-94: Reported by ACI Committee 315DIDIER ANGEL LOPEZ RINCONNessuna valutazione finora

- PVC Waterstop - Design Guide: Suggested Master SpecificationDocumento4 paginePVC Waterstop - Design Guide: Suggested Master Specificationarvin jay santarinNessuna valutazione finora

- GB50107-2010 混凝土强度检验评定标准Documento16 pagineGB50107-2010 混凝土强度检验评定标准tanminweeNessuna valutazione finora

- Principles and Practices of Stud Welding: State-Of-The-Art PaperDocumento13 paginePrinciples and Practices of Stud Welding: State-Of-The-Art Paperalbert limantonoNessuna valutazione finora

- Hot Weather Concreting: ACI 305R-99Documento20 pagineHot Weather Concreting: ACI 305R-99Antu IsabelNessuna valutazione finora

- Ground Improvement TechniquesDocumento17 pagineGround Improvement TechniquesMuhil Doss100% (1)

- Fema 353Documento201 pagineFema 353JANJGM100% (2)

- A1081A1081M-12 Standard Test Method For Evaluating Bond of Seven-Wire Steel Prestressing StrandDocumento5 pagineA1081A1081M-12 Standard Test Method For Evaluating Bond of Seven-Wire Steel Prestressing StrandDiego Egoávil MéndezNessuna valutazione finora

- ETL 1110-2-321 Reliability of Navigation Structures PDFDocumento23 pagineETL 1110-2-321 Reliability of Navigation Structures PDFAnonymous huM1Y0DlLNessuna valutazione finora

- C 890 - 91 R99 - Qzg5maDocumento5 pagineC 890 - 91 R99 - Qzg5maRafael CardenasNessuna valutazione finora

- Concrete Quality Control Planning According To UNI EN 13670Documento10 pagineConcrete Quality Control Planning According To UNI EN 13670Querubin R Yolando Jr.Nessuna valutazione finora

- Forming and Shoring CatalogDocumento54 pagineForming and Shoring Cataloglucnewarchi100% (1)

- DMRB All Parts Jan 2012Documento492 pagineDMRB All Parts Jan 2012vijaya guniputiNessuna valutazione finora

- Aashto Rigid Pavement DesignDocumento5 pagineAashto Rigid Pavement DesignJorge Luis MezaNessuna valutazione finora

- Structural Integrity AssessmentDocumento4 pagineStructural Integrity Assessmentrenzo1221100% (1)

- Procedure For Accessment of Concrete StructureDocumento267 pagineProcedure For Accessment of Concrete StructureSuthaNessuna valutazione finora

- Compaction and Jet Grouting PDFDocumento48 pagineCompaction and Jet Grouting PDFMaha KaryaNessuna valutazione finora

- Deformed and Plain Carbon-Steel Bars For Concrete ReinforcementDocumento8 pagineDeformed and Plain Carbon-Steel Bars For Concrete Reinforcementzendaoui amineNessuna valutazione finora

- Astm C143Documento4 pagineAstm C143RegineDagumanFuellasNessuna valutazione finora

- Vibrations of Soils and FoundationsDocumento3 pagineVibrations of Soils and FoundationsHarishNessuna valutazione finora

- Construction Productivity AssessmentDocumento12 pagineConstruction Productivity AssessmentsprathNessuna valutazione finora

- Investigation of Grey Cast Iron Water Mains To Develop A Methodology For Estimating Service LifeDocumento4 pagineInvestigation of Grey Cast Iron Water Mains To Develop A Methodology For Estimating Service LifeyaofuzhangNessuna valutazione finora

- Astm C341Documento4 pagineAstm C341Angel VargasNessuna valutazione finora

- Product Data Sheet: Sika® RetarderDocumento4 pagineProduct Data Sheet: Sika® RetarderBlhoeNessuna valutazione finora

- Aci 207.1R-5Documento30 pagineAci 207.1R-5Orlando Manriquez LNessuna valutazione finora

- Pub 408Documento1.330 paginePub 408Matt Nelson100% (1)

- Pipe Jacking and Microtunneling Design Guide National Utility Contractors AssociationDocumento1 paginaPipe Jacking and Microtunneling Design Guide National Utility Contractors AssociationmahmoudbadwyNessuna valutazione finora

- Astm D5199-01Documento4 pagineAstm D5199-01thaiduyduc123Nessuna valutazione finora

- Performance Specification For Post Tensioned Works.Documento15 paginePerformance Specification For Post Tensioned Works.Tharanga PradeepNessuna valutazione finora

- Evaluation of Seismic Performance in Mechanically StabilizedDocumento4 pagineEvaluation of Seismic Performance in Mechanically StabilizedyupalinNessuna valutazione finora

- Astm C94Documento11 pagineAstm C94benzenten0% (1)

- Finite Element Analysis of Castellated Steel - MR WAKCHAURE, A V SAGADEDocumento8 pagineFinite Element Analysis of Castellated Steel - MR WAKCHAURE, A V SAGADEpradz71Nessuna valutazione finora

- Ac 193 PDFDocumento46 pagineAc 193 PDFDaniella Corredor100% (1)

- Din en 12716Documento32 pagineDin en 12716taisiz kashanehNessuna valutazione finora

- Certification: Structural Steel and Bolting Special Inspector Exam ID: S1Documento2 pagineCertification: Structural Steel and Bolting Special Inspector Exam ID: S1Ammar A. AliNessuna valutazione finora

- Standard Test Method For Measuring Length of Concrete Cores (C 1542.c1542m)Documento2 pagineStandard Test Method For Measuring Length of Concrete Cores (C 1542.c1542m)jjaavenidoNessuna valutazione finora

- Corrugated Steel Pipe, Metallic-Coated, For Sewers and DrainsDocumento10 pagineCorrugated Steel Pipe, Metallic-Coated, For Sewers and DrainsFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- EM 1110-2-2002 - Evaluation and Repair of Concrete Structures 1Documento185 pagineEM 1110-2-2002 - Evaluation and Repair of Concrete Structures 1PDHLibraryNessuna valutazione finora

- Pre-Bid Attach02-GB 50021-2009 Code For Investigation of Geotechnical EngineeringDocumento276 paginePre-Bid Attach02-GB 50021-2009 Code For Investigation of Geotechnical EngineeringArdion Fikri ZatamiNessuna valutazione finora

- A325MDocumento8 pagineA325MmsbarretosNessuna valutazione finora

- Steel Structure AssessmentDocumento23 pagineSteel Structure AssessmentYudi Agung NugrohoNessuna valutazione finora

- Wind Tunnel Testing For Tall BuildingsDocumento7 pagineWind Tunnel Testing For Tall BuildingsSilver Olguín CamachoNessuna valutazione finora

- Astm c1461Documento4 pagineAstm c1461Júlio RosaNessuna valutazione finora

- Physical Testing of Gypsum, Gypsum Plasters and Gypsum ConcreteDocumento8 paginePhysical Testing of Gypsum, Gypsum Plasters and Gypsum ConcreteRajendra PashteNessuna valutazione finora

- Stability Analysis of Pipe Racks For PDFDocumento162 pagineStability Analysis of Pipe Racks For PDFkurnoyNessuna valutazione finora

- ACI318M 2008 - Appendix DDocumento31 pagineACI318M 2008 - Appendix Dccq0707Nessuna valutazione finora

- ACI 304.2R-96 Placing Concrete by Pumping PDFDocumento25 pagineACI 304.2R-96 Placing Concrete by Pumping PDFAhmad Zaid100% (1)

- FAQ Steel Rusting 1Documento2 pagineFAQ Steel Rusting 1Joseph Marriott AndersonNessuna valutazione finora

- Geotechnical Investigation ReportDocumento40 pagineGeotechnical Investigation ReportJoseph Marriott AndersonNessuna valutazione finora

- Personal-Family Disaster Preparedness Plan - No PhotosDocumento8 paginePersonal-Family Disaster Preparedness Plan - No PhotosJoseph Marriott AndersonNessuna valutazione finora

- Plant Electrical MemoryDocumento3 paginePlant Electrical MemoryJoseph Marriott AndersonNessuna valutazione finora

- Why Terrorism Does Not WorkDocumento37 pagineWhy Terrorism Does Not Workbritt100% (1)

- Reading 4 PDFDocumento28 pagineReading 4 PDFJoseph Marriott AndersonNessuna valutazione finora

- Traders Doha Qatar - Site 907-2013Documento49 pagineTraders Doha Qatar - Site 907-2013Joseph Marriott AndersonNessuna valutazione finora

- Construction Sites Qatar April 2012Documento32 pagineConstruction Sites Qatar April 2012Joseph Marriott AndersonNessuna valutazione finora

- Joint Treatment Materials For Gypsum Board Construction: Standard Test Methods ForDocumento14 pagineJoint Treatment Materials For Gypsum Board Construction: Standard Test Methods ForJoseph Marriott AndersonNessuna valutazione finora

- Qatar Construction Sites Magazine August 2012Documento32 pagineQatar Construction Sites Magazine August 2012Joseph Marriott Anderson100% (3)

- EcoMENA Newsletter - May IssueDocumento17 pagineEcoMENA Newsletter - May IssueSalman ZafarNessuna valutazione finora

- D4221 1518350-1Documento4 pagineD4221 1518350-1Joseph Marriott AndersonNessuna valutazione finora

- Workshop: Name of Student:-Linda Leon Toma Energy Engineering Department First YearDocumento13 pagineWorkshop: Name of Student:-Linda Leon Toma Energy Engineering Department First YearLinda Leon TomaNessuna valutazione finora

- 4 - Cylinder Injection Engine (2.0l Engine) (AXA)Documento166 pagine4 - Cylinder Injection Engine (2.0l Engine) (AXA)TintinPicasoNessuna valutazione finora

- 1 OnlineDocumento21 pagine1 OnlineBành Đức MinhNessuna valutazione finora

- EN10255 Pipe SizeDocumento3 pagineEN10255 Pipe SizeStefan CristescuNessuna valutazione finora

- Chapter 2 - Lubrication (Added)Documento32 pagineChapter 2 - Lubrication (Added)Najip TalibinNessuna valutazione finora

- 183-19 Wpqc-W162-6''-Asme XiDocumento1 pagina183-19 Wpqc-W162-6''-Asme Xibouchoucha jebaliNessuna valutazione finora

- ME 525 April 17, 2020 Internal Combustion Engine Performance Problems Set 1 InstructionsDocumento2 pagineME 525 April 17, 2020 Internal Combustion Engine Performance Problems Set 1 Instructionssixela arugalNessuna valutazione finora

- PSC AE QuestionsDocumento9 paginePSC AE QuestionsDipayan MisraNessuna valutazione finora

- Sans Titre PDFDocumento1 paginaSans Titre PDFjoker63000Nessuna valutazione finora

- Overview of ACMV Design PDFDocumento23 pagineOverview of ACMV Design PDFJojo TangalinNessuna valutazione finora

- Assignment: - Design of Pneumatic Conveyer Dryer: SpecificationDocumento4 pagineAssignment: - Design of Pneumatic Conveyer Dryer: SpecificationPraween NishadNessuna valutazione finora

- Hiace Techstream 1st RunDocumento3 pagineHiace Techstream 1st RunStephen MasemoNessuna valutazione finora

- Valve Range Strainer SupplierDocumento8 pagineValve Range Strainer SupplierRAVIKIRAN BARDENessuna valutazione finora

- Valve Body Identification Guide Valve Body Identifi Cation GuideDocumento11 pagineValve Body Identification Guide Valve Body Identifi Cation GuideUlloaEliasNessuna valutazione finora

- BE Specs VG1000 M9000 TableDocumento3 pagineBE Specs VG1000 M9000 TableKumar sssssNessuna valutazione finora

- Astm E23-2018Documento26 pagineAstm E23-2018kavin100% (1)

- Basic Steel Selection Based On BS 970 en SeriesDocumento8 pagineBasic Steel Selection Based On BS 970 en SeriesAmarendra Pendse100% (1)

- Pleasant Street Hydraulic ManualDocumento607 paginePleasant Street Hydraulic ManualbadralislamNessuna valutazione finora

- SL-SN.0 Drum Brake - 03.09Documento38 pagineSL-SN.0 Drum Brake - 03.09Cem DufourNessuna valutazione finora

- RCC & PSC Class Notes (Vivek Gupta) PDFDocumento329 pagineRCC & PSC Class Notes (Vivek Gupta) PDFSTARCAST ENTERTAINMENT100% (2)

- C15 Acert Spec SheetDocumento4 pagineC15 Acert Spec SheetMalasquez Leon XavierNessuna valutazione finora

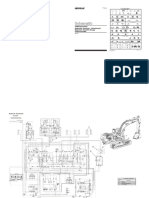

- 330B Excavator Hydraulic Variable Gauge Undercarriage Hydraulic Systems - AttachmentDocumento2 pagine330B Excavator Hydraulic Variable Gauge Undercarriage Hydraulic Systems - Attachmentnilton acNessuna valutazione finora

- MAIN Air Compressor - Instruction Manual HV2-200Documento32 pagineMAIN Air Compressor - Instruction Manual HV2-200Black ScorpionNessuna valutazione finora

- Mos Mid Question BankDocumento24 pagineMos Mid Question BankJohny SkNessuna valutazione finora

- Ti Nspire CX Cas If97 DocuDocumento23 pagineTi Nspire CX Cas If97 DocuJohan GalloNessuna valutazione finora

- Applied Mechanics SopDocumento2 pagineApplied Mechanics Sopneerajmohanvp100% (3)

- Manual John Deere 244JDocumento18 pagineManual John Deere 244JYoriel GuzmanNessuna valutazione finora

- Comparativo Llegada Stock de Seguridad 14012023Documento6 pagineComparativo Llegada Stock de Seguridad 14012023Jesus Sarmiento VillanuevaNessuna valutazione finora

- Agrotron M: Evolving AgricultureDocumento13 pagineAgrotron M: Evolving Agriculturejohn deereNessuna valutazione finora

- ChE 122 Lecture Notes 03 II. Basic Concepts and The First Law (2.7-2.10)Documento4 pagineChE 122 Lecture Notes 03 II. Basic Concepts and The First Law (2.7-2.10)MarkVergelBorjaNessuna valutazione finora