Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Nickel-Iron For Cast Iron: Data Sheet

Caricato da

Sandro ChiliquingaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Nickel-Iron For Cast Iron: Data Sheet

Caricato da

Sandro ChiliquingaCopyright:

Formati disponibili

DATA SHEET E-11

METRODE PRODUCTS LTD

HANWORTH LANE, CHERTSEY

SURREY, KT16 9LL

Tel: +44(0)1932 566721

Fax: +44(0)1932 565168 Sales

Fax: +44(0)1932 569449 Technical

Fax: +44(0)1932 566199 Export

NICKEL-IRON FOR CAST IRON Email: info@metrode.com

Internet: http//www.metrode.com

Alloy type If welding is carried out without preheat it is desirable to

minimise the width of the HAZ by using a low heat input

Nominally Fe-55% Ni alloy for the repair and joining of

and low interpass temperature. A skip welding technique

cast iron.

can be beneficial in helping to achieve this.

Materials to be welded For thicker section welds and highly restrained welds

ASTM BS preheat in the range 150-250°C may be necessary. Light

A602, A47, A338, A220 2789 – SG irons peening to reduce contraction stresses can also be

6681 – Ductile irons beneficial but care should be taken not to exhaust the

ductility of the weld metal.

Applications Buttering the joint faces, or sides of the repair cavity,

The NiFe alloy is suitable for welding all grades of cast prior to filling can also be desirable whether a preheat is

iron but particularly for spheroidal graphite (SG), used or not.

nodular or ductile irons and some alloy cast irons. It On completion of welding the workpiece should be

provides compatible strength, ductility and toughness, allowed to cool slowly, using insulation if necessary.

coupled with good machinability.

Additional information

The NiFe consumables can also be used on some of the

high alloy austenitic irons (Ni-Resist). The flake The NiFe weld metals produce higher strength than the

graphite grades are welded with a preheat of 300-350°C pure nickel cast iron types and are therefore preferable for

but the SG grades are best buttered using low heat input, dissimilar joints, nodular irons and higher strength cast

and low temperature techniques to avoid HAZ hot irons. The NiFe types are also less sensitive to hot

cracking. cracking caused by pick-up of impurities such as

phosphorus which are often present in castings. The low

Note the martensitic Ni-Hard cast irons and white irons

matrix contraction coefficient of NiFe is also enhanced in

are generally considered to be unweldable because they

the higher carbon electrode deposits by expansion

are too crack-sensitive.

accompanying graphite precipitation and results in lower

The NiFe consumables are also suitable for welding stresses in heavy repairs; the possibility of cold cracking

transition joints between cast iron and cast steels, and is therefore reduced.

cast iron and mild/low alloy steels.

Related alloy groups

Typical components are machine bases, pump bodies,

engine blocks, gears and transmission housings. The pure nickel types (data sheet E-10) are also used for

welding cast iron.

Welding guidelines

Products available

Welding is often carried out without preheat but heavy

multipass deposits or highly restrained joints may require Process Product Specification

preheat 150-250°C. MMA CI Special Cast NiFe AWS ENiFe-CI

Prior to welding surfaces should be prepared by careful CI-Met NiFe AWS ENiFe-CI

gouging and/or grinding using limited amounts of heat to

MIG 55NiFe BS NA47

avoid propagating cracks. The area to be welded should

be cleaned as far as practicable from sand, oil, grease,

paint or rust. Preheating can help to remove impregnated

oil on used castings which are being repaired.

Rev 04 10/03 DS: E-11 (pg 1 of 3)

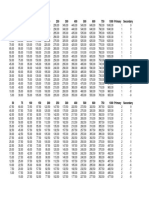

General Data for all MMA Electrodes

Storage 3 hermetically sealed ring-pull metal tins per carton, with unlimited shelf life. Direct use from tin is

satisfactory.

For electrodes that have been exposed:

Redry 100 – 150°C/1-2h to restore to as-packed condition. Maximum 150° C, 3 cycles, 10h total.

Storage: Recommended ambient storage conditions for opened tins (using plastic lid): < 60% RH, > 18°C.

Fume data Fume composition, wt % typical:

3

Fe Mn Ni Cr Cu F Ba OES (mg/m )

3.5 1 2 <0.2 <0.5 12 <0.5 5

CI SPECIAL CAST NiFe NiFe MMA electrode for most grades of cast iron

Product description MMA electrode with special basic-graphite flux (no barium compounds) on a 55%Ni alloy core wire. Good

refining action provides maximum resistance to cracking and freedom from porosity.

Recovery is about 95% with respect to core wire, 70% with respect to whole electrode.

Specifications AWS A5.15 ENiFe-CI

BS EN 1071 E C NiFe-CI 1

DIN 8573 (E NiFe-1 BG)

ASME IX Qualification QW432 F-No --

Composition C Mn Si S P Fe Ni Al Cu

(weld metal wt %) min -- -- -- -- -- bal 45.0 -- --

max 2.0 2.5 2.0 0.03 0.03 bal 60.0 1.0 2.5

typ 0.5 1.5 0.5 0.010 0.005 42 55 <0.1 <0.1

All-weld mechanical As welded typical

properties Tensile strength MPa 400

0.2% Proof stress MPa 230

Elongation % 10-12

Hardness HV 170-200

Operating parameters DC +ve or AC (OCV: 50V min)

ø mm 2.5 3.2 4.0

min A 60 70 90

max A 80 110 150

Packaging data ø mm 2.5 3.2 4.0

length mm 305 355 355

kg/carton 13.5 15.0 15.0

pieces/carton 618 450 297

CI-MET NiFe NiFe MMA electrode on bi-metallic core wire

Product description MMA electrode with special basic-graphite flux (no barium compounds) on bi-metallic Fe clad Ni core wire.

Good refining action provides maximum resistance to cracking and freedom from porosity. The bi-metallic core

wire minimises the risks of over-heating normally associated with NiFe MMA electrodes and produces excellent

operability.

Recovery is about 95% with respect to core wire, 70% with respect to whole electrode.

Specifications AWS A5.15 ENiFe-CI

BS EN 1071 E C NiFe-CI 1

DIN 8573 (E NiFe-1 BG)

ASME IX Qualification QW432 F-No --

Rev 04 10/03 DS: E-11 (pg 2 of 3)

CI-MET NiFe (continued)

Composition C Mn Si S P Fe Ni Al Cu

(weld metal wt %) min -- -- -- -- -- bal 45.0 -- --

max 2.0 2.5 2.0 0.03 0.03 bal 60.0 1.0 2.5

typ 0.5 1.5 0.5 0.010 <0.01 42 55 <0.1 <0.1

All-weld mechanical As welded typical

properties Tensile strength MPa 400

0.2% Proof stress MPa 230

Elongation % 10-12

Hardness HV 170-200

Operating parameters DC +ve or AC (OCV: 50V min)

ø mm 2.5 3.2 4.0

min A 60 75 100

max A 80 120 155

Packaging data ø mm 2.5 3.2 4.0

length mm 300 350 350

kg/carton 13.5 15.0 15.0

pieces/carton 789 468 300

55NiFe Solid MIG wire for welding cast irons

Product description Solid wire for MIG.

Specifications BS 2901 pt 5 NA47

BS EN 1071 S C NiFe-1

DIN 8573 (MSG NiFe-1)

ASME IX Qualification QW432 F-No --

Composition C Mn Si S P Ni Fe Cu Co

(wire wt %) min -- -- -- -- -- 52.0 bal -- --

max 0.15 1.0 0.5 0.02 0.03 60.0 bal 0.5 2.0

typ 0.05 0.7 0.2 <0.01 <0.01 58 40 0.01 0.05

All-weld mechanical Typical values as welded MIG (Ar-5%CO2)

properties Tensile strength MPa 400

0.2% Proof stress MPa 230

Elongation % 24

Hardness HV 150

Typical operating MIG

parameters Shielding Ar / Ar + 1-2%O2 / Ar + 2-25%CO2 / 100%CO2

Current DC+

Diameter 1.2mm

Parameters 200A, 28V

Packaging data ø mm MIG

1.2 15kg spool

1.6 15kg spool

Fume data MIG fume composition, wt %:

3 3

Fe Mn Cr Ni Cu OES (mg/m )

35 2 <0.1 30 <0.5 1.7

Rev 04 10/03 DS: E-11 (pg 3 of 3)

Potrebbero piacerti anche

- YintroDocumento6 pagineYintroJoshua StrykrNessuna valutazione finora

- Ni Inco 4421 Weldingofflakeandspheroidalgraphiteni ResistcastingsDocumento6 pagineNi Inco 4421 Weldingofflakeandspheroidalgraphiteni ResistcastingsLeandro Dilkin ConsulNessuna valutazione finora

- 90cual Mig WireDocumento1 pagina90cual Mig WireAris WicaksonoNessuna valutazione finora

- TDS 351do enDocumento1 paginaTDS 351do enMumkoNessuna valutazione finora

- Repair and MaintenanceDocumento4 pagineRepair and MaintenanceElMacheteDelHuesoNessuna valutazione finora

- Job Knowledge 100Documento3 pagineJob Knowledge 100Mehmet SoysalNessuna valutazione finora

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocumento4 pagineA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16Nessuna valutazione finora

- UTP Brazing Filler MetalsDocumento8 pagineUTP Brazing Filler MetalsIvan Dulic100% (1)

- Welding of Nickel AlloysDocumento4 pagineWelding of Nickel AlloysMuhammed SulfeekNessuna valutazione finora

- Welding Consumables For Hydro Power StationsDocumento16 pagineWelding Consumables For Hydro Power StationsMohamed FaragNessuna valutazione finora

- Welding of Cast IronDocumento35 pagineWelding of Cast IronincaurcoNessuna valutazione finora

- Copper AlloysDocumento4 pagineCopper AlloysMuhammed SulfeekNessuna valutazione finora

- Welding of Ferritic Cryogenic SteelsDocumento2 pagineWelding of Ferritic Cryogenic SteelsMuhammed SulfeekNessuna valutazione finora

- Stainless Steel Welding by Weld RealityDocumento50 pagineStainless Steel Welding by Weld RealitylightwinterdayNessuna valutazione finora

- Welding Consumables For Cast Iron MaterialsDocumento4 pagineWelding Consumables For Cast Iron MaterialsskidanjeNessuna valutazione finora

- Metrode Instructions For 625 Wires D20Documento5 pagineMetrode Instructions For 625 Wires D20haran2000Nessuna valutazione finora

- Zeron SmawDocumento4 pagineZeron SmawJoe FizzoNessuna valutazione finora

- Weldability of Materials - Nickel and Nickel AlloysDocumento5 pagineWeldability of Materials - Nickel and Nickel AlloysmanimaranNessuna valutazione finora

- Sif Tig BrazingDocumento1 paginaSif Tig BrazingJeremy PhilipNessuna valutazione finora

- Railrod: Data SheetDocumento1 paginaRailrod: Data Sheetmohamed AdelNessuna valutazione finora

- High Strength Ni-Mo Low AlloyDocumento5 pagineHigh Strength Ni-Mo Low Alloymohamed AdelNessuna valutazione finora

- 309mo Stainless Steels: Data SheetDocumento5 pagine309mo Stainless Steels: Data SheetFilipe CordeiroNessuna valutazione finora

- Alloy 625 ConsumablesDocumento4 pagineAlloy 625 ConsumablesRodrigo CarneiroNessuna valutazione finora

- B Bã-Hler Nibas 70 20-Fd Fcaw 02Documento1 paginaB Bã-Hler Nibas 70 20-Fd Fcaw 02kamals55Nessuna valutazione finora

- Welding "Grade 91" Alloy Steel: Less Than 1.05%Documento5 pagineWelding "Grade 91" Alloy Steel: Less Than 1.05%Anonymous nw5AXJqjdNessuna valutazione finora

- Final Welding of Ti Alloys and MG AlloysDocumento32 pagineFinal Welding of Ti Alloys and MG AlloysArjyajyoti GoswamiNessuna valutazione finora

- Gas Tungsten Arc Welding Practice:: Jobs 19-J1-J19 (Plate)Documento8 pagineGas Tungsten Arc Welding Practice:: Jobs 19-J1-J19 (Plate)Willy UioNessuna valutazione finora

- Met 05 Nonferrous WeldingDocumento16 pagineMet 05 Nonferrous WeldingRaghu vamshiNessuna valutazione finora

- MIP Bohler Welding Austria 364Documento1 paginaMIP Bohler Welding Austria 364c131508Nessuna valutazione finora

- Esab DublexDocumento8 pagineEsab DublexSuphi YükselNessuna valutazione finora

- 347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)Documento4 pagine347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)Prem NautiyalNessuna valutazione finora

- Welding of Ni SteelDocumento4 pagineWelding of Ni SteelVikas Kumar PathakNessuna valutazione finora

- BS EN 1011-3-2000 - Recommendations For Arc Welding of Stainless Steels PDFDocumento25 pagineBS EN 1011-3-2000 - Recommendations For Arc Welding of Stainless Steels PDF0502ravi100% (1)

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocumento7 pagine22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptNessuna valutazione finora

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocumento3 pagineConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390Nessuna valutazione finora

- Welding Austenitic Manganese Steel RailDocumento6 pagineWelding Austenitic Manganese Steel RailaladinsaneNessuna valutazione finora

- 15 MM 74Documento28 pagine15 MM 74Sravan Kumar50Nessuna valutazione finora

- Technical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data Sheet Brazetec S Brazetec S Brazetec S Brazetec S 5 5 5 5Documento1 paginaTechnical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data Sheet Brazetec S Brazetec S Brazetec S Brazetec S 5 5 5 5IonutCiobanuNessuna valutazione finora

- Welding of Nickel AlloysDocumento12 pagineWelding of Nickel AlloysErick HoganNessuna valutazione finora

- Fox - FFDocumento1 paginaFox - FFGustavo NietoNessuna valutazione finora

- C 70 SuperthermDocumento2 pagineC 70 SuperthermMandeep SinghNessuna valutazione finora

- Avesta 2205 VDX Ac DCDocumento1 paginaAvesta 2205 VDX Ac DCpipedown456Nessuna valutazione finora

- Welding Consumable DSMW-0024.1 - WokaDur - S80-Ni-TIG - ElectrodeDocumento3 pagineWelding Consumable DSMW-0024.1 - WokaDur - S80-Ni-TIG - ElectrodeJOLLY JAYA SENTOSANessuna valutazione finora

- P91 - Modified 9crmo: Alloy TypeDocumento7 pagineP91 - Modified 9crmo: Alloy TypeHanLe DuyNessuna valutazione finora

- Welding of Nickel AlloysDocumento12 pagineWelding of Nickel Alloysaj87_goswamiNessuna valutazione finora

- Welding Nickle AlloyDocumento2 pagineWelding Nickle AlloytuanNessuna valutazione finora

- Data Sheet A-12Documento7 pagineData Sheet A-12anon_928750560Nessuna valutazione finora

- UTP For OffshoreDocumento16 pagineUTP For Offshorekamals55Nessuna valutazione finora

- Mn-Mo Gas Shileded (E90T1-D3, E100T5-D2) PDFDocumento1 paginaMn-Mo Gas Shileded (E90T1-D3, E100T5-D2) PDFborovniskiNessuna valutazione finora

- CERTILAS EN Edition2023 313Documento1 paginaCERTILAS EN Edition2023 313Alireza KhodabandehNessuna valutazione finora

- Special Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresDocumento10 pagineSpecial Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresCarlos PadillaNessuna valutazione finora

- 8000 5 WeldingDocumento11 pagine8000 5 Weldingjosf78Nessuna valutazione finora

- Durum GesamtkatalogDocumento220 pagineDurum GesamtkatalogAdhie WaelacxhNessuna valutazione finora

- Cu Ni FabricationDocumento28 pagineCu Ni FabricationAli Varmazyar100% (1)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantDa EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantValutazione: 3.5 su 5 stelle3.5/5 (3)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesDa EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNessuna valutazione finora

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Da EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Nessuna valutazione finora

- Secondary Primary 1000 750 600 500 400 300 250 200 150 100 75 50Documento5 pagineSecondary Primary 1000 750 600 500 400 300 250 200 150 100 75 50Sandro ChiliquingaNessuna valutazione finora

- English Pedagogical Module 1: Back To School!Documento24 pagineEnglish Pedagogical Module 1: Back To School!Sandro ChiliquingaNessuna valutazione finora

- Wide-Vue Analog Panel Meters: Ordering InformationDocumento10 pagineWide-Vue Analog Panel Meters: Ordering InformationSandro ChiliquingaNessuna valutazione finora

- #2 Yellow: Non-Fluorescent Magnetic ParticlesDocumento2 pagine#2 Yellow: Non-Fluorescent Magnetic ParticlesSandro ChiliquingaNessuna valutazione finora

- PeneCert ASTM E1417 Test MatrixDocumento1 paginaPeneCert ASTM E1417 Test MatrixPP043Nessuna valutazione finora

- Consumable and Accessory Warranty StatementDocumento2 pagineConsumable and Accessory Warranty StatementSandro ChiliquingaNessuna valutazione finora

- Penetrant Testing Process Guide Methods A B C DDocumento1 paginaPenetrant Testing Process Guide Methods A B C DNos GoteNessuna valutazione finora

- NDT AdvancedDocumento6 pagineNDT AdvancedMSN4321Nessuna valutazione finora

- 10124942Documento3 pagine10124942Sandro ChiliquingaNessuna valutazione finora

- Oil-Based Fluorescent Magnetic Particle Suspension: Product Data SheetDocumento4 pagineOil-Based Fluorescent Magnetic Particle Suspension: Product Data SheetSandro ChiliquingaNessuna valutazione finora

- 14A Aqua-Glo™: Water-Based Fluorescent Magnetic Particle SuspensionDocumento3 pagine14A Aqua-Glo™: Water-Based Fluorescent Magnetic Particle SuspensionSandro ChiliquingaNessuna valutazione finora

- Fluorescent Magnetic Particle Premix: Product Data SheetDocumento3 pagineFluorescent Magnetic Particle Premix: Product Data SheetSandro ChiliquingaNessuna valutazione finora

- #2 Yellow: Non-Fluorescent Magnetic ParticlesDocumento2 pagine#2 Yellow: Non-Fluorescent Magnetic ParticlesSandro ChiliquingaNessuna valutazione finora

- UVA LED LampDocumento2 pagineUVA LED LampSandro ChiliquingaNessuna valutazione finora

- 2800 Series Digital Panel Meters: Inputs SpecificationsDocumento2 pagine2800 Series Digital Panel Meters: Inputs SpecificationsSandro ChiliquingaNessuna valutazione finora

- 2020 Price List: Certification ProgramsDocumento2 pagine2020 Price List: Certification ProgramsFirman BhaktiwinayaNessuna valutazione finora

- Megohmmeter/IR TesterDocumento2 pagineMegohmmeter/IR TesterSandro ChiliquingaNessuna valutazione finora

- Rayst Infrared ThermometersDocumento5 pagineRayst Infrared ThermometerslcandoNessuna valutazione finora

- Lower Explosive Limits of Combustible GasesDocumento1 paginaLower Explosive Limits of Combustible GasesSandro ChiliquingaNessuna valutazione finora

- Data Sheet of The Machine.Documento4 pagineData Sheet of The Machine.Sandro ChiliquingaNessuna valutazione finora

- 8K Series Pumps: Stainless Steel Multistage Centrifugal PumpsDocumento12 pagine8K Series Pumps: Stainless Steel Multistage Centrifugal PumpsSandro ChiliquingaNessuna valutazione finora

- Series 1500/2500 Safety Relief ValvesDocumento12 pagineSeries 1500/2500 Safety Relief ValvesSandro ChiliquingaNessuna valutazione finora

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocumento8 pagineAD01166M NUFLO Liquid Turbine Flow Meters Data SheetdediekosNessuna valutazione finora

- Addendum - Cross Reference Factors - Multilingual - 10111833 - R000 PDFDocumento1 paginaAddendum - Cross Reference Factors - Multilingual - 10111833 - R000 PDFSandro ChiliquingaNessuna valutazione finora

- Smart Senso AS8900Documento12 pagineSmart Senso AS8900Sandro ChiliquingaNessuna valutazione finora

- User Maintenance Manual: Europa Advanced 4520 Venus Advanced 4951 Calisto Advanced 4953Documento48 pagineUser Maintenance Manual: Europa Advanced 4520 Venus Advanced 4951 Calisto Advanced 4953Sandro ChiliquingaNessuna valutazione finora

- Smart Senso AS8900Documento12 pagineSmart Senso AS8900Sandro ChiliquingaNessuna valutazione finora

- Operating Manual - ALTAIR 4X African Mining - 10125485 - R000 PDFDocumento50 pagineOperating Manual - ALTAIR 4X African Mining - 10125485 - R000 PDFSandro ChiliquingaNessuna valutazione finora

- Multiple Files Are Bound Together in This PDF Package.: Click Here To Download The Latest Version of Adobe ReaderDocumento1 paginaMultiple Files Are Bound Together in This PDF Package.: Click Here To Download The Latest Version of Adobe ReaderSandro ChiliquingaNessuna valutazione finora

- Aib ZT ZR55 75 90Documento138 pagineAib ZT ZR55 75 90nidnitrkl05129650% (2)

- Pricelist Juli 2023 UserDocumento108 paginePricelist Juli 2023 Userfitri heriyati pratiwiNessuna valutazione finora

- Cleaning Validation MACO Swab Rinse Ovais PDFDocumento5 pagineCleaning Validation MACO Swab Rinse Ovais PDFAnonymous yBhOAi5UHNessuna valutazione finora

- Alakliphiles ProjDocumento24 pagineAlakliphiles ProjReshmi Jadwani100% (2)

- Landing NippleDocumento4 pagineLanding NippleMohamed Abd El-MoniemNessuna valutazione finora

- Scat PornDocumento72 pagineScat PornCallum Biggs0% (1)

- Lecture Notes 19 - Accuracy and PrecisionDocumento5 pagineLecture Notes 19 - Accuracy and PrecisionSurendra RamkissoonNessuna valutazione finora

- Chemical Resistance GuideDocumento20 pagineChemical Resistance GuideDarien EdwardsNessuna valutazione finora

- PH4211 Statistical Mechanics: Problem Sheet 2Documento4 paginePH4211 Statistical Mechanics: Problem Sheet 2Roy VeseyNessuna valutazione finora

- CM Heavy-Duty Crane Hooks BrochureDocumento12 pagineCM Heavy-Duty Crane Hooks Brochuretvmehta01Nessuna valutazione finora

- Water Hardness Case StudyDocumento15 pagineWater Hardness Case StudyTaima GhNessuna valutazione finora

- Pharmaceutical Industry in IndiaDocumento0 paginePharmaceutical Industry in IndiaBhuvan MalikNessuna valutazione finora

- Understanding Vacuum Pump LubricantsDocumento21 pagineUnderstanding Vacuum Pump LubricantsengrsurifNessuna valutazione finora

- CNG Price List 2010Documento17 pagineCNG Price List 2010Swastik MahapatraNessuna valutazione finora

- Influence of Adding Short Carbon Fibers On The Flexural Behavior of Textile-Reinforced Concrete One-Way SlabDocumento18 pagineInfluence of Adding Short Carbon Fibers On The Flexural Behavior of Textile-Reinforced Concrete One-Way SlabShaker QaidiNessuna valutazione finora

- Aqueous Reactions and Solution Stoichiometry: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDocumento51 pagineAqueous Reactions and Solution Stoichiometry: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenGopi SureshNessuna valutazione finora

- Foundry Workshop ManualDocumento22 pagineFoundry Workshop Manuallakshya100% (1)

- Shahjalal University of Science and Technology, SylhetDocumento3 pagineShahjalal University of Science and Technology, SylhetSourav SutradharNessuna valutazione finora

- 3 Fire Extinguisher SystemsDocumento29 pagine3 Fire Extinguisher SystemsLikaaNessuna valutazione finora

- Polypro VC 17Documento2 paginePolypro VC 17hauvuNessuna valutazione finora

- AMPCO 18 SandDocumento1 paginaAMPCO 18 SandS BHATTACHARYYANessuna valutazione finora

- Presentation Additive Solutions For Caps ClosuresDocumento38 paginePresentation Additive Solutions For Caps Closuresanon_727968717Nessuna valutazione finora

- 13 Science 9 Unit 13 Mole Concept Study GuideDocumento72 pagine13 Science 9 Unit 13 Mole Concept Study GuideGen BautistaNessuna valutazione finora

- TS TVS TFS ProtocolsDocumento16 pagineTS TVS TFS ProtocolsTaulehia Pulefou SemisiNessuna valutazione finora

- Magnum CV and Magnum IT Valves Installation InstructionsDocumento86 pagineMagnum CV and Magnum IT Valves Installation InstructionsWattsNessuna valutazione finora

- Sikacrete Fire Protection Mortar 201102Documento12 pagineSikacrete Fire Protection Mortar 201102maximgh100% (1)

- Synthesis of Dothiepin and Doxepin by Grignard Reactions in TolueneDocumento6 pagineSynthesis of Dothiepin and Doxepin by Grignard Reactions in TolueneJuan Carlos VillotaNessuna valutazione finora

- MutationDocumento11 pagineMutationJennifer ValdezNessuna valutazione finora

- Textile PrintingDocumento72 pagineTextile Printingspringstar96% (25)

- Kitchen Safety Awareness: Bureau of Workers' Compensation PA Training For Health & Safety (Paths)Documento45 pagineKitchen Safety Awareness: Bureau of Workers' Compensation PA Training For Health & Safety (Paths)Sunil SNessuna valutazione finora